Help needed with Duet 3 6hc TMC5160 StealthChop config

-

It is incredible what this TMC5160 driver can do according to the datasheet.

https://www.trinamic.com/fileadmin/assets/Products/ICs_Documents/TMC5160A_Datasheet_Rev1.14.pdf -

I am thinking of buying the Duet 3 board. Does activating stealth chop now work without any problems?

-

@N3XT3D See the conditions listed by DC42 above

That is still and likely always going to be the case.

-

at the moment I don´t have time to test again. But the homing sequence didn´t help yet, only adding stepper dumper to isolate the frame from the motors has helped for me. However, this reduce the print quality.

I read in a post on facebook that useing 1.8° stepper motors instead of 0.9° helped.

I ordered some more motors to test, maybe the moon motors are not the best for the Duet board. I don´t know what the problem is. But I´m not alone with this problem. -

I really like the Duet boards, the build quality and firmware are great. But if an SKR board with TMC 2209 drivers manages to be that quiet, I don't think that should be a problem with the Duet. The Stealth Chop 2 function is the same. It is crucial for me that my printer should be quiet. So if nothing can change in the current situation, at least that's how I understood it, it will probably not be worth switching to the Duet 3 board for me. Please correct me if I have misunderstood or told something wrong.

-

@N3XT3D I think the biggest factor will be the motors.

It's also my understanding that stealthchop isn't really intended for 3d printer use at all, but in the right situation and expectations it can work.

If there's a secret to it, I don't know what it is though.

-

Both TMC5160 and TMC2209 have stealthChop. It's a little more complicated to configure on the TMC5160 because that chip also has coolStep. Also, stall detection doesn't work in stealthChop mode, so you have to switch to spreadCycle while doing stall detect homing.

TMC2209 is a little different because it doesn't have coolStep and because stall detection only works in stealthChop mode.

In both cases there are some limitations:

- stealthChop doesn't work well at high speeds. That's why there is a changeover speed defined. Above that speed, the driver switches over to spreadCycle. Unfortunately there is a jolt when that happens. The higher the changeover speed, the worse the jolt.

- stealthChop can't react quickly to changes in load. So if your printer is executing a travel move and the nozzle hits a blob or overhang, it is likely to skip steps if the driver is in stealthChop mode.

The TMC2130 drivers used on the Prusa Mk3 with the Einsy board are similar to the TMC5160 drivers but without external mosfets. Prusa defines two printing modes: fast and quiet. My guess is that in quiet mode, they reduce the speed of travel moves so that the drivers can operate in stealthChop mode throughout.

So my suggestion is to use one of the following configurations:

- StealthChop changing over to spreadCycle a very low speed. Compared to running in spreadCycle always, this reduces standstill noise with some motors.

- StealthChop changing over to spreadCycle at a little over your normal maximum printing speed. It will switch to spreadCycle for travel moves, except very short ones. This will only be viable if the jerk at switchover is tolerable.

- Limit your travel speed so that you can keep the printer in stealthChop mode always.

-

@dc42 First of all, thank you very much for the detailed answer.

Then I probably misunderstood that in principle. I thought you couldn't activate stealth chop at all. Unfortunately I can hardly assess how loud this jolt is. My wish would be to be able to print up to 100mm / s (maximum) in the steahlthchop and to be able to switch to the spreadcycle for the travel speed.

Does the jolt depend on the Coolstep function? Or to put it another way, would this jolt also occur with the TMC 2209 drivers under the same conditions? I tried to find a couple of videos on Youtube that have a Duet 3 board built in to get an impression of what they sound like, but you can't find anything useful.Because with my printer with Duet 2 Wifi I have the problem that the printer without a stepper motor damper for X and Y is not acceptable because of the noise. I already reported on this in this forum. Here is the video too.

https://www.youtube.com/watch?v=jcsMTAzeeRE&t=2s

From this state I would like to turn off without "cheating" with the dampers. Otherwise I love the board and really don't want to leave the Duet boards. Therefore the consideration of switching to a Duet 3 board.

-

Those motors in the video sound much noisier than normal, as if you don't have interpolation enabled. What microstepping settings are you using?

The jolt when switching modes applies to the TMC2209 as well. From the TMC2209 datasheet:

As a first step, both chopper principles should be parameterized and optimized individually (SpreadCycle settings may be programmed to OTP memory). In a next step, a transfer velocity has to be fixed. For example, StealthChop operation is used for precise low speed positioning, while SpreadCycle shall be used for highly dynamic motion. TPWMTHRS determines the transition velocity. Read out TSTEP when moving at the desired velocity and program the resulting value to TPWMTHRS. Use a low transfer velocity to avoid a jerk at the switching point.

