Help in printing ABS

-

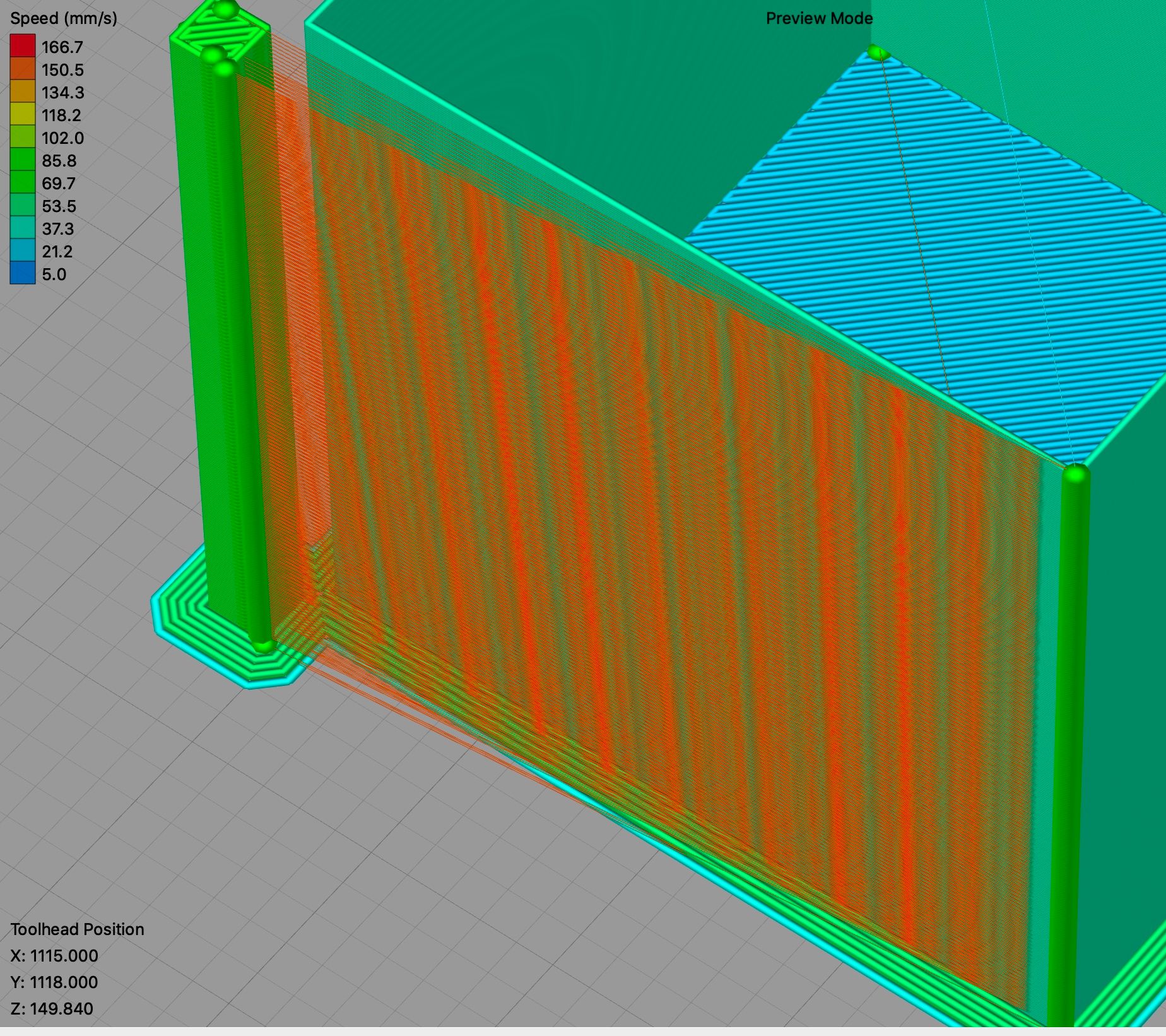

Hi, I'm struggling with artefacts in ABS printing.

