Duet3 Expansion Board 3HC - No CAN-Connection

-

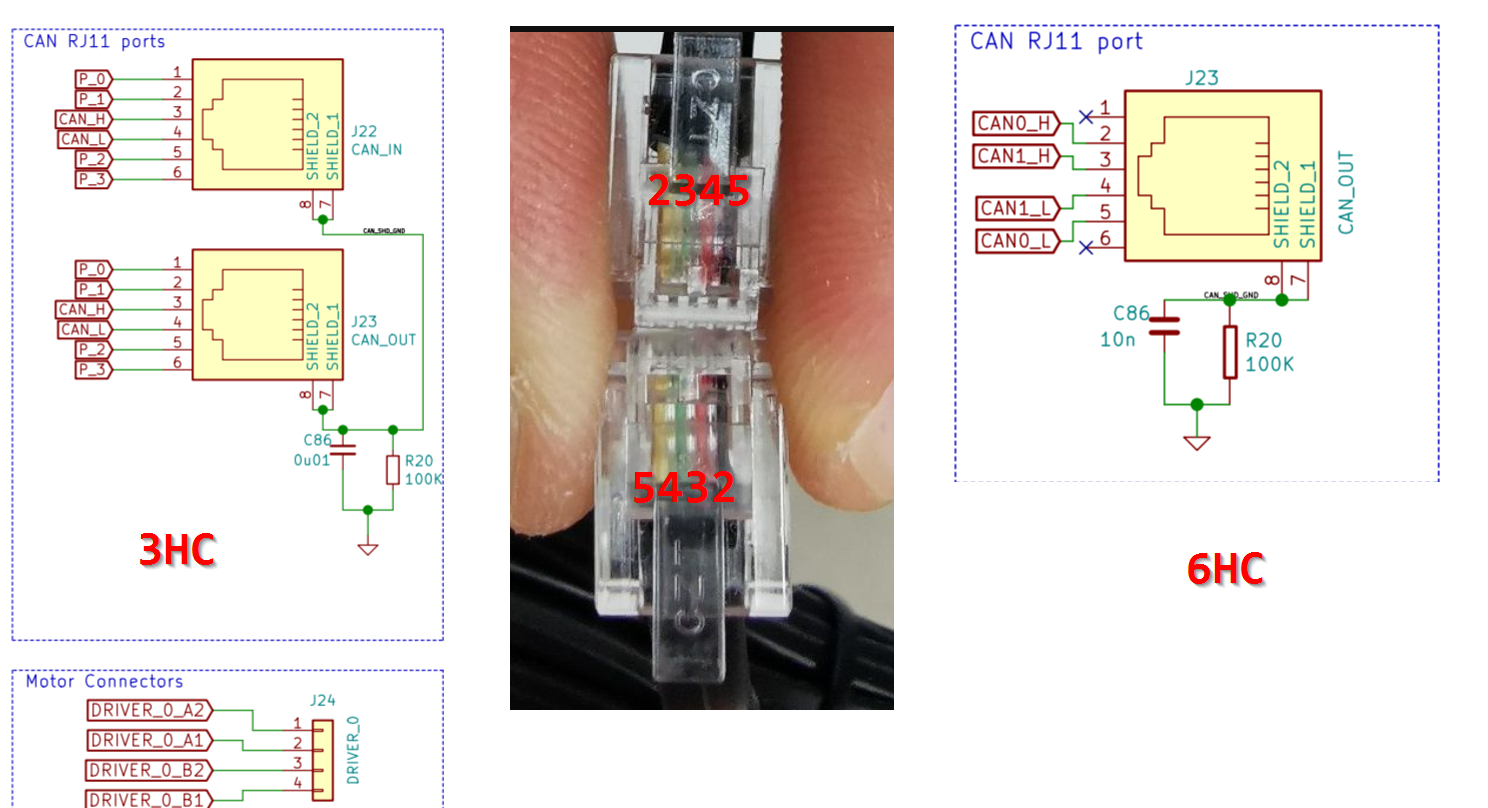

CAN H and L should not be crossed (twisted pair does not cross the pins). So pin 3 from the 6HC to pin 3 on the 3HC, but @CR3D shows cabling that connet 5 to 1, and 3 to 4 so thats wrong.

-

@bearer I can tell only what I did and that works for me. So pin 1 is pin 1, pin 4 is pin4 and the two in the middle is crossed. At least at my working setup. Im on the sofa with my tablet. So im a bit limited.....

-

@Chriss if your way was right it would work for OP.. the black and yellow are not used by the 3HC, and the green and red are (incorrectly) crossed over.

-

Hmmmmm....

https://duet3d.dozuki.com/Wiki/Getting_Started_With_Duet_3

Says

Only a single twisted pair is required, connected to pins 3 and 4 (the middle 2 pins) of the connector.But yours seems crossed to me. (Yes I had to correct my former words.)