A jerk occurs when switching at higher velocities, because the back-EMF of the motor (which rises with the velocity) causes a phase shift of up to 90° between motor voltage and motor current. So when switching at higher velocities between voltage PWM and current PWM mode, this jerk will occur with increased intensity. A high jerk may even produce a temporary overcurrent condition (depending on the motor coil resistance). At low velocities (e.g. 1 to a few 10 RPM), it can be completely neglected for most motors. Therefore, consider the switching jerk when choosing TPWMTHRS. Set TPWMTHRS zero if you want to work with StealthChop only. -

I used 16x micro stepping with interpolation. The change to 1.8 ° stepper motors brought some improvement, reducing the motors to 1A as well. The motor dampers made the printer quieter, but the vibration in the motor is so strong that you can even see it in the printed part.

This is my config.g

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.4 on Sat Dec 28 2019 21:53:43 GMT+0100 (Mitteleuropäische Normalzeit) ; General preferences ; Aktuelle Duet Wifi Firmware Version: 3.1.0 - Stand: 17.05.2020 ; Paneldue Information: Hardware Version: Panel Due v3.0a - 57600 baud - aktuelle Version: 1.24 - Stand: 11.05.20 M575 P1 S1 B57600 ; set Panel Due Baudrate to 57600 G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"XY Cube" ; set printer name M667 S1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 F3 S1 ; physical drive 0 goes forwards - Changed TOFF for reduced motor noise F4 is default M569 P1 F5 S1 ; physical drive 1 goes forwards - Changed TOFF for reduced motor noise F4 is default M569 P2 F3 S1 ; physical drive 2 goes forwards - Changed TOFF for reduced motor noise F4 is default M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X200.1 Y200.1 Z1600.00 E412.493 ; set steps per mm M566 X500.00 Y500.00 Z30.00 E400.00 ; set maximum instantaneous speed changes (mm/min) M203 X12000.00 Y12000.00 Z150.00 E2100.00 ; set maximum speeds (mm/min) M201 X2000.00 Y2000.00 Z100.00 E5000.00 ; set maximum accelerations (mm/s^2) M204 P1000 T2000 ; set accelerations of printmoves to 1000 and for travelmoves to 2000 (mm/s^2) M906 X1600 Y1600 Z1600 E1600 I30 ; set motor currents (mA) and motor idle factor in per cent ; M593 F32 ; Set Dynamic Acceleration to cancel ringing at 48 Hz M84 S30 ; Set idle timeout M671 X30:270:30:270 Y270:270:30:30 P0.7 ; Define Bedleveling screws, 0,7mm pitch ; Pressure advance M572 D0 S0.07 ; Pressure advance - 0.113 ; Axis Limits M208 X-11 Y0 Z0 S1 ; set axis minima M208 X306 Y321 Z500 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M558 P1 C"zprobe.in+zprobe.mod" H3 F100 T12000 I0 B0 ; set Z probe type to unmodulated and the dive height + speeds - A5 S0.02 optional fuer multiprobe selbsttest G31 P500 X-2 Y-16.4 Z3.05 ; set Z probe trigger value, offset and trigger height - 3.05 for CFK; 3.02 for Buildtak; 2.724 for Powdercoated Springsteel; 3.152 for ALU - Wert kleiner wird Abstand Größer. M557 X30:270 Y30:270 S40 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 A"Druckbett" ; configure sensor 0 as thermistor on pin bedtemp - A"Printbed" M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S100 ; set temperature limit for heater 0 to 100C M307 H0 A154.1 C2269.2 D1.0 V24.0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 A"Nozzle" ; configure sensor 1 as thermistor on pin e0temp - A"E3DV6 Hotend" M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C M307 H1 A368.0 C157.4 D3.7 V24.0 B0 S1.00 ; disable bang-bang mode for the nozzle heater and set PWM limit ; Fans M950 F0 C"fan0" Q250 ; create fan 0 on pin fan0 and set its frequency M106 P0 C"Bauteil Lüfter" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 C"Heatbreak Fan" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Limit axis movement M564 H1 S1 ; movements only work with homed Axis; H1 = forbid movement of axes that have not been homed; S1 = limit movement within axis boundaries ; Custom settings are not defined M912 P0 S-4 ; Set correction for CPU Temperature ; Miscellaneous M911 S23 R28 P"M913 X0 Y0 G91 M83 G1 Z1 E-1 F1000" ; set voltage thresholds and actions to run on power loss -

I suggest you send M350 without parameters, to confirm that interpolation really is enabled. It's not impossible that there is a non-printing character between the I and the 1 in your M350 command.

-

Exactly, I cross-checked via the console and the M350 command whether the parameters are active.

-

In that case, I think the movement speeds in your video must be hitting the mid-band resonance frequency band of the motors. I have a similar thing in my delta, it's noisy during homing but silent when printing.

