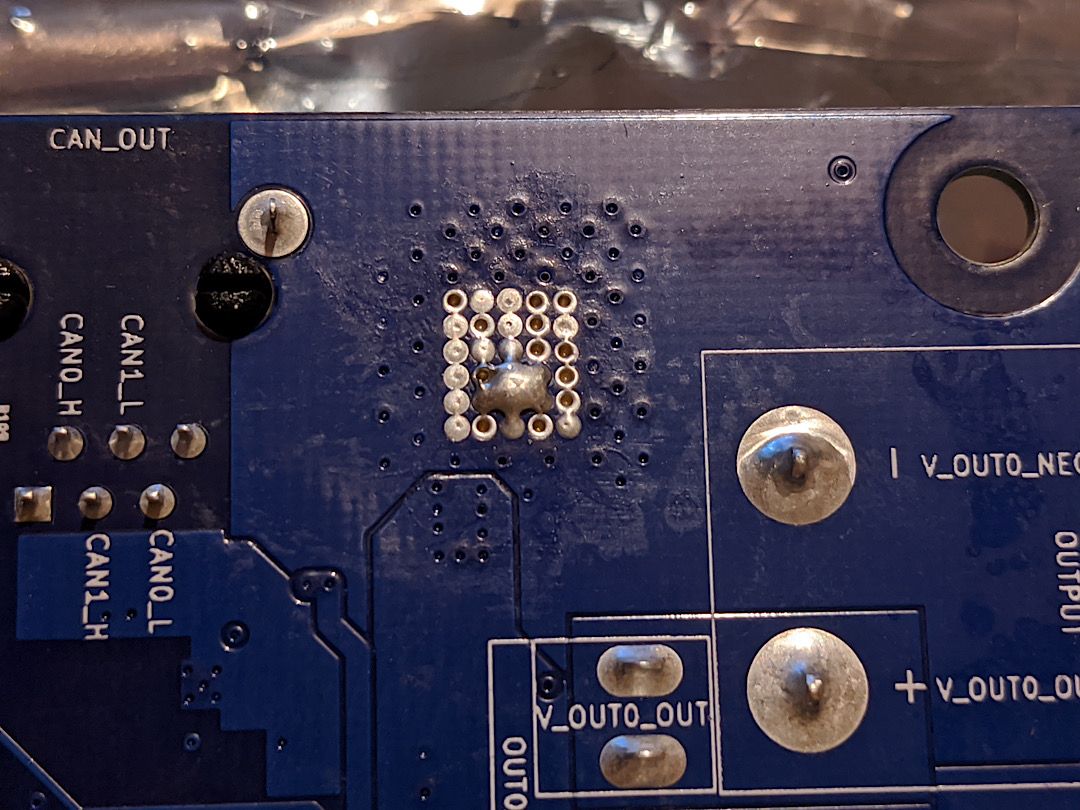

Solder on the bottom of the Duet 3

-

Got my Duet 3 on Monday, very exciting ha ha

Just having a good look at it and noticed there seems to be some inconsistent soldering on the bottom, I don’t know if this is fine or if it will effect the board so just wanted some clarification.

-

It's fine

-

@jens55 cool thanks.

