Smart Effector part cooling

-

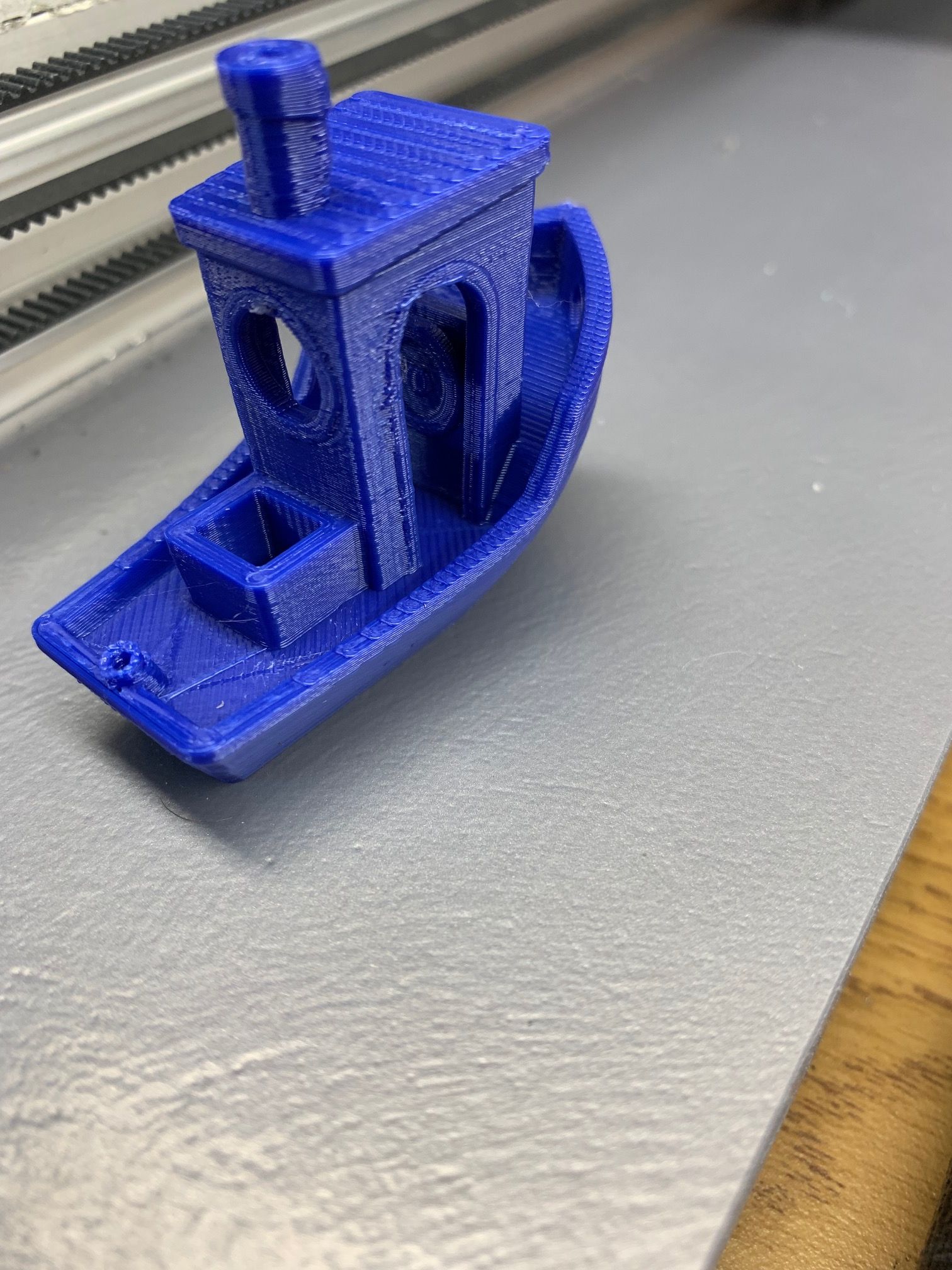

As a follow up, I lowered the fan duct on the effector by aprox 2,25mm because I noticed it was quite higher than other printers. The Benchy was significantly better, but still showed a bloop on on of the stern corners. See photo. I beginning to suspect that may!be the fan is not powerful enough for part cooling tasks...

