BL-Touch and problems

-

@stuartofmt said in BL-Touch and problems:

Also - Its not clear that you have the correct form for your M557 line.

The M557 command he has in there is perfectly fine.

-

@n3ovo said in BL-Touch and problems:

I know i can do better.but no to bad for the first print.

It looks pretty good for a first print!

Now that you have everything functional it's time to do some calibration. Mainly the extruder and all that entails. This guide might help you along.

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40

Then you may want to look into tuning pressure advance once the extruder is calibrated.

https://duet3d.dozuki.com/Wiki/Pressure_advance

After that it's all a matter of learning the slicer settings.

-

Just When you though it was SAFE ... More Problems... Printer is working .. Started tuning the printer and i seem to have a problem. It is only printing on one side of the bed. I tried to print a case for the i7 screen .. I know i am jumping the gun. I wanted to protect the Screen.

Anyway here is a Picture Only the Right Half:

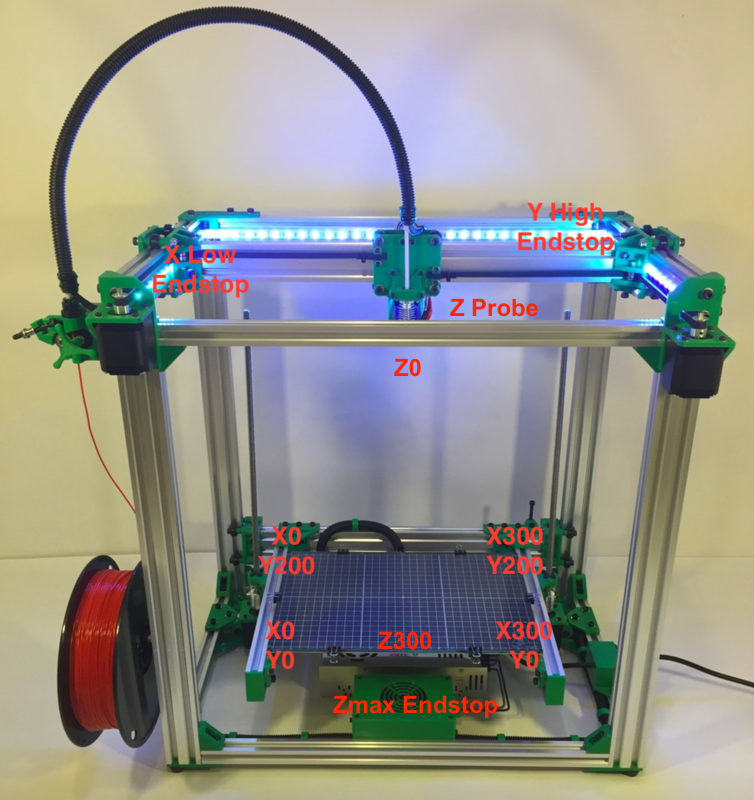

As you can see it prints right up to the X limit Switch hits and the closes of the BOX .....

Any thoughts Would help .. I know it is something that i have done Just don't know

I am using CURA 4.7;Cura 4.7 Config Before Printing M501 ;Read stored parameters M201 X500.00 Y500.00 Z100.00 E5000.00 ;Setup machine max acceleration M203 X9000.00 Y9000.00 Z180.00 E6000.00 ;Setup machine max feedrate M204 P500.00 R1000.00 T500.00 ;Setup Print/Retract/Travel acceleration M205 X8.00 Y8.00 Z0.40 E5.00 ;Setup Jerk M220 S100 ;Reset Feedrate M221 S100 ;Reset Flowrate G28 ;Home All ;G29 S2 ;Reset Saved Bed Level G29 S0 ;Auto bed Level and then Use it G92 E0 ;Reset Extruder G1 Z2.0 F3000 ;Move Z Axis up G1 X15 Y30 Z0.28 F5000.0 ;Move to start position G1 X15 Y275 Z0.28 F1500.0 E15 ;Draw the first line G1 X18 Y275.0 Z0.28 F5000.0 ;Move to side a little G1 X18 Y30 Z0.28 F1500.0 E30 ;Draw the second line G92 E0 ;Reset Extruder G1 X150 Y150 Z2.0 F3000 ;Move to center of table then Move Z Axis upHere is My config.g

