Need help to config file for ender 3 pro

-

@Phaedrux OK THANKS WHAT DO YOU THINK ABOUT THIS CONFIG

M906 X700 Y700 Z700 E800 I30 ; set motor currents (mA) and motor idle factor in per centMY MOTOR VERY HOT

-

I think your CAPSLOCK key is stuck in the on position. Fix that first.

I think those motor currents are alright for the stock motors of the Ender. I use about the same on my Maestro + Ender 3 Pro.

Unfortunately again the Creality motors aren't a great pairing for the Duet Wifi.

-

@Phaedrux sorry for the caps look

Now my printer working Almost perfect.

I have a problem with lines.

On y axis itray A lot of xyz test cube

On the y side have small ringing I checked the entire frame.

I pulled the straps, there's no difference.

My ender 3 upgrade all axis With linar rail.

Is there any chance that these lines are a software problem and not a hardware problem? Thnks for the help

)

) -

Try reducing your X Y jerk by half

M566 X1200.00 Y1200.00

-

@Phaedrux ok i well change it to x600 y600?

-

That would be half yes.

-

@Phaedrux thnks ijust wanted to know that I understood you right.

-

@Roei3d ok itray x600 y600 no change tray x400 y400 no change the left cube is xy400 the right xy600, all my print very good quality but the ringing make my crazy what ineed to do now?

-

It's possible to over tighten the belts. Try loosening them a bit.

You can try dropping motor current slightly too. -

@Phaedrux itry to loss the belt no change, how I change motor current

? M906? And to what current I change?This is my updated config after some changes and my last print I uploaded is with this config

General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Ender 3 Pro BLV" ; set printer name

M918 P1 E4 F2000000 ; configure direct-connect display; Network

M551 P"" ; set password

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S0 ; physical drive 3 goes backwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80 Y80 Z400 E406 ; set steps per mm

M566 X400 Y400 Z50 E3000 P1 ; set maximum instantaneous speed changes (mm/min)

M203 X12000 Y12000 Z900 E6000 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2)

M906 X700 Y700 Z700 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X235 Y235 Z240 S0 ; set axis maxima; Endstops

M574 X1 Y1 S1 ; set active high endstops

M574 Z1 S2 ; set endstops controlled by probe; Filament runout sensor ;Filament run-out sensor triggers a pause

M591 D0 P2 C3 S1; Z-Probe

M307 H3 A-1 C-1 D-1 ; disable heater on PWM channel for BLTouch

M558 P9 H2.5 F350 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-40 Y-12 Z9.408 ; set Z probe trigger value, offset and trigger height

M557 X30:220 Y30:220 S40 ; define mesh grid; Heaters

M305 P0 T98801 B4185 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S100 ; Set temperature limit for heater 0 to 120C

M305 P1 T98801 B4185 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S250 ; Set temperature limit for heater 1 to 280C; Fans

M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S0.8 I0 F10 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S0.8 I0 F20 H1:0 T45 ; set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 S"hotend" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Pressure Advance

M572 D0 S0.35; Miscellaneous

M501 ; Load saved parameters from non-volatile memory

T0 ; Select first tool; BLTouch startup

G4 S2 ; Pause a couple seconds

M280 P64 S160 ; Clear any alarms

G4 S2 ; Pause a couple seconds

M402 ; retract pin just in case; Custom settings are not defined

; Miscellaneous

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@Roei3d said in Need help to config file for ender 3 pro:

M906 X700 Y700 Z700 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

Try 600 for X and Y, if slightly loosening the belt doesn't help.

What slicer are you using? Does it have any acceleration and jerk control enabled that may be changing it to a different value than what you have specified in your config?

Can you share a sliced gcode file?

-

@Phaedrux I use cura no jerk and acceleration not enabled in cura, when igi home I upload my last minion print gcode

-

@Phaedrux XYZ NO INFIIL.gcode

this is my gcode xyz cube 0 infiil itray chang m906 to x600 y600 no change -

If you do a simple cylinder do you also see the ringing pattern? That would indicate something other than corner ringing that would start strong at a change in direction and then lessen as it moves away from the edge. It's quite hard to tell from those silver prints since the fronts aren't illuminated.

Can you post a video of it printing?

-

@Phaedrux https://youtu.be/nBy0lpH--Uk

In cylinder I hardly see anything.

-

Try lowering the acceleration and jerk for the Y axis. Perhaps the big heavy mirror is making it shake on direction changes.

-

@Phaedrux yaaaaaaaa I fix it thnks for your help. My hotend and cooling part fan was Vibrates slightly

It's due to their frequency settings.

I couldn't find a frequency that would make them stop vibrating.

