I write a tiny macro

t0

g1 y100 x100

t1

g1 y100 y100

I started the macro via the DWV, T0 was active wen I started it. The tool drove to y100 x100 picked up the new tool and the head stopped after the pickup and I executed M122 via the CodeConsole

m122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.5.4 (2024-11-24 10:47:10) running on Duet 3 MB6HC v1.0 or earlier (SBC mode)

Board ID: 08DJM-956L2-G43S4-6JTDL-3SS6L-1876H

Used output buffers: 10 of 40 (39 max)

=== RTOS ===

Static ram: 155464

Dynamic ram: 93856 of which 2144 recycled

Never used RAM 91528, free system stack 119 words

Tasks: SBC(2,rWait:,1.1%,797) HEAT(3,nWait 6,0.0%,321) Move(4,nWait 6,0.0%,211) CanReceiv(6,nWait 1,0.1%,771) CanSender(5,nWait 7,0.0%,329) CanClock(7,delaying,0.0%,346) TMC(4,nWait 6,9.3%,53) MAIN(2,running,89.5%,139) IDLE(0,ready,0.0%,29), total 100.0%

Owned mutexes: Telnet(MAIN)

=== Platform ===

Last reset 21:21:33 ago, cause: power up

Last software reset at 2025-02-26 14:52, reason: User, Gcodes spinning, available RAM 91424, slot 2

Software reset code 0x6003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task SBC Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

MCU temperature: min 41.2, current 41.5, max 42.3

Supply voltage: min 23.8, current 23.9, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 12.0, current 12.1, max 12.1, under voltage events: 0

Heap OK, handles allocated/used 99/26, heap memory allocated/used/recyclable 2048/632/240, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: standstill, SG min 0, mspos 888, reads 41360, writes 6 timeouts 0

Driver 1: standstill, SG min n/a, mspos 8, reads 41367, writes 0 timeouts 0

Driver 2: standstill, SG min 26, mspos 568, reads 41361, writes 6 timeouts 0

Driver 3: standstill, SG min 0, mspos 280, reads 41361, writes 6 timeouts 0

Driver 4: standstill, SG min 0, mspos 936, reads 41361, writes 6 timeouts 0

Driver 5: standstill, SG min 0, mspos 264, reads 41360, writes 6 timeouts 0

Date/time: 2025-03-07 07:44:43

Slowest loop: 54.58ms; fastest: 0.04ms

=== Storage ===

Free file entries: 20

SD card 0 not detected, interface speed: 37.5MBytes/sec

SD card longest read time 0.0ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 125, segments created 6, maxWait 1762317ms, bed compensation in use: mesh, height map offset 0.000, max steps late 0, min interval 0, bad calcs 0, ebfmin 0.00, ebfmax 0.00

no step interrupt scheduled

Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0

=== DDARing 0 ===

Scheduled moves 244, completed 244, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 1], CDDA state -1

=== DDARing 1 ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

Heater 15 is on, I-accum = 0.0

=== GCodes ===

Movement locks held by null, null

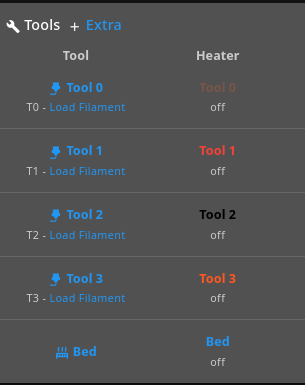

HTTP* is doing "M116" in state(s) 0 9 0, running macro

Telnet* is doing "M122" in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger* is idle in state(s) 0

Queue* is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

File2 is idle in state(s) 0

Queue2 is idle in state(s) 0

Q0 segments left 0, axes/extruders owned 0x40000003

Code queue 0 is empty

Q1 segments left 0, axes/extruders owned 0x0000000

Code queue 1 is empty

=== CAN ===

Messages queued 18453, received 180246, lost 0, errs 0, boc 0

Longest wait 2ms for reply type 6013, peak Tx sync delay 384, free buffers 50 (min 49), ts 10239/10239/0

Tx timeouts 0,0,0,0,0,0

=== SBC interface ===

Transfer state: 5, failed transfers: 0, checksum errors: 0

RX/TX seq numbers: 59813/59813

SPI underruns 0, overruns 0

State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x24cfc

Buffer RX/TX: 0/0-0, open files: 0

=== Duet Control Server ===

Duet Control Server version 3.5.4 (2024-11-25 17:32:26, 64-bit)

Telnet+Executed:

> Executing M122

Trigger+Start:

> Executing M409 K"network" I1 (32 more codes pending)

>> Macro config.g: Idle

Trigger+Pre:

> Executing M409 K"volumes" I1 (32 more codes pending)

>> Macro config.g: Idle

Trigger+ProcessInternally:

> Executing M409 K"volumes" I1 (32 more codes pending)

>> Macro config.g: Idle

Trigger+Post:

> Executing M409 K"volumes" I1 (32 more codes pending)

>> Macro config.g: Idle

HTTP:

Buffered code: M116

Buffered codes: 24 bytes total

>> Doing macro 0:/macros/test.g, started by M98 P"0:/macros/test.g"

>> Suspended code: G1 Y100 Y100

>>> Doing macro tpost1.g, started by T1

Trigger:

>> Finishing macro config.g, started by system

Code buffer space: 4096

Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 0

Full transfers per second: 37.42, max time between full transfers: 71.2ms, max pin wait times: 66.5ms/42.1ms

Codes per second: 0.05

Maximum length of RX/TX data transfers: 5560/720

ok

Here is the tpost1.g at the time of the execution:

root@blimy:~/SD-Card/sys# cat tpost1.g

; tpost1.g

; called after tool 1 has been selected

;

; Wait for set temperatures to be reached

M116

; P1

I have removed the "P1" as a result from previous part of the thread.

Cheers, Chriss