Duet Maestro 2 stops mid print

-

@dc42 @droftarts Is it possible to get quicker response? Asking me one question without providing solutions/option is just time wasted. I really need to get this working ASAP. I've open this thread 3 days ago and still no closer to a solution. I do understand the covid-19 thing, but I guess it should be easier to help now.. Please..

I'm sure you would have a diagnostics tool or something? How do we troubleshoot this?

Is it GCode - Is it hardware.. Where do I start? What can cause this error.. This is questions only the programmer/designer can answer.. Please Please.

Please tell me what else you need from me so that I can get everything and we can get this resolved.. Please.

-

Attitude isn't going to help anyone diagnose an intermittent problem, which is difficult enough when one has physical access to the board - let alone over a forum.

While you wait, you could turn the printer on, leave it idle, and occationally check the M122 output to see of the last reset cause changes to reset button when its not printing as well.

-

@bearer Not attitude. Asking. Would be easier if I knew Duet 3D had a call logging system. But as it stands, they dont. I can see the moderators are helping everybody randomly. Just unfair to be asked to wait without knowing that my fault is being attended too.. How long should I wait.. What is fair? I paid for a product that I can't use. I can't work..

I also agree that it is difficult to diagnose without access to the board.. I'm available on skype. Please contact me. I can whatever you need.

And yes, I did keep the printer on all day, for the last 3 days without the problem.. No Reset. Only when It is printing.

-

@massynrt I have been discussing this with @dc42, and it takes time to get the answers. In the meantime, I help other people.

Unfortunately, most of your M122 reports show user software resets (indicating M999, emergency stop or software update). The rest were reset button, or power up. There really isn't anything from those reports that indicate what's going on. It is not for lack of trying to understand what the problem is, or expending time to try to sort it out for you; it's just unknown.

Ultimately, we think that a warranty replacement is justified, as there seems to be something causing these resets, possibly a component on the board, but it's impossible to diagnose this at a distance. While it could just be the reset switch, we think this is unlikely, so would prefer that it isn't removed from the board.

So then the question is how to handle the replacement. To replace the Maestro, or return it and buy a Duet 3? It may be possible to get a replacement Maestro from Da Vinci (though not until the 17th April), but it looks like they don't have Duet 3 in stock. So would have to be sent from the UK.

What would be your preferred outcome?

Ian

-

First outcome would like to get it working. Then on the 17th Davinici csn send me a new one. Ill send this one

back if not fixed. -

@massynrt said in Duet Maestro 2 stops mid print:

Okay, I've contacted Roland (Duet 3D order fulfilment) to see if we can set up anything with Da Vinci Labs, or if we just send you one from the UK and you return the old one to them.

First outcome would like to get it working.

That's going to take some more investigation, and some time. I don't think this is a firmware issue; it's hardware, wiring or power related.

Has the Duet worked correctly at any point? I know it's new, but did you print with it before mounting it, or have any successful prints? How frequently does it cut out?

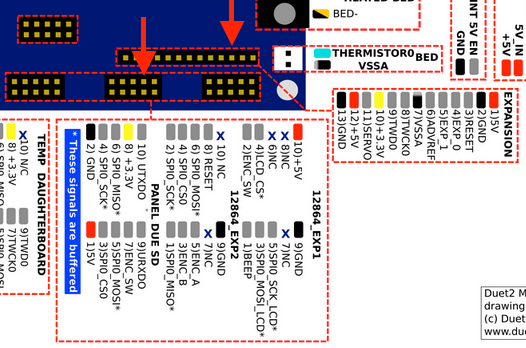

Check there's nothing shorting on it, front or back. The heads of your mounting screws do look a little large; they're not touching anything, are they? Check they're not making contact underneath them, too. Have a good look at the pins dc42 mentioned (pin 3 of the 13-pin expansion connector J21 and to pin 8 of the 12864 LCD connector P1), front and back, to see if there's any stray solder or anything that may conduct, especially as there's a ground pin right next to it on the expansion connector:

While it seems unlikely that the reset button is to blame, can you gently pull the button of the switch, to see if it is stuck in a little way (maybe it's close, and vibration is causing it to trigger). It doesn't look like it from your picture, though.

Please take a good picture of the wiring and post it here. The ones you posted earlier where rather dark, and low resolution.

