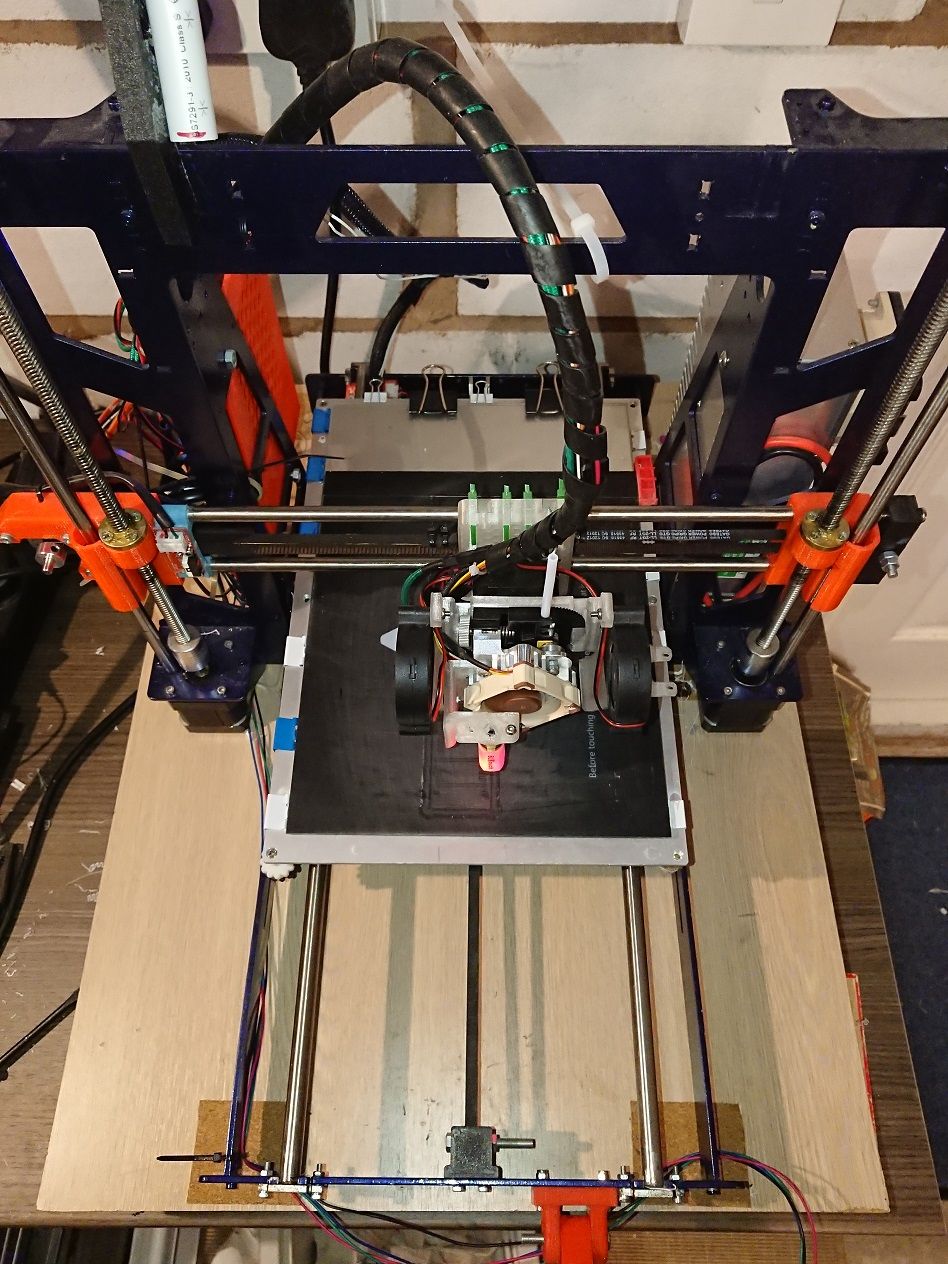

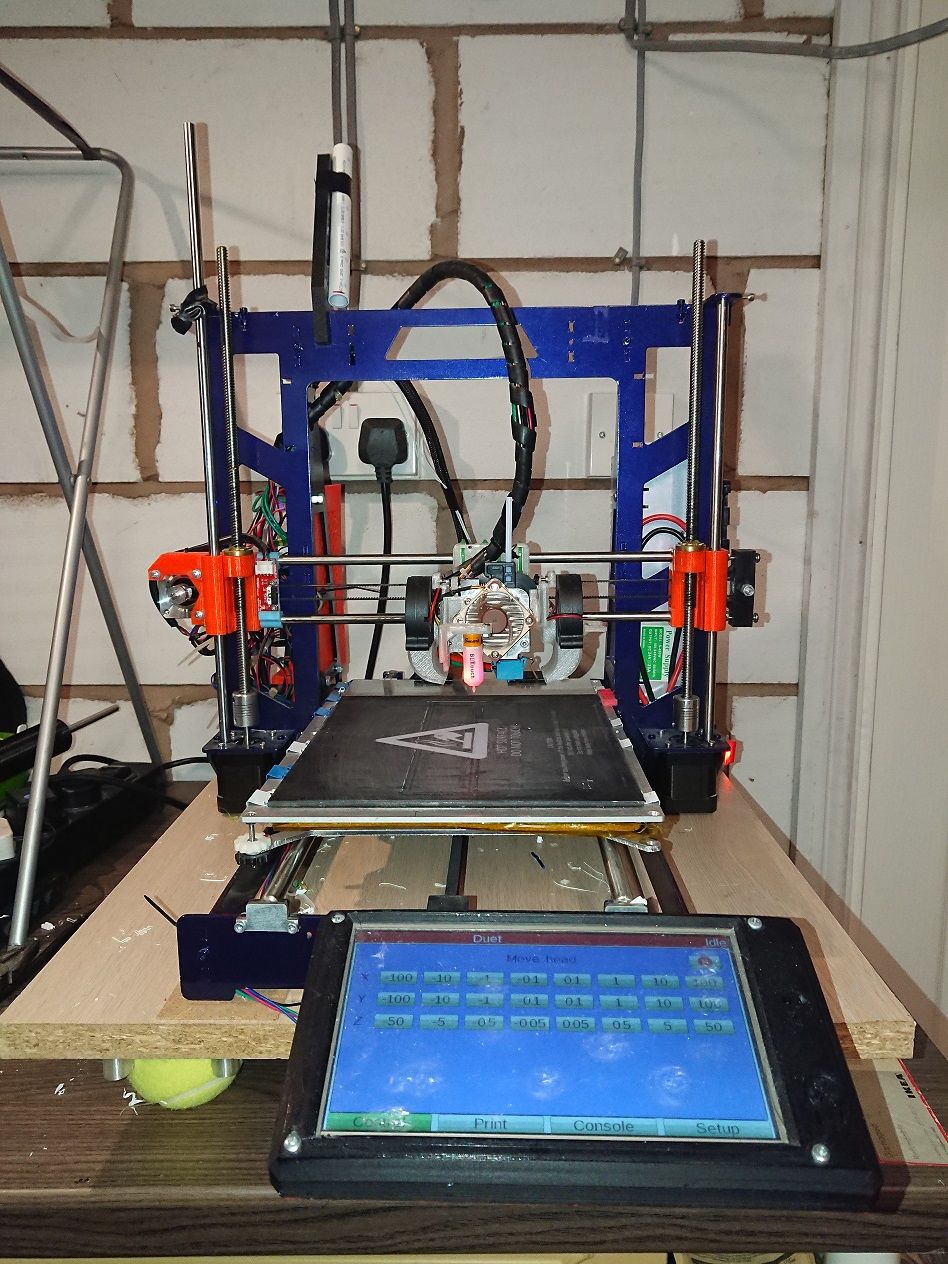

@droftarts, I'm definitely not winning any lightweight carriage contests  but I tend to print slow (flexi) so ringing isn't a problem at those speeds.

but I tend to print slow (flexi) so ringing isn't a problem at those speeds.

Reworked a few of the parts and shaved about 10g off, but that's still not a huge amount, hasn't made much difference but every few -g counts. Further weight reduction is in the pipeline, but more as an experiment with a flex-drive and a 10:1 gear + 3:1 gear on the titan aero (totaling 30:1), no idea if that will work but I'll take a punt for the cost of it. Their standard direct drive replacement kit is 40:1, so its not too far behind, and I'll take a view on backlash once its built.