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Tue Aug 25 2020 21:43:23 GMT-0400 (Eastern Daylight Time) ; General preferences M29 S1 ; Load height map from file, activate bed compensation default name 0:/sys/heightmap.csv G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"CR10s_Pro" ; set printer name M918 P1 E4 F2000000 ; configure direct-connect display ; Network M551 P"n3ovo3" ; set password M552 P192.168.1.66 S1 ; enable network and set IP address M553 P255.255.255.0 ; set netmask M554 P192.168.1.1 ; set gateway M586 P0 S1 ; enable HTTP M586 P1 S1 ; enable FTP M586 P2 S1 ; enable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S0 ; physical drive 3 goes backwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E136.00 ; set steps per mm started at 93 M566 X1200.00 Y1200.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z180.00 E6000.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E1000 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S100 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S 1 ; set axis minima M208 X300 Y300 Z390 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe ; BLTouch - via exp.heater7 M558 P9 C"^zprobe.in" H4 R0.2 F1000 T4000 ; Set Z probe type/mode 9. H=Dive Height. F=Speed the bed M950 S0 C"exp.heater7" ; G31 P45 X25 Y5 Z2.69 ; Z probe trigger value, offset in relation to nozzle. And trigger height adjustment M557 X55:290 Y25:290 P6:16 ; Define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M140 H0 ; map heated bed to heater 0 M143 H0 S150 ; set temperature limit for heater 0 to 150C M308 S1 P"e0temp" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q600 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency M106 P2 S1 H1:0 T45 ; set fan 2 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 ; define tool 0 G10 P0 X45 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M591 D0 C3 P1 E1 S1 ; Turn on functionality for a filament run-out switch ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M501 ; M501: Read all stored parameters ;M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

Test manually

i assume from your config that the bed is 300x300

issue G0 X0 Y0

see that the head moves to one edge of the bed

then issue G0 X300 Y300 and see if its moves to the opposite side of the bed

-

@n3ovo said in BL-Touch and problems:

M501 ;Read stored parameters M201 X500.00 Y500.00 Z100.00 E5000.00 ;Setup machine max acceleration M203 X9000.00 Y9000.00 Z180.00 E6000.00 ;Setup machine max feedrate M204 P500.00 R1000.00 T500.00 ;Setup Print/Retract/Travel acceleration M205 X8.00 Y8.00 Z0.40 E5.00 ;Setup Jerk

Remove those lines from your cura start gcode. Also make sure that you have reprap gcode flavor selected.

