Chamber heater, multi-heater tools, ... implementation started

-

Hi,

I started implementing the extended status information (using M304 S3 and M304 S4).

My main goal was to see and control the chamber heater.

For this I changed the code in that way, that the mapping between the heaters, drives and tools ( resp. bed / chamber ) are calculated from the S3-status information every 8 seconds (instead of using the S1-status information). For updating the status I poll the S4-status every second (instead of the currently used S0 status). I changed the fieldTable[] and the function ProcessReceivedValue() to handle the needed information.

I added an additional icon for the chamber and made the icons dynamic to see only the configured tools / bed / chamber as in the web-control.

If a tool has more than one heater, the tool can take as many columns as heaters assigned to that tool:

I started to implement the drives in the same way (for the extrusion multiplier).

But this solution takes a lot of space on the display - especially if you define the same tool more than one times (e.g. for multi color printing with a diamond hot end).So my question is:

Is it necessary to access the extrusion multiplier for all the drives of a multi-drives tool separately or is it sufficient to set the multiplier for all drives to the same value?This could be implemented with a new popup-window were you can select the drive and adjust it...

By the way: It is possible to assign more than one heater to the bed or the chamber.

But the status information (S3/S4) gives not an array of values for bed- and chamber-heater.

Or am I missing something?

Will the status be extended for these configurations in future? -

You´re the man! I´ve been waiting for the chamber heater. In the meantime i just defined my chamber heater as the bed, since i dont have a bed heater anyway.

Would you be able to fit more information if the screen was in portrait mode?What do you mean exactly by a multi drive tool?

-

@tojosaja said in Chamber heater, multi-heater tools, ... implementation started:

So my question is:

Is it necessary to access the extrusion multiplier for all the drives of a multi-drives tool separately or is it sufficient to set the multiplier for all drives to the same value?That sounds like a question for @deckingman

-

@t3p3tony said in Chamber heater, multi-heater tools, ... implementation started:

@tojosaja said in Chamber heater, multi-heater tools, ... implementation started:

So my question is:

Is it necessary to access the extrusion multiplier for all the drives of a multi-drives tool separately or is it sufficient to set the multiplier for all drives to the same value?That sounds like a question for @deckingman

With a mixing hot end such as a Diamond? Short answer, no it isn't necessary. Longer answer... If you change the extrusion multiplier for one filament, then effectively you are changing the mixing ratios. So if you had one filament that was thicker or thinner than the others, you could achieve the same effect as the extrusion multiplier by changing the mixing ratio for that particular filament. Note that the sum of all the extrusion ratios would not be unity in this instance.

Edit. But if you had multiple tools with separate nozzles, then you might need to be able to set the extrusion multiplier for each one. -

Thanks for your replies.

When modifying or creating a user interface it's always good to know how it is used by other people.

So I try to find out what are common used configurations of tools to be sure that I don't miss anything:

1) Heated chamber

A heated chamber is used by a lot of people and is not supported by the paneldue (this was the reason, why I started... ;-))

Multi-heater configurations are possible, but not supported by the status messages from the duet.2) Heat bed

Most people use a heat bed. Heat bed is configured by default. Is it possible to set it in the configuration as not present?

Multi-heater configurations are possible, but not supported by the status messages from the duet.3) Hotends / Tools

a) one or more normal-single-tool(s), each consists of one separat drive/extruder, heater and nozzle.

This is the most common tool, I think.b) a multi nozzle tool. From the sight of configuration it is the same as a)

(e.g. chimera, kraken)c) mixing tools, with separat drive/extruder per filament, one or more heaters (commonly used by all extruders), one commonly used nozzle

(e.g Diamond hot end, cyclops)Do I miss a tool or is something wrong?

Multiple definition of tools

Some people define the same extruder in different tools.

This can be done to use a one-extruder-printer as a multiple-extruder-printer with manual filament change.

(Using a pause on tool change)As a I read in tutorials it is also commonly used for mixing tools.

