Creatr Leapfrog – Converted to DuetWifi

-

Let’s see what kind of electronics I have to deal with DUET Wi-Fi board....

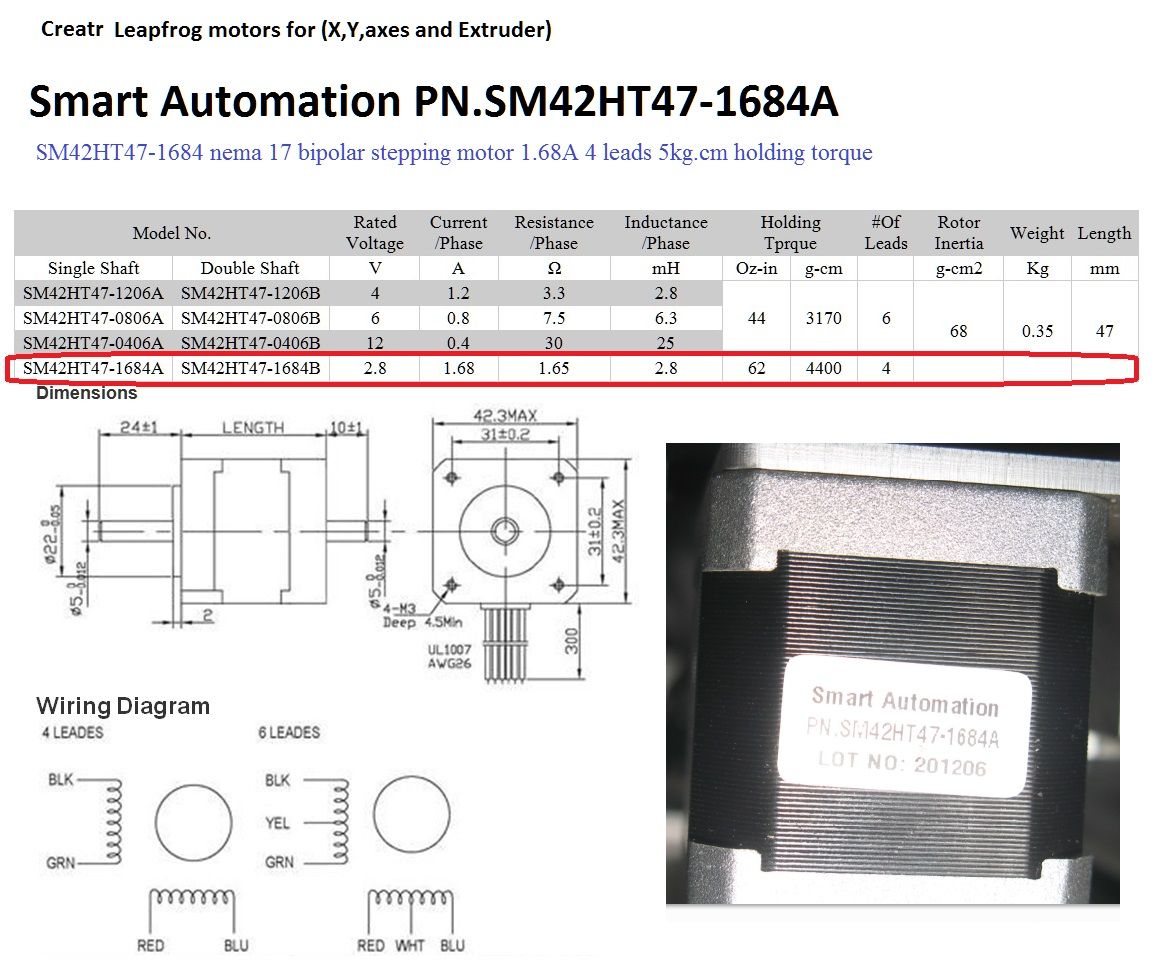

The motors:

The printer has 5 stepper motors:

X-axis: (1pcs) Smart Automation PN.SM42HT47-1684A

Y-axis 2pcs) Smart Automation PN.SM42HT47-1684A

2pcs) Smart Automation PN.SM42HT47-1684A

E-extruder: (1pcs) Smart Automation PN.SM42HT47-1684A

All these 4 motors are the same: SM42HT47-1684 nema 17 bipolar stepping motor 1.68A 4 leads 5kg.cm holding torque)

And here is the motor and the datasheet:

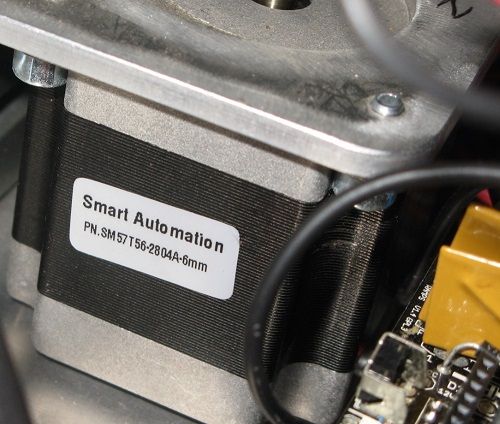

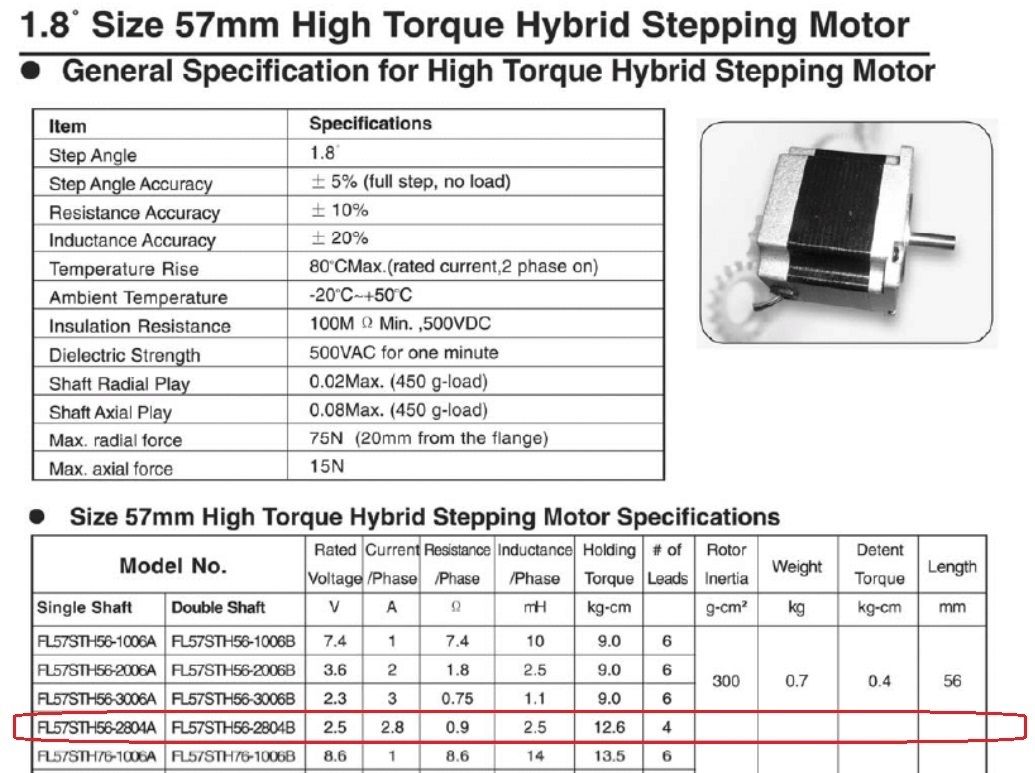

The Z-axis motor, is a much bigger stepper motor:

Z-axis: (1pcs) Smart Automation PN.SM57T56-2804A-6mm

I haven’t the datasheet for that motor, but I think that is very similar to this motor :

According to the DUET guideline for the motorsI think that I can drive the X, Y and E motors directly with DUET Wi-fi board, but I’m not sure for the Z-motor.

The options that I have to drive the motors are:

- Drive them directly from the Duet wifi board (I’m not sure if I can do that with the Z-motor because it seems that it has 2.8 A current)

- Use the Duet Expansion Breakout Board (I don’t know where to find it)

- Use the Stepper Motor Driver TB6600 (cheap from e-bay)

- Or keep the old external drivers (Microstep Driver CW230)

I would appreciate any suggestion …..

-

@gianakop said in Creatr Leapfrog – Converted to DuetWifi:

Drive them directly from the Duet wifi board (I’m not sure if I can do that with the Z-motor because it seems that it has 2.8 A current)

its normally recommended to drive motors at about 80% of their rated current (at rated current they can have 80C temperature rise depending on the motor!)

