@dc42

Peopoly uses one linear motor on each X and Y axis and two linear rail blocks on each Y-axis rail. On their printer it seems to work even though there is some cantilever pulling/pushing going on. Thomas Sanladerer shows some details on the printer on his review video.

STōN-WoLF printer also has kinematic configuration that could be a bit more suitable for linear motors.

I've had (Chinese) ball screws on my Z-axes and they are ok, but they still have slight Z-wobble and they do have noticeable amount of backlash. Using linear motors also on Z-axis would definitely be expensive, but I'm curious if there would be better in every other way (speed, noise, precision, no moving parts, no grease). Preventing bed from dropping hard when unpowered is an issue too.

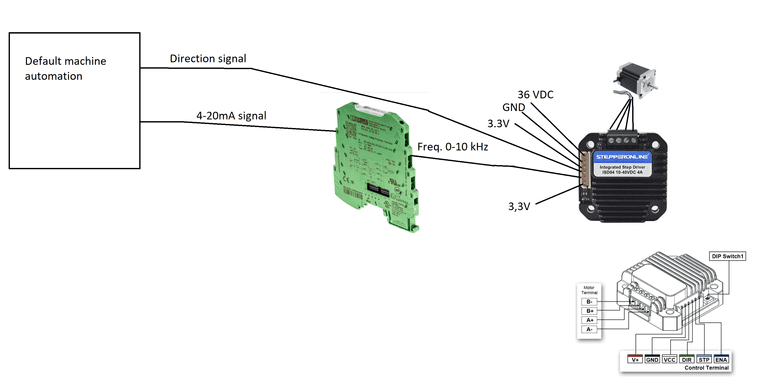

Many of the examples of DIY linear motors on YT and on Internet use 3-phase setup and drive the motor with VFD or what I assume is a BLDC drive. If it would be possible to use 2-phase setup instead and use directly say 6HC stepper drivers then that would very simple if possible. Or could ODrive Pro-board be used through CAN-connection to Duet to drive a 3-phase linear motor? I do realise that this would be expensive, but e.g. one Clearpath servo imported to Europe costs >400€ and that doesn't even include belt drive components.