So I returned to ender 3 stock fun and changed frequency now Hard to see ringing Thank you so much for your time and for your help.

And everyone who helped

,

You think I should change my config like before? -

@Roei3d said in Need help to config file for ender 3 pro:

You think I should change my config like before?

Well you can try increasing your speed values as part of your tuning.

Maybe see here: https://forum.duet3d.com/topic/14250/tuning-jerk-accel-speed-settings/3

-

@Phaedrux thnks my last print look very good thnks for your help

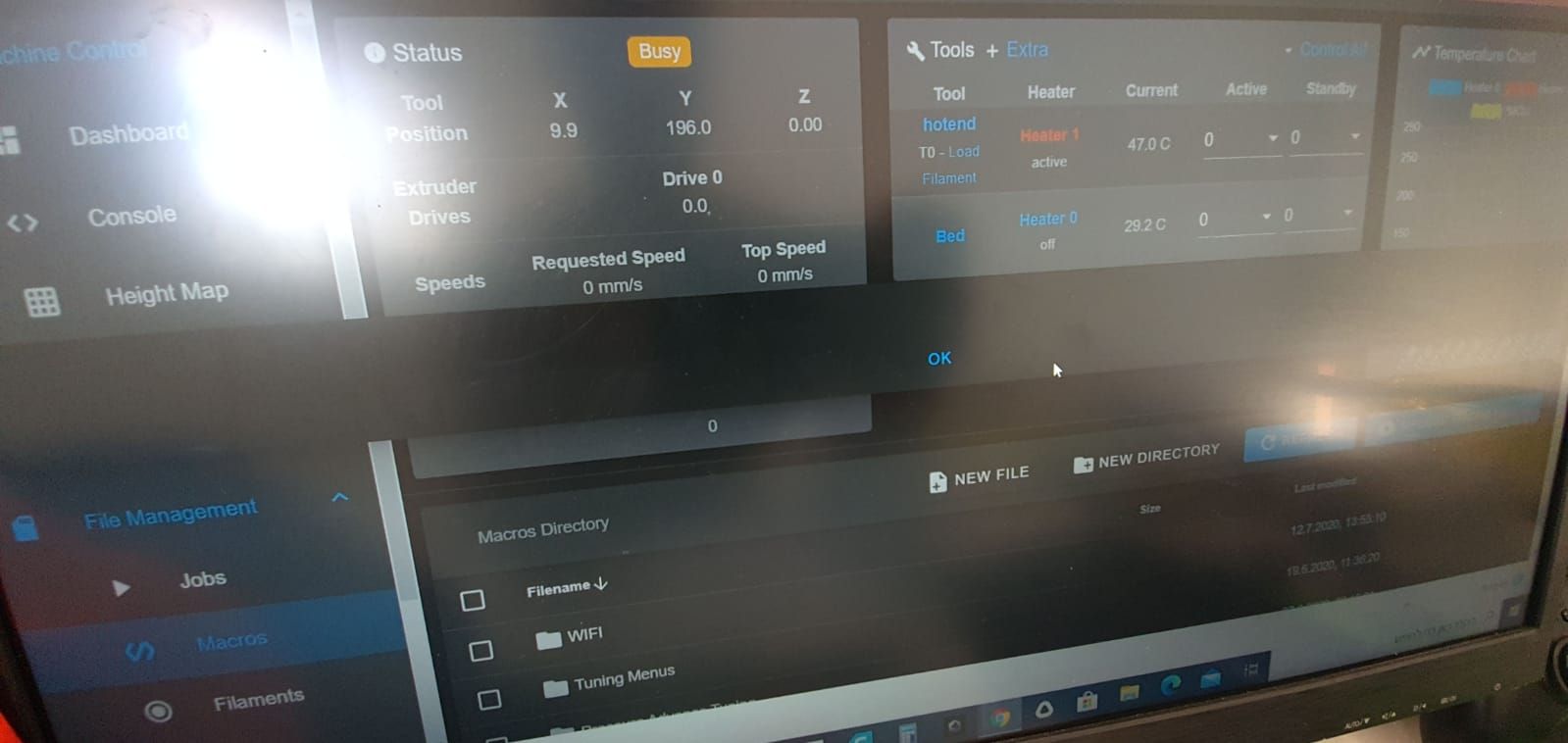

ihave problem whit my duet web when irun macro iget blank status i see only "ok"

only "ok"

if change to dwc1 isee all' how to fix it ? -

@Roei3d Are you running Firmware 3.1.1 and DWC 3.1.1 now? If you're still running firmware 2.x you either need to upgrade to 3.1.1 or change your DWC version to something like 2.0.7 that came with firmware 2.05.1