So if the motor is rated to 2.8A then you can use a Duet 2 set to 2.2A

-

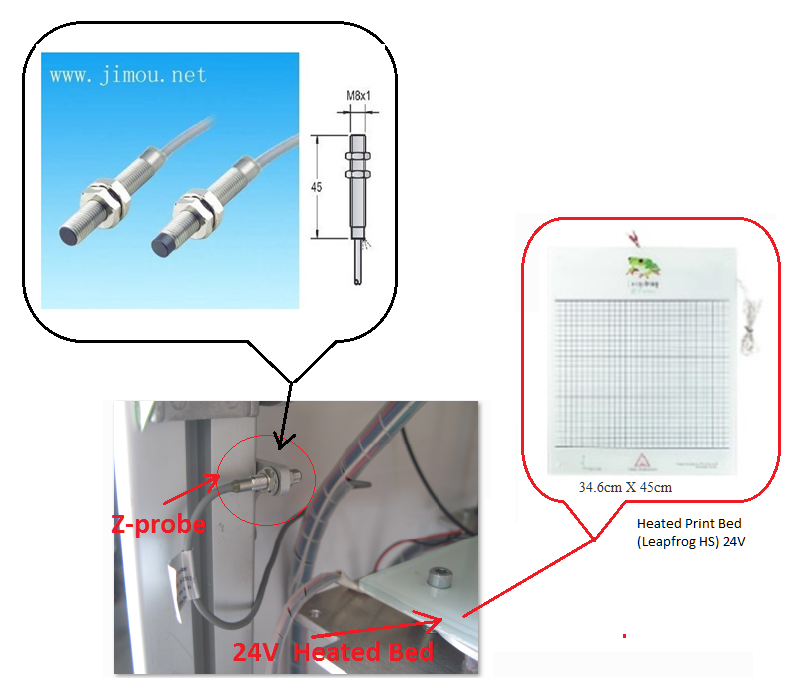

Some other parts of the printer that I’m going to keep before the restoration are:

- The powersuply, that is a : S-400-24 24V POWER SUPLY

- The bed that is the : Heated Print Bed (Leapfrog HS) ( thermo glass bed with dimensions 34.6cm X 45cm and powered with 24V

- The Z-probe : A JIMOU sensor 10-30V DC 150 mA https://bit.ly/32yzCS8

Last but not least I have to mention that Creatr is a Cartesian 3D printer in which the print bed moves only in the Z-axis using one stepper motor, X-axis and Y-axis are moving independently . X-axis uses one stepper motor and Y-axis uses two stepper motors. The extrusion system is direct with extruder and extrusion motor moving together.

-

@T3P3Tony said in Creatr Leapfrog – Converted to DuetWifi:

So if the motor is rated to 2.8A then you can use a Duet 2 set to 2.2A

Thank you @T3P3Tony , That 2.2A setup will be for all the motors? or I can make it only for the Z-motor and for the other X, Y i can use a different curent setup?

-

@gianakop said in Creatr Leapfrog – Converted to DuetWifi:

That 2.2A setup will be for all the motors? or I can make it only for the Z-motor and for the other X, Y i can use a different curent setup?

You can individually set the motor current for each driver that a motor is connected to (e.g. your Z-axis stepper would be 2.2A while your X stepper and two Y axis steppers would be some other value).

-

https://duet3d.dozuki.com/Wiki/Gcode#Section_M906_Set_motor_currents

The gcode command you would use in your config.g file would be M906 for setting the motor currents.

-

@gianakop Just wanted to thank you for your contribution! My leapfrog nema 17 motors were missing the model number stickers so I was never able to look up the specs. I'm tearing down my unreliable Creatr and will be using it's parts to upgrade my incoming TronXY x5sa Pro that will arrive in a couple days.

Anyways, I registered just to add to your info what I've found about the nema 23 motor.

