Blobbing/zitting that wipe/retract won't fix?

-

Firmware retraction can be adjusted on the fly, so it's useful during the tuning phase. There are a few other situations where firmware retraction is required, like mixing hotends to be able to retract all of the extruders at once. Other than that there isn't much difference than setting the slicer to do it. the slicer can also control some wipe and coast features which may be beneficial, though pressure advance is usually enough to make those unnecessary. Simplify3D can be configured to use firmware retraction, a quick google should find the steps.

Can you post a .3mf from PrusaSlicer so we can see what the entire printer setup and print settings are?

-

@phaedrux Sorry it's taken so long for me to get back to you. I went on vacation shortly after your last message.

I've been tinkering all morning, even designed a new "calibration" print to figure out what's the optimal PA value to use, and... yeah still nothing. The biggest improvement is still going from Simplify3d to PrusaSlicer, and it's because PrusaSlicer has "coast" sort of built in. That is, on the outer perimeter, it stops before it completes the loop to account for the extrusion width at the start and end of the perimeter.

I simulated this in Simplify3d by adding 0.5mm coast and it helps a lot there too.

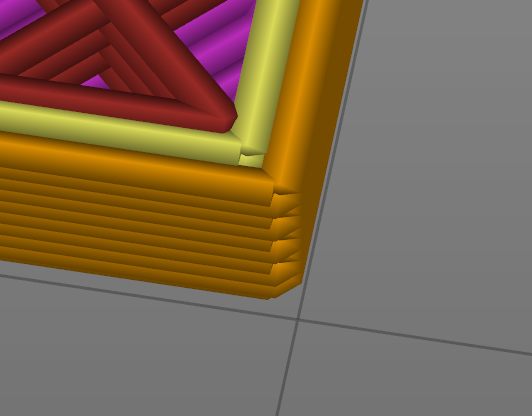

Here's the best print I've gotten so far today, using PrusaSlicer:

I know there's quite a bit of ringing, I have to turn down the jerk on XY and that'll fix that right up (I copied your settings you posted blindly, whoops). The zits/seams on the corners are much better, but they're still there.

And here's the .3mf for this print job: https://www.dropbox.com/s/aw8wqs696kqcvnt/xyzCalibration_cube.3mf?dl=0

I've gone through what it could possibly be, logically, and I'm stumped. I'm starting to wonder if my tension isn't high enough on my idler and PA isn't able to jerk the filament up fast enough, or if it's just this filament. I am using the most garbage PLA I have right now to run these tests, I wonder how much of an impact it has. I'm printing at a pretty low temp (180c) so retraction/PA should have more of an impact on blobs/zits, but it doesn't seem to change much if I print hotter. I'm going a little nutty-bananas now

-

Coast-to-end is a poor substitute for pressure advance.

Small blobs/zits are cause by insufficient retraction. My experience is that without pressure advance and with ordinary PTFE tubing and 1.75mm PLA, the retraction length need to be a little less than 1% of the Bowden tube length. With the correct pressure advance and with Capricorn tubing, it can be reduced.

-

@dc42 100% agreed, I hate that I'm using coast. That's why I don't want to use it, although in PrusaSlicer's case, it's a tiny coast just to account for the thickness of the line that gets extruded, so I can see why they included it by default.

I have 1mm of retraction right now, and e3d recommends less than 1.5mm for retraction (I believe). Any more than 2mm and I get jams/clogging. I just went through that brutal experience before my vacation. It's a direct drive, so no bowden tube here. I should be able to get away with small retraction.

I'm going to try with no wipe and see if PA can do its job more effectively. That's the only variable I haven't eliminated.

Update:

Disabled wipe, upped retraction to 1.5mm. Ignoring the stringing and the gaps (this filament pops/fizzes a bunch, I think it has a ton of moisture in it, it's almost 6 years old), I think this is the best looking blobbing so far. Now what do I try from here?

-

@shensmobile said in Blobbing/zitting that wipe/retract won't fix?:

Disabled wipe, upped retraction to 1.5mm. Ignoring the stringing and the gaps (this filament pops/fizzes a bunch, I think it has a ton of moisture in it, it's almost 6 years old), I think this is the best looking blobbing so far. Now what do I try from here?

Better filament!

-

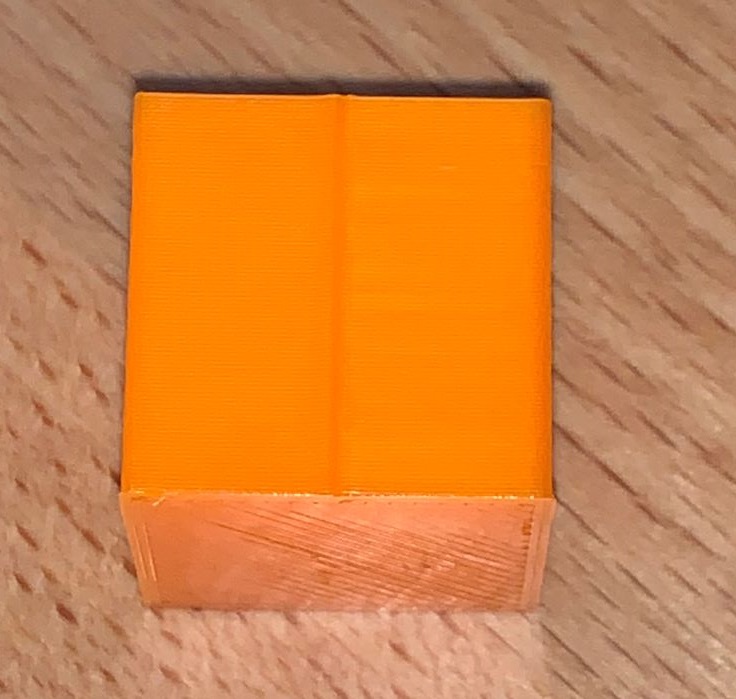

I printed with higher quality filament and the seam/sitting is definitely still there. I did the calibration cube again with the following settings:

2mm retract

60mm/s retract speed

No wipe/coast

180c print temp

Aligned seam at the rear of the cubeHere's the seam along the back:

The rest of the print is fantastic (no voids, straight walls, great looking X and Y cutout) but this damn seam is still there. What's crazy is that I upped PA from S0.05 to S0.09 gradually throughout the print. The seam doesn't seem to be improving at all, and neither do the corners or the look of the top infill. I almost feel like maybe PA isn't taking?

The command I'm supposed to be issuing at the start of the file to trigger PA is M572 D0 S0.05 right? And inserting that command (with a new S value) at various points in my GCode should change PA from that point onwards, right? If so, I wonder if there could be another configuration setting that's preventing PA from being effective.

-

I think what you're seeing there is related to the fact that retraction isn't instant. If it's retracting there, and if you're not doing retraction during a wipe, the nozzle will have to stop there momentarily to do the retraction, and that non-zero time spent with not-yet fully retracted filament is simply causing that extra little bit that blobs slightly at the start and end points, making that seam. If you're not retracting there, and it's going from one side of that seam into interior lines, then some combination of PA and acceleration and jerk in X or Y might reduce that, but you'll almost certainly never get rid of it completely.

What would be an interesting test, if you want to insert g-code in at various levels of the print to see the effect, would be to start with low jerk, acceleration, and max speed of your extruder, and up those values at certain intervals, and see if the seam changes in appearance. I'll bet it does. Up to a point, anyway; beyond a certain speed, depending on the extruder, you simply might be unable to retract it any faster without stripping and slipping.

-

@shensmobile said in Blobbing/zitting that wipe/retract won't fix?:

The command I'm supposed to be issuing at the start of the file to trigger PA is M572 D0 S0.05 right? And inserting that command (with a new S value) at various points in my GCode should change PA from that point onwards, right? If so, I wonder if there could be another configuration setting that's preventing PA from being effective.

Yes, assuming the tool you print with uses extruder drive 0 (D0 in the corresponding M563 command).

What retraction speed do you use?

-

I don't think that seam is that bad honestly. Perfect cubes and cylinders don't give the seam hiding algorithm much to work with. It's always going to be visually apparent when it's exposed on a flat face like that. Most models have nooks and crannies or sharp corners that can be used to mask the seam location.

I noticed that the new Cura 4.2 has s smart seam setting that supposedly helps hide it better. Maybe give that a try with a more complex model.

-

@sethipus said in Blobbing/zitting that wipe/retract won't fix?:

I think what you're seeing there is related to the fact that retraction isn't instant. If it's retracting there, and if you're not doing retraction during a wipe, the nozzle will have to stop there momentarily to do the retraction, and that non-zero time spent with not-yet fully retracted filament is simply causing that extra little bit that blobs slightly at the start and end points, making that seam. If you're not retracting there, and it's going from one side of that seam into interior lines, then some combination of PA and acceleration and jerk in X or Y might reduce that, but you'll almost certainly never get rid of it completely.

What would be an interesting test, if you want to insert g-code in at various levels of the print to see the effect, would be to start with low jerk, acceleration, and max speed of your extruder, and up those values at certain intervals, and see if the seam changes in appearance. I'll bet it does. Up to a point, anyway; beyond a certain speed, depending on the extruder, you simply might be unable to retract it any faster without stripping and slipping.

Cube on left is without wipe, cube on right is with wipe. Doesn't appear to make a difference. I think the issue is that PA is appearing to do nothing. Even if marginal, my printer is not doing anything different at different PA values.

@dc42 said in Blobbing/zitting that wipe/retract won't fix?:

@shensmobile said in Blobbing/zitting that wipe/retract won't fix?:

The command I'm supposed to be issuing at the start of the file to trigger PA is M572 D0 S0.05 right? And inserting that command (with a new S value) at various points in my GCode should change PA from that point onwards, right? If so, I wonder if there could be another configuration setting that's preventing PA from being effective.

Yes, assuming the tool you print with uses extruder drive 0 (D0 in the corresponding M563 command).

What retraction speed do you use?

60mm/s. I wonder if it's because my extruder accel/jerk are too high. They're at 4000/4000, perhaps when PA is doing its thing, my extruder can't keep up with those values and slips? If that sounds reasonable, which do you think would be most effective to drop? Accel or Jerk?

-

Where I've seen pressure advance make a difference is for instance at a sharp corner (like these cubes) where the extruder isn't starting or stopping a line, but is decelerating into the corner and accelerating back out of it. With PA on I've seen those corners go from fairly blobby (similar to your seam) to pretty darn smooth and non-blobby. Note that in the case of corners that are not start or end points the nozzle isn't going to be stopping, just slowing down and speeding up. In the case of a start/end point for a line, the nozzle will in fact stop briefly if it's doing any retraction/z-lift and whatnot, and it's this complete stop for a non-zero length of time that's resulting in that seam.

For kicks you could try this print with zero z-lift and zero retraction and see what happens to the seam. You'll probably get other artifacts that you don't want though (why we have z-lift and retraction...).