Heavy Aluminum bed too slow for autotune.

-

Wait, isn´t the Objet a Polyjet machine that prints with resin?

Can you share a picture? -

The build plate is 330 x 340 x 35mm. Basically solid. Top plate is a milled/ground slab of aluminum with a pocket on its bottom for the heater. The bottom half is the "lifter" plate (also aluminum) and is fixed to 3 leadscrews.

-

@Phaedrux said in Heavy Aluminum bed too slow for autotune.:

https://duet3d.dozuki.com/Wiki/Tuning_the_heater_temperature_control#main

Maybe you missed my post?

If auto tuning fails with a message that the temperature is not rising fast enough, this indicates that either you are using too low a P value in the M303 command, or the dead time in the existing model is much too low for your heater. You can increase the dead time using the M307 command. For example, sending M307 H0 D30 will increase the dead time to 30 seconds. The actual dead time will be known after a successful auto tuning.

-

It is. I've removed the polyjet head from a broken objet and put ... lol ... a prusa i3 mk3s extruder I had lying around on it.

-

-

@tjhinton You may need to use an extreme value for D for the initial tuning. 99999. Once it tunes successfully once you'll have the actual D value.

And yes, it looks like there is a typo in that section. P=D. I'll fix that, thanks.

-

@Phaedrux said in Heavy Aluminum bed too slow for autotune.:

And yes, it looks like there is a typo in that section. P=D. I'll fix that, thanks.

Actually, no. That's not a typo. The P value is the PWM value. And it's saying that having a reduced PWM value can also cause that error message to occur.

-

Even with an extreme D value, I get "auto tune cancelled because temperature is not falling"

This is because the bed heater turns off, but heat is still diffusing outward toward that peripheral thermistor. There's a delay before the temp starts to drop appreciably.

-

For reference, I'm at P1, or 100% PWM. and it's an SSR, so I wouldn't want to PWM it fast anyway for M303, right?

-

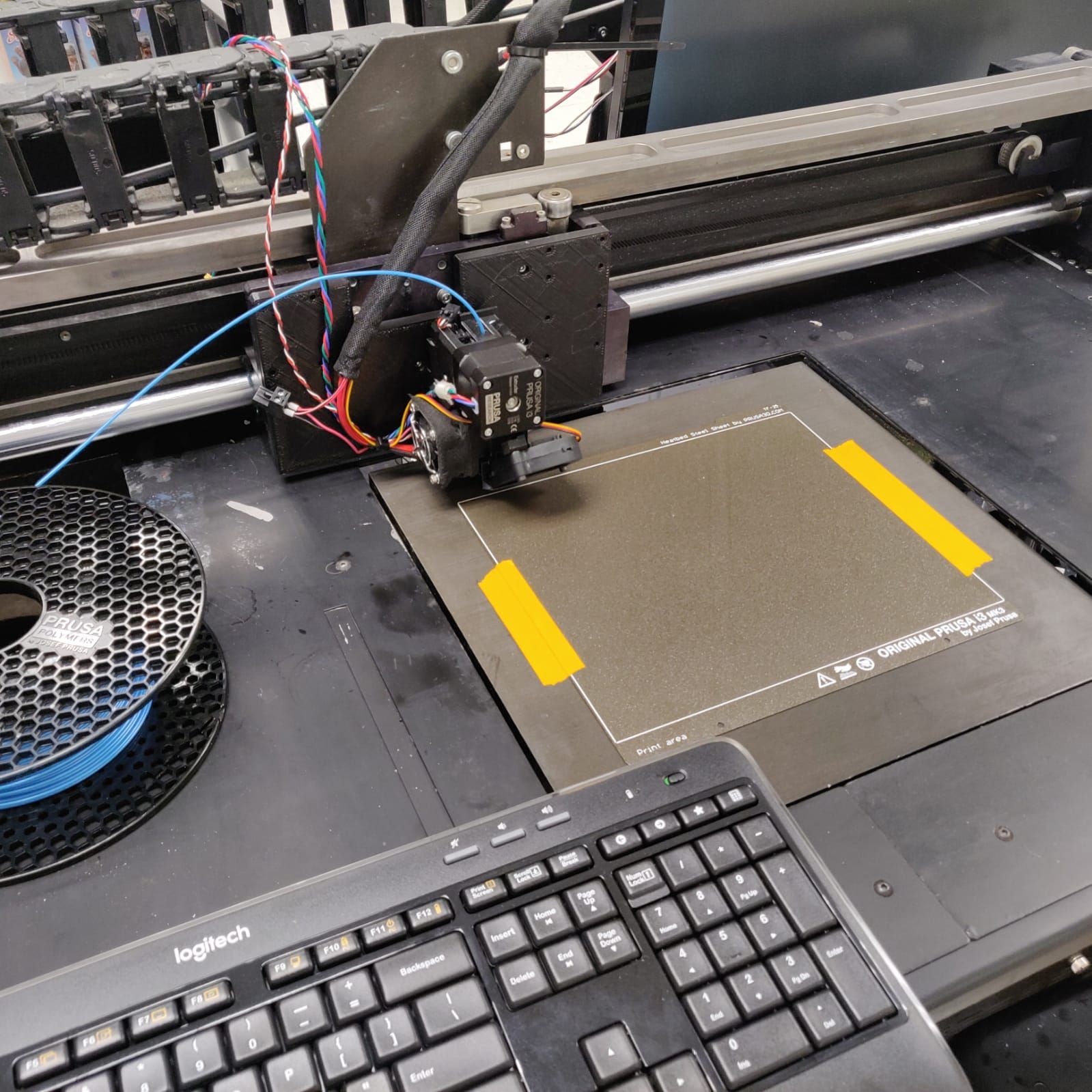

Image of the machine.

-

@tjhinton Well there's two parts to that. There is the PWM duty cycle and the PWM frequency. 100% duty cycle is what you should be using (and sounds like you are.) Frequency is 10hz by default I believe, which should be perfectly fine for an SSR.

Is there any way to move/add a thermistor to be in closer contact to the heating pad rather than just at the edge of the plate? Having a tighter feedback loop would probably solve your problem.

-

@tjhinton said in Heavy Aluminum bed too slow for autotune.:

"There are a couple of things that will catch you right away - generally, the first layer is put down with extra bed temperature. In your case you have zero control over the bed temperature as shutting off the heater will not drop the temperature in a reasonable amount of time."

My understanding is that tuning catches this, assuming you do it right and set up the tune in an appropriately controlled situation - such as in an enclosed print volume.No, tuning assumes that the heater has some real control, that the bed cools when you remove power and that it heats when you apply power. What you have is a giant hunk of aluminum that does what it wants and only takes slight hints from the heater.

If you are not doing FFF then all my comments do not apply !

-

I could do that. And I've thought that it would fix my issue. It's not simple to do. But it would mean the edge temp of the bed isn't correct, and it's not addressing the underlying problem - I can't use a bed that's lagging. That should be possible, right? All beds lag to some extent. I'm just outside the tolerance of M303 as is.

-

Yes you would be trading one problem for another, but the new problem can be worked around more easily.

Personally, I think the heater control loop should be as tight as possible to the heat source. That allows for best control of the actual heater. In order to compensate for the lag time of heat saturation of the large plate you can simply add a wait time. The amount of time needed can be measured and should stay constant. That could be handled with a simple G4 dwell command in your startup gcode or preheat macro.

With RRF3 and the ability to use conditional gcode and sensor pins, you could use both thermistors in tandem and control the heater pad with one, and then wait to start the print when the plate is at the right temp.

-

I love this idea! Thank you. Going to try the tandem.