Bed leveling/twist

-

Hi All,

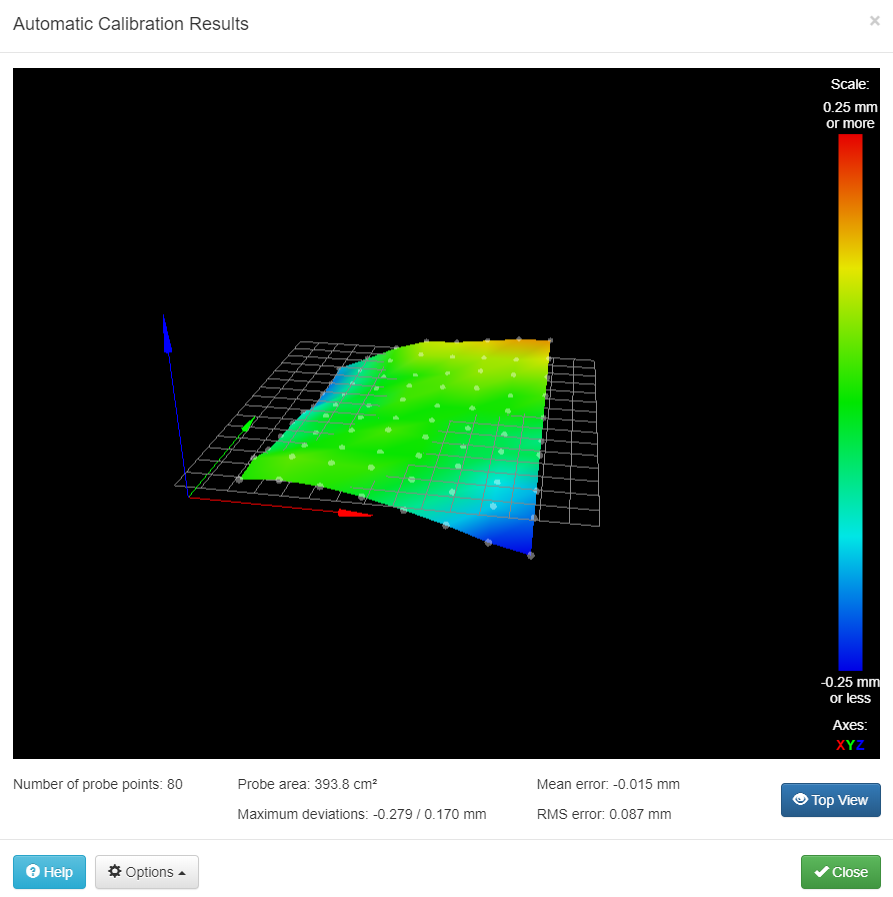

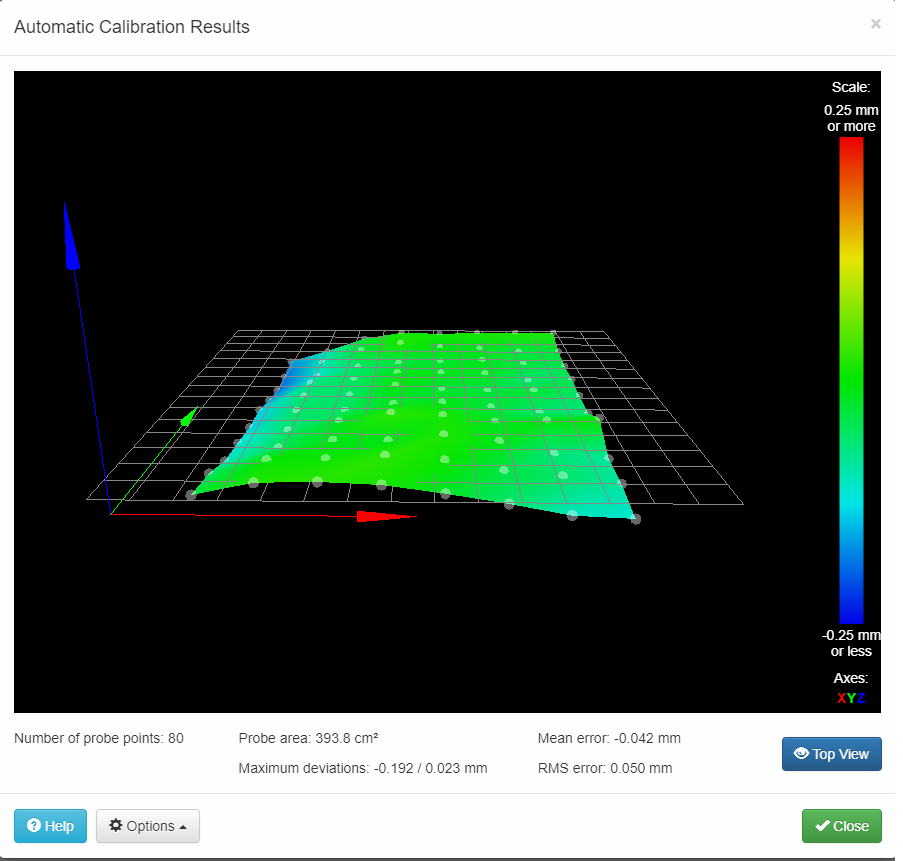

Having some rather entertaining issues with trying to level the bed, looks from the results like a bit of a twist is going on, but cant get my head around trying to fix it, and before i start modifying blindly, figured I'd raise it and see what people think.

The rod end heights are non adjustable, without some filing to release it from its constraints (which...if it needs it, or otherwise, I'm happy to get on and do it), and if additional parts needed to raise it, again I'll fabricate.

With mesh leveling it prints absolutely fine, but its going to be constantly adjusting height up to the fade height limit which isn't particularly great.

Any ideas/insight would be greatly appreciated

D

Printer details:

Printer Type: Cartesian, steel frame

Probe: BLTouch

Bed: 220x320mm heated aluminium, floating glass top surface

Y Carriage hardware:4 igus bushes, 10mm rods, 3 point leveling (back left, front left, fixed center right), aluminium mount plate (not particularly strong aluminium at that either)Firmware Name: RepRapFirmware for Duet 2 WiFi/Ethernet

Firmware Electronics: Duet WiFi 1.02 or later

Firmware Version: 2.02(RTOS) (2018-12-24b1)

WiFi Server Version: 1.22

Web Interface Version: 1.22.6 -

Can you post some photos of the printer?

I recently had an apparent bed twist on my E3D Tool Changer. It turned out to be caused by the bench that it was sitting on not being flat, which was causing the whole frame of the printer to twist.

