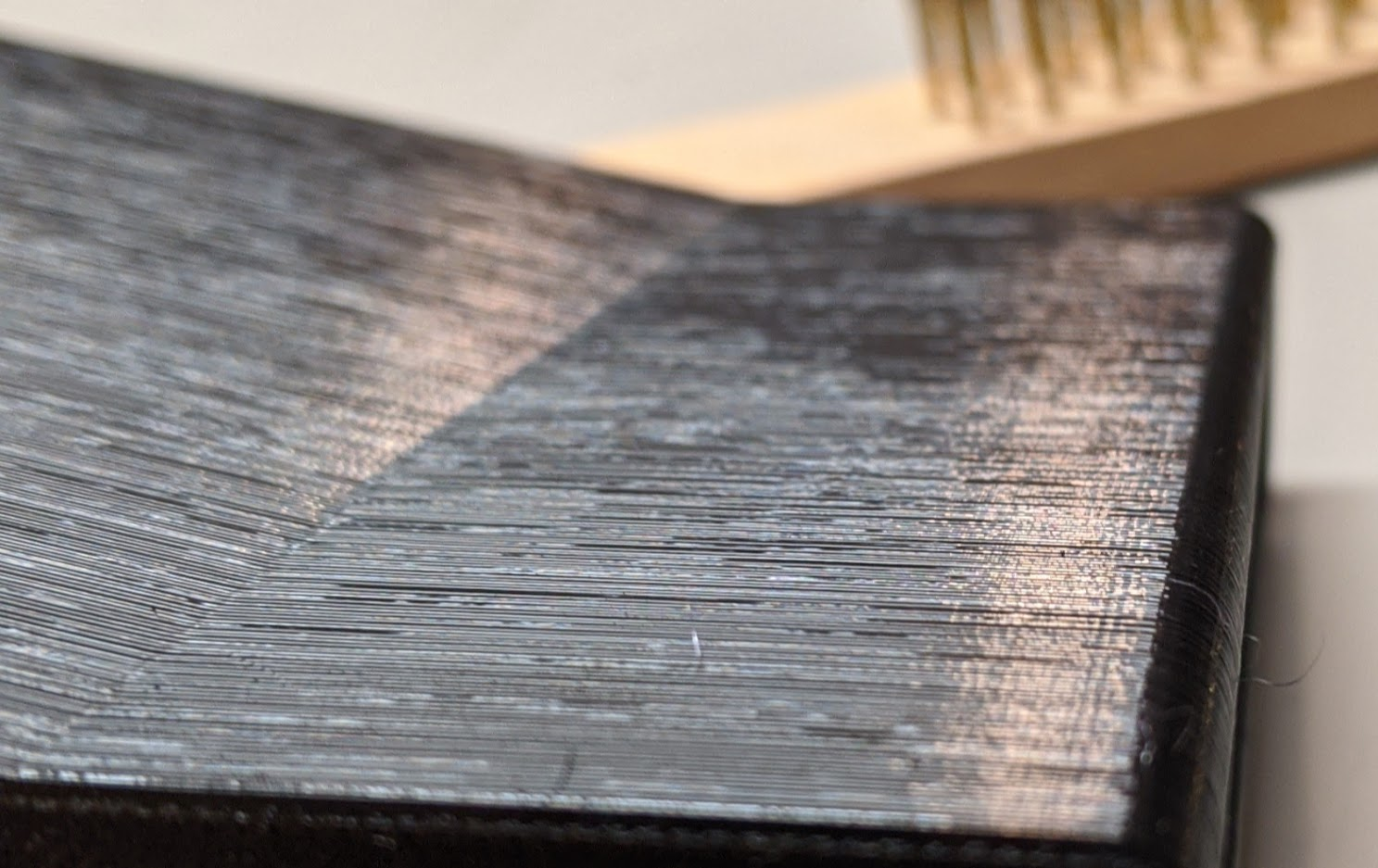

Issues with print quality, wall surface rough.

-

@CorvoDewittV2 Did you buy it as a kit ? Did you ask them (where you bought it from or the guys who designed it) if the have experience with this issues ? Perhaps it is a common issue and they know the most common cause in their design that can cause it.

-

@Corexy Thank you for the advice! I went through the Z axis very carefully, and made no change to the print quality

I will try those setting tomorrow! I will also try a lower extruder current, cause why not at this point lol. You said you have a V-Core, how did you set it up so it works as intended???? I've been at this for 2 months and have made little change!!! Thanks again!

I will try those setting tomorrow! I will also try a lower extruder current, cause why not at this point lol. You said you have a V-Core, how did you set it up so it works as intended???? I've been at this for 2 months and have made little change!!! Thanks again! -

@Scachi They have a Facebook group I have been posting in, with no help from the mods. One guy has actually been helping a lot, we are still chit-chatting about this thing. I really don't understand why I am having such an issue. It's so frustrating.