-

So the lower connector in OPs photo is correct if you want to be pedantic about colour coding, but top one is reversed. Easier to check the colours if you flip one end up side down so the pins line up 1:1, 2:2 etc.

In any case @CR3D needs to swap the red and green wires on one end of his cable.

-

@bearer

Ok thank you very much! I will test it

-

@bearer

Which cable did you buy? I can not find a right one at the moment...

-

@CR3D said in Duet3 Expansion Board 3HC - No CAN-Connection:

Which cable did you buy? I can not find a right one at the moment...

I didn't, don't have an expansion but I would just terminate my own as needed (already have the tools for RJ45 so it will do RJ11, RJ12 and RJ14 as well).

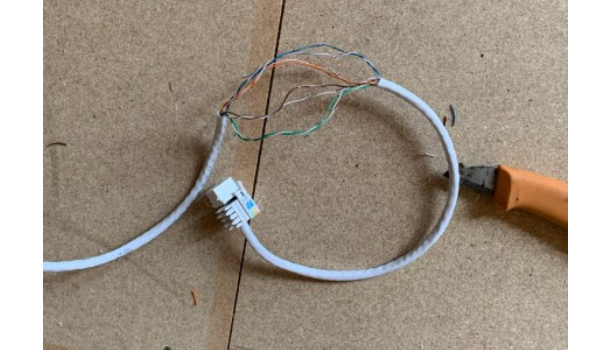

But if you purchased the cable made like that, that is a little surprisng, not a standard setup for phones afaik. Aaaanyways, what you can do as a work-around is just cut one end off, strip the insulation back and connect the green to red, and red to green as demonstrated by my brother with an RJ45 jack here:

(and then as he did, invite a friend with the tools to come fix it later:) -

@CR3D said in Duet3 Expansion Board 3HC - No CAN-Connection:

Which cable did you buy? I can not find a right one at the moment...

DC42's commendation is to use high speed ADSL2 cables such as these https://www.kenable.co.uk/en/computer-cables-peripherals/adsl-rj11-cables/7935-adsl-2-high-speed-broadband-modem-cable-rj11-to-rj11-05m-black-007935-5055383479351.html

