RRF 3 Z home not triggering.

-

M292

Warning: the height map has a substantial Z offset. Suggest use Z-probe to establish Z=0 datum, then re-probe the mesh.

9 points probed, min error 1.050, max error 1.650, mean 1.378, deviation 0.219

Height map saved to file 0:/sys/heightmap.csvM292

Error: Some computed corrections exceed configured limit of 0.50mm: 1.585 0.865post leveling

M122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.1.1 running on Duet WiFi 1.02 or later

Board ID: 08DLM-996RU-N8PS4-7JKDA-3S86M-9BAZN

Used output buffers: 3 of 24 (20 max)

=== RTOS ===

Static ram: 27980

Dynamic ram: 94036 of which 32 recycled

Exception stack ram used: 512

Never used ram: 8512

Tasks: NETWORK(ready,396) HEAT(blocked,1224) MAIN(running,1632) IDLE(ready,80)

Owned mutexes: WiFi(NETWORK)

=== Platform ===

Last reset 00:08:31 ago, cause: software

Last software reset at 2020-06-03 01:05, reason: User, spinning module GCodes, available RAM 8720 bytes (slot 2)

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0441f000 BFAR 0xe000ed38 SP 0xffffffff Task MAIN

Error status: 0

MCU temperature: min 34.5, current 35.2, max 35.4

Supply voltage: min 12.1, current 12.2, max 12.3, under voltage events: 0, over voltage events: 0, power good: yes

Driver 0: standstill, SG min/max 0/1023

Driver 1: standstill, SG min/max 0/437

Driver 2: standstill, SG min/max not available

Driver 3: standstill, SG min/max not available

Driver 4: standstill, SG min/max not available

Date/time: 2020-06-03 01:13:56

Cache data hit count 854313108

Slowest loop: 14.99ms; fastest: 0.13ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 4.3ms, write time 2.0ms, max retries 0

=== Move ===

Hiccups: 0(0), FreeDm: 169, MinFreeDm: 167, MaxWait: 85235ms

Bed compensation in use: mesh, comp offset 0.000

=== MainDDARing ===

Scheduled moves: 112, completed moves: 112, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1

=== AuxDDARing ===

Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1

=== Heat ===

Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 199.92ms; fastest: 0.09ms

Responder states: HTTP(2) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8- WiFi -

Network state is active

WiFi module is connected to access point

Failed messages: pending 0, notready 0, noresp 1

WiFi firmware version 1.23

WiFi MAC address bc:dd:c2:2d:64:61

WiFi Vcc 3.38, reset reason Unknown

WiFi flash size 4194304, free heap 22208

WiFi IP address 192.168.1.44

WiFi signal strength -40dBm, reconnections 0, sleep mode modem

Socket states: 4 0 0 0 0 0 0 0

- WiFi -

-

-

I don't see errors (error counts or hiccups) in M122.

You should try the test of loosing one side and run the test again. Releasing the side is only for the test.

One idea is your little screw is connected to a plastic part. This part is much weaker than all the steel/brass around, so it will flex much more under pressure.

-

@JoergS5 what should i make loose? i mean why would i have all these issues?

i never had any problems with the ramps before. the auto bed level worked fine, everything worked fine, i just wanted a quieter printer and more features than that old ramps could provide me.

i would honestly say that theres nothing physically wrong with my set up but im down to try what ever.

-

@joehsmash My idea was that the Z movemement stuck because you have pressure between left and right side. This was the reason for my proposal. But if you know that this is not the reason, you don't need to make this test of course!

-

@JoergS5 also about that little screw, thats not an issue. its currently not holding any weight other than to just hold the clamp onto the lead nut so that my axis switch stays in place.

as i said before i could cheat it but it would just cause more issues.

-

No problem, don't do anything I propose if you don't want to.