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

@Corexy Thank you for the advice! I went through the Z axis very carefully, and made no change to the print quality

I will try those setting tomorrow! I will also try a lower extruder current, cause why not at this point lol. You said you have a V-Core, how did you set it up so it works as intended???? I've been at this for 2 months and have made little change!!! Thanks again!

I will try those setting tomorrow! I will also try a lower extruder current, cause why not at this point lol. You said you have a V-Core, how did you set it up so it works as intended???? I've been at this for 2 months and have made little change!!! Thanks again!Mine's still new in the box, untouched. Been to busy with work and a house reno job to start it.

I have preemptively ordered some bits to do the Z axis and bed how I want though, and will start a build thread when I kick it off.

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

@Scachi They have a Facebook group I have been posting in, with no help from the mods. One guy has actually been helping a lot, we are still chit-chatting about this thing. I really don't understand why I am having such an issue. It's so frustrating.

It's certainly not a kit to learn on, moreso a base on which to start an advanced build I'd say.

I must say it's smart of them to stick with selling the mechanical bits rather than a finished printer, as it removes a lot of responsibility for print quality etc.

You might try posting in the reprap forums "corexy" section, as there's a few experts available there too.

-

Worn nozzle or PTFE tube perhaps?

-

@Phaedrux I've replaced both

-

@Corexy I will check out the reprap forums too! Should have build a voron, or a railcore....

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

@Corexy I will check out the reprap forums too! Should have build a voron, or a railcore....

That might not be totally fair...there's a bunch of V cores out there (and here).

Just keep going over it, you'll get it. 3D printing is a total pain in the arse on its best day, they are fickle machines.

Use those settings and let's see some pics.. Those prints aren't that bad. I've seen plenty worse on here.

-

Its just for the money I've spent tying to solve this, it should be better. I am wondering if the lead screws or nuts are bad. I started a print before I left for work with a cube right next to each lead screw, to see if its better or worse by one. We will see. I also had forgot spacers inside the idle pulleys between the bearings, but reassembled that properly, no difference. I am running out of things to change. Maybe I need to change our the printed parts? The only printed parts are the ones that hold the idle pulleys, maybe I should print them out of something other then PETG. I mean that's what they suggest, but I am really running out of things to try. I could try swapping around some of the Z axis motors too. I tried a lower current for the extruder, no difference. What jerk and acceleration should I be using for a genuine e3d Titan?

-

Did you do a temp tower test? Also did you look into moving the fans down a bit? I think they’re blowing right in the heat block.

Since you’re closer on temps and resolved the backlash nut issues, It might be to do another test with the fans off.

If you have a the step or stl files for your hotend, please post them and I’ll design proper ducts for you.

-

@mwolter OMG really?????? That would be amazing. I tried with like 40% fan but it didn't look better, ill try with no fan tonight, and post the step files. I went with the 40x10 fans to keep the hotend as small as possible, but I also would be fine with losing a bit of print volume for a better cooling solution. Thank you so much!!!

Edit: Yeah I have done temp towers, 200-230 all kinda look the same.

-

-

@mwolter @Corexy I am also using these, do you think that is a problem? I will try the stock spring type when I get home. Maybe I should try printing some too.

https://www.amazon.com/Befenybay-Aluminium-Flexible-Coupling-Connector/dp/B07RMZCLZ3/ref=sr_1_3?dchild=1&keywords=3d+printer+coupling&qid=1594218589&sr=8-3 -

@CorvoDewittV2 personally I prefer the solid couplers. They provide more support and are typically more axially concentric. IMO spring or spider (like in your link) couplers are only used to make up for design or construction flaws.

-

@mwolter I'll try printing some solid ones as my lead screws are straight and aligned. 5 walls of PETG should be good?

-

-

Have you tried those settings yet? I'd do that before you work on it mechanically.

One trick I've found with PETG is that if you are getting blobs building up on the nozzle tip, drop the extrusion multiplier (not the esteps) until it stops happening. PETG prefers to be slightly under extruded.

I've got those same plum couplings on my other printers and haven't had any problems with them. Why did you change them from the standard ones anyway?

I've got nothing else I can tell you from the information you've given until you do the steps I listed on post some pics. Best you do the same cube an benchy for comparison. Definitely there's some Z wobble there, but lets see it without the over extrusion first.

-

@Corexy Not yet I am still at work, ill be home in 2 hours. I just though spring ones were dumb, I changed them when I build the thing, IDK if I even printed much of anything with the stock couplings. Do you think the 0.9 deg motors would cause an issue on the XY?

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

@Corexy Not yet I am still at work, ill be home in 2 hours. I just though spring ones were dumb, I changed them when I build the thing, IDK if I even printed much of anything with the stock couplings. Do you think the 0.9 deg motors would cause an issue on the XY?

0.9 deg motors are supposed to be the correct ones to use for X and Y, Z as well I am told.

You need to run all of your steppers at 75-85% of their rated current. That's the done thing apparently, and is better than guessing.

I haven't seen what your fan duct is doing, but it is definitely not good to have it blowing on the heater block.

Let's see how those prints work out, and take it from there.