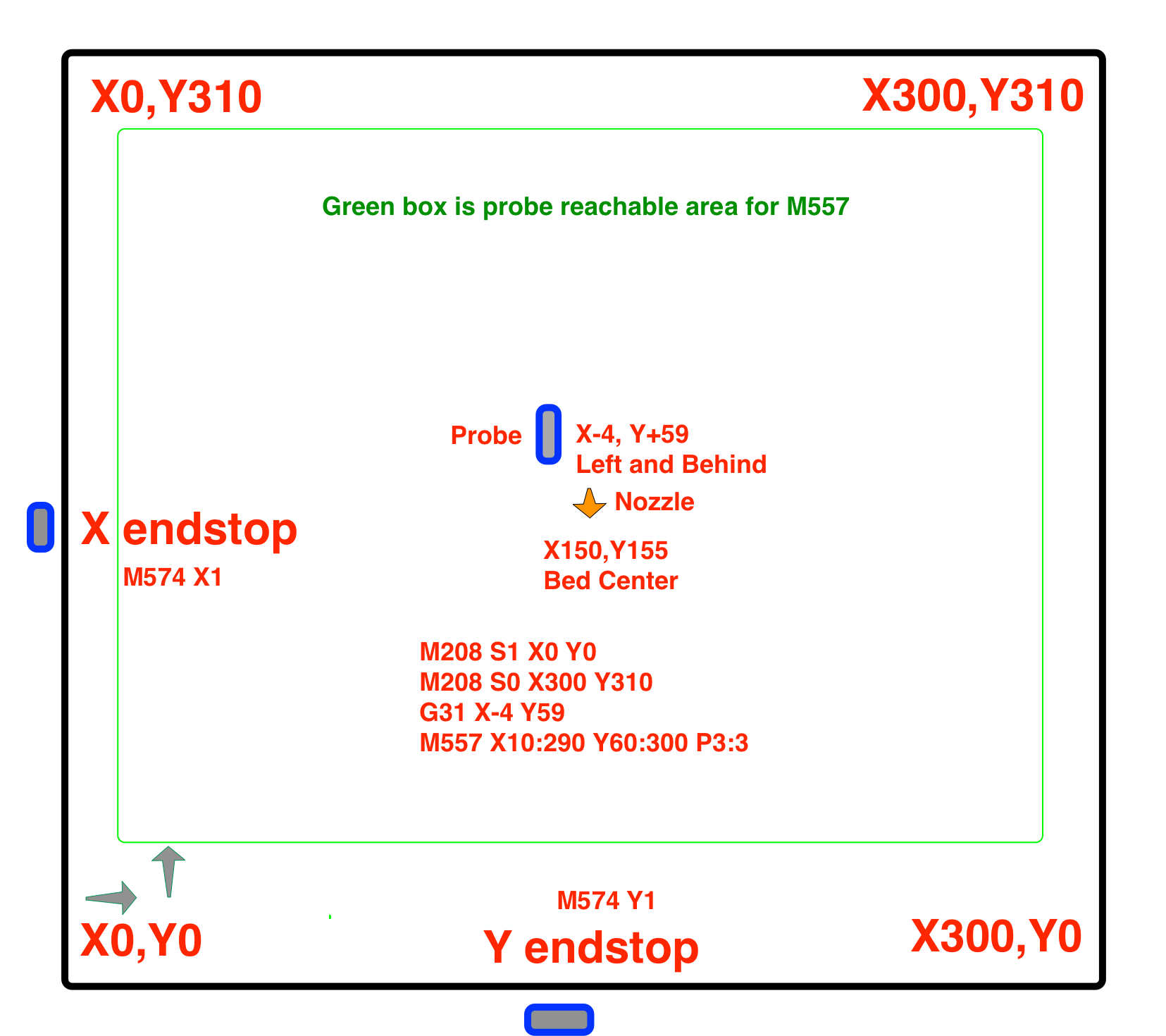

It seems like your axis minima maxima is not quite right.

0,0 should be the front left corner of the bed. If the nozzle can go further to the left or front than that, the minima would then be negative.

-

Just checked accordance on the printer If I type 0 0 it's up in the front left hand corner If I type 300 300 it's in the back right hand corner It goes to the center at 15150 I can hit any part of the bed and with a tape measure as close as I can possibly get it's right on the money So why is the program Why when I print does it go crooked It looks like when I print it it only thinks it has half a bed but only half on x why seems okay

-

"Origin at center" in cura(or some other slicer You are using) machine settings perhaps ?

Or....

G10 P0 X45 Y0 Z0

Why Do You have tool offset 45mm for X axis ??

-

@BoA said in BL-Touch and problems:

"Origin at center" in cura(or some other slicer You are using) machine settings perhaps ?

Or....

G10 P0 X45 Y0 Z0

Why Do You have tool offset 45mm for X axis ??

bingo!

-

@Veti yes it moves just what it should

thanks

-

Ok i removed all the Commands from cura. did not help ,, cant find out why, I started and old laptop with cura with the same out come and this ran before with no problem. Yes i changed it to RepRap did not help ... told cura to print in the centre of bed, Still no good same outcome ...

went tonight and got PrusaSlicer ran the same g-code that i have been trying and no good // still printer off one side???

I am thinking i have a bad update to the ROM/Web

