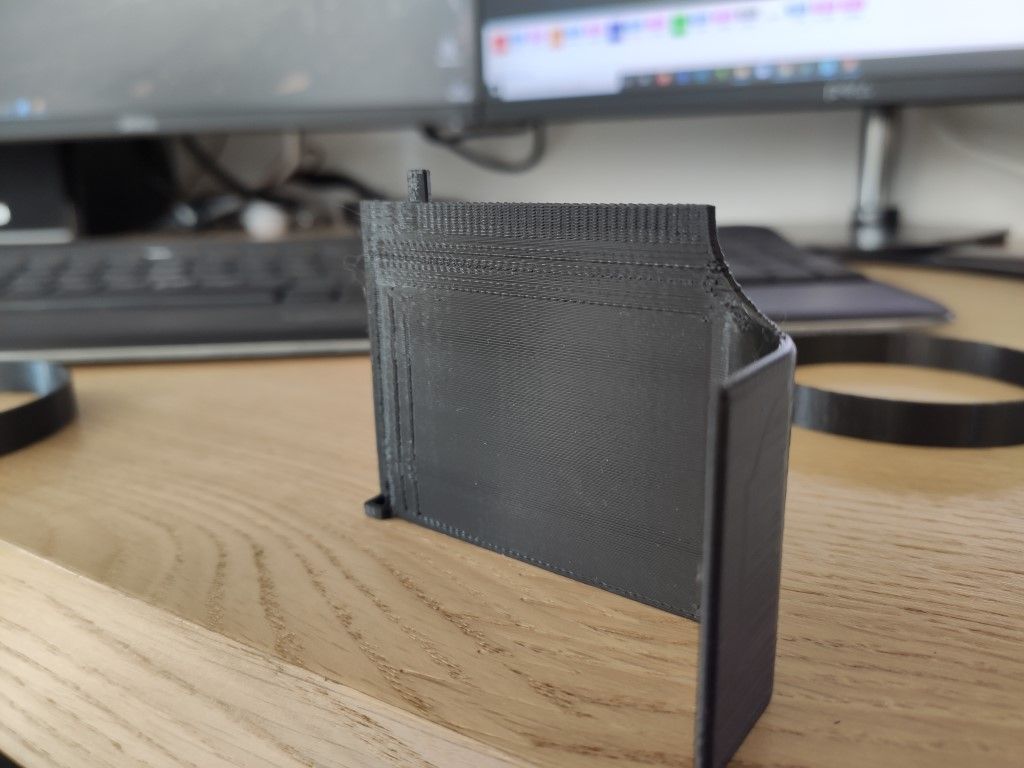

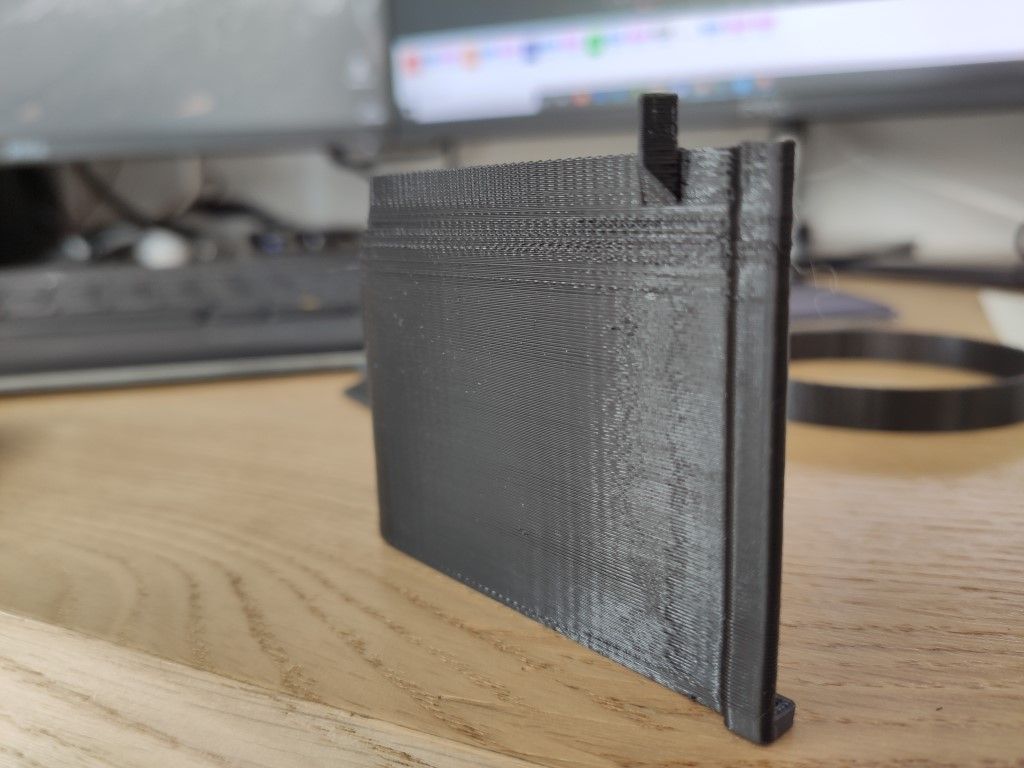

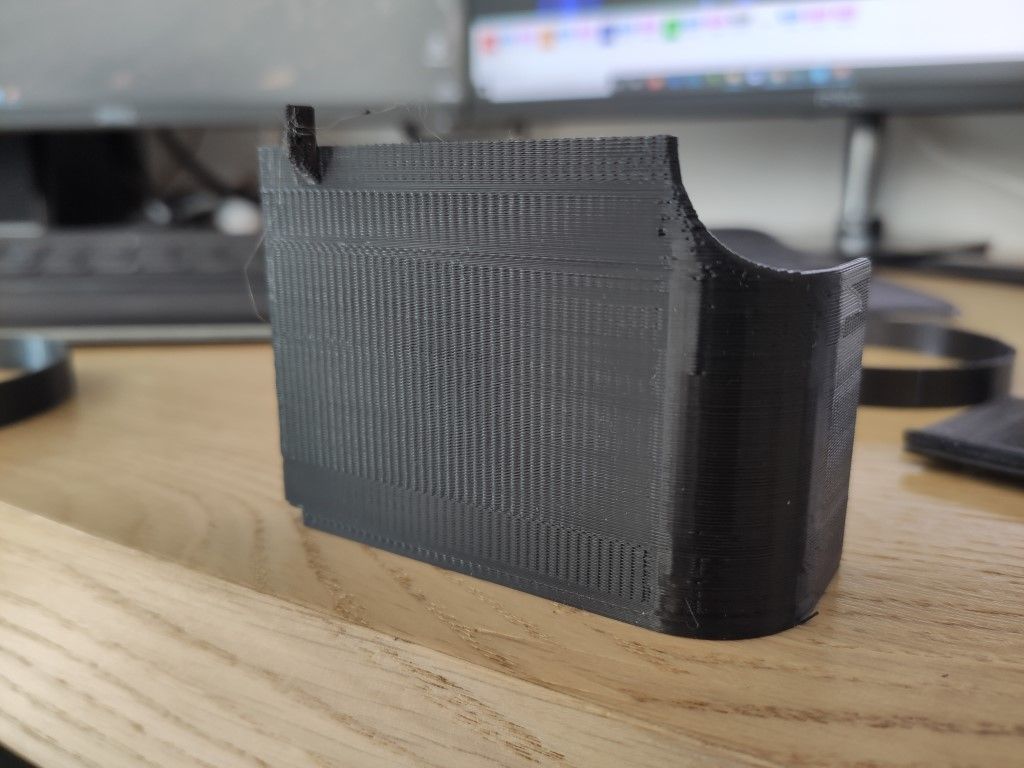

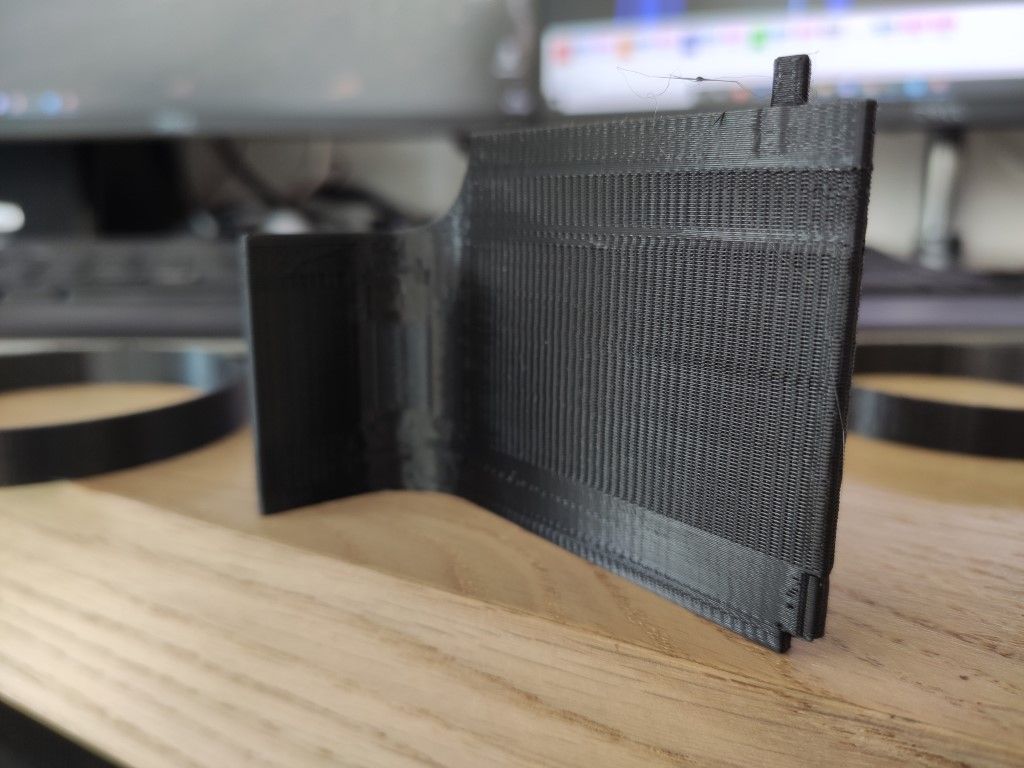

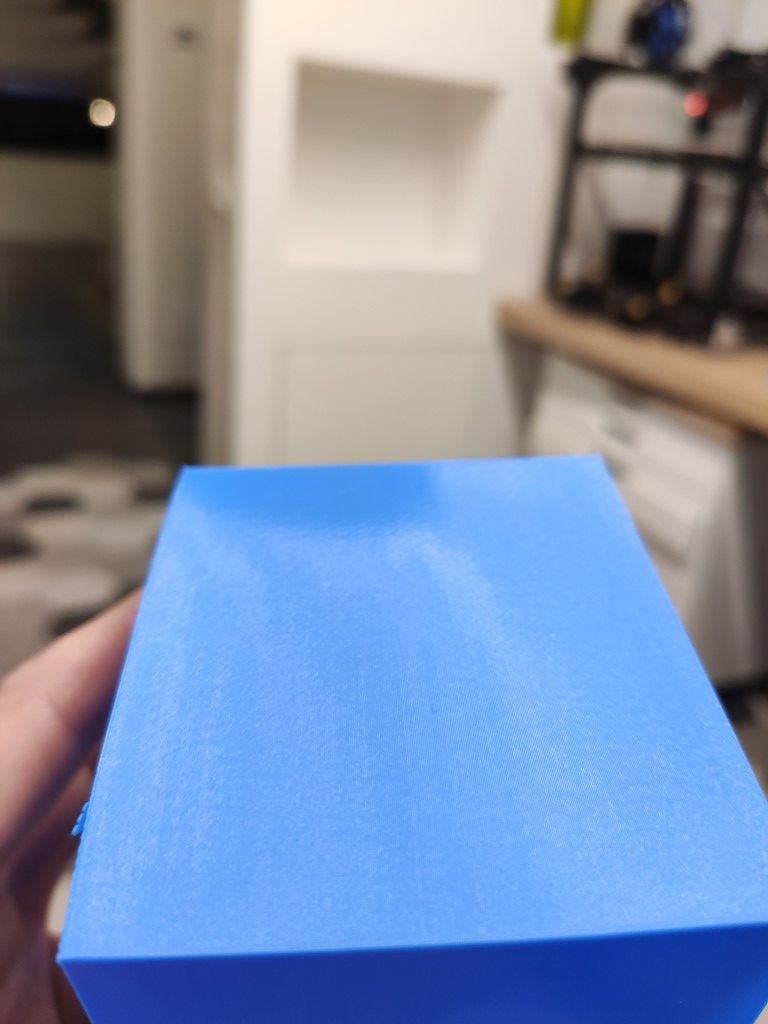

Suddenly bad print quality !

-

-

what kind of printer is it?

what material is that?post a picture of your printer as well.

-

Thank you for your answer .

PLA geeteck , printed at 200 C° speed 50 mm/s

Printer modded D-bot it always printed perfectly without artifacts.

this is my printer and usually print results.

https://forum.duet3d.com/topic/11576/d-bot-reworked-very-happy-with-results-achieved/2?_=1579440529686 -

the wheels can fail.

disconnect the belt and check if you can move everthing without any resistance.

also check for play. -