Have you tried configuring coolStep?

-

The volume is actually extremely loud throughout.

The faster the speed, the more extreme it becomes. If you print a cylinder with only one perimeter as a spiral, you will see very strong resonances in the print image due to the constant change in the speed of the motors due to the Corexy structure.

At some speeds the resonances are stronger, e.g. at 30mm/s at 60mm/s, on the other hand, the printer is "quietest", which is also outside the normal range. I have adjusted the M569 F parameter and tested between 1-10 during operation and at a standstill. The result would definitely be small.

I don't know how else to configure Coolstep, but I would definitely try it out. -

I have read through the documentation and will test and report it.

-

@N3XT3D this is exact the same problem that I have from the beginning with the duets boards.

duet wifi 2 (sorry a clone) and a original duet 3. Which Motors you are using?

when I use a SKR GTR board with klipper and TMC5160 it is much quiter, but I had skipped layers when it switch between

steahltshcoop and coolstep.

@dc42 I have still no answare how I can test with a different RSens parameter, all other firmwares use 0.075Ω only the duets use 0.050Ω can be this the difference? -

@dc42 said in Help needed with Duet 3 6hc TMC5160 StealthChop config:

Both TMC5160 and TMC2209 have stealthChop. It's a little more complicated to configure on the TMC5160 because that chip also has coolStep. Also, stall detection doesn't work in stealthChop mode, so you have to switch to spreadCycle while doing stall detect homing.

TMC2209 is a little different because it doesn't have coolStep and because stall detection only works in stealthChop mode.

In both cases there are some limitations:

- stealthChop doesn't work well at high speeds. That's why there is a changeover speed defined. Above that speed, the driver switches over to spreadCycle. Unfortunately there is a jolt when that happens. The higher the changeover speed, the worse the jolt.

- stealthChop can't react quickly to changes in load. So if your printer is executing a travel move and the nozzle hits a blob or overhang, it is likely to skip steps if the driver is in stealthChop mode.

The TMC2130 drivers used on the Prusa Mk3 with the Einsy board are similar to the TMC5160 drivers but without external mosfets. Prusa defines two printing modes: fast and quiet. My guess is that in quiet mode, they reduce the speed of travel moves so that the drivers can operate in stealthChop mode throughout.

So my suggestion is to use one of the following configurations:

- StealthChop changing over to spreadCycle a very low speed. Compared to running in spreadCycle always, this reduces standstill noise with some motors.

- StealthChop changing over to spreadCycle at a little over your normal maximum printing speed. It will switch to spreadCycle for travel moves, except very short ones. This will only be viable if the jerk at switchover is tolerable.

- Limit your travel speed so that you can keep the printer in stealthChop mode always.

This could also be programmed for the Duet 3 board. The two Printing Modes like Prusa.

The two speed mode.This is very interesting.

What exactly is the speed limit for StealthChop?You can tell us the exact Speed values ?

Or it is probably different for each stepper Motor ?I have 0.9 stepper drivers on a Delta printer.

StealthChop will certainly not be able to do this. At the high speeds. -

This post is deleted! -

@dc42 said in Help needed with Duet 3 6hc TMC5160 StealthChop config:

Did you adjust the homing procedure to meet the stealthChop tuning requirements, as I explained in a previous post?

btw in the imminent RRF 3.2beta you will be able to read out the values of the PWM_SCALE and PWM_AUTO registers, to see the result of stealthChop tuning.

Hi,

sorry i was absont for some time now, as I got father and time was somehow limited.

In the meantime is added dampers, which helped a lot in the standardconfig (=spreadcycle) mode and changed all plastic parts for metal parts from the BLV cube project. (Metal parts are now available)

Are there any news in general?

I will work now though the configuration and tests several cases.I saw also, that the RRF3.2beta is already available.

Is the "read out" of values for the stealthchop already integrated?

Could be some help for "debugging"?I will come for sure with more questions soon....

Thanks

-

@dc42 said in Help needed with Duet 3 6hc TMC5160 StealthChop config:

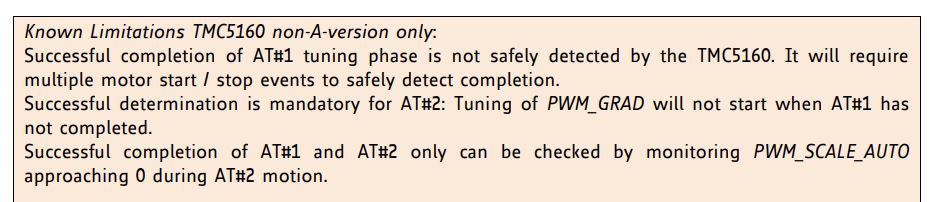

TMC5160

Could this be somehow connected to our problem?