.6mm e3dv6 stringing petg any ideas?

-

Drop the extrusion width to nozzle width. I find that helps a lot.

Oh look! How timely!

https://www.youtube.com/watch?v=Ceaz2cYBd_o

https://www.youtube.com/watch?v=Ceaz2cYBd_o -

@ChrisP dry for sure, opened yesterday, immediately issues, dried for 12 hours in dryer, still issues, on op of that my work room where everything happens is attm 15% humidity so not likely moisture issues...

-

@Phaedrux never had this issues with .4 or .5mm nozzle, will drop and see

-

-

I think you will get better results with a smaller nozzle with petg. We print a lot of Neat brand petg here and this is what works for me to produce perfect parts that don't need to be cleaned up. Set your travel jerk and travel speed as high as you can. On my ultimaker3 I run 400mm/s travel. This will help to keep material from oozing away during travel moves by having more time for the nozzle to be engaged with your part and less time spent disengaged. Also, plan your printing layout to keep parts as close together as possible. You can place a prime tower between them if you have to. Keep your retraction as low as possible and avoid using z hop. Print around 35mm/s - 50mm/s 245-265c 85c bed temp and minimal part fan speed unless you're bridging. If you're going to print with a large noz you might have to lower your temps to around 220 to make the material less runny but might find a lower layer adhesion and lower flow rates resulting in slower print speeds.

-

@LeckieTech said in .6mm e3dv6 stringing petg any ideas?:

I think you will get better results with a smaller nozzle with petg.

As I said, .2-.5 never had a problem, but printing with small nozzle is slow, .6 is the smalles acceptable I want to deal with on this printer (other printers handle smaller nozzles, this one I don't care too much about "beauty" only speed, it's my new "draft printer"), .5 mm layers (these tests are .35mm layers but normally I print .5mm layers with .6mm nozzle) so yes, I know, smaller nozzle - less stringing

always were, always will be. I still need solution with .6 (or maybe even .8)

always were, always will be. I still need solution with .6 (or maybe even .8)run 400mm/s travel

2020 profiles are way #$^%$#& than I was lead to believe so till I reinforce the frame 200mm/s is the safe max. Reinforcement already in the mail. As it is right now it does move 600mm/sec with 6000mm/sec/sec accel without skipping steps BUT the whole frame twists during the moves so that needs to be solved first.

Print around 35mm/s - 50mm/s

70 is kinda minimum usable, 80-100mm/sec is the target, 35-50 is too slow for draft prints. 50 is ok for small intricate parts but if I need to push few kilos of plastic into a part I don't want to wait a week to do it

.. I was probbly unclear in the original post, not going for "beauty" here, just speed and as little postprocessing as possible, and everything works great except stringing so that needs to be sorted out and this printer can go to "production"

.. I was probbly unclear in the original post, not going for "beauty" here, just speed and as little postprocessing as possible, and everything works great except stringing so that needs to be sorted out and this printer can go to "production"

245-265c 85c bed temp

printbite requires 90C bed to work good with petg

this petg difference in strength between 230 and 270 is non existing, 230 part don't break between layers, on the other hand, 260C print have shitty overhang, no bridging and support is impossible to remove220 to make the material less runny but might find a lower layer adhesion and lower flow rates resulting in slower print speeds.

weirdly enough, this dasfilament petg sticks so good to itself that 220C 100mm/sec and layer adhesion is as good as it gets, part does not delaminate when it breaks. Not the same experience I had with other petg brands.

-

I'm printing with a 0.6mm nozzle and 60-80mm/s with PETG and the stringing is pretty minimal even over long prints. So it's definitely possible. Maybe it comes down to different brands and formulations.

-

@Phaedrux said in .6mm e3dv6 stringing petg any ideas?:

I'm printing with a 0.6mm nozzle and 60-80mm/s with PETG and the stringing is pretty minimal even over long prints. So it's definitely possible. Maybe it comes down to different brands and formulations.

Never tried petg with .6 before, I'm printing ABS mostly and PETG i printed mostly with .2 and .3, little bit with .5 and never had stringing issues.

