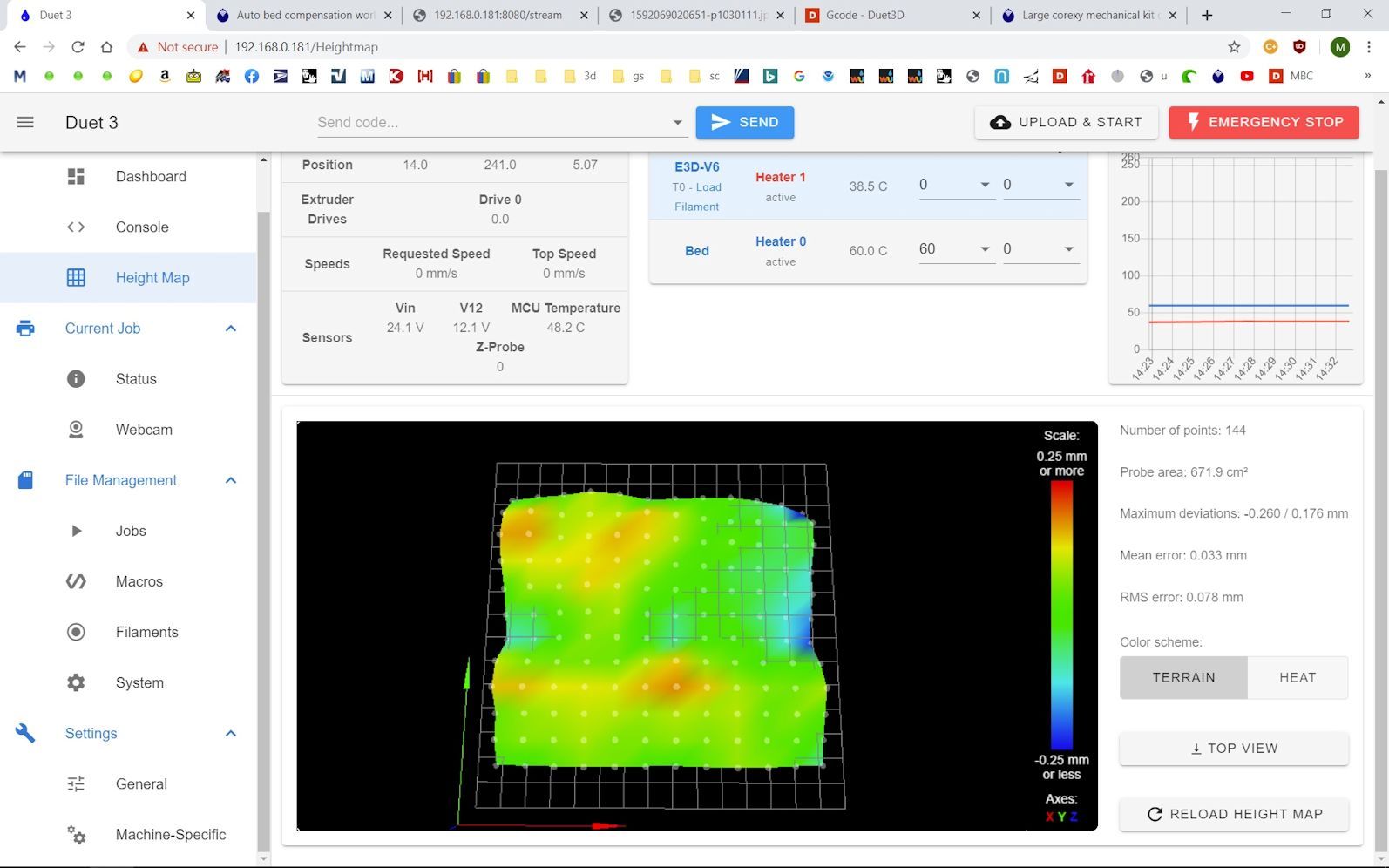

Auto bed compensation working just not very well

-

@Phaedrux Sounds good, thanks

Also sorry , did not see slicer start script,

G90 ; absolute positioning T0 ; select tool M109 S200 ; wait for hotend temp M190 S60 ; wait for bed temp G28 ; home all axes G29 S1 ; load height map G1 X130.0 Y15 Z0.0 F2000 ; move tool G1 X40.0 E10 F1000 ; prime nozzle G92 E0 ; reset extruder G1 E-.65 ; retract 1 mm -

Hi,

You can also try forcing the probe to average a fixed set of readings.

For example in M558 an A value of 5 and a S value of -1 the firmware will take 5 readings at each point then average them.

While averaging takes longer I think you would get a truer picture of your bed.

Frederick

-

That is what @Phaedrux did in the above files I believe.

-

Not quite. I have it probe up to 10 times or until it gets two consecutive consistent readings, but it won't average them. Averaging them would only be desirable if the probe results themselves were always shifting around and never consistent. We'd only want to go down that route it it was probing all 10 times and never getting two results the same. In such a case you'd get an error saying unable to get consistent probe result and it would halt the routine.

-

-

have you tuned the extruder? The second half of a good first layer is the right flow rate for the height from the bed.

-

Now that you've got a good height map generated you can use G29 S1 to load a saved heightmap instead of redoing it every time.

Print something like this to test the heightmap over the entire surface of the bed rather than a full print of a small section. Much faster this way and will give a better idea if the mesh compensation is working.

-

@Phaedrux I have confirmed the amount extruded by measuring 100mm of filament and then extruding 100mm. Comes out to within about a mm.

-

@Phaedrux

New test print, Since this is a 3 layer print the pictures mask what the first layer looks like. As I watched the first layer being put down generally speaking the right side of the print was laid more closely to the bed than the left. On the left the layer lines were thinner and rounded under a magnifier. As the nozzle progressed from right to left I watched the Z stepper wheel lower the bed. This is what was happening with the previous print with the holes, started good on the right and got worse as it went left. Is there anything left that can be done?

And I do appreciate your time and effort to help me out on this!Front of printer is on the left, did it that way to avoid shadows, but got some anyway.

Want to mention that h.e. is a genuine e3dv6 and the Z lead screws are T8-2 instead of the more common T8-8. More turns per inch as opposed to T8's = better resolution I'm told.Upper right

-

Just to confirm, you have 3 motors for your 3 bed lead screws for the auto leveling, right?

Are you sure the positions are correct?

Is there much deviation after each iteration of G32?

-

Just 2 lead screws and 1 stepper , I use G32 to adjust the 3 spring loaded bed leveling screws. Very little variation between iterations, day to day = some change, .03 +or-.

-

What is your nozzle width? What slicer are you using? What line width and layer height are you using for the first layer?

-

The only other thing I noticed is the trigger height is a bit high.

G31 P25 X-4 Y59 Z3.20When the BLTouch is mounted correctly the base of the probe should be ~8mm above the nozzle tip which leads to a trigger height of ~2mm, when you get too far away from that the BLtouch can be a bit off sometimes. It has a sweet spot.

-

Nozzle .4mm, S3d V4.12, flh 90%, flw 100%

Bltouch base is now 8.25mm above bed (mechanical limitation prevents 8mm) with nozzle touching bed, new trigger height = 1.40mm.