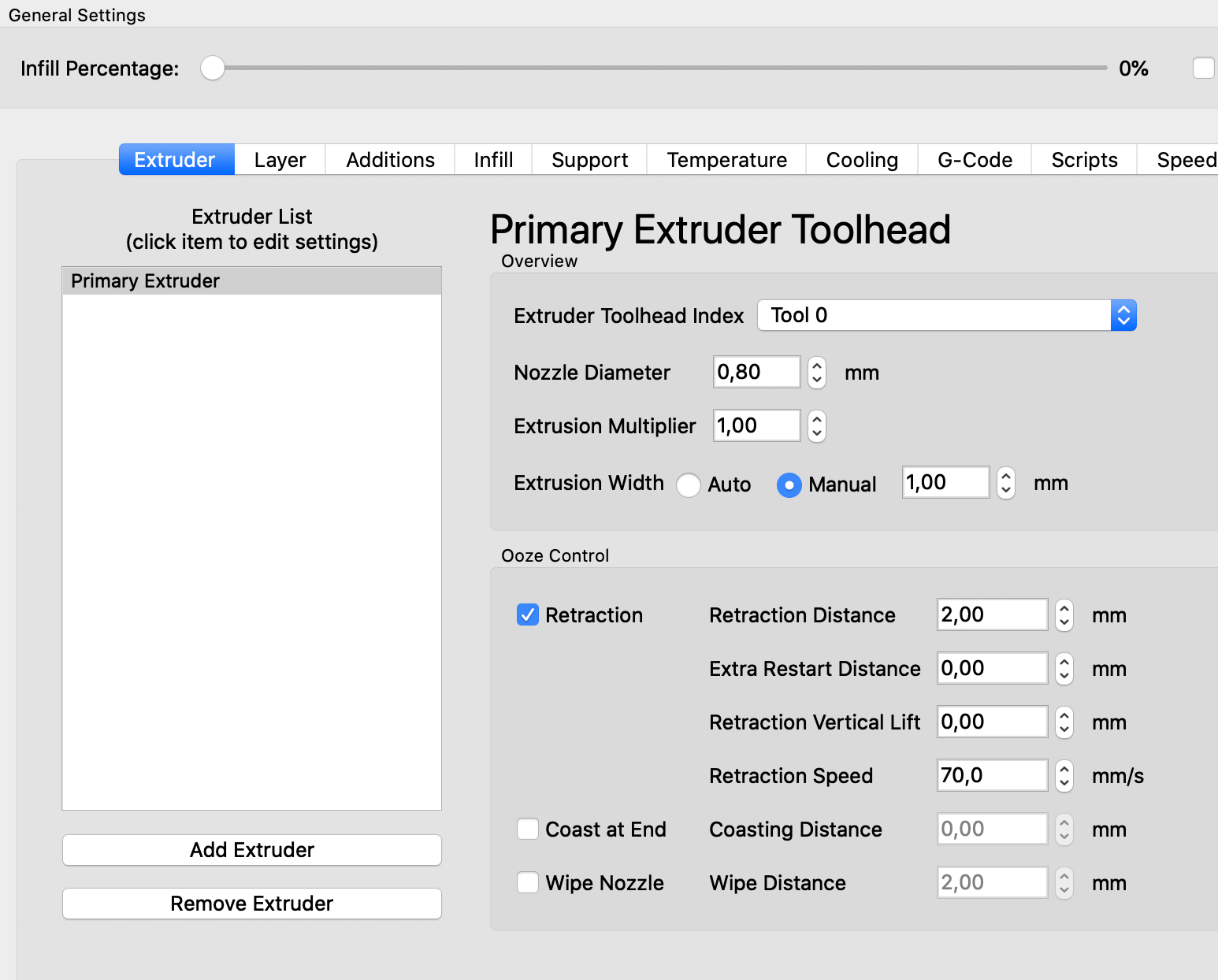

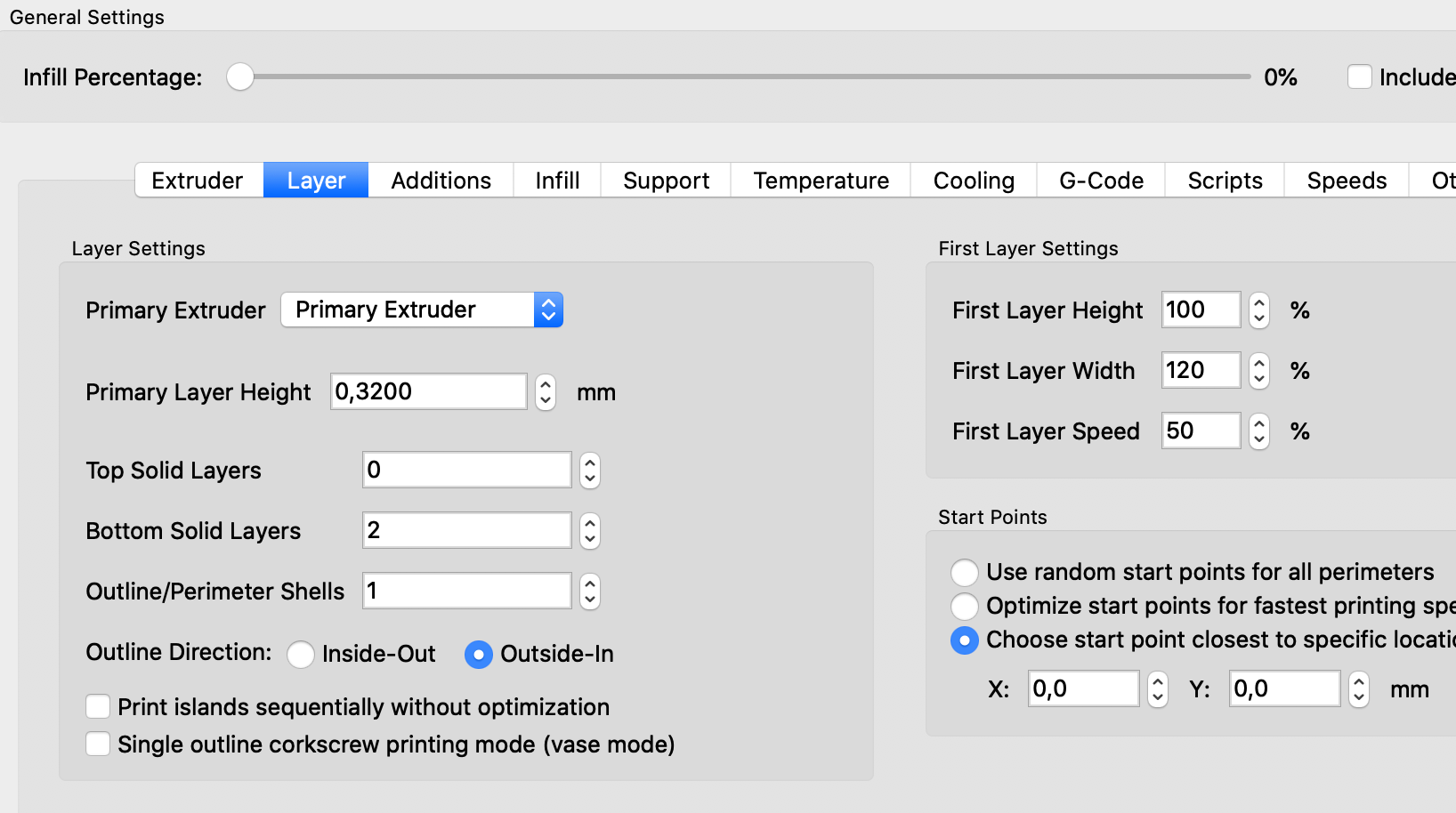

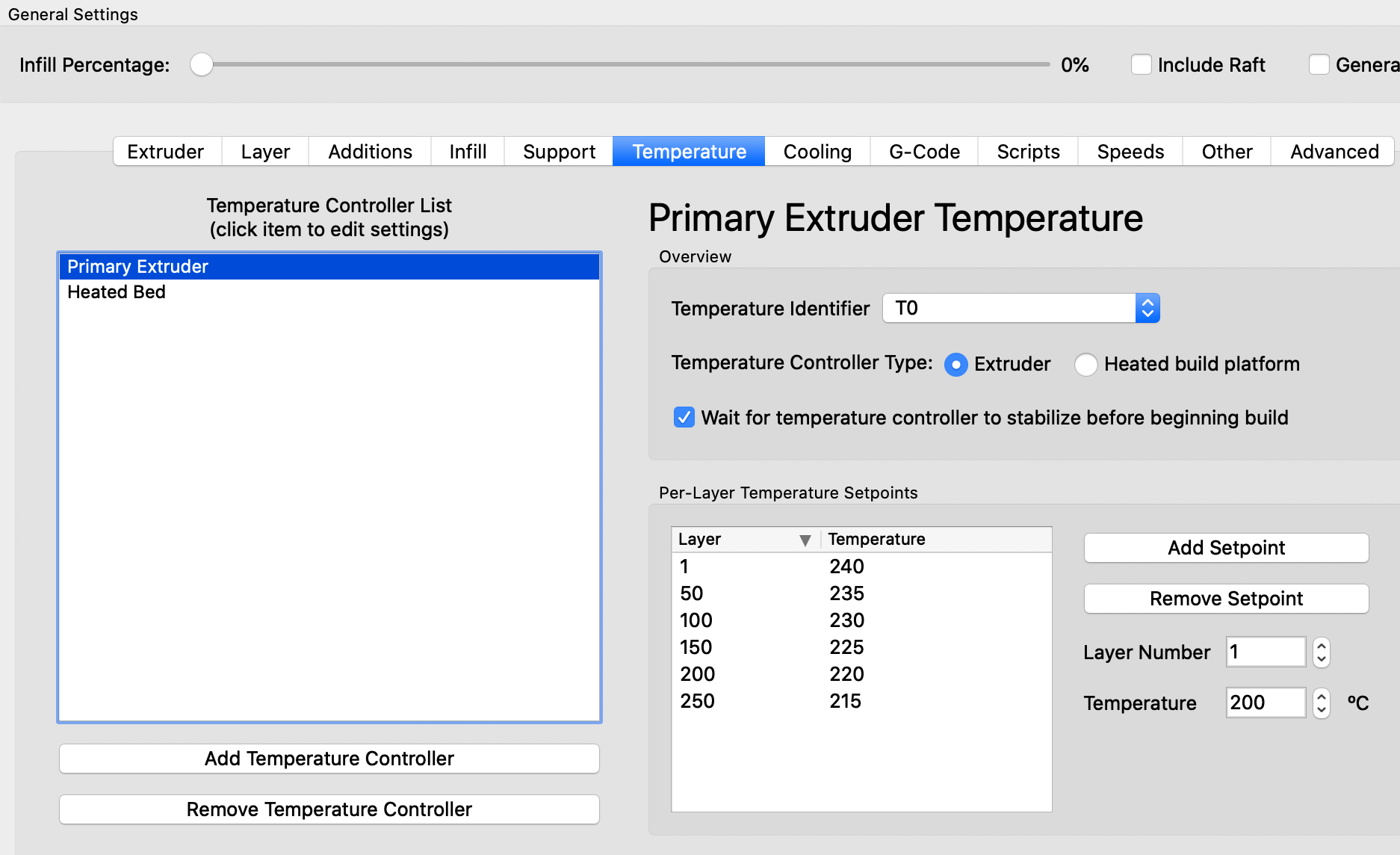

I printed this cube to verify extrusion. Set to 1mm width gives 1 ~ 1.02mm maybe. and lowering temp as the print goes but I cancelled before going too low.

Any suggestions? Please se all settings below.

Settings

-

The 0.8 mm nozzle will complicate things a bit.

I print a LOT of ABS with a 0.4 mm nozzle. I have tried larger nozzles and always had problems- 0.8 mm is pretty big so you'll have to do a lot of experimenting with pressure advance and nonlinear extrusion.

Set the bed temperature about 105C, extruder to 240C, chamber 50C.