The stringing started with the white one on .6, I used some blue translucent one from octo-something (german or dutch don't remember) and didn't have issues, also 2.6kg of dasfilament black petg also passed trough this .6 nozzle no stringing issues, but this white one is killing me...

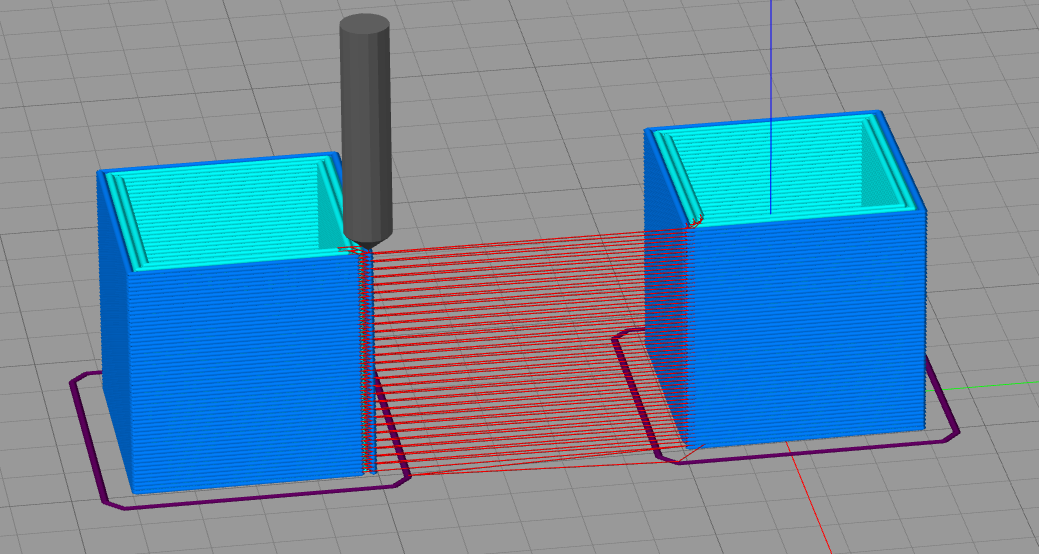

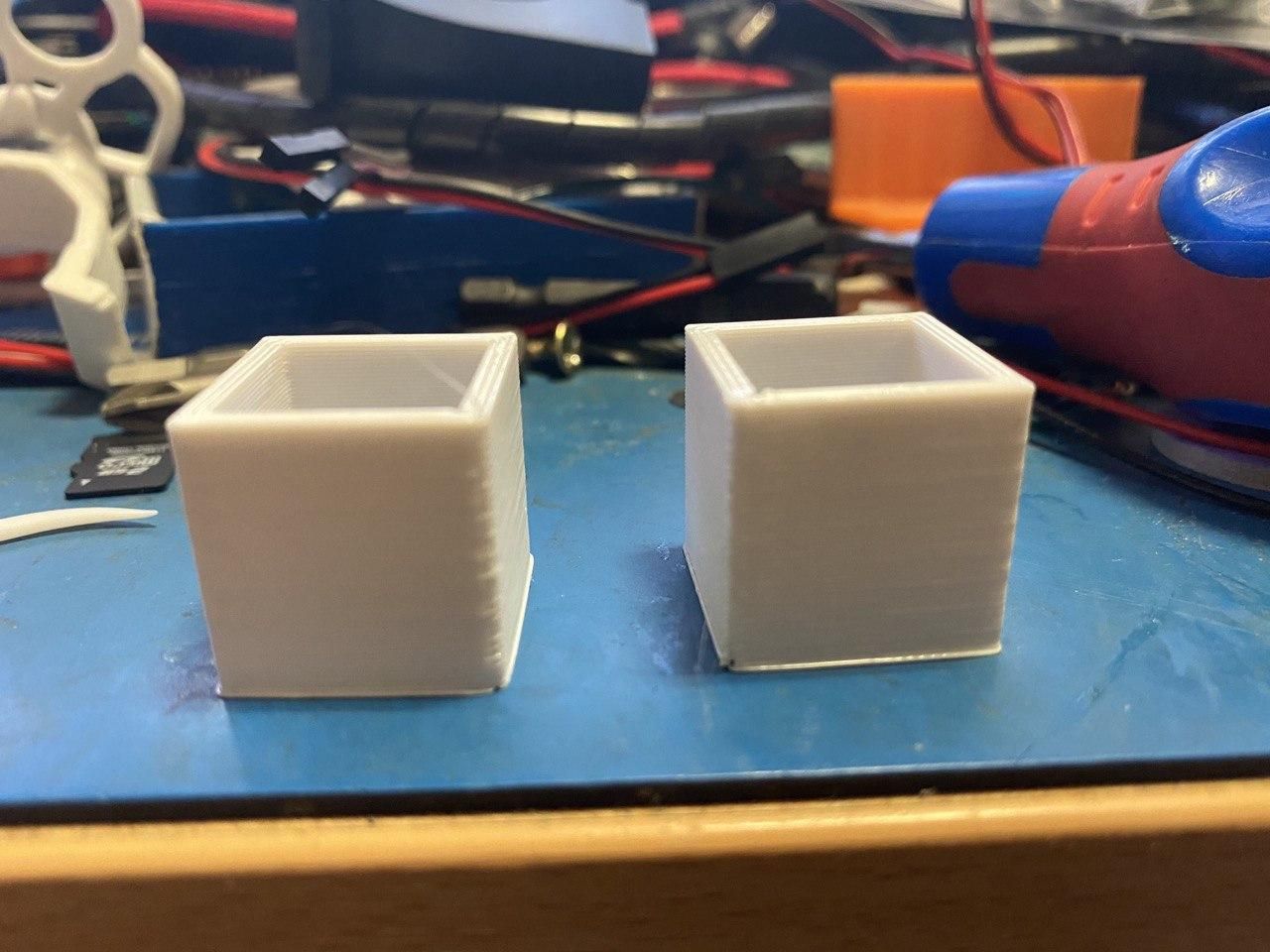

also, if you look at the image with "cubes", no stringing, exactly the same settings with the cones or pillars and it's ratsnest

I'll check out IdeaMaker and PS next, maybe something buggy in S3D code, would not be the first time :(. In the meantime I'm printing updated x-carriage so that both part cooling fans can work as this one was intended for G5 so when I mounted BMG second blower had to be sacrificed. New x-carriage should allow for better cooling, maybe that will help with stringing and small layer size .. will see .. but that one is printed in ABS with a lot of support in the chamber so it's kinda slow, I doubt I'll be able to mount it today

-

@Phaedrux said in .6mm e3dv6 stringing petg any ideas?:

Drop the extrusion width to nozzle width. I find that helps a lot.

-

Hmm, I don't use S3D, so maybe try a different slicer?

Are you printing inner walls before outer walls before infill? When it travels to the next pillar does it have something to wipe against as it travels or is it already at the exterior and so only draws a string as it moves?