-

@bearer

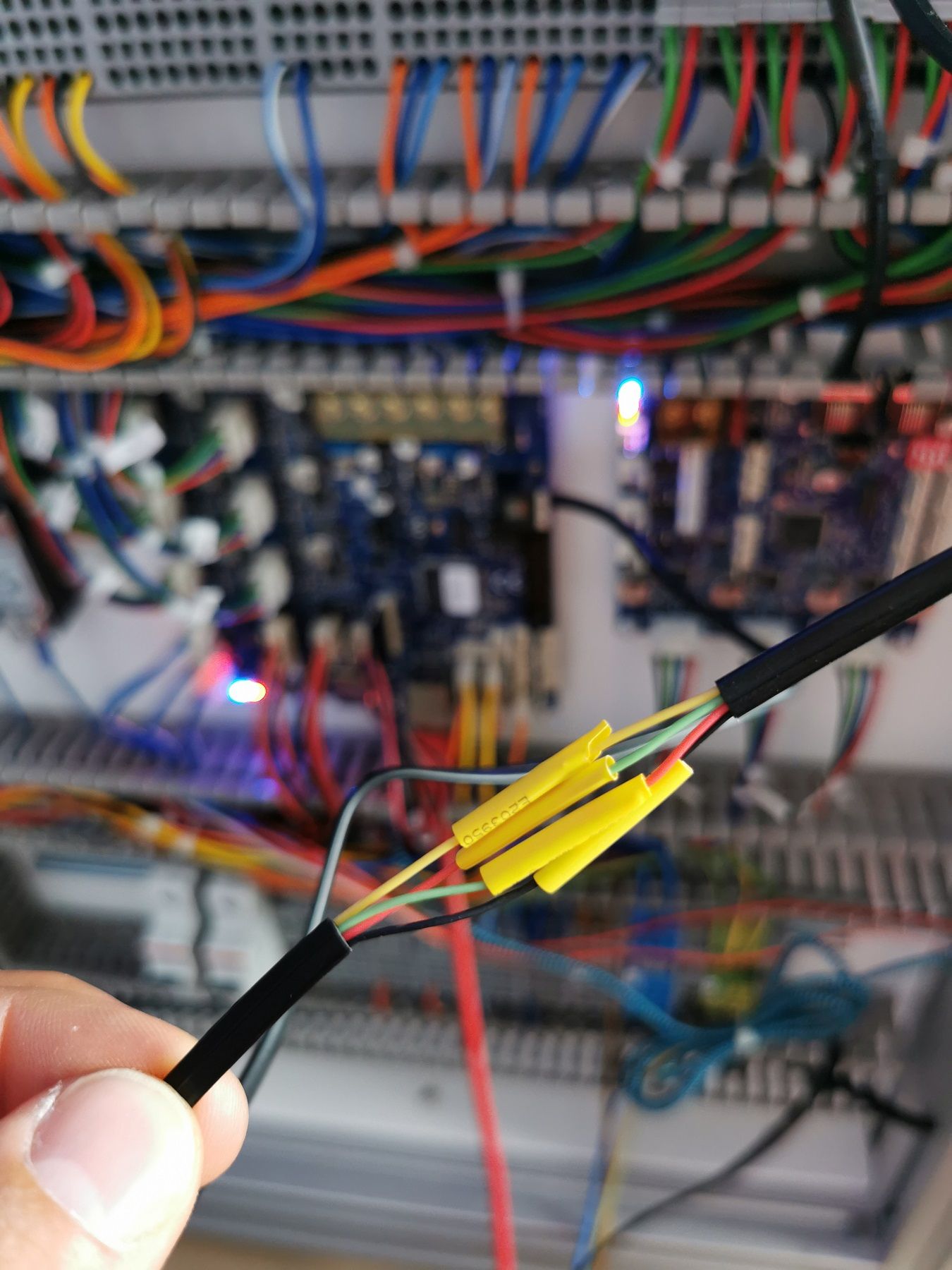

I made the same today... and it works!!!!

Thank you a lot

Now I have other "Problems"... but I am not sure. Perhabs I should open a new Thread....

-

(you didn't need the black and yellow, but it won't hurt either)

if its still CAN related you'll probably still attract the right people, if not move to another thread as it makes it easier for the community to help you

-

@bearer

To be honest, I don't know what it has to do with it yet.

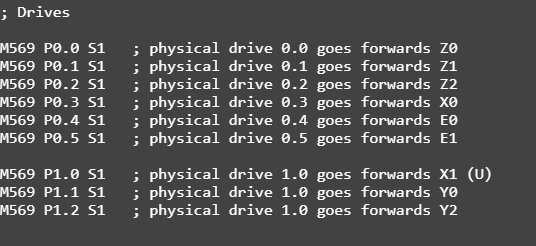

But it still has to do with the 3HC.I connected 9 motors to my printer.

It is a Cartesian with triple Z-axis and IDEX systemMotherboard:

3x Z-axis

1x X-axis

2x extrudersExpansion board

1x U-axis

2x Y-axis

The endstops are connected to the mainboard:

The drives which are attached to the mainboard work wonderfully. Even if I check the limit switches, the signals are correct. However, the homing of the U-axis and the Y-axis is not yet working properly.

The Homing File of the U-Axis looks like the X-Axis.

The motors rotate very slowly and do not react correctly to the limit switch. even if homing is canceled, the motors continue to rotate ...

I can't really explain it to myself honestly ...

-

if i'm reading that right you have the endstops on the main board?

ref https://duet3d.dozuki.com/Wiki/Duet_3_firmware_configuration_limitations

-

@bearer

Yes, I had that in mind!

I had already tested putting these endstops on the expansion board. So far the same problem .. but I can test it again ...

-

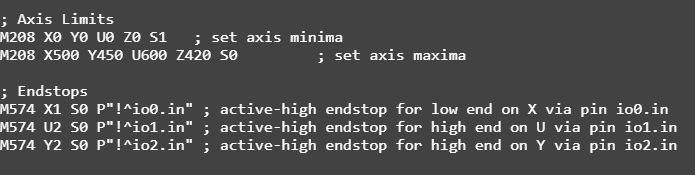

@CR3D if you use RRF3, M574 S0 is no longer supported: "Endstop type S0 (active low switch) is no longer supported in M574 commands." please check https://duet3d.dozuki.com/Wiki/Gcode#Section_M574_Set_endstop_configuration and use S1 with ! instead.

-

@CR3D said in Duet3 Expansion Board 3HC - No CAN-Connection:

So far the same problem

post the config for that when you do, copy past the text and use the formatting function here makes it much easier to read. (on the toolbar with bold, italics, its the fifth from the left to format as code which makes it nice and readable)

-

-

I have now connected the endstops of the Y-Axis and those of the U-Axis on the 3HC ... unfortunately without success ...

Here is the config...