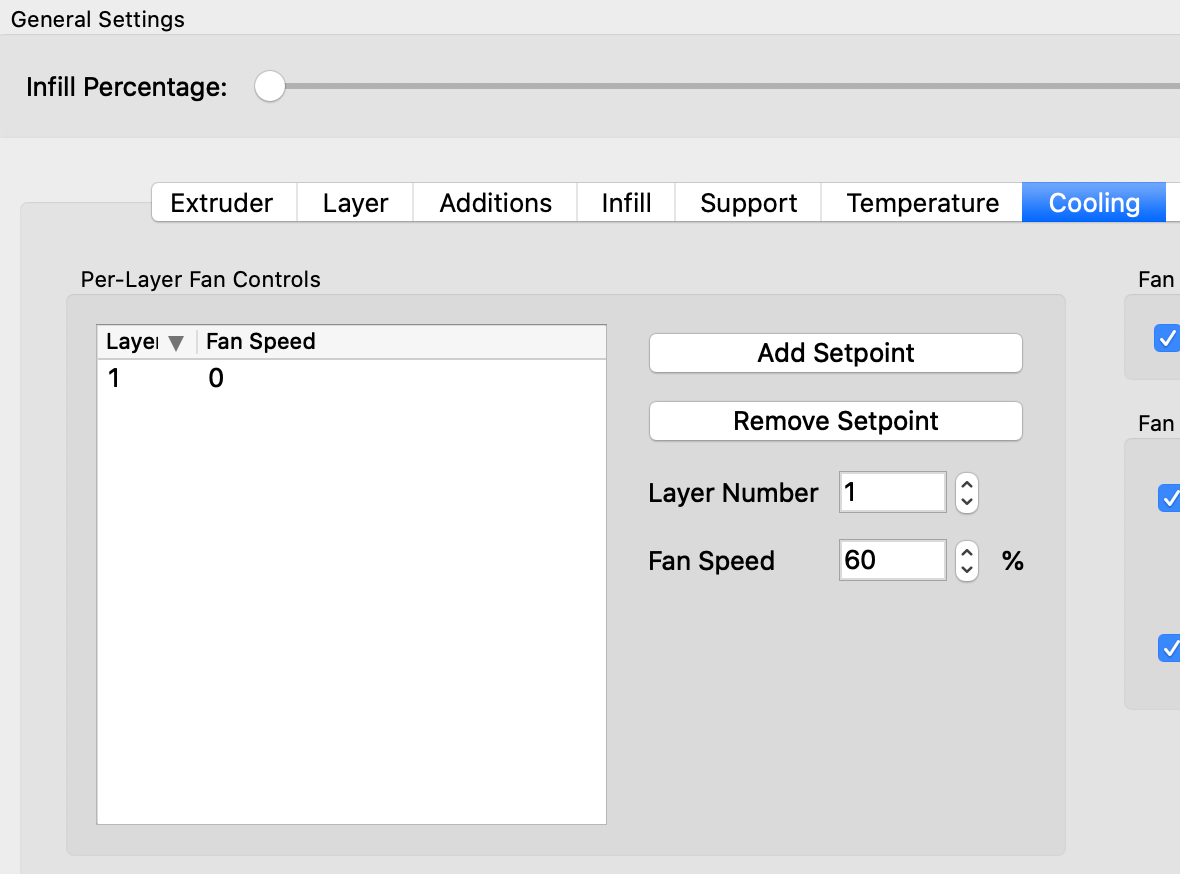

Lift on retract, retract on layer change.

No print cooling fan.

Line width = nozzle diameter or slightly larger. You might go to 1 mm.I print first layer 30- 40 mm/sec or so, and all other layer and features at about 80 mm/sec, except bridges slower. With a 0.8 mm nozzle, you'll have to go slower to ensure that the hot end can keep up with the movement speed. Try 30-40 mm/sec.

You appear to be getting some accumulation of crud to the sides of the lines being printed. I think that may indicate that the layers are a bit too thin and/or slight overextrusion. Try adjusting one or the other and see if that stuff goes away.

If you can, get rid of the % values in the slicer. Enter the numbers as mm. It will save having to do mental gymnastics as you try to figure out what is going on.

What are the acceleration and jerk settings?

-

I have pretty much exclusively printed in ABS or ABS blends. I'd suggest starting with a .4mm nozzle with .5mm extrusion width. Retraction distance of .5mm and at least .5mm z-hop (retraction vertical lift).

For temps, my bed is set to 105c and the extruder is set to 246c for the entire print. Do not reduce temps on higher layers.

Your printer really needs to be in an enclosure or you will have issues. My printer chambers are actively heated and maintains 70c for the duration of the print. If you can't actively heat it, at least get it in a box where it can passively heat up.

As for your filament, my favorites are IC3D and 3DxTech. They need to be kept dry.