-

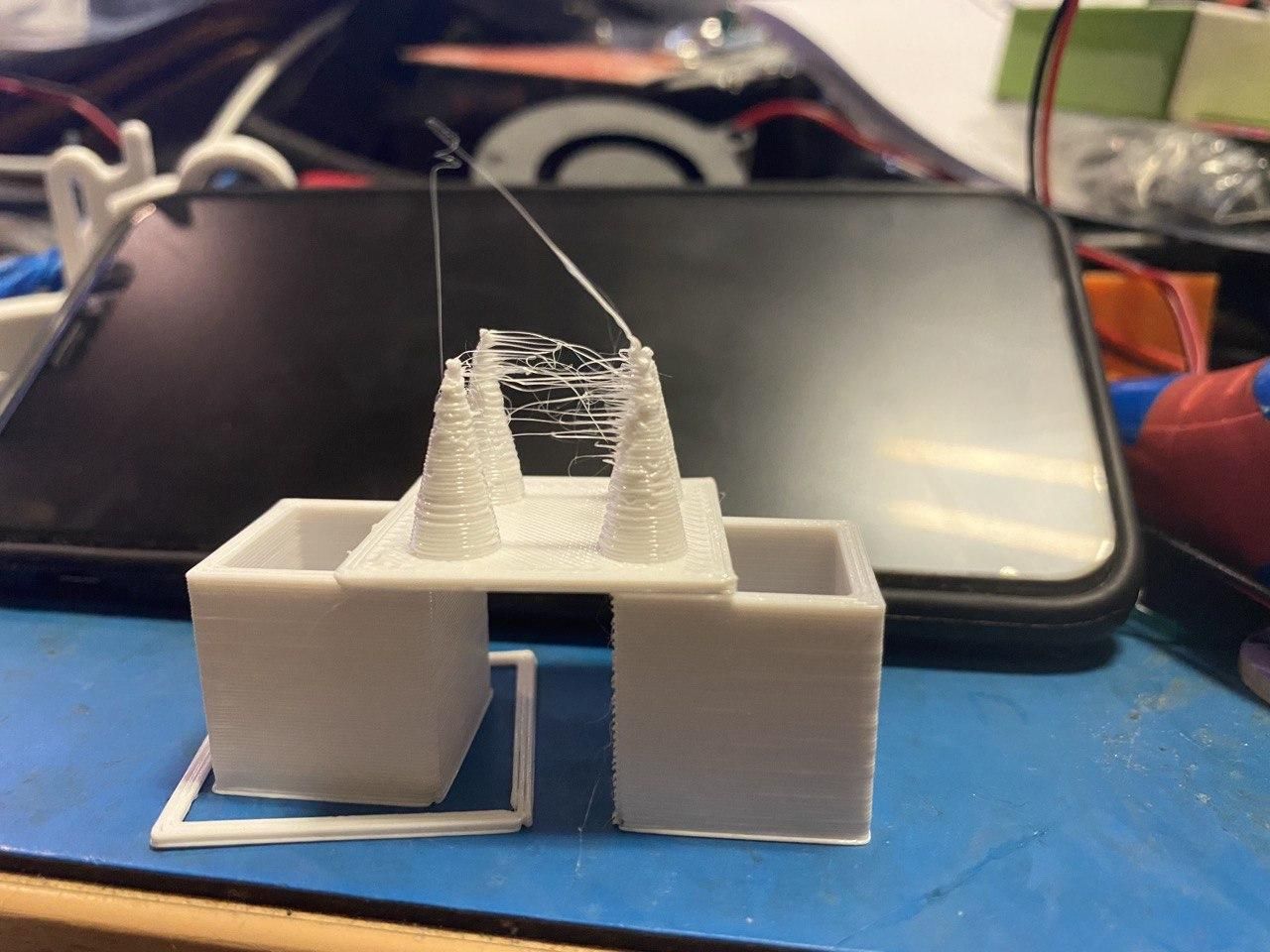

I was closely examining the g-code to see what's going on. There's no stringing (or very little) with 2 cubes, with these cones, on the bottom half of the cone - no stringing, top of the cone terrible stringing. The cones are disgusting mostly cause there's a lot of gaps and filament missign due to me increasing retraction and coasting and wipe too much.

What the code does is do inside perimeter, start sucking and wipe across infill, and then exits the cone to go to next one. Problem seem to be that .6 is soo leaky that from the middle of the cone up there's not enough room to wipe the nozzle and the plastic drips out.

Not only that, for e.g. I move nozzle outside of bed, extrude few cm, grab that by hand and move, the string stretches from the nozzle for 3 meters EASY!!! and it's not breaking, it thins out but it just keep comming, the tiny string exits the nozzle and pulls and pulls and pulls and does not break... this is some chewy filament

spool. Never had this type of problem with petg before.

spool. Never had this type of problem with petg before. -

@arhi Ah, in the original post, it looked like you were just trying to perfect the mini stringing test so I made my recommendations based on my findings with my own stringing test. My custom machine is under driven, rigid and running 24 volts so the 400mm/s is not an issue for me. More or less just letting you know what works for the material Ive been printing hundreds of spools of. But in any case, these small fast tests in my experience are hardly ever going to print the way a larger part will. The layer times are so short and that alone makes all the difference. The way I got this little guy printed was to print a block beside it to have the layer times more realistic.

