Hotend and Heated bed reading 2000deg celcius and fault

-

for some reason my hotend fans stopped spinning. should i tune the hotend without fans?

im not sure what the problem is, the two fans stopped spinning last night, but when i click on TestFans, they do just fine and start spinning and after the test they go off. -

@NEVER-LUCKY said in Hotend and Heated bed reading 2000deg celcius and fault:

should i tune the hotend without fans?

No.

What do you have in your config.g for fans? How are the fans wired?

-

@NEVER-LUCKY said in Hotend and Heated bed reading 2000deg celcius and fault:

TestFans,

Test fans sounds like a factory test macro. Do not use it.

Does the hotend fan spin briefly at power on?

-

They are wired fine because TestFans Macro runs perfectly but after that they turn off completely and there is no way to turn even on of the two on. Im using an alwaysOn fan aswell to cool the drivers and that is running just fine. only the two hotend fans are not spinning.

; Configuration file for Duet Maestro (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Sat Jan 18 2020 15:59:57 GMT+0100 (Central European Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Colossus" ; set printer name M665 R154 L324 B150 H700 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z80.00 E663.00 ; set steps per mm M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; set minimum Z ; Endstops M574 X2 S1 P"xstop" ; configure active-low endstop for high end on X via pin xstop M574 Y2 S1 P"ystop" ; configure active-low endstop for high end on Y via pin ystop M574 Z2 S1 P"zstop" ; configure active-low endstop for high end on Z via pin zstop ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 R85 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S130 ; set temperature limit for heater 0 to 130C M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ; Tools M563 P0 S"Extruder_TOOL" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

i cant find a thing about fans in config

-

@Phaedrux said in Hotend and Heated bed reading 2000deg celcius and fault:

Test fans sounds like a factory test macro. Do not use it.

at power on neither of the two spin

-

Ok, I'm guessing you didn't choose any fans when running the configurator.

How do you have the fans connected?

You said that when you ran TESTFANS the fans would spin?

Can you post the contents of that macro? -

; Test Routine for Duet 2 Maestro August 2018: Test PWM fans ;Start logging M929 P"test3log.txt" S1 M291 P"Once OK is pressed all 3 fans should come on full power" R"Fan Test" S2 ; Full on fan test M106 P0 S255 M106 P1 S255 M106 P2 S255 G4 P5000 M291 P"Once OK is pressed all 3 fans should change to half power" R"Fan Test" S2 ; Full on fan test M106 P0 S180 M106 P1 S180 M106 P2 S180 G4 P5000 M291 P"Once OK is pressed all 3 fans should turn off" R"Fan Test" S2 ; Full on fan test M106 P0 S0 M106 P1 S0 M106 P2 S0 -

Ok, well at least we know the fans work.

If you have recently generated that config.g using the configurator, you can re-open it in the configurator and make some changes to it there and re-export it.

In DWC, in the sys folder, you will see a little button next to the config file saying something like edit with config tool. I haven't tried it yet myself, but it should open the configurator with your current settings and allow you to make changes. You'll just need to select the fan ports you are using there.

Hopefully that will get you rolling. I have to step out for a bit. Good luck.

-

thanks !

ill try it -

i remember what happened, when i was adding and removing things from ;Heaters, i accidentally deleted ;Fans...

soo stupid..One question: is it normal that the extrude/retract button in DWC doesnt work when the hotend isnt hot enough?

if that is correct, then at what temp will it start working? 200? -

@NEVER-LUCKY search the gcode wiki for cold extrude.

-

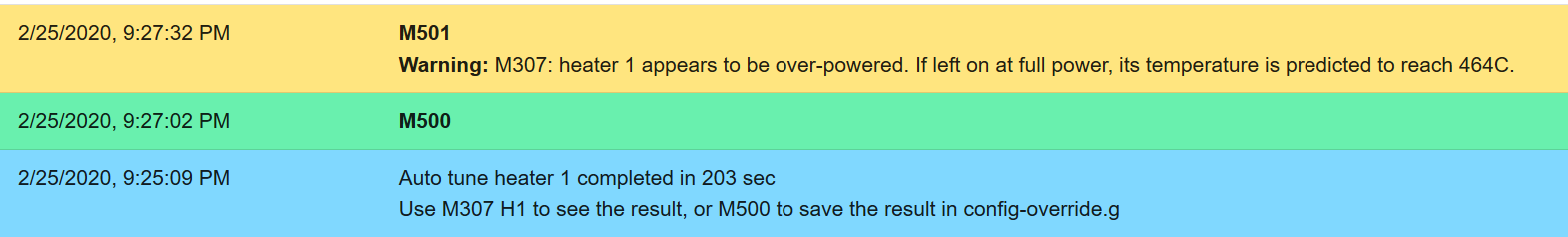

i tuned both the bed and hotend, and now i sent M501, is this message good or bad?

i will also include config-override.g

; config-override.g file generated in response to M500 at 2020-02-25 21:27 ; This is a system-generated file - do not edit ; Delta parameters M665 L324.000:324.000:324.000 R154.000 H700.000 B150.0 X0.000 Y0.000 Z0.000 M666 X0.000 Y0.000 Z0.000 A0.00 B0.00 ; Heater model parameters M307 H0 A156.8 C352.1 D6.7 S1.00 V23.7 B0 M307 H1 A439.3 C131.4 D3.6 S1.00 V24.2 B0 ; Workplace coordinates G10 L2 P1 X0.00 Y0.00 Z0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 G10 L2 P9 X0.00 Y0.00 Z0.00 -

@NEVER-LUCKY said in Hotend and Heated bed reading 2000deg celcius and fault:

is this message good or bad?

It's neither. It's just telling you how hot it thinks the heater will get if it were to get full, uncontrolled power, as could happen in a fault situation.

The only way to deal with that is to evaluate your safety precautions and decide if you are comfortable printing with those risks. Never leave the printer unattended. Have a smoke detector nearby. Have a fire extinguisher nearby. Consider adding a thermal cut out fuse. Or, and this is the only solution that really solves the problem, is to change to a lower powered heater that can't physically get that hot.

-

noted.

does my config file look good or is there anything missing? Is the printer ready to print or do i need more test?; Configuration file for Duet Maestro (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Sat Jan 18 2020 15:59:57 GMT+0100 (Central European Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Colossus" ; set printer name M665 R154 L324 B150 H700 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z80.00 E663.00 ; set steps per mm M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; set minimum Z ; Endstops M574 X2 S1 P"xstop" ; configure active-low endstop for high end on X via pin xstop M574 Y2 S1 P"ystop" ; configure active-low endstop for high end on Y via pin ystop M574 Z2 S1 P"zstop" ; configure active-low endstop for high end on Z via pin zstop ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 R85 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S130 ; set temperature limit for heater 0 to 130C M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 S"Extruder_TOOL" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@NEVER-LUCKY said in Hotend and Heated bed reading 2000deg celcius and fault:

Is the printer ready to print or do i need more test?

See https://duet3d.dozuki.com/Wiki/Step_by_step_guide#Section_Commissioning_tests

We can’t really answer that for you. If you have completed commissioning, tested everything, and checked it works, then it probably is time to move on to calibrating the extruder, configuring your slicer, and doing some test prints.

Ian

-

I'm not a delta guy, but have you gone through this?

-

Very well.

Thank you all for staying and helping resolve the issues. @droftarts @Phaedrux @dc42 @appjaws

Cheers !!

-

@Phaedrux ill check it out, thanks a lot for your help!