You can have a tool for each base color and one or more additional tools for mixing colors.

The slicer is configured to change only the tool on color change.

The definition of the mixing ration of the colors are defined in the printer configuration or the start gcode of the part.This is the point I asked me whether it is a good idea (or not) to list the used extruders / drives as separate columns, if a tool has more than one drive. On the other hand the question is, what the extrusion on the paneldue (!) is used for.

I used it only for changing the extrusion rate during a print, if I see over- or under-extrusion. The next print I adjust the slicer settings accordingly. For this I would adjust the extruder multiplier for a mixing tool only for all extruders in the same way.

(in my understanding the extruder multiplier should be used to compensate different filament diameter and the mixing ratio should be for what it is named. Never understood, why a sum of all mixing ratios different from 100% is allowed and not normalized... but that's another topic...)What are you using for the extruder-multiplier on the paneldue?

Suggestion for the paneldue layout

My suggestion for the paneldue layout would be to have one column per tool / bed / chamber.

In case of multi-heater-tools adding additional column(s) (as in the picture in my post before).

On the print page the extrusion rate will be shown only if the tool has only one drive/extruder.What are you thinking?

-

@nitrofreak using the paneldue in portraid mode would force the people to change their paneldue holder or enclosures if integrated in the enclosure... and I don't know, if that would help...

With a multi drive tool I mean a tool with a tool definition with more than one drive (or extruder) with a given mixing ration (e.g. diamond hotend)

-

@tojosaja said in Chamber heater, multi-heater tools, ... implementation started:

@nitrofreak using the paneldue in portraid mode would force the people to change their paneldue holder or enclosures if integrated in the enclosure... and I don't know, if that would help...

With a multi drive tool I mean a tool with a tool definition with more than one drive (or extruder) with a given mixing ration (e.g. diamond hotend)

How hard would it be for you to make an optional portrait mode? especially for retro fitment a vertical layout is much better because you can easily align it with a vertical wall. In my opinion it is especially easy to handle.

A lot of printers that have a heated chamber have (by chance) also a good use case for the vertical layout

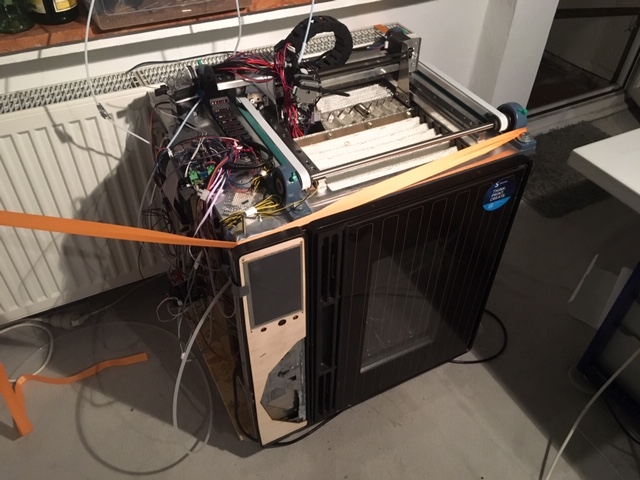

And mine:

I think its a very natural spot to have the panel in a vertical layout. It gives space for the oven door on the side.

I think heated build chambers are the future, so maybe a vertical layout is also the future...? -

I see, it would be a good feature to have a portrait mode. But I think you have to rearrange most of the buttons, partly it will be necessary to find shorter texts for buttons... in all supported languages...

And there are different display sizes in the moment in addition...

... a lot of work...

Then you will have to do that all with compiler switches, because the memory of the paneldue is limited (this means: no switch of orientation by setting page - you will need to change the firmware if you change the orientation).

And at the end the firmware will be more difficult to maintain, because of the double amount of test-cases...

... sorry, for me it is too much working time ...

@dc42 What do you think about?By the way: That's my enclosure with the paneldue above the door...

-

@tojosaja, were you able to make any more progress on this? If so, is there any way to access your version of the firmware? What you have done looks excellent.