If you're sure you are not pressing the reset button before sending the M122 commands, then we need to have a good look at the board to see if there's anything obviously damaged. Can you please take a good, well-lit, high resolution picture of both sides of the board, preferably with nothing connected, and post them here.

That's all I can think of at the moment.

Ian

-

The printer did print a few prints fine. Just randomly started to reset.

Here is what I've done so far today.

- I've rewired the printer completed. New connectors, new wires - No success.

- I've moved the location of the board to the bottom frame, as to reduce vibrations - No success.

- I've reformatted the sdcard - No success.

- I've created new gcode, Cura, Slic3r, PrusaSlicer. Fast, Slow. High, Low, whatever.. - No success.

- I've moved the X Limit switch from the gantry. - - No success.

- I've added a fan on the Duet. - No success.

Observations:

- Before the printer reset, the is definitely some weird printing going on... As if the g code is corrupt. I've noticed it on most of the fails.

- I have a good success rate, printing "longer" moves.. Like a base plate. But as soon as the detail start, and "movement - I might go for a while, of crash quick..

I'm really tired/frustrated

-

; Configuration file for Duet Maestro (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.8 on Tue Mar 31 2020 16:02:15 GMT+0200 (South Africa Standard Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Cooper" ; set printer name; Network

M552 P192.168.0.9 S1 ; enable network and set IP address

M553 P255.255.255.0 ; set netmask

M554 P192.168.0.1 ; set gateway

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E837.00 ; set steps per mm

M566 X800.00 Y800.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X9000.00 Y9000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-115 Y-100 Z0 S1 ; set axis minima

M208 X115 Y120 Z300 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"^zprobe.mod" ; create servo pin 0 for BLTouch

M558 P9 C"zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X9 Y-65 Z1.65 ; set Z probe trigger value, offset and trigger height

M557 X-100:100 Y-50:50 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S100 ; set temperature limit for heater 0 to 100C

M307 H0 A75.4 C81.7 D2.1 V24.1 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M307 H1 A554.4 C258.9 D5.7 V24.0 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Fans

; Tools

M563 P0 S"Titan Aero" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

-

@massynrt Thanks for all the pictures and files. It sounds like something is 'loose', and the short rapid moves cause it to 'wobble' and do 'something'. I'll have a good look at the pictures for dry solder joints.

Regarding the print failures, it does look like it's printing very hot. I wonder if the heater is going open circuit. But then it could just be because it's the first infill layer supporting a top layer (so it fills in) and isn't making good contact with the layer below, while printing a bit too hot, so flops into the holes. Some slicers are better at sorting this out than others.

I'll get back to you if I see anything.

Ian

-

@massynrt said in Duet Maestro 2 stops mid print:

Related to the above:

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

...

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0tempT100000 B4138 is the default thermistor setting, for a Honeywell 135-104QAD-J01 thermistor that shipped with hot ends from RepRapPro, who have been out of business for 4 years! So I doubt you have the correct thermistor settings, and likely the temperature your heaters are reporting is not accurate. All 100k ohm thermistors have a resistance of 100k ohms at 25C, and will be fairly accurate at room temperature, but they report very differently as they get hotter. So please check what thermistors you have in your bed and hot ends, and set them correctly, then you have a chance of accurately setting extrusion temperature.

Ian

-

I've updated.. Don't know how I forgot to change that back. I copied/pasted so many times trying to fix this..

; Configuration file for Duet Maestro (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.8 on Tue Mar 31 2020 16:02:15 GMT+0200 (South Africa Standard Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Cooper" ; set printer name; Network

M552 P192.168.0.9 S1 ; enable network and set IP address

M553 P255.255.255.0 ; set netmask

M554 P192.168.0.1 ; set gateway

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E837.00 ; set steps per mm

M566 X800.00 Y800.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X9000.00 Y9000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-115 Y-100 Z0 S1 ; set axis minima

M208 X115 Y120 Z300 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"^zprobe.mod" ; create servo pin 0 for BLTouch

M558 P9 C"zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X9 Y-65 Z1.65 ; set Z probe trigger value, offset and trigger height

M557 X-100:100 Y-50:50 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S100 ; set temperature limit for heater 0 to 100C

M307 H0 A75.4 C81.7 D2.1 S1.00 V24.1 B0

M140 H0

; map heated bed to heater 0

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M307 H1 A340.0 C140.0 D5.5 S1.00 V0.0 B0; Fans

; Tools

M563 P0 S"Titan Aero" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

-

@massynrt I've had a good look at the pictures, can't see anything that looks problematic. Any one else see anything?