-

@arhi said in .6mm e3dv6 stringing petg any ideas?:

I was closely examining the g-code to see what's going on. There's no stringing (or very little) with 2 cubes, with these cones, on the bottom half of the cone - no stringing, top of the cone terrible stringing. The cones are disgusting mostly cause there's a lot of gaps and filament missign due to me increasing retraction and coasting and wipe too much.

What the code does is do inside perimeter, start sucking and wipe across infill, and then exits the cone to go to next one. Problem seem to be that .6 is soo leaky that from the middle of the cone up there's not enough room to wipe the nozzle and the plastic drips out.

Not only that, for e.g. I move nozzle outside of bed, extrude few cm, grab that by hand and move, the string stretches from the nozzle for 3 meters EASY!!! and it's not breaking, it thins out but it just keep comming, the tiny string exits the nozzle and pulls and pulls and pulls and does not break... this is some chewy filament

spool. Never had this type of problem with petg before.

spool. Never had this type of problem with petg before.You need longer layer times

-

@LeckieTech said in .6mm e3dv6 stringing petg any ideas?:

layer times

yes, but

... it works flawlesly with .3mm

... it works flawlesly with .3mm

I just finished the new version of the x-carriage monstrosity and will have better cooling now so we'll see, usually small pieces if one don't want to add extra object at distance to slow everything down, can be solved by better cooling

so we'll see ..

so we'll see ..In any case, looks like big parts are tuned now. Weird I need 2.5mm retraction with direct drive but it works so I'll live with it. I replaced also the big extruder motor with small pancake, hopefully it has enough umpf to work like the old one did

-

@arhi 0.3mm, yes, this is what I was trying to say the first time around lol. For 2 reasons a smaller nozzle will work better. Picture a bottle of water upside down with the cap off, this is your 0.6mm nozzle. Now picture the same bottle with the cap on and a hole half the size in the cap. The water is still going to run out, but not nearly as fast. May even be by a factor of less than half if you consider the factor of displacement and hydraulics - PETG oozes out, air rushes in to fill the void. Secondly, if its solid infill you get nearly double the layer time since your slicer will only shift over for 0.3 instead of 0.6 allowing your cooling fans to do their job. You can absolutely print with a 0.6mm nozzle, you're just going to have a hell of a time tuning it for small details where layer times are next to none.

-

@arhi Have you tried experimenting with the part cooling? More air, less air? Does it make any difference to the stringing? I find that dropping the temperature to as low as one can get away with and using the highest possible travel speeds help. Does your slicer alow you to print smaller details at slower speeds? That can help too.

But it might just be a function of that particular reel of filament. The "G' part of PET-G varies hugely between brands. Even the dye can have an effect. I once had to make some parts that had to be a "slide fit" dovetail joint. After a bit of experimentation, I got them to fit together just right and could print them all day long. But when I changed to a different colour filament (same type and brand) I had to adjust the clearances and re-slice. So if the filament dye can affect the dimensional accuracy, maybe it can have an effect on the "stringiness" too? -

@deckingman said in .6mm e3dv6 stringing petg any ideas?:

@arhi Have you tried experimenting with the part cooling? More air, less air?

That is where I'm at.

Since I had to convert quickly my x-carriage to accommodate BMG as I had some troubles with my self-modified G5 the cooling was sub-par. I designed and printed the new one yesterday, it's ugly as hell but cooling is now great, I have 2 fairly strong 5015 blowers hitting the tip of the nozzle, high pressure, huge air volume, fine control (they go down to 5% and you can hear each %, I don't have good visualisation yet of the airflow, need to get me some of that oil railway modelers use for simulating smoke; on the other hand the water bowl test shows the good flow and high pressure).I just finished two prints and am not happy. With 100% part cooling fan difference to the poor cooling wrt stringing is negligible. I can't understand wtf is going on, this amount of cooling would prevent most of other PETG I have to even extrude at this temperature. I tested quickly the blue translucent one and the output is perfect, it's only this white thing that fails to run ok.