Checked all the wheels and everything seems fine , no evident play . Any idea on how I could identify the problem?

-

How much filament have you run through your nozzle? Did you get a hardened nozzle or have you been using a brass one? Have you used any filaments that are abrasive like carbon fiber or glow-in-the-dark? Any materials that hydrolyze? (200ºC for PLA would be too hot in my machine & would definitely make trouble unless I kept the filament moving)

When I had a (previously dialed in) material suddenly experience a drop in quality that couldn't be explained by mechanical or electrical malfunction in the past it turned out to be the nozzle - it had accumulated residue on the inside and had worn away on the outside to the point where the orifice was no longer producing a circular and consistent output stream.

-

I'm inclined to think this could be an extrusion/nozzle issue.

If you've already taken your belts off and really checked for carriage wheels for travel and play, I'd change the nozzle for a fresh one. While the nozzle was out I'd also (carefully so as not to make a mess) extrude a bit of plastic through the hot end before putting a new one in, just so as to push any contaminants out as well.

The fact that it was fine then just started happening suggests it's a sudden failure that should be reasonably apparent.

-

-

If you're going to change the nozzle, it's well worthwhile purging the hot end, giving your extruder gears a clean/adjustment, and checking your esteps for that filament at the desired print temp.

Try printing that PLA at a nice safe 210 degC, which should be fine if your temp sensor is working.

Nice printer! Love the Z axis.