I'm happy to authorise a warranty replacement for this board. Please see our warranty policy here, and a link to the Warranty Return Form is at the bottom: https://www.duet3d.com/warranty

Unfortunately, it won't be possible to arrange a replacement from Da Vinci Labs, and due to current restrictions couriers are not operating until 17th April, but we'll send a replacement by DHL as soon as it's possible to do so.

Ian

-

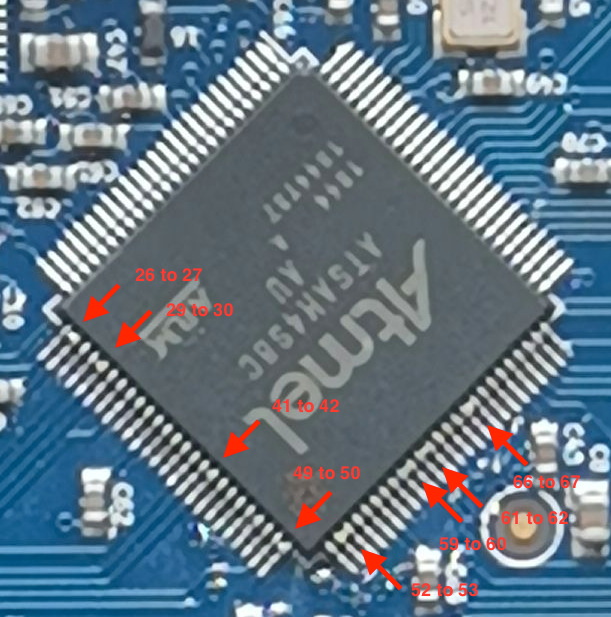

@massynrt I was discussing with @dc42 if we wanted the board back or not. I suggested that we ask you to remove the reset switch, but he thought it very unlikely that this was causing the problem, and it would be better to check the soldering on the reset pull-up resistor, R84, which is near U2 on the Maestro. However, in looking at this, dc spotted a solder bridge on the pins of the processor. On further investigation, there seems to be quite a few!

List of possible shorts: 26 to 27, 29 to 30, 41 to 42, 49 to 50, 52 to 53, 59 to 60, 61 to 62, 66 to 67

Most notably, pin 60 is Reset, while pin 59 is one of the SD card pins.It is unusual to see shorts that close to the plastic package though, unless the soldering has been reworked by hand, and it might even be a trick of the light. Please can you check whether those pairs look shorted, and if possible get a sharper photo. We find it best to pull the camera away a bit and use digital zoom. For example, this is from my iPhone SE (I know, but I like a phone that fits in my pocket...):

If you have solder wick, you can try removing the solder bridges. Even wiping a fine-tipped, clean soldering iron on the pins, and pulling in the direction away from the chip, might be enough to remove the solder bridge.

Let me know how you get on, and sorry for the inconvenience.

Ian

-

Even wiping a fine-tipped, clean soldering iron on the pins, and pulling in the direction away from the chip, might be enough to remove the solder bridge.

some good flux makes that easier, solder will follow the heat and pull away the bridges

-

Sorry guys. That seem to be only jpg compression or Huawei playing tricks on us. None of those bridges on the cpu. Ill use my dslr to supply with better images. Will do it in the morning..