What's worse, the normal part suffer from too much retraction, and printing too bigger parts next to each other - no stringing, get small ones and everything falls apart even with this much air.

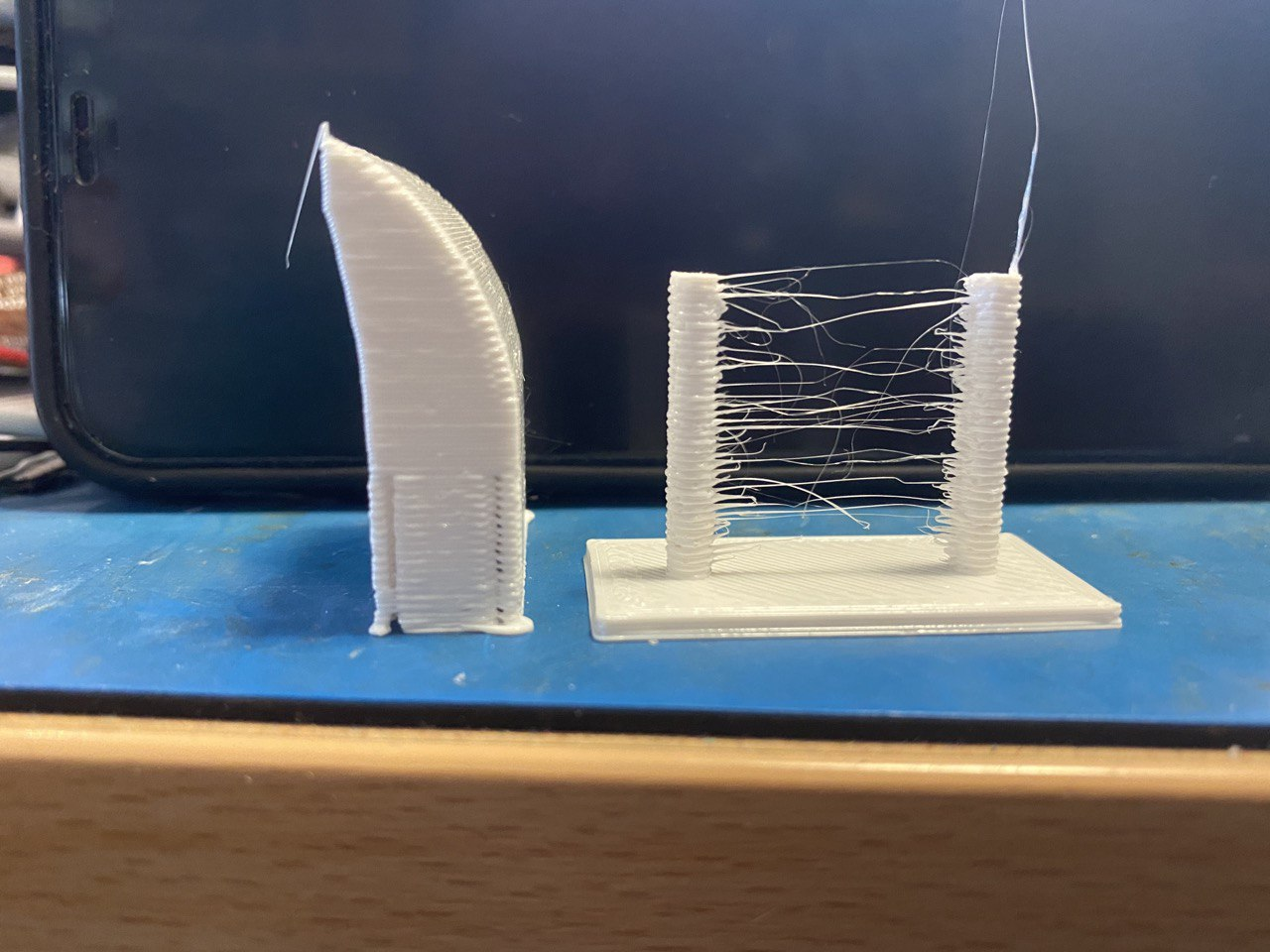

Here you can see what I mean .. both part that suffer from this much retraction and the darn strings... I'll drop the temp even lower but going below 220C for PETG makes zero sense to me... what kind of PETG runs @210 ?!?