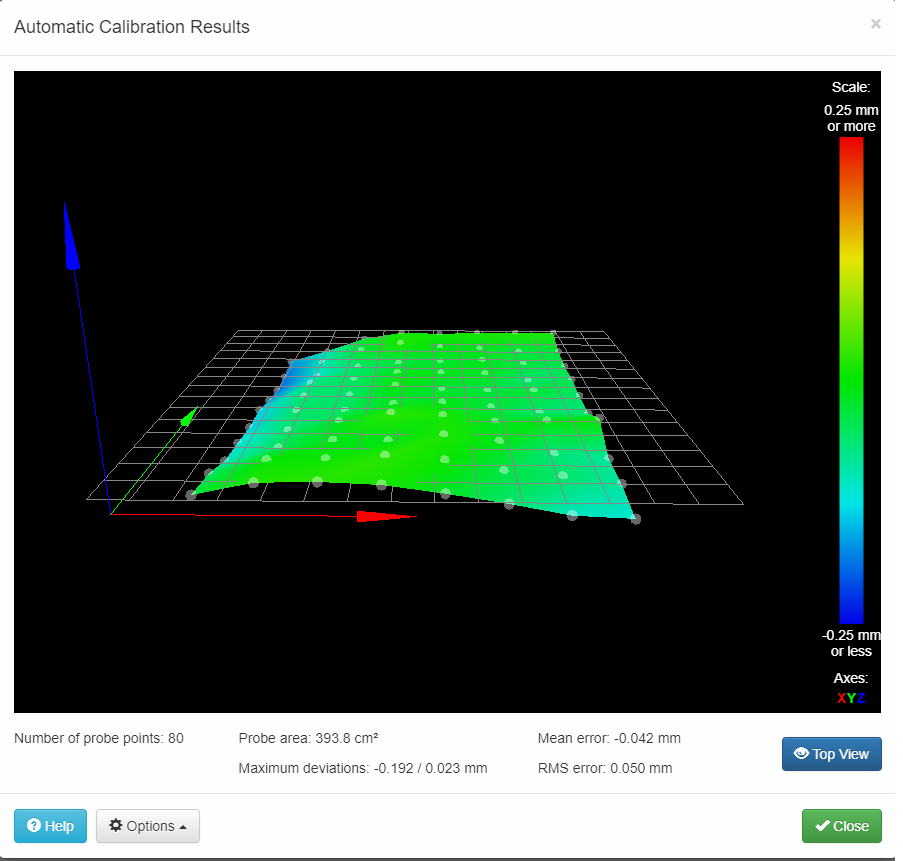

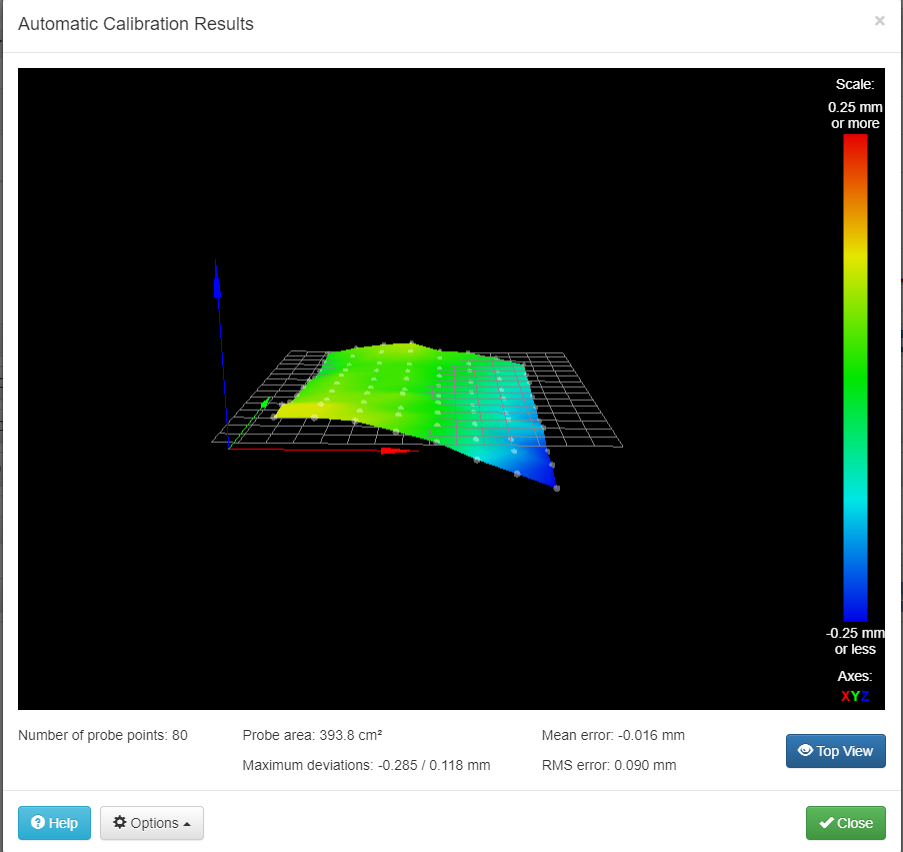

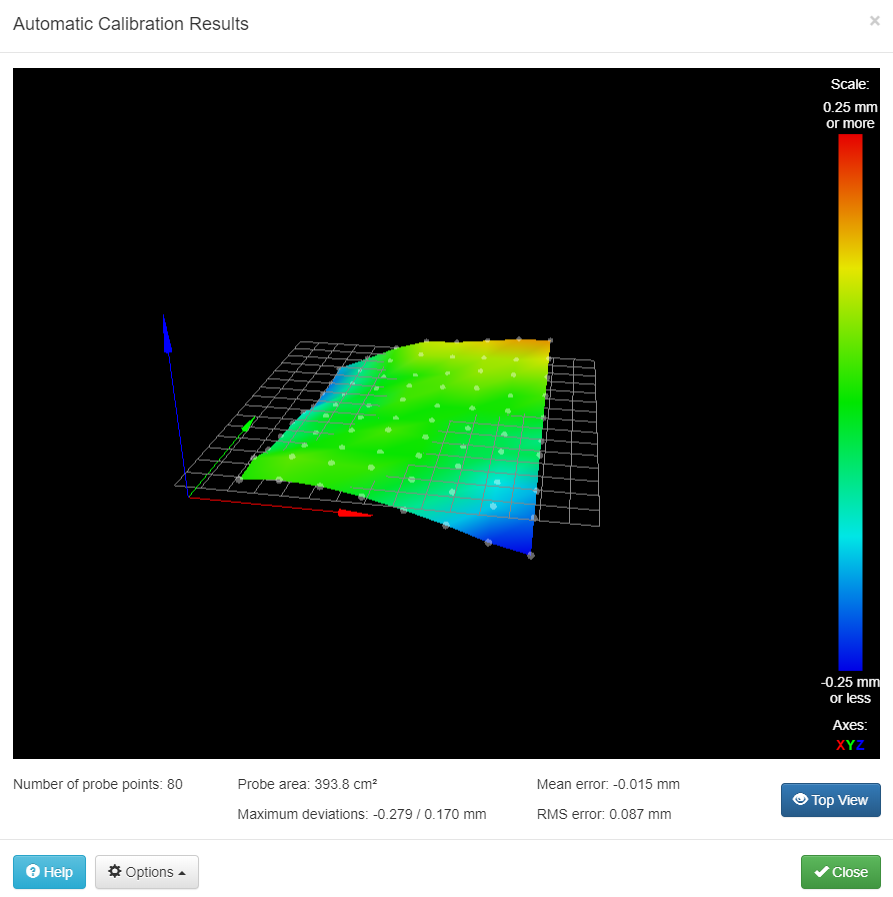

The deviation, I think...is catered for by the nozzle offset and trigger height (unsure, but it feels like it should?), the probe can access the whole printable area. I think this may be a good time to rework the X-axis with a linear rail + rod setup. That sounds like a better plan than just upping the rods to 10mm from 8mm and adding yet more weight.

On further inspection, it looks like the actual y-carriage itself doesn't look quite square/true, 1 of the corners looks not quite straight, so choices...replace with a machined aluminium sheet, or get the carbide tools out and make one out of 3mm CF. The spare 220x220 CF bed I have kicking around was a nice upgrade but so..so..messy to make.

D