PanelDue 4.3 Screen problem

-

@blt3dp I dont think so because if that was the reason then the corruption would occur in the begining layers. But in my case, for example in 100 layer object ABS print, it starts at the 50th-60th layers

-

Is there any chance that the case is pressing on the glass screen? I managed to damage a 5" screen when I put it in case. There are tracks that in effect are on the glass and very close to the edge, it is easy to damage them. Perhaps the temperature change is increasing/decreasing pressure on parts of the screen?

-

@vakur said in PanelDue 4.3 Screen problem:

But as 45°C is not a high temp.

Your LCD panel may disagree with your assessment. You're saying when the temp drops the corruption goes away. That seems a likely cause then, no?

The ribbon cable is only needed if you're using the PanelDue SD card slot. You could relocate the panel further away if you used the 4 wire cable instead.

-

@gloomyandy there is a possibility, I may have damaged it, I should install a new panel and try it.

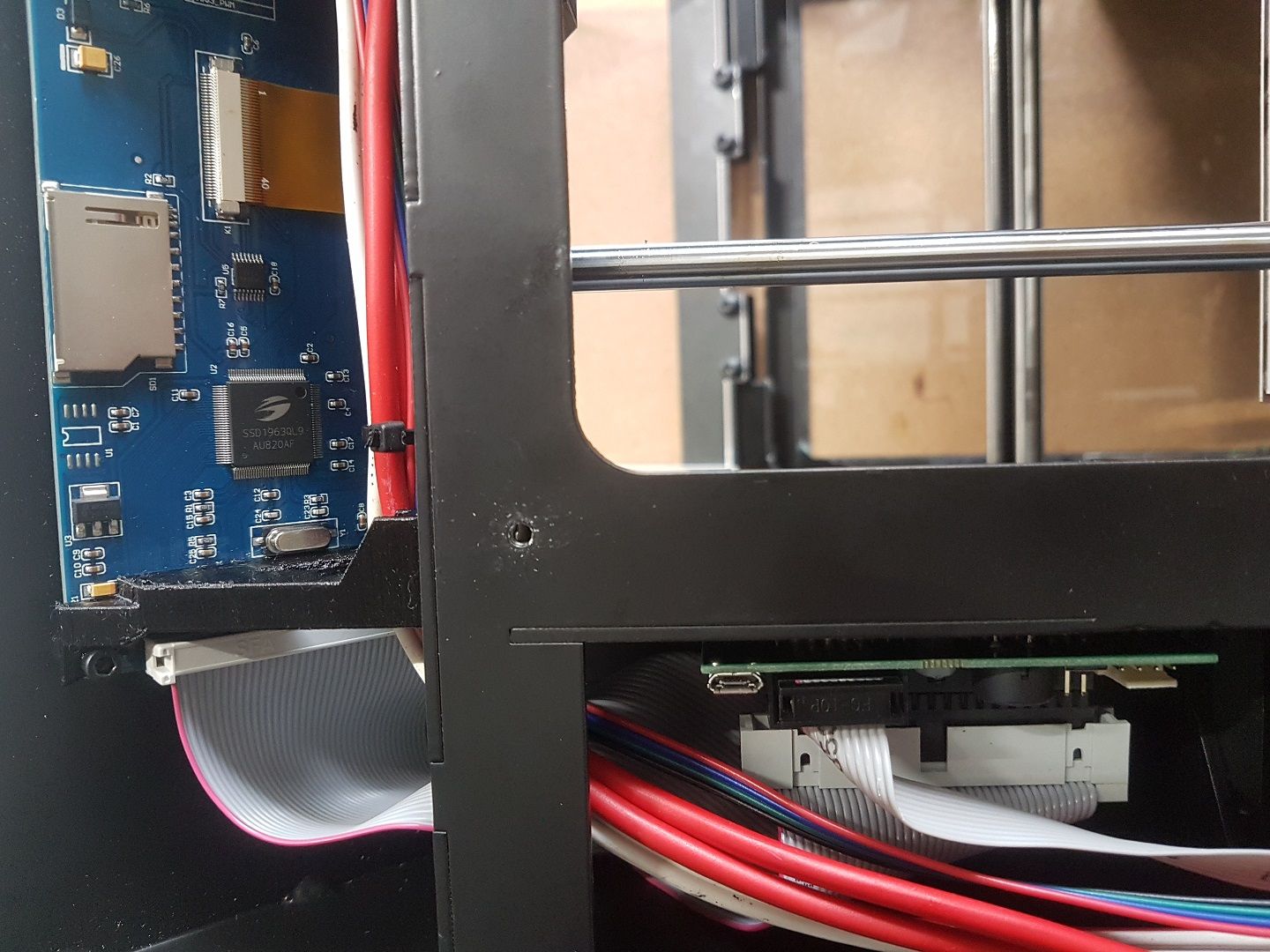

@Phaedrux this is the section with lcd connections

-

I doubt the damage is to the LCD panel itself, rather along the flatflex or ribbon conections, solder joint or plastic parts that result in poor connection as the temperature heats up. Simple test is to mount the PanelDue directly to the LCD to rule out the ribbon?

To me it looks like youre using a

female idc connector with a stackable header? those pins are much slimmer than the regular square pins. -

It looks like a signal timing issue to me, but it could be either in the signal from the PanelDue controller to the display (which your ribbon cable between the two will make much worse) or in the signal internal to the display. So you may find that it works up to a higher temperature if you mount the PanelDue controller directly on the display, as I intended when I designed it.

-

@bearer

Yes i am using stackable header. Is there any other type of connection you can suggest that fits there?

@dc42

I cannot connect the LCD directly to the controller because there is not enough space for it. Actually I have been using it for a year like this and this problem just appeared.

Would it be useful if i try:- reducing the maximum heatbed temp to 100°C (I've tried. Distortion intensity decreases)

- improving connections

- moving the controller from the heatbed side to the other side

- increasing the distance between other cables and the controller

-

@vakur said in PanelDue 4.3 Screen problem:

Is there any other type of connection you can suggest that fits there?

I used the normal female and just applied some superglue to the idc connector and cut of the corner that conflicted the 4 pin connector.

If you can't temporarily try without the ribbon cable, try gently wiggling it when the problem occurs and see if it affects it one way or the other.

-

@bearer Thank you for your suggestion. It seems that the best way to understand the cause of the problem is to take the panel due out and try it out. Actually, the reason I asked this problem was to find out if there was a definite reason. As I understand that the problem stems from my use.

-

Most probably, overheating caused this problem. I moved the controller from the heatbed side to the other side and the problem solved for now.