Hope this helps..

-

looks like underextrusion + stringing are the two main issues you experience here ..

you need to tackle them one by one ..

wrt underextrusion, dunnno what extruder are you using but if it's not some magnum / vulcano or similar you might have issues shooting 0.8x0.32mm at 60mm/sec so dropping speed to 40mm/sec would be my first test for solving underextrusion. second test would be to use high quality filament, as many available on the market are not that good .. also you need to print hot if you want higher print speed and good flow so I assume your temp drop was just to test if stringing will be better at lower temp .. keep the temp 240 or higher.

as for stringing, .8mm is a big hole and hot filament want to drip

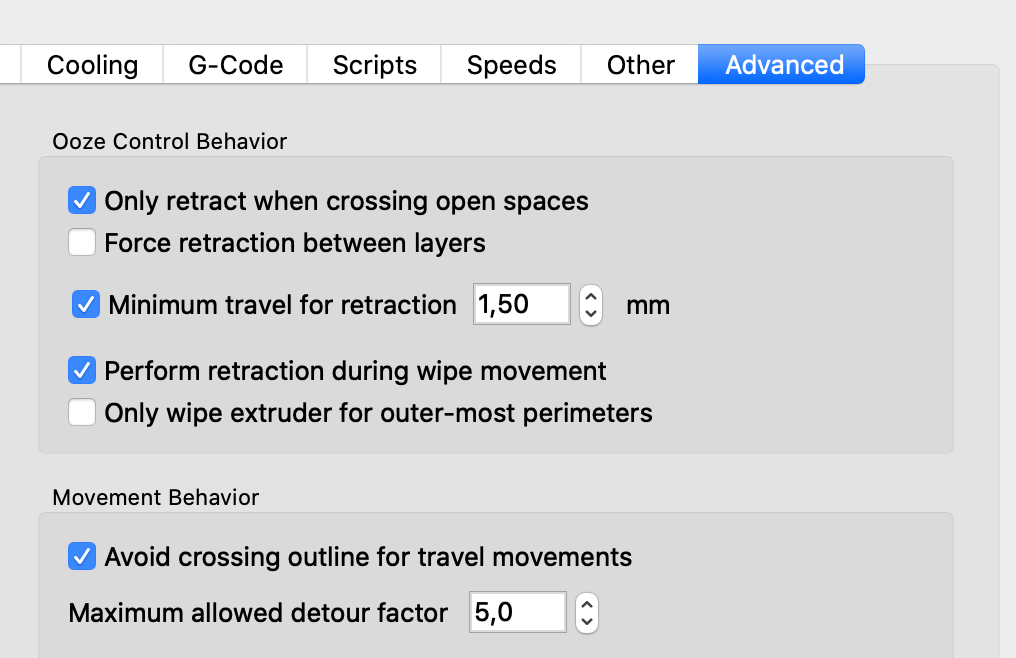

retraction does not help here too much so keep retraction to 1mm or less and turn on both coasting and nozzle wipe. First turn on coasting only, set bigger value (5mm) and you will notice holes in the print at the end of the line, measure hole length and retract from coasting distance, fine tune till you have no holes and no stringing, for finetuning afterwards turn on wipe.

retraction does not help here too much so keep retraction to 1mm or less and turn on both coasting and nozzle wipe. First turn on coasting only, set bigger value (5mm) and you will notice holes in the print at the end of the line, measure hole length and retract from coasting distance, fine tune till you have no holes and no stringing, for finetuning afterwards turn on wipe.vertical lift - try for yourself, for me vertical lift helps for other stuff (thin tall features) but increases stringing so keeping lift at 0 reduces stringing for me... note that this sometimes works opposite and that with vertical lift you have less stringing so test it out.

and finally, make sure the filament is dry and that it's not too old (I recently tested some filament sitting in original box vacuum packed for few years and had all sort of issues with it)

-

Something I just thought about that I don't see many other's doing.. I do use a print cooling fan with ABS at around 30% starting after a few layers. Again, this is in a heated chamber, but I find it greatly enhances surface finish.

-

Thanks for the answers,

i did use way too fast extrusion speed and too high temp.

Printing in 30m/s at 220C works alot better! Doing a new PA-tuning run as I got some things happening in the corners.