Smart Effector part cooling

-

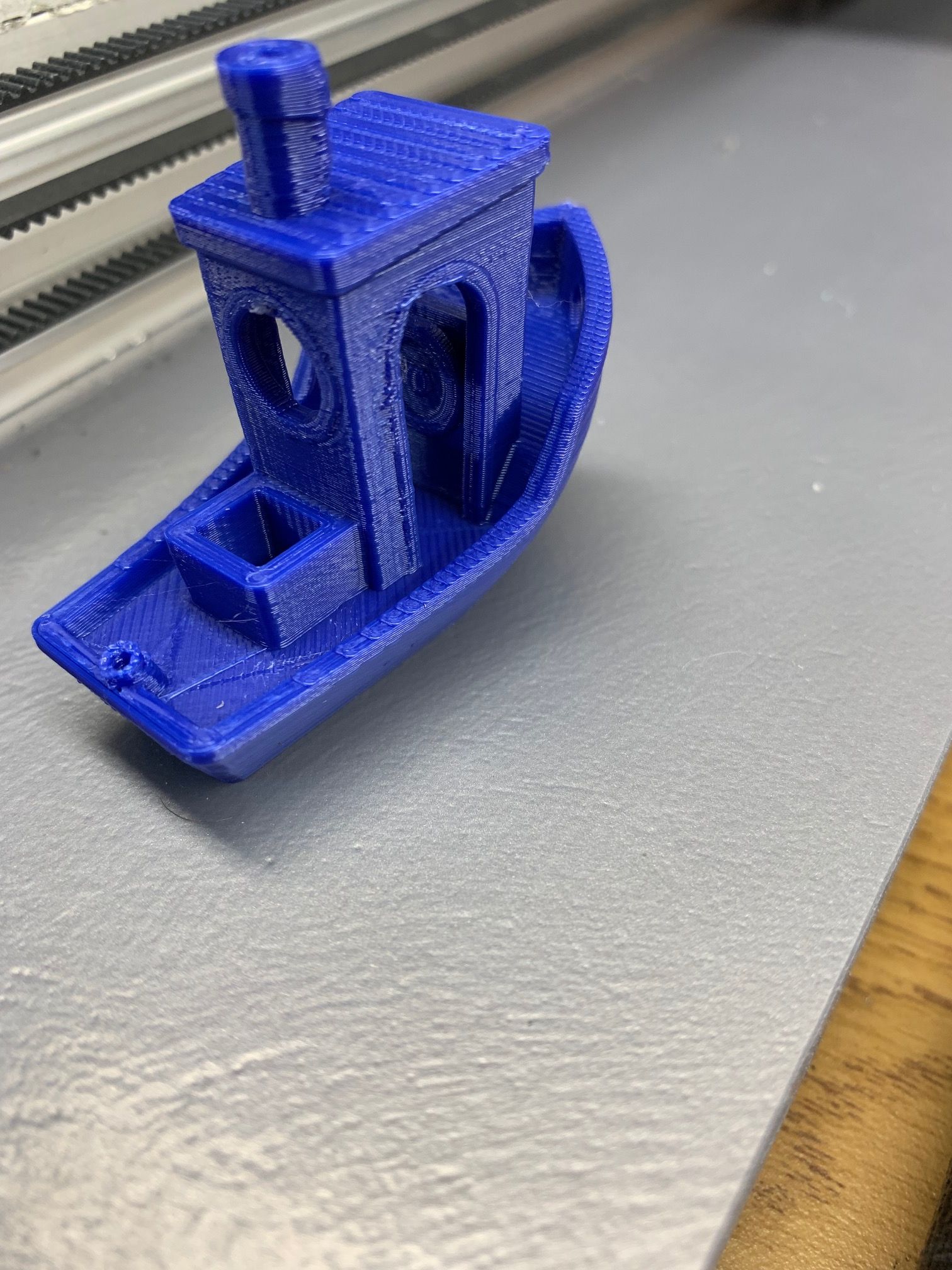

well, then... Everything seems to be accounted for, but still doesn't nail one of the corners of the stern of the Benchy. My last test was with a lower temperature (by 10°C) but no change at all.

I will try another filament now and wait until tomorrow to get new 40mm fans...

-

What infill % are you using? I typically use 20%.

-

15% is my default

-

@FelixH In case you missed it, I edited my last post and included some pictures of a benchy I ran last night

-

yes, I saw it. Not bad at all.

mine is not half bad either, only this little bloob of plastic on one corner. I'm printing with a different filament with a different color... let's see...

-

@FelixH I recognize my print could be better, but I don't normally print benchys. I fired up the printer, calibrated, sliced the model and printed. I wanted to see what my results would be as a comparison.

Try 20% infill, see if that makes a difference.

-

The test with another filament was even worse...

@bricor could you send me a picture of your part cooling fan? -

@FelixH what exactly do you need a picture of, the fan or the label on the fan or the whole assembly?

Did you try the print at 20% infill?

-

@bricor said in Smart Effector part cooling:

@FelixH what exactly do you need a picture of, the fan or the label on the fan or the whole assembly?

Did you try the print at 20% infill?

Just a picture of the fan would be enough, I guess. I going to try the 20% right now. Stay tunned!

-

-

Looks exactly like the one I've just installed. 9 blades. I'm printing right now and it looks better than with the other fan, which only had 7 blades...

-

@FelixH are you still printing at 15% infill?

The reason I ask is that making multiple changes makes it difficult to diagnose the issue and determining what exactly fixed the issue.

-

@bricor yeah, that's the scientific method, one step at a time. Today I printed another Benchy with the new cooling fan. I went much better than yesterday, and yes, I'm still at 15%.

It still doesn't master that one corner, but it's much better than before. Maybe it prints way too fast, I don't know. I guess that at slower speed, it would have more time to cool down. Right now a Benchy on this printer is 1 hour 7 minutes.

Do you have the same duct as I have?

-

@FelixH I am using the 270 version of this https://www.thingiverse.com/thing:2808152. I believe you mentioned the same.

For S&Gs you may want to try 20% infill, it may give you a result, worth the try.

My print time is about the same at 20% infill. -

@bricor I'm on it

-

@bricor I'll be dammed!

It looks much better in real life, I must say.

At this point, I'm going ahead and hypothesize that the cooling problem is over but there is still retraction tuning to be done...

-

@FelixH if you’re using the stock extruder that may be part of the issue. Extruder calibration may also help. If that’s done you may want to try printing at 95% extrusion (set in DWC).

Slicer settings may also help, like align the seams/layer start point. -

I'm using the original E3D hotend I ordered from Duet. I came with an all-metal barrel, which I know it is prune to give problems on a Bowden system. I don't know why don't they send the one with a teflon lining, as nearly all deltas are Bowden...

I'll have a look at the retraction settings and I'll try to tune it a bit more, but it's getting close to good-enough-for-me, as I don't print artistic things or figurines. I have a Photon for that...

-

@FelixH My apologies, when I said extruder I meant filament drive.

The hotend assembly you are describing is top notch. I would stay away from any teflon lined hotend (heat break). I only use all metal hotends. -

@bricor said in Smart Effector part cooling:

@FelixH My apologies, when I said extruder I meant filament drive.

The hotend assembly you are describing is top notch. I would stay away from any teflon lined hotend (heat break). I only use all metal hotends.On a Telegram group I'm in, they are famous for getting stuck continuously...