Does it make any difference to the stringing?

I was sure the difference will be great, but, no, I'm observing no difference

I find that dropping the temperature to as low as one can get away with and using the highest possible travel speeds help.

Just going to let it print PETG @215C, makes zero sense to me to go that low for PETG but looks like I have 3kg spool of something that's filled with some additives. I expected to have to raise the temp up from 250 what I normally use for PETG due to larger nozzle and higher speeds but...

Does your slicer alow you to print smaller details at slower speeds? That can help too.

Not many details that I expect with .6 nozzle.

Anyhow, after I'm done with ideas wrt temp and cooling I'm 'bout to try to see how different speeds affect stringing. The move speed is now at 200, and this print it's going to go to 400 (can do now as replaced the huge e motor with pancake one)

But it might just be a function of that particular reel of filament. The "G' part of PET-G varies hugely between brands. Even the dye can have an effect. I once had to make some parts that had to be a "slide fit" dovetail joint. After a bit of experimentation, I got them to fit together just right and could print them all day long. But when I changed to a different colour filament (same type and brand) I had to adjust the clearances and re-slice. So if the filament dye can affect the dimensional accuracy, maybe it can have an effect on the "stringiness" too?

Well I just mentioned somewhere that "very white" and "super black" always behave for me different from all other colors. I suspect both use heavy dose of pigment that affect them a lot. Wife's father was a famous painter and he always corrected me that blues are not the most expensive and that good white is always the most expensive color in the set. I noticed all the "filled" filaments (metal dust, glow in dark, wood, carbon fiber...) are lot stringy compared to normal non-filled filaments, maybe the pigment that make this white does the same thing but I feel this type of stringiness is different. I did a lot of printng with PP and HDPE and this feels like those plastics. You cannot, with hand, break off the string from the nozzle, you pull and pull and pull and pull and like those magic color handkerchiefs coming out of clown's nose it just keeps coming out of the nozzle.

-

hmmmm... this is weird behavior with 205C I'm getting over extrusion ?!?!?!?!

anyhow, dropping to 205C (how the hell petg prints at 205C beats me)