-

-

@JoergS5 i see what you saying.

the way this gantry works is there are these clips that hold the axis end stops in place, that sandwiches the top of the gantry to the lead nut so that when it pushes the nozzle into the bed it will tilt the gantry and raise one of the sides which inturn triggers one of the switches.

on a side note, if the gantry gets too much out of level it puts lots of pressure on the lead screw and the linear rail and as such will not allow the switches to trigger.

right now theres is no pressure between the right and the left screws because i have manually leveled the gantry. only the firmware keeps pushing it out of level.

-

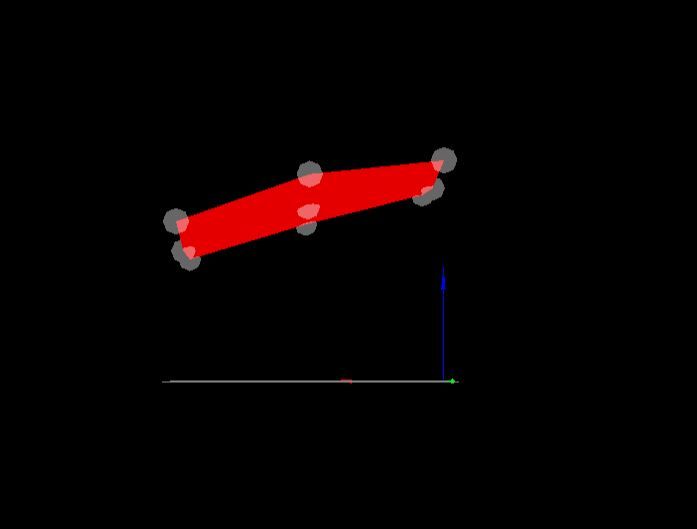

I want to share a last idea what could be wrong: the endstop is very near to the construction above:

Maybe it bumps into the upper part before the switch is activated sometimes.

-

if i take the axis clamps off theres nothing to stop the gantry from just raising until the lead nuts come out of the gantry and it will just sit there and spin forever

-

@JoergS5 right now the NC switch is in an inverted state, the entire weight of the gantry is resting on the lead nut, and the switch clamp is clamped to the leadnut and snugged up to the bottom of the gantry. so that when the nozzle hits the bed, it raises the gantry approx 1mm which causes either of the switches to trigger.

-

@joehsmash said in RRF 3 Z home not triggering.:

if i take the axis clamps off theres nothing to stop the gantry from just raising until the lead nuts come out of the gantry and it will just sit there and spin forever

I didn't mean to remove anything, only to loose one side. (With loose I mean: Do not tighten the screws but loosen them, so that they can give way a little.)

-

@joehsmash said in RRF 3 Z home not triggering.:

@JoergS5 right now the NC switch is in an inverted state, the entire weight of the gantry is resting on the lead nut, and the switch clamp is clamped to the leadnut and snugged up to the bottom of the gantry. so that when the nozzle hits the bed, it raises the gantry approx 1mm which causes either of the switches to trigger.

Ok I understand. That's a good idea and is very precise!

-

Subtle switch trip https://imgur.com/a/RrO48ah

-

I am not sure, but while watching the video, I think I see some subtle rotations of the endstop while it activates. The rotation means Z movement because the endstop is connected to the trapezoid spindel. Maybe this is the reason for your differing values.

-

@joehsmash i dont mean to be a smart a$$ im not,

ive just had this machine apart and back together so many times now that im sure i can build it in my sleep.

i would just like to be able to get back to the auto level like i had before and get back to printing.

-

@JoergS5 i could snug up the lead nut inside the gantry arm for sure. i have some .001 shim here.

-

@joehsmash The video is counting down from 0.25 to 0, at position 0:12 the endstop rotates a bit. This changes the measured value. Because the endstop is assembled on the trapezoid spindle and the rotation itself changes the Z position.

-

@JoergS5 to which i will do in the AM, as i will have to dissasemble the whole gantry and top half of the printer to get them out.

thanks for your help thus far... some times i wish there was just a chat button haha