Pay for config / json files for my corexy printer build.

-

@stevo said in Pay for config / json files for my corexy printer build.:

when I turn the machine on the bl will just flash red and will not deploy at the z axis homing stage.

Try adding this to the end of your config.g to clear any BLTouch errors and retract the pin just in case.

; BLTOUCH PREP ; G4 S1 M280 P7 S160 I1 ; Alarm Release and Push-Pin UP just in case it's in alarm and deployed G4 S1 M402 ; Retract probe just in case it's downM558 P5 H5 F500 T4000 X0 Y0 Z1

G31 P25 X0 Y-25.3 Z0.0 ;You've still got some probe settings duplicated in the endstops and zprobe section.

-

Thank you that's done the trick !

-

Evening all,

Just wanted to ask when the printer has finished its task how / where do I ask it to lower the bed and come back to the homing corner minima on x and y to cool print head down bearing in mind my origin is the centre of the build plate.

M104 S0 ;Turn off extruder heater

G91 ;Relative positioning

G1 Z 10 E-5 F300 ; Lower bed by 10mm and retract filament by 5mm

G1 S1 Y-150 X-150 F500 ;Move nozzle 150mm home direction out of the way of finished print.

M84 ;Motors off

G90 ;Absolute positioning -

Does this help? https://forum.duet3d.com/topic/6760/stop-g

-

@zapta thank you !

-

Evening all just wondered if one of you kind folk could cast an eye over my config file to see if it could be improved in any way please speeds and placement of codes within the file.

As always your comments greatly received

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2 on Tue Jul 23 2019 21:10:42 GMT+0100 (BST); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder movesM669 K1 ; Select CoreXY mode

; Network

M550 P"CORE XY" ; Set machine name

M552 S1 ; Enable network

;*** Access point is configured manually via M587

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S1 ; Physical drive 0 goes forwards

M569 P1 S1 ; Physical drive 1 goes forwards

M569 P2 S0 ; Physical drive 2 goes backwards

M569 P3 S1 ; Physical drive 3 goes forwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80.00 Y80.00 Z1600.00 E415.00 ; Set steps per mm

M566 X900.00 Y900.00 Z30.00 E2400 ; Set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z144.00 E1200.00 ; Set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; Set accelerations (mm/s^2)

M906 X800.00 Y800.00 Z2000.00 E800.00 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-220 Y-220 Z0 S1 ; Set axis minima

M208 X220 Y220 Z660 S0 ; Set axis maxima; Endstops

M574 X1 Y1 S0 ; Set active low and disabled endstops

M574 Z1 S2 ; Define Z to use Probe. Home to Min.

M558 P5 H5 F500 T4000 X0 Y0 Z1 ; Set Z probe type/mode 5. Not using on XY, but using it on Z.

G31 P25 X2 Y32 Z0.0 ; Z probe trigger value, offset in relation to nozzle. And trigger height adjustment; BLTOUCH PREP

G4 S1

M280 P7 S160 I1 ; Alarm Release and Push-Pin UP just in case it's in alarm and deployed

G4 S1

M402 ; Retract probe just in case it's down; Z-Probe

M574 Z1 S2 ; Set endstops controlled by probe

M307 H7 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch

M558 P9 H15 F120 T6000 ; Set Z probe type to bltouch and the dive height + speeds

G31 P500 X32 Y2 Z0.96 ; Set Z probe trigger value, offset and trigger height

M557 X220:220 Y-220:220 S20 ; Define mesh grid; Heaters

M140 H-1 ; Disable heated bed

M305 P1 T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S280 ; Set temperature limit for heater 1 to 280C; Fans

M106 P0 S0 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; BLTOUCH PREP

G4 S1

M280 P7 S160 I1 ; Alarm Release and Push-Pin UP just in case it's in alarm and deployed

G4 S1

M402 ; Retract probe just in case it's down; Automatic saving after power loss is not enabled

; Custom settings are not configured

; Miscellaneous

T0 ; Select first tool -

@stevo If I was being really pedantic I'd say that you have disabled thermostatic mode for your part cooling fan (M106 P0 H-1) which is fine, but the comment after says "Thermostatic control is turned on" (should say "off").

But I'm not feeling pedantic so I won't make that comment.

Seriously, nothing leaps out as being obviously amiss. I think you are at the stage of playing around with things to see if the end result looks any better or can be printed faster without degrading quality. One good thing about Duet is that you can play around with things "one the fly".

If you want, you can give your heaters and fans names for example such as "Hot end" rather than the default "heater 1" (M305 "S") or "Part fan" rather than "fan 0" (M106 "C").