-

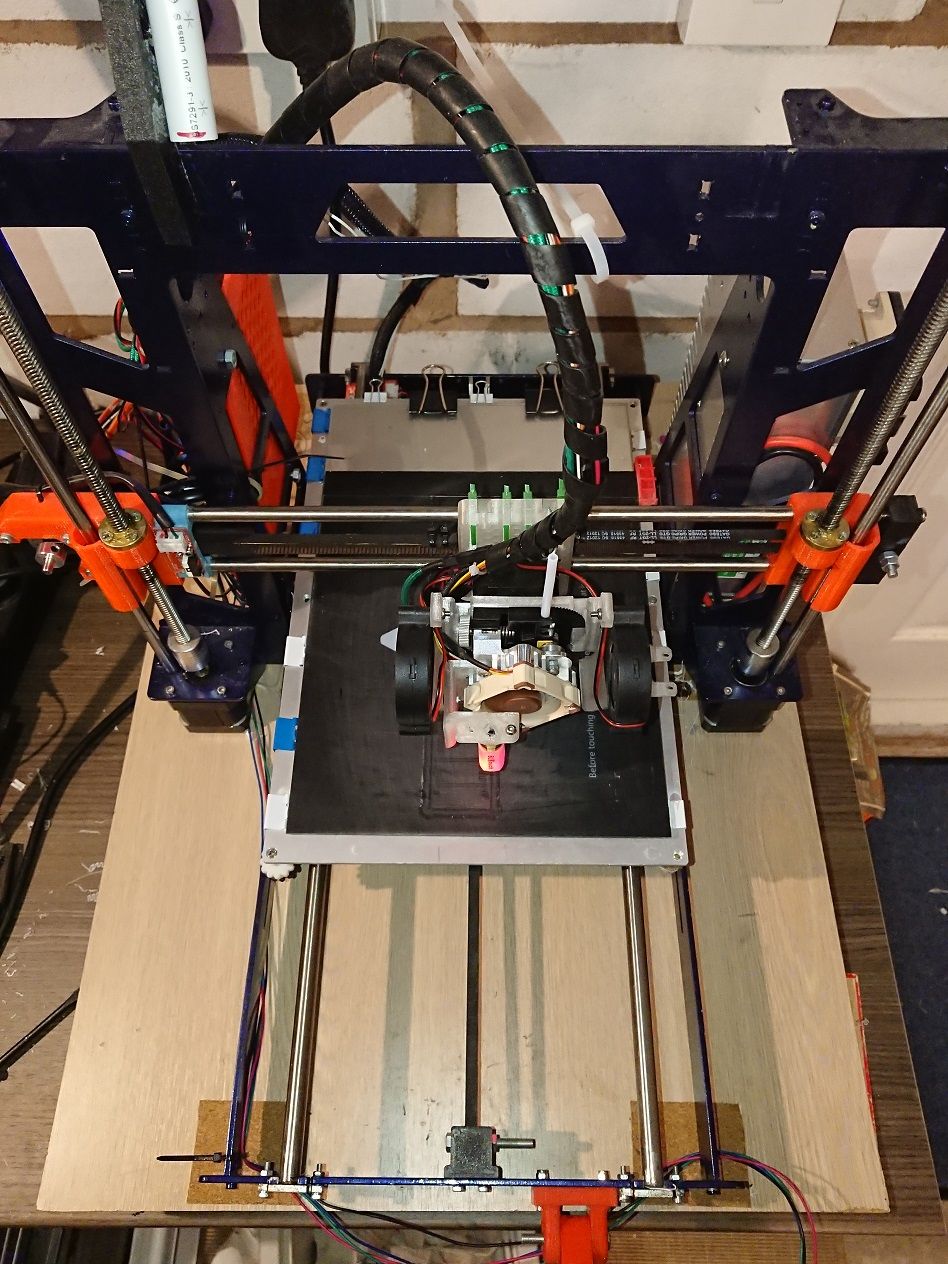

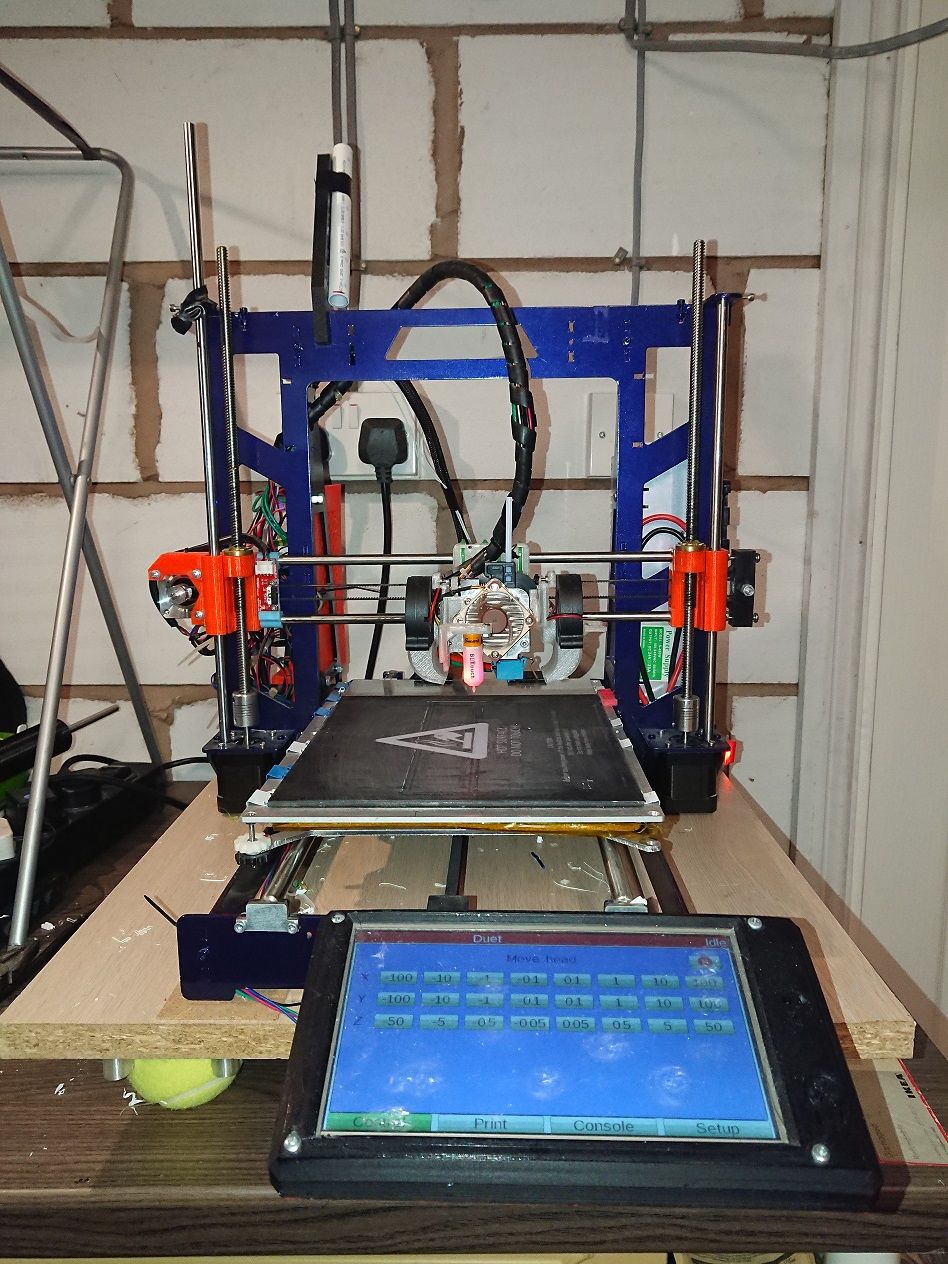

Photos as requested, please excuse the mismatched length Z rods...one of those "ill swap it out later.." that never happened.

Its been absolutely fine printing (we are well into the 4 figures of hours) so electrically its rock solid, parts dimensions are accurate and square (when its a square), but printing large items, I can see it constantly tweaking the Z height.

From putting a spirit level across the rods (and then the wooden base) the RH looked to be about 2mm down left to right, identical measurements front of rods to back of rods so I've just slid 2mm worth of board under the LHS under the tennis balls to even it up. Re-running the calibration now.