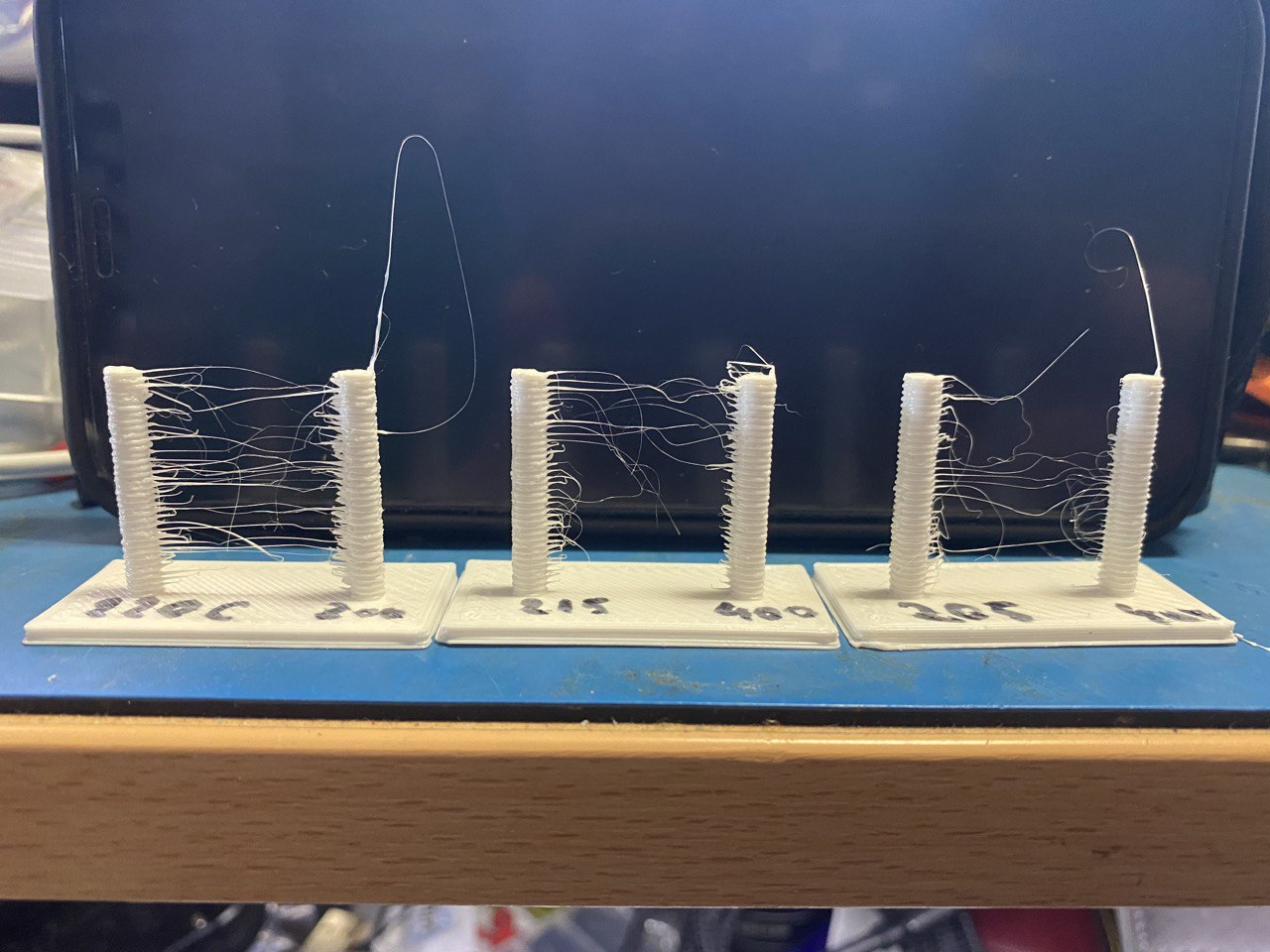

left to right

220C 200mm/sec move

215C 400mm/sec move

205C 400mm/sec moveM201 X1000.00 Y1000.00 Z150.00 E3000.00 M566 X500.00 Y500.00 Z100.00 E3600 so jerk 500, acceleration 1000 (not sure what's the max speed it achieves on this short move between pilars)

-

@arhi As you say - weird. Must just be weird filament.

Ref the railway modellers smoke - I use E cigs and make my own "juice". The ingredient that produces the visible vapour is vegetable Glycerine - that's probably the same stuff that railway modellers use. Check out YouTube videos on how to make a "smoke machine" using Glycerine. Something like a foil dish heated with a tea light candle or three works well.

I've managed to produce a lot a visible vapour but trying to visualise air flow is another matter altogether. You need a dark background and lighting is very tricky to get right.

-

Have you thought of playing with temps a little bit more ?

I primarily use Das-Filament's PETG and I usually print the first layer at 230c then back to 225c after that with fan at 80% after layer 5.

But oddly this week i opened a new roll of PETG from Das-Filament "metallic blue" I popped it in the printer and ran it with my usual profile using S3D.

As soon as it started laying the first layer down it just didn't look right, lots and lots of oozing and stringing, I put it down to being a colour I haven't printed with before, with it being a supposed metallic.

But a few layers in and it didn't get any better and it just smelled wrong compared to what PETG normally smells like when it is printing if you know what I mean.

So I stopped the print and the material seemed very brittle and it was very crystalline.

So I fell back on to the usual diagnostic routine and started by checking it was dry (I dried it) nope still doing the same, then I printed a temp tower for PETG and all was showing far too hot, for a laugh I printed it again using a PLA set of G-code, this time the stuff printed as smooth as butter and the best temp showed to be at 190c .

Next thing I did was check it was actually PETG, as it was printing very much like PLA, the box and bag it came in all said PETG, I contacted Roman @ Das-Filament and he assures me it is 100% PETG.

But im at a loss as to why this particular roll of PETG wants to print at PLA temps.