-

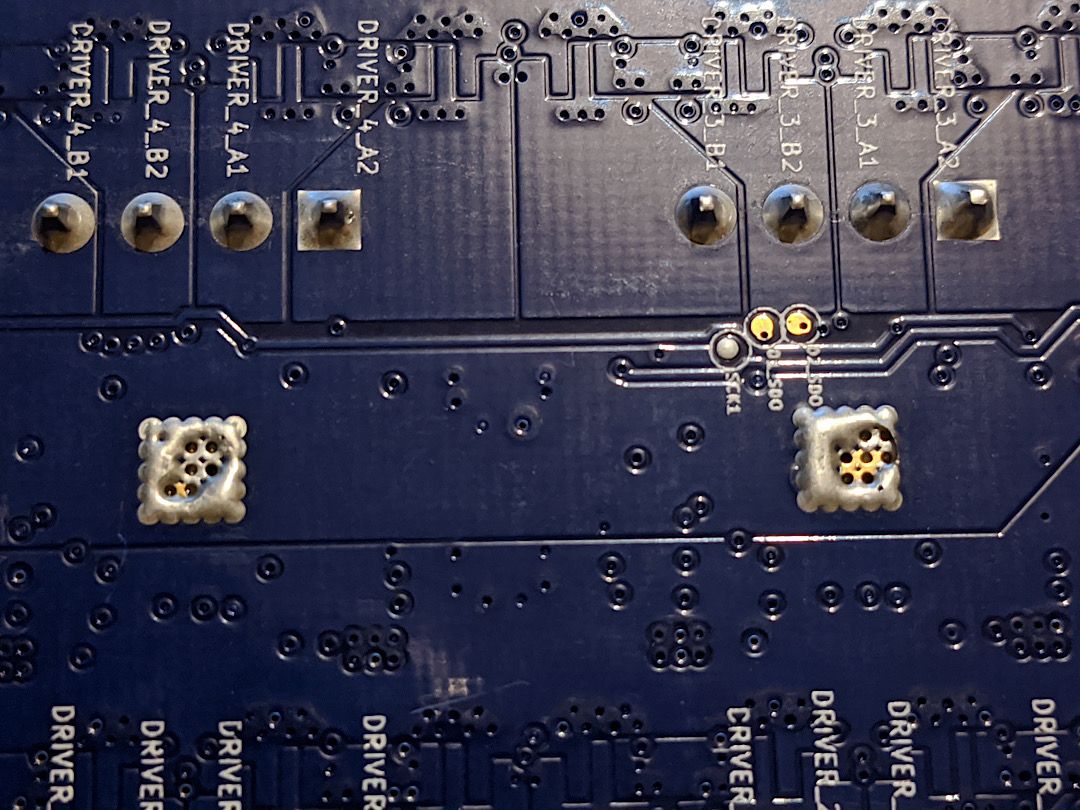

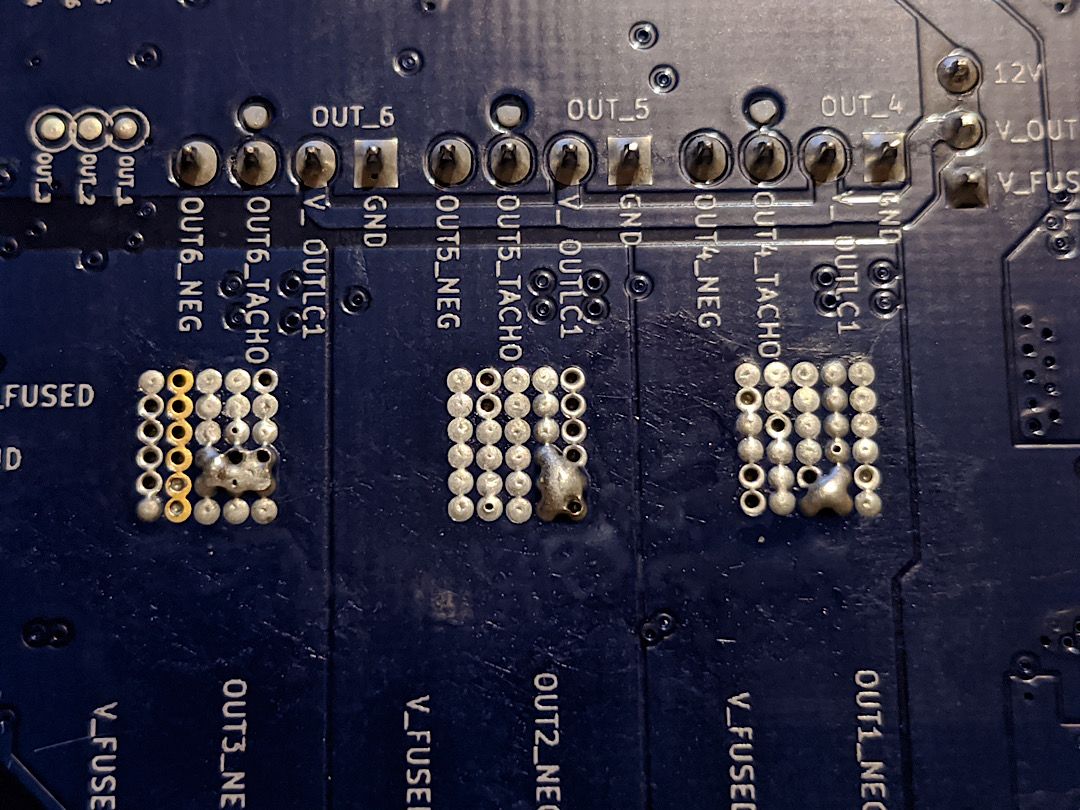

Yeah it doesn't look all that great but those grids of holes are for transferring heat away from the chips that sit above them.

@T3P3Tony : That seems excessive though.

-

Its not an issue at all, the wave soldering that is used to solder the through hole components on the bottom of the board also sometime leaves some solder on the vias used to transfer the heat. We may mask them in the future but it does not effect the performance.

-

@T3P3Tony thanks, that's good to hear

-

You may want to rub out the residual flux even though its more likely than not "no clean" flux that is used. Isopropyl alcohol is a good choice.

-

@bearer will give it a go, I have a silly amount of IPA from resin printing lol

-

@bearer said in Solder on the bottom of the Duet 3:

You may want to rub out the residual flux even though its more likely than not "no clean" flux that is used. Isopropyl alcohol is a good choice.

no need to remove the flux residue either.

-

@T3P3Tony said in Solder on the bottom of the Duet 3:

Its not an issue at all, the wave soldering that is used to solder the through hole components on the bottom of the board also sometime leaves some solder on the vias used to transfer the heat. We may mask them in the future but it does not effect the performance.

A few points on solder in thermal vias:

-

It’s bad if the vias to suck in solder from the top side. This can cause bad joint to the thermal pad in the bottom, voiding the whole point of the thermal connection. This is the matter of designing the via pattern and solder paste pattern to minimize the possibility. Via size matters.

-

If the board goes to a wave, it is good if the vias suck in solder from bottom. This much improves the thermal flow.

-

You don’t want to cover the vias from bottom and leave top side uncovered. This creates pockets of air under the chip, possibly covered with solder paste or melted solder from the top. All kinds of funny effects (up to exploding chips) can result.

-

You can tent the vias on both sides, but tented vias for thermal pads are tricky.

And folks at Duet3D know all this already.

I’m just commenting out from my manufacturing experience why it is made the way it is, and why I think it is according good engineering practice, even though it might not always look pretty.

I’m just commenting out from my manufacturing experience why it is made the way it is, and why I think it is according good engineering practice, even though it might not always look pretty. -