-

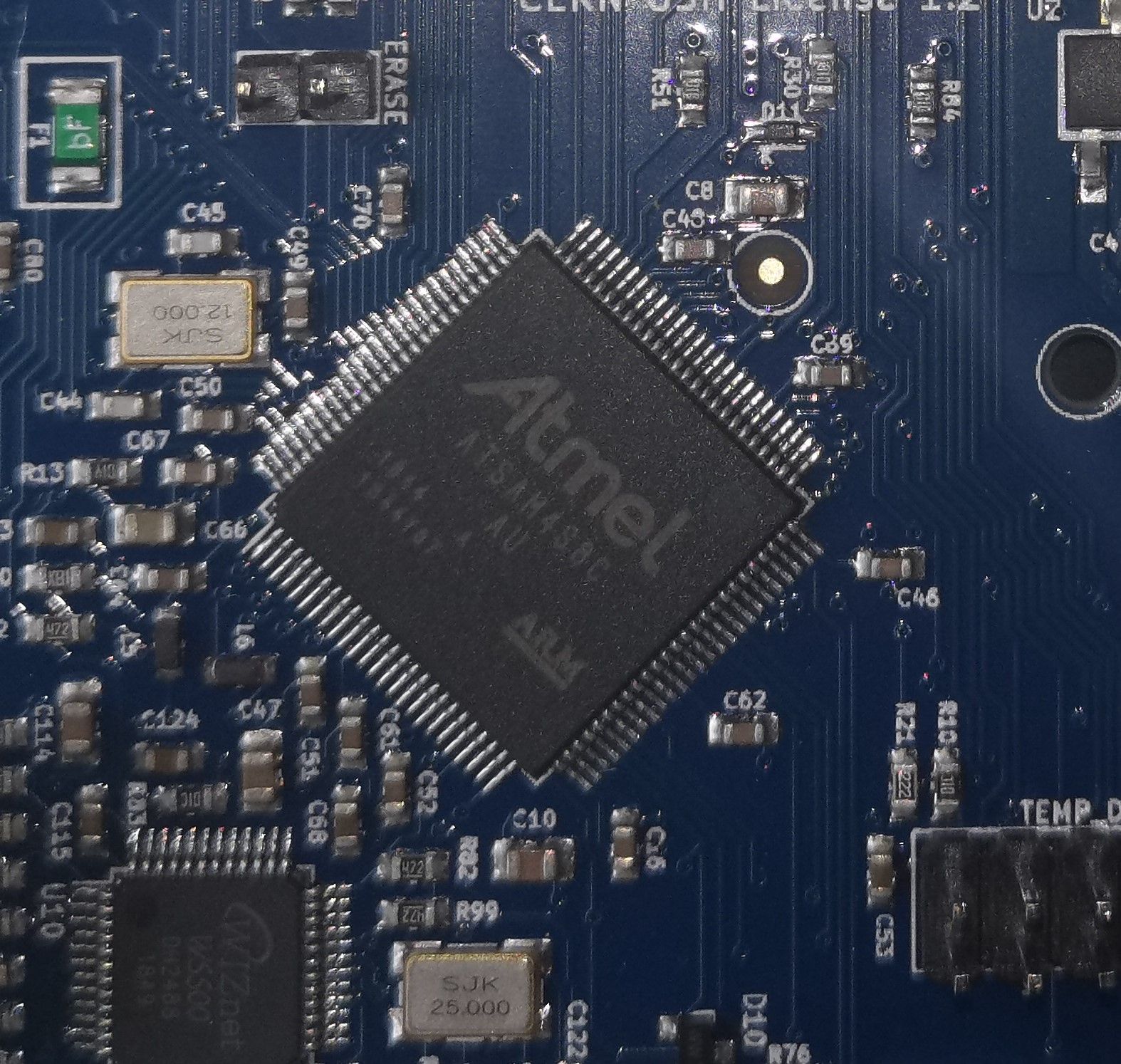

Here is an updated image of the CPU..

-

@massynrt oh that’s disappointing, thought we were on to something! Though with that many bridges, it would be amazing if it worked at all!

I can also see R84 looks okay, too, but please visually check that.

Okay, back to plan A. Do you want to try desoldering the reset switch? Ideally with hot air rework station, or qwikchip, so the chances of lifting pads is minimised.

Ian

-

Sorry for my silly question.. I cant find R84. I looked at the whole pcb and could not find any problems. Even did a good old shock test while it was at operating temp. Does not reset. Almost certain it is not the button or a loose component.

I dont have any fancy tools to remove the.button. Only solder sucker and iron. But this will be last resort only after confirmation of warranty replacement as advised.

I will send you a pm with and alternative solution.

-

@massynrt R84 is in the top right of your DSLR picture of the processor.

I think it’s probably a faulty component that builds capacitance, until something triggers it causing the board to reset. Could also be heat related, as it doesn’t happen when board is idle, only when running. Possibly just a faulty processor with the above issues. Really difficult to say!

Ian

-

Quick question.. the connectors for the motors are upside down vs the meastro. Thus, i have to redo them.. although the red blue green black is still the same.. .

What is the reason? Do i have to redo, or will it still work?