Main:

; Configuration file for Duet 3 (firmware version 3) ; General preferences G90 ; send absolute coordinates... M82 ; and absolute extruder moves M550 P"I444-S" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards Z0 M569 P0.1 S1 ; physical drive 0.1 goes forwards Z1 M569 P0.2 S1 ; physical drive 0.2 goes forwards Z2 M569 P0.3 S1 ; physical drive 0.3 goes forwards X0 M569 P0.4 S1 ; physical drive 0.4 goes forwards E0 M569 P0.5 S1 ; physical drive 0.5 goes forwards E1 M569 P1.0 S1 ; physical drive 1.0 goes forwards X1 (U) M569 P1.1 S1 ; physical drive 1.0 goes forwards Y0 M569 P1.2 S1 ; physical drive 1.0 goes forwards Y2 M584 X0.3 Y1.1:1.2 U1.0 Z0.0:0.1:0.2 E0.4:0.5 ; set drive mapping M350 X16 Y16:16 Z16:16:16 E16:16 I1 ; configure microstepping M92 X80.00 Y35.56:35.56 Z4000:4000:4000 E415:415 ;set steps per mm M566 X900 Y900:900 Z12:12:12 E120:120 ;set maximum instantaneous speed changes (mm/min) M203 X30000 Y30000:30000 Z300:300:300 E9000:9000 ;set maximum speeds (mm/min) M201 X1000 Y1000:1000 Z20:20:20 E1000:1000 ;set accelerations (mm/s^2) M906 X1400 Y4200:4200 Z1200:1200:1200 E1000:1000 I30 ;set motor currents (mA) M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 U0 Z0 S1 ; set axis minima M208 X500 Y450 U600 Z420 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!io0.in" ; active-high endstop for low end on X via pin io0.in M574 U2 S1 P"!1.io1.in" ; active-high endstop for high end on U via pin io1.in M574 Y2 S1 P"!1.io2.in" ; active-high endstop for high end on Y via pin io2.in ; Z-Probe (Piezo) M558 P5 I1 C"io3.in" R0.5 H5 F400 6000 ; Z probe type -> Piezo M557 X120:400 Y20:400 P04:04 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp1" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M308 S2 P"temp2" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin temp2 M950 H2 C"out2" T2 ; create nozzle heater output on out2 and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ; Fans M950 F0 C"out7" Q500 ; create fan 0 on pin out7 and set its frequency M106 P0 S0 H1 T50 ; set fan 0 value. Thermostatic control is turned on M950 F1 C"out8" Q500 ; create fan 1 on pin out8 and set its frequency M106 P1 S1 H2 T50 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"out4" Q500 ; create fan 2 on pin out4 and set its frequency M106 P2 S1 H-1 ; set fan 2 value. Thermostatic control is turned off M950 F3 C"out5" Q500 ; create fan 3 on pin out5 and set its frequency M106 P3 S1 H-1 ; set fan 3 value. Thermostatic control is turned off ; Tools M563 P0 S"Links" D0 H1 F0:2 ; define tool 0 G10 P0 X0 Y0 Z0 S0 R0 ; set tool 0 axis offsets G10 P0 R0 S0 ; active and standby temperatures M563 P1 S"Rechts" D1 H2 X3 F0:3 ; define tool 1 G10 P1 Y0 U0 Z0 S0 R0 ; set tool 1 axis offsets G10 P1 R0 S0 ; active and standby temperatures ; Custom settings are not defined ; Open Door Switch M581 T0 C"1.io3.in" S0 C0 ;trigger #2 (calls trigger2.g) ; LED M950 F3 C"out3" Q500 ; create fan 3 on pin out5 and set its frequency M106 P3 S1 ;set fan 3 value. Thermostatic control is turned off ; Miscellaneous M501 ; load saved parameters from non-volatile memory T0 ; select first tool M572 D0 S0.03The X-Homing is working:

; homex.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v3.1.3 on Fri Jun 19 2020 21:08:48 GMT+0200 (Mitteleuropäische Sommerzeit) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-505 F1800 ; move quickly to X axis endstop and stop there (first pass) G1 H2 X5 F6000 ; go back a few mm G1 H1 X-505 F360 ; move slowly to X axis endstop once more (second pass) G1 H2 Z-5 F6000 ; lower Z again G90 ; absolute positioningThe Y Homing is not working for example:

; homey.g ; called to home the Y axis ; ; generated by RepRapFirmware Configuration Tool v3.1.3 on Fri Jun 19 2020 21:08:48 GMT+0200 (Mitteleuropäische Sommerzeit) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 Y455 F1800 ; move quickly to Y axis endstop and stop there (first pass) G1 H2 Y-5 F6000 ; go back a few mm G1 H1 Y455 F360 ; move slowly to Y axis endstop once more (second pass) G1 H2 Z-5 F6000 ; lower Z again G90 ; absolute positioningThe U-Axis also...

and I think the motors have hardly any power ... so those that are connected to the 3HC ..

-

the limit switches are displayed correctly ...

-

@CR3D but now this could be valid? "Endstop switches connected to the main board cannot control motors on an expansion board. This is planned to be fixed in release 3.2.0." from https://duet3d.dozuki.com/Wiki/Duet_3_firmware_configuration_limitations

Endstops are on the main board, the steppers for U and Y on the expansion board. X is both on main board. Would explain X working, U and Y not.