D

-

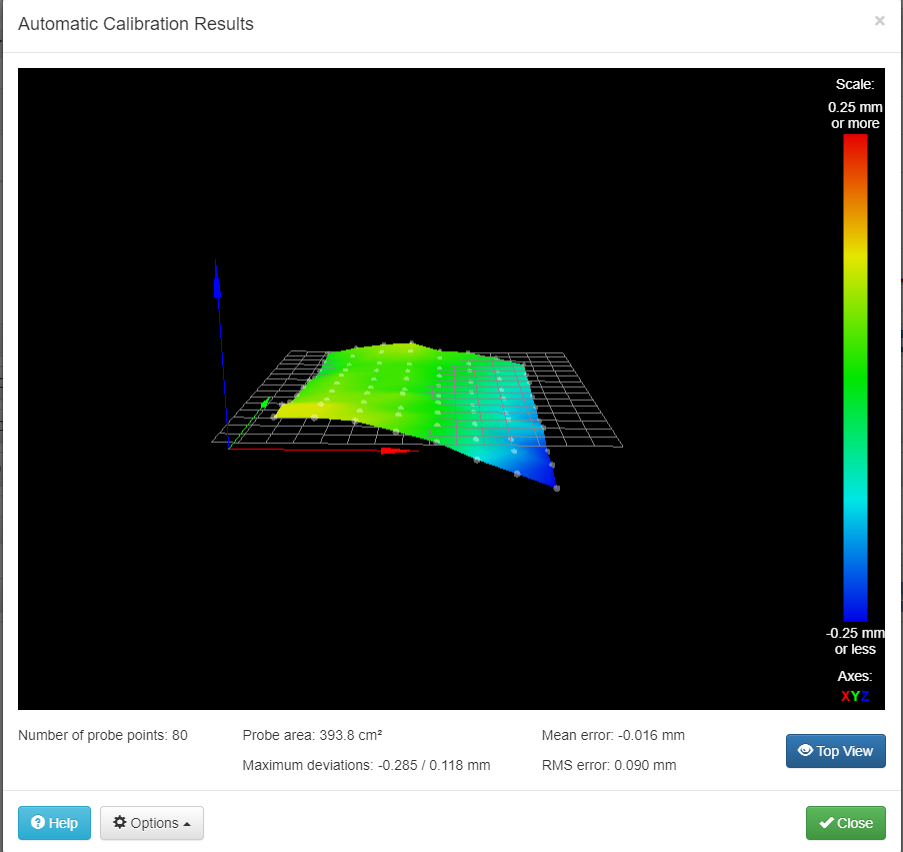

Results post 2mm adjustment of surface:

Looking better, going to remove the 2mm packing and re-run just to confirm the change. Certainly interesting...as the surface its mounted on is flat

D

-

@datasquirrel The height adjusting screw is missing from the right front corner of the table (see first picture).

And your height map confirms that corner is low. That may be some of the issue?

-

@timcurtis67, screw is missing that side as i'm doing 3 point leveling, the screw that side is in the middle of right side of the bed, so to adjust the front right corner up, I'd lower the rear left first.

I originally tried 4 point, but it caused problems (cant remember what they were when I built it but it was enough to go..hm..no..lets go 3 point)

-

Thanks for the photo. The reason for the twist is likely to be that the two smooth rods that the bed slides on are not exactly parallel but are relatively twisted, so that the bed rotates slightly about the Y axis as it moves in the Y direction. I had exactly this issue with my Ormerod printer.

-

Measured the rod->wooden base front and back of the right rod, it was out by about -0.15mm on the front. The left rod is out by 0.8 so that will be the next to get adjusted I think.

Some filing later, and a few layers of foil tape [hack] to raise up the front of the right hand rod, and some minor screw adjustment later, its looking much better:

Still not quite as good as I'd like it, but for a first pass its not too bad. I'll have to draw out a diagram to work out what needs tweaking to adjust what corner as the moment is around the right hand leveling screw.

Thanks for the help

D

-

@datasquirrel I'd guess that the curve across the bed is due to the mass of the X carriage being offset in front of the X rails. This is bending the rails, and is worst in the middle. It's a common problem with vertical, Prusa i3 style X axes, and few X carriages try to centralise the mass over the rods to minimise this. And it looks worse than it is due to the position of the BLTouch, which is even further forward than the nozzle, so reads a bigger deviation than the nozzle does. Can you relocate the BLTouch elsewhere, closer to the nozzle?

Ian

-

@droftarts, I'm definitely not winning any lightweight carriage contests

but I tend to print slow (flexi) so ringing isn't a problem at those speeds.

but I tend to print slow (flexi) so ringing isn't a problem at those speeds.Reworked a few of the parts and shaved about 10g off, but that's still not a huge amount, hasn't made much difference but every few -g counts. Further weight reduction is in the pipeline, but more as an experiment with a flex-drive and a 10:1 gear + 3:1 gear on the titan aero (totaling 30:1), no idea if that will work but I'll take a punt for the cost of it. Their standard direct drive replacement kit is 40:1, so its not too far behind, and I'll take a view on backlash once its built.

The deviation, I think...is catered for by the nozzle offset and trigger height (unsure, but it feels like it should?), the probe can access the whole printable area. I think this may be a good time to rework the X-axis with a linear rail + rod setup. That sounds like a better plan than just upping the rods to 10mm from 8mm and adding yet more weight.

On further inspection, it looks like the actual y-carriage itself doesn't look quite square/true, 1 of the corners looks not quite straight, so choices...replace with a machined aluminium sheet, or get the carbide tools out and make one out of 3mm CF. The spare 220x220 CF bed I have kicking around was a nice upgrade but so..so..messy to make.

D