-

the axial fan blowing almost directly against a wall will not give you good cooling results. When my delta was still up and running, I used https://www.thingiverse.com/thing:3229241 with reasonable success.

-

@FelixH Take a look at these past posts. They might help. (the parts that relate to the AKLP config)

https://forum.duet3d.com/topic/13813/aklp-ckeck/2?_=1584349301962

One point to mention, I'm using a Bontech QR extruder.

I just checked, I'm using a PT100 so use the posted data for reference only and focus on the bits that apply directly to your machine like delta parameters and speeds. Not the extrusion and thermistor parameters.

-

@bricor

I see from one of your posts that you seem to fill in the delta settings without running a delta calibration... is that right?; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ;M665 R133.969 L272.869 B110 H287.79 ; Set delta radius, diagonal rod length, printable radius and homed height ;M666 X0 Y0 Z0 ; Put your endstop adjustments here, or let auto calibration find them M665 L288 R138 H304.65 B110.0 X0 Y0 Z0 M666 X0 Y00 Z0 A0.00 B0.00also, how come your height is 304 if you are using the Kossel frame?

finally, I found this value for the thermistor setting (original from E3D):

M305 P1 B4725 C7.060000e-8could somebody confirm it is correct?

-

@FelixH The Delta values in my config file are the default settings I use based on measurements. I set the tower heights (end stop switches) also based on measured values (that is why they are set to 0 in the config file). I then run auto calibration each time I start the printer. I only need to run auto calibration twice to get the desired result.

I posted the exact measurements of my printer, you should get the same results for height plus 8.5mm for the V6 compared to the Volcano that I use.

The thermistor values you posted are correct, I use the same for my other printers that use a standard E3D thermistors.

-

well, then... Everything seems to be accounted for, but still doesn't nail one of the corners of the stern of the Benchy. My last test was with a lower temperature (by 10°C) but no change at all.

I will try another filament now and wait until tomorrow to get new 40mm fans...

-

What infill % are you using? I typically use 20%.

-

15% is my default

-

@FelixH In case you missed it, I edited my last post and included some pictures of a benchy I ran last night

-

yes, I saw it. Not bad at all.

mine is not half bad either, only this little bloob of plastic on one corner. I'm printing with a different filament with a different color... let's see...

-

@FelixH I recognize my print could be better, but I don't normally print benchys. I fired up the printer, calibrated, sliced the model and printed. I wanted to see what my results would be as a comparison.

Try 20% infill, see if that makes a difference.

-

The test with another filament was even worse...

@bricor could you send me a picture of your part cooling fan? -

@FelixH what exactly do you need a picture of, the fan or the label on the fan or the whole assembly?

Did you try the print at 20% infill?

-

@bricor said in Smart Effector part cooling:

@FelixH what exactly do you need a picture of, the fan or the label on the fan or the whole assembly?

Did you try the print at 20% infill?

Just a picture of the fan would be enough, I guess. I going to try the 20% right now. Stay tunned!

-

-

Looks exactly like the one I've just installed. 9 blades. I'm printing right now and it looks better than with the other fan, which only had 7 blades...

-

@FelixH are you still printing at 15% infill?

The reason I ask is that making multiple changes makes it difficult to diagnose the issue and determining what exactly fixed the issue.

-

@bricor yeah, that's the scientific method, one step at a time. Today I printed another Benchy with the new cooling fan. I went much better than yesterday, and yes, I'm still at 15%.

It still doesn't master that one corner, but it's much better than before. Maybe it prints way too fast, I don't know. I guess that at slower speed, it would have more time to cool down. Right now a Benchy on this printer is 1 hour 7 minutes.

Do you have the same duct as I have?

-

@FelixH I am using the 270 version of this https://www.thingiverse.com/thing:2808152. I believe you mentioned the same.

For S&Gs you may want to try 20% infill, it may give you a result, worth the try.

My print time is about the same at 20% infill. -

@bricor I'm on it