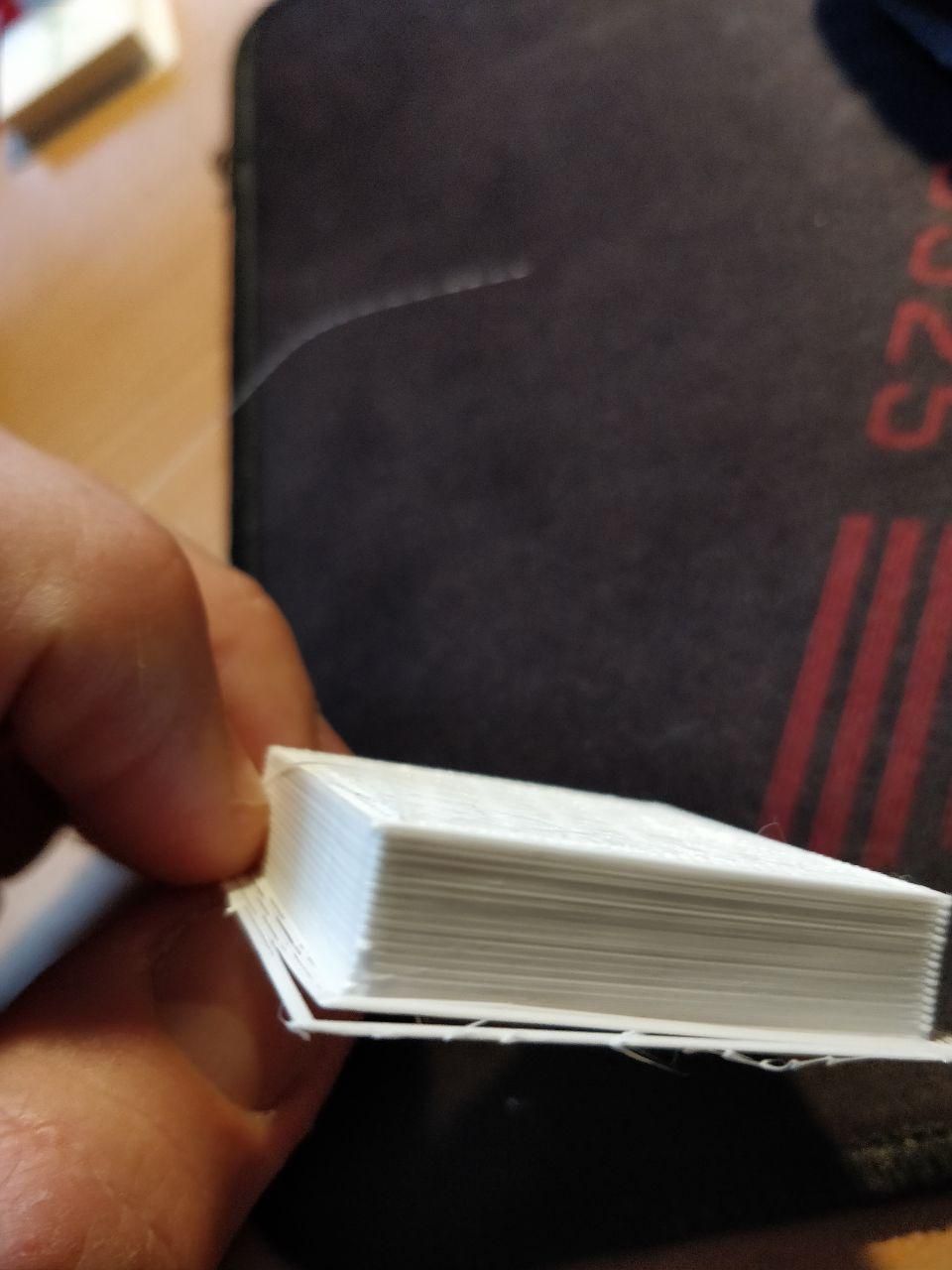

Wierd lines on the test cube sides

-

Here are some possibilities:

-

Your machine has play in the joints (causing backlash), and the slicer has decided to print the perimeters in opposite directions on alternate layers.

-

You have not run heater tuning, so the bed heater is running in bang-bang mode

-

-

@dc42 hello, here is what was printed with Matter Control:

so, walls quality is more or less okay so in the previous example, I suspect, the problem is overextrusion after retract. According to S3D troubleshooting guide, it could be solved by the negative extra restart distance (or I have problems in the extruder - incorrect low speed or jerk).

But, according to Duet docs, extra restart distance is generally bad practice and pressure advance should be used instead.

-

Hi @skayred !

It's hard to see from this angle, but it seems to me that your part is solid?

If so, any (even a very very very slight amount) of over-extrusion can cause effects like this, because there is no other place the excess material can go but off the side of the part (or build up on top and cause the head to eventually collide with it) Plus as DC said maybe each layer is printed in different direction, and there you have it.If the part is indeed solid, then please try to print it not 100% solid, or decrease the extrusion factor a few percent (10% to be sure for the test) and show us the results

-

-

@skayred Probably not ... maybe if you have many perimiters, but unlikely

-

@denke in that case, maybe I am missing some calibration models? Like, I didn't calibrate extrusion width and so on, just started printing test cubes with 3 perimeters at once. If you know what to do first, it would be nice to hear

-

I think you need to fix the backlash in the mechanism before you can calibrate the extruder. Once the layers stack properly on top of each other you can adjust extruder calibration based on line/wall width measurement.

-

@mrehorstdmd hello,

just checked all towers - it slides properly, and I have preloaded PTFE nuts there, so I didnt find any play there.

@dc42 after PID tune, I repeated very first G-code, it seems to be just a little better (no random lines) but overextrusion right at the beginning is still there. Going to experiment with negative restart distance

-

Small update - I just printed 66mm diameter turbine impeller and identified interesting thing - one arm ball at one exact position was going out of magnet's center. I have added some bearing grease, and it prevented the balls from escaping, so impeller was printed without any issues, just really small bowden scars. Still not dimensionally accurate but I think it was the problem

-

Another update - seems to be fixed. What I did:

-

First of all, I have replaced all steppers - old ones were faulty, their shafts were possible to move along, about 3-5mm. New ones don't have these issues and work normally on 2A

-

Replaced 6-factor calibration with 8 factors

-

And finally, adjusted cartesian scale

-

-

@skayred said in Wierd lines on the test cube sides:

- First of all, I have replaced all steppers - old ones were faulty, their shafts were possible to move along, about 3-5mm. New ones don't have these issues and work normally on 2A

Move in the direction of the shaft? This might be by design. All steppers that I've disassembled so far were not constricted to carry any load on the shaft other than rotational. If a stepper motor is new, then it might just have enough friction in the internal parts for it to appear to work, but this will change the longer it runs or depending on the temperature. The coils were centered vertically only by the magnet from my observations.

But perimeters are printed inside-out, could it be the problem?

But perimeters are printed inside-out, could it be the problem?