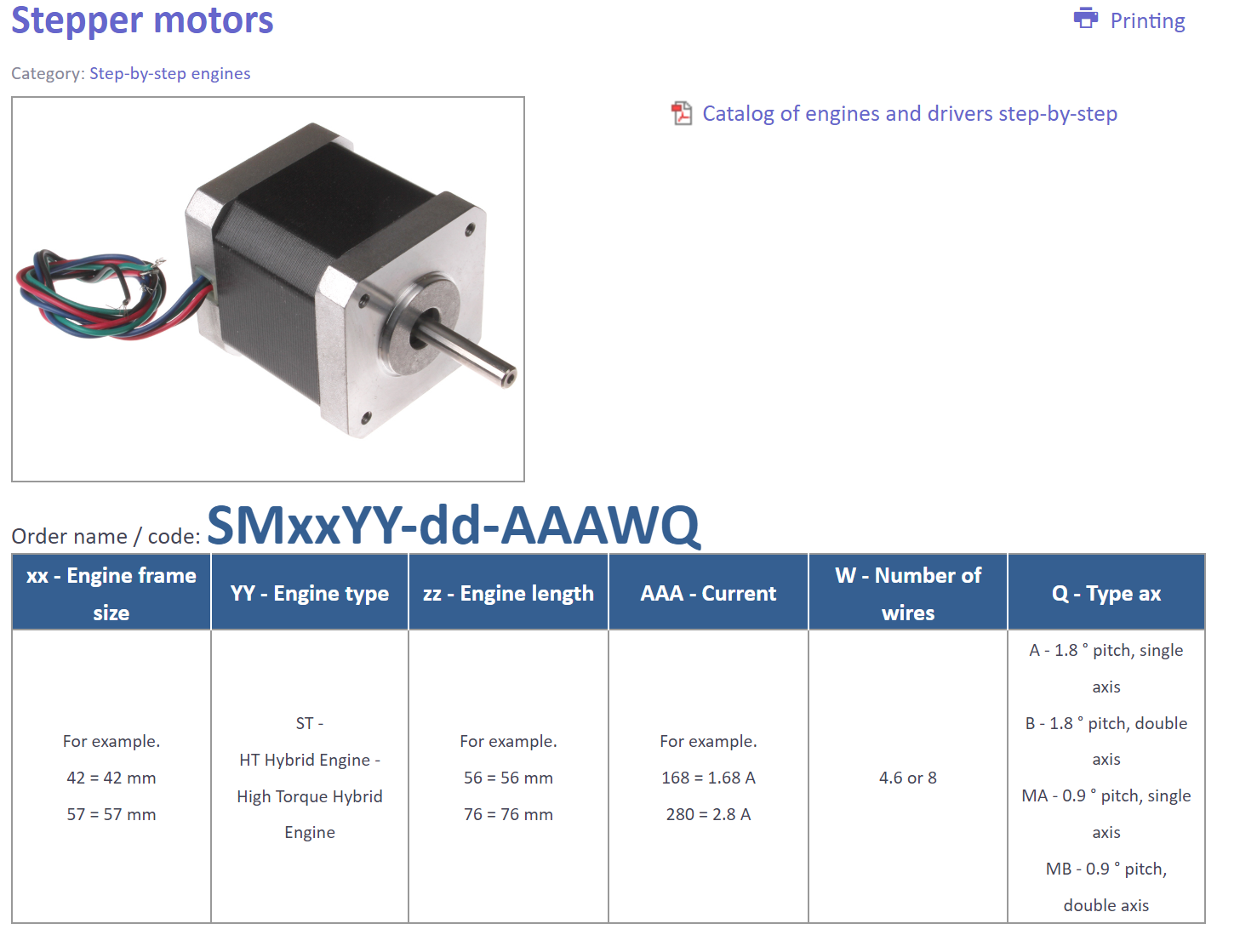

http://www.multiprojekt.ro/produse/motoare-pas-cu-pas/motoare-pas-cu-pas-stepper

So my guess would be

SM = stepper motor

57 = width of motor

T = most likely "Torque"

56 = length of motor

280 = 2.8 a

4 = 4 wires

A = 1.8 pitch single axisYou can also refer to this pdf for future motor references.

-

@Red-Sand-Robot said in Creatr Leapfrog – Converted to DuetWifi:

@gianakop said in Creatr Leapfrog – Converted to DuetWifi:

That 2.2A setup will be for all the motors? or I can make it only for the Z-motor and for the other X, Y i can use a different curent setup?

You can individually set the motor current for each driver that a motor is connected to (e.g. your Z-axis stepper would be 2.2A while your X stepper and two Y axis steppers would be some other value).

This is Amazing! I think that the Duet board will change completely my old Creatr!

-

@vangc21 said in Creatr Leapfrog – Converted to DuetWifi:

So my guess would be

SM = stepper motor

57 = width of motor

T = most likely "Torque"

56 = length of motor

280 = 2.8 a

4 = 4 wires

A = 1.8 pitch single axisYou can also refer to this pdf for future motor references.

Thank you so much for your reply and for your help!!!

However, your decision to use the old Creatr only for spare parts in order to upgrade your TronXY x5sa Pro, makes me feel that I'm trying something that is not worth at all. Anyway I also have and another 3d Printer the Ender 3 Pro and in case that Creatr's upgrade fails I'll upgrade my Ender 3 according this tutorial "Ender 3 Pro and Duet Maestro Guide " -

@gianakop It depends on what other printers you have on hand. In my case, I bought the creatr for $150 off someone on Craigslist. I tried to get it to a good working state but was never able to get decent prints off it. So, I parted it for parts to upgrade my Tronxy X5sa Pro.

The glass plate worked perfectly for the x5sa pro. I'll probably use the 40x40 aluminum extrusion to strengthen the frame of the x5sa. First, I have to measure and cut it to fit the x5sa.

-

Hi gianakop ,

we share the same problem.

I received my Leapfrog from my employer who was more than happy when somebody carried it out of the office.-here we are.

I had problems with y stepper noise, but now all steppers are quiet, thanks to advise from this forum.

I also improved the filament cooling by aluminum fairings. I changed the z probe to ordinary microswitch because of my limited skills in electronics. Maybe You have tried the original one?

Now I´m working with the second extruder and dual extruding and thermistors.