You could try firmware retraction (G10 /G11). It won't work any better than your slicer but you can play around with it "on the fly" which is a far easier way to tune the retraction settings.

You could also play around with pressure advance (M572).

-

Thank you for the input always appreciated !

-

I have been tinkering with the driver speed settings in the config file only would this have any effect on the bltouch operation as when the x and y axis has homed and the head moves to the centre the bed raises a little before the bltouch has lowered the pin then changes its mind and lowers the bed.

The bltouch then flashes red -

You can add a bit of a pause delay to the probe movements with M558 R0.5. This gives the BLTouch a half second chance to settle before starting to probe.

-

Afternoon everyone,

I wonder if I could seek some clarification please Part cooling fan and hot end fan operate as they should during the print apart from the part cooling fan not turning off when the print has finished which I'm guessing I need to add a line to my S3D end code this is what I have in the config g file .; Fans

M106 P0 S0 I0 F500 H-1 ; Part cooling fan

M106 P1 S1 I0 F500 H1 T35 ; Hot end fan set to come on and off at 35and S3D end code.

G91 ; relative positioning

M104 S0 ; extruder heater off

G1 E-1 F300 ; retract the filament

G1 Z15 F1000 S2 ; lift Z relative to current position

G1 S1 Y-445 F1800 ; move quickly to Y axis endstop and stop there (first pass)

G1 Y5 F1000 ; go back a few mm

G1 S1 Y-445 F360 ; move slowly to Y axis endstop once more (second pass)

G1 S1 X-445 F1800 ; move quickly to X axis endstop and stop there (first pass)

G1 X5 F1000 ; go back a few mm

G1 S1 X-445 F360 ; move slowly to X axis endstop once more (second pass)

G90 ; absolute positioning

M84 ;steppers off

G90 ;absolute positioning -

@stevo Add "M106 S0" to your end gcode.

-

Thank you

-

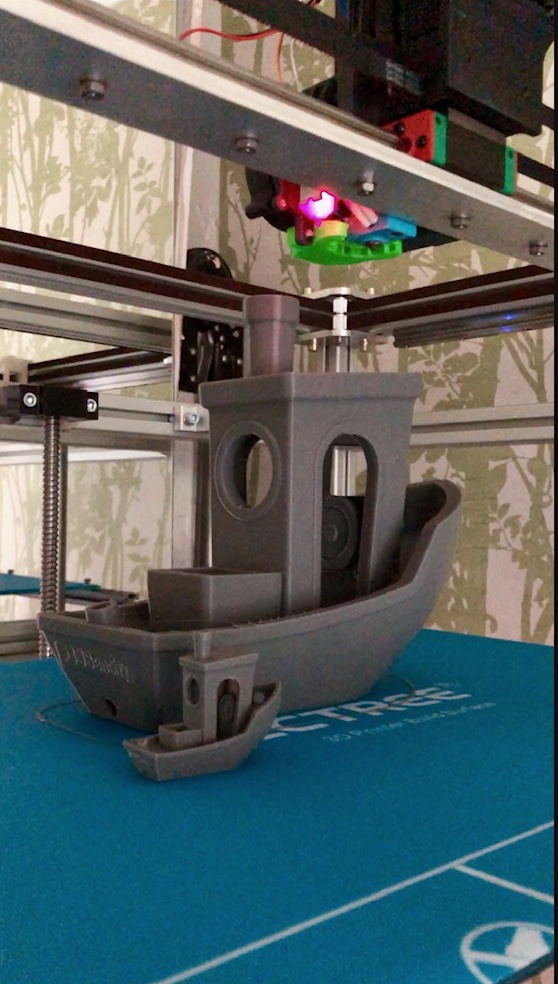

Just wanted to thank all those that have and continue to help me on my build thought I would share a pic of last nights print.

Still trying to get my head around the intricacies of S3D some good and some bad lol

-

Looking good.

-

@stevo, looks very good. Maybe now you can help me achieving similar print quality

-

@stevo Glad to see the progress you've made since 26th June. All without paying a bean too.

I hope you understand why we pointed you in the right directions for you to do it yourself, rather than take your money and do it for you. If you haven't done so already, you'll soon be helping others with the knowledge that you have now gained.

I hope you understand why we pointed you in the right directions for you to do it yourself, rather than take your money and do it for you. If you haven't done so already, you'll soon be helping others with the knowledge that you have now gained. -

Thanks again everyone for your continued help much appreciated and will hopefully be confident enough to help others.