Massive skewed prints

-

Hello

I have massive skews on my prints and on X and y axes on my core xy printer.

I used belt tensioners to align everything perpendicular and at equal distance but the problem remains.

When I make movements on x/y (manually jog) , axes move well. I had random Y movements when I moved X axe before.

The only things that makes me think about, is that I use 2 GT2 different belt manufacturers because I didn't have length enough.

Any idea ?

ThanksHere is my config.g file :

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Tue Aug 11 2020 15:50:14 GMT+0200 (heure d’été d’Europe centrale); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode; Drives

M569 P0.0 S0 ; physical drive 0.0 goes forwards

M569 P0.1 S0 ; physical drive 0.1 goes forwards

M569 P0.2 S1 ; physical drive 0.2 goes forwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M584 X0.0 Y0.1 Z2:3 E0.4 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X200.00 Y200.00 Z400.00 E415.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z600.00 E3600.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z120.00 E2500.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z600 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

M671 X258:-10 Y0:0 S0.5 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis

M572 D0 S0.025; Trinamic Drive Tuning

; Tune tpwmthrs (V) so stealthchop runs at appropriate speeds

; and tune thigh (H) to avoid shifting into fullstep mode

M569 P0 V50 H50 D3 ; X - Set tpwmthrs so StealthChop runs up to 46.9mm/sec (try V47)

M569 P1 V50 H50 D3 ; Y - Set tpwmthrs so StealthChop runs up to 46.9mm/sec

M569 P2 V95 H95 D3 ; Z - Set tpwmthrs so StealthChop runs up to 31.2mm/sec; Stealthchop parameters

;M915 P0 S10 F1 R1

;M915 P1 S10 F1 R1

;M915 P2 S10 F1 R1

;M915 P0 H200 F1 R1 S10 T20

;M915 P1 H200 F1 R1 S10 T20

;M915 P2 F1 R1 T95; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X295 Y290 Z600 S0 ; set axis maxima; Endstops

M574 X1 S1 P"io1.in" ; configure active-high endstop for low end on X via pin io1.in

M574 Y1 S1 P"io2.in" ; configure active-high endstop for low end on Y via pin io2.in; Z-Probe

M950 S0 C"io7.out" ; create servo pin 0 for BLTouch

M558 P9 C"^io7.in" H5 F480 T8000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X40 Y5 Z2.25 ; set Z probe trigger value, offset and trigger height

M557 X50:271 Y70:264 S20 ; define mesh grid; Heaters

M308 S0 P"temp1" Y"thermistor" T95000 B3950 ; configure sensor 0 as thermistor on pin temp1

M950 H0 C"out2" T0 ; create bed heater output on out2 and map it to sensor 0

M307 H0 B0 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 S-273.15 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp0" Y"thermistor" T500000 B4723 C1.196220e-7 ; configure sensor 1 as thermistor on pin temp0

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S320; Fans

M950 F0 C"out4" Q500 ; create fan 0 on pin out4 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"out5" Q500 ; create fan 1 on pin out5 and set its frequency

M106 P1 H-1

;M106 P1 S255 H1 T200 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings

M564 H0; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue -

@Touchthebitum I'd guess you have two different pitches of belt, or pulleys with different numbers of teeth on the X and Y motors. Though different belt tension between the two belt can also cause this. Show us a picture!

Ian

-

@droftarts

but if I jog 10mm on every axe, it is correct, travel is 10mm...

I have : Gates 6mm GT2 Fiber Glass Reinforced Belt and GT2 Belt ,2mm pitch, 6mm width Neopren reinforced fiberglass from the other manufacturer.

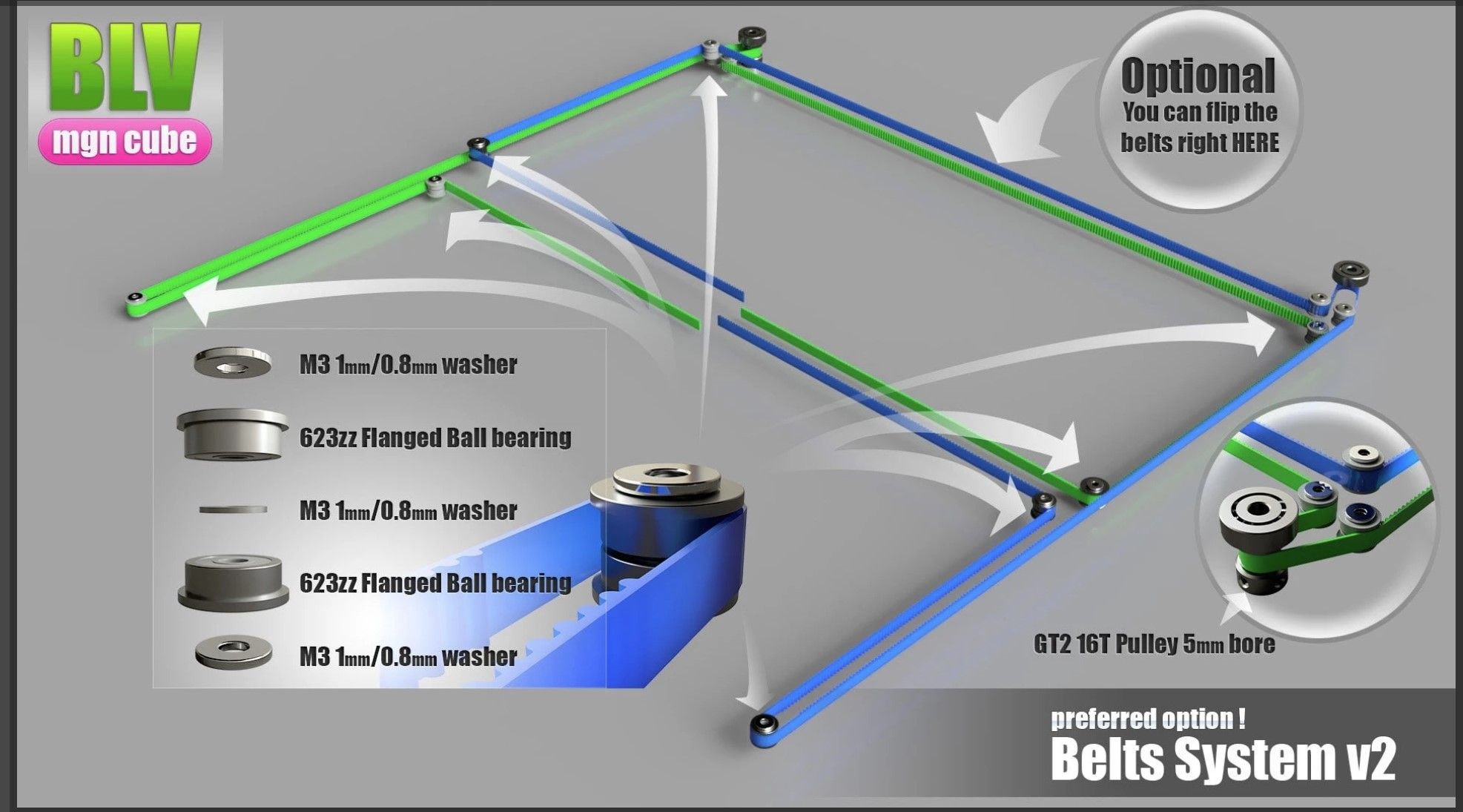

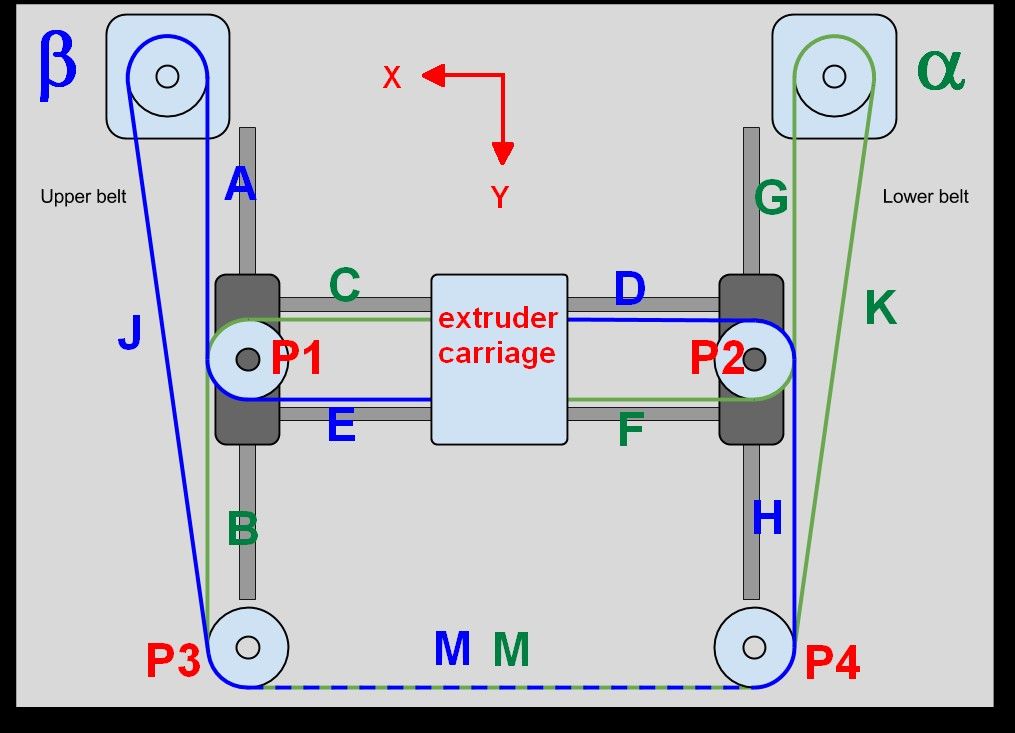

Pulley are : GT2 Pulley 16 Teeth 5mm bore -

Photos of the belt paths will help. From the top looking down.

Sounds like a pulley/belt path out of alignment.

-

-

Well I mean your actual printer, not an idealized diagram.

-

I don't understand because yesterday I printed a small piece without x/y axes problems ...

-

Here is the setup

-

It looks like maybe your belts heading to the carriage aren't totally parallel with the rail.

-

@Phaedrux

Maybe.

Could 2 belts with 2 different elasticity grade cause this problem? It seems that one is more soft... -

I found the problem. It was a loosen screw on one of the x/y motors.

Thanks for your help.