Part cooling fan duct design advice

-

@MegaAndy Most ducts seem to destroy the airflow, especially that from axial fans because of the very low static pressure. My latest part cooling solution uses two tiny 30mm blowers mounted close to the nozzle but with no ducting. I did a bit of a write up on my blog not long ago - section 2 of this post - https://somei3deas.wordpress.com/2020/04/28/my-6-input-mixing-hot-end-part-8/

Seems to work well although testing has been limited........

-

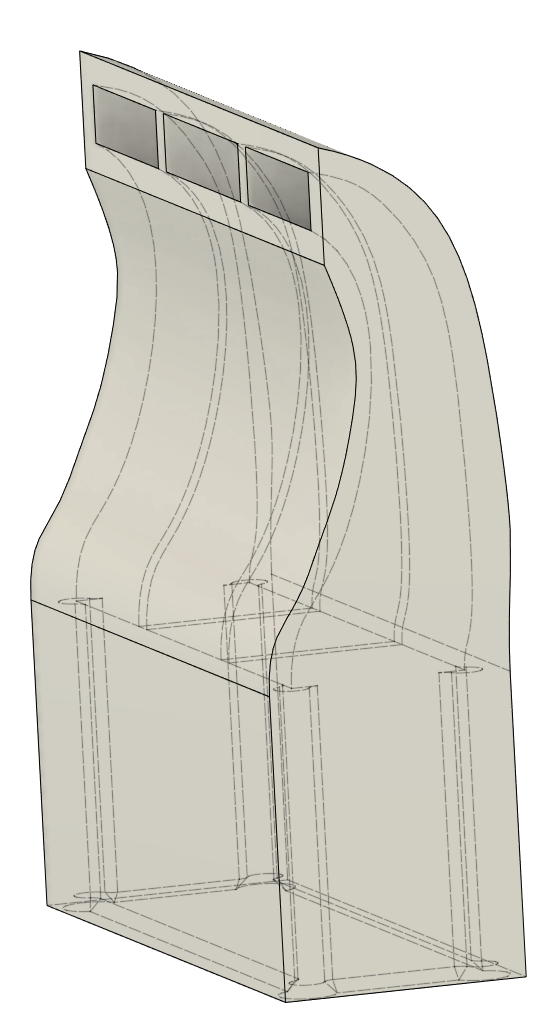

I made this:

https://www.myminifactory.com/object/3d-print-121644And it has interchangeable nozzles for both fans. This way you can easily test different nozzle design, use only one fan etc etc.. It works imo great, at 100% fan speed it will freeze PLA so fast it won't properly stick to the bottom layer even if you up the nozzle temp a lot.. for normal printing 60-70% cooling for PLA is more than enough to get perfect overhangs and bridges. Note also that there are different 5015 fans, not all are the same, I do have some "dragons" that push a lot of air trough.

-

@deckingman Thanks, I guess the only way of me doing that would be to redesign the whole carriage to mount fans better. It's also annoying the 5015 blower fans are not available mirrored to line up the outputs in a design like this. I guess one takeaway from that though is to constrict as little as possible and just deflect in the right direction.

-

@arhi Thanks,

Looking at that design, I have not seen anything like this and can't work out how that cooling works, it looks like the air wouldn't be pointing at the nozzle?Ah I have seen the see more button on Myminifactory and see the attachments you use to extend to the nozzle now. Will have a look at that to see what I can learn from it, thanksVery good point about the 5015 fans too, I have two that (I think? maybe not and that's my problem) put out a decent amount of air but I have a box of 3 of them that seem like way less airflow so i have never bothered using them. It seems there is no reputable manufacturer of 5015 or at least I haven't found any.

-

@MegaAndy Just to add that, unless you are extruding a lot of plastic (using large diameter nozzles and/or large layer heights), then the amount of cooling air required is surprisingly small. Direction is far more important than volume IMO.

-

@MegaAndy the whole point there is that x-carriage itself does not limit the flow almost at all so the nozzle you push on to it is what's doing it. I tried a lot of simulations and they were too far away from what's happening in real life, especially during the print itself with bed below, weird shape of the objects being print etc etc.. so I made it like this and then made a whole bunch of different nozzles to try it out.... and after a lot of plastic I decided to go with simplest possible design ... no circling around the nozzle, no fancy ducting, no speed matching ... nothing .. just a bend to point the air in general direction and that's it... easy to print, works better than all the "fancy" things I tried that looked 10000x better in simulation

-

@arhi Thanks, I see I need to go for simplest possible redirection towards the nozzle. I have basically come to this conclusion before but am amazed how much flow is lost even with a very simple duct. I think where I have gone a little wrong is how low down the blower fans are, requiring quite a bit of redirection over not much distance. The ducts also mount by pushing into the end of the blower fan so I better check if that's having a negative effect too.

-

I use B5015E24B-BSR fan on my printer. It has high static pressure, which really made it better than few other I tried. Only problem with it is that its quite loud and big (50mm body/frame). I've also noticed that having fan duct go over fan's mouth rather than in it makes it much quieter.

-

@Visionary Thanks, I run 12V so the B5015E12B-BSR looks to be the equivalent with the same CFM and pressure. Really useful that they actually show proper specifications so that looks hopeful. I have not had all these specs available where I have purchased before and any info that was given is unlikely true. Only thing I can use as reference is that the B5015E12B-BSR is 12V 0.3a when what I have is 12V 0.15a or 0.18a so that's got to count for something. I will not mind about noise if they cool well!

-

I thought I would just follow up with what I have done based on the comments here. I have made some ducts that I tried to restrict the air flow as little as possible. They attach around the end of the fan instead of inside of the fan to restrict air flow less. Also I tried to keep the area of the the duct as large as possible to constrict flow as little as possible.

When turning the fans on and feeling with my hand the airflow feels much better than before. The overhang quality seems much better but I have limited testing for now and I think I can improve further.

Unfair test as different filament but yellow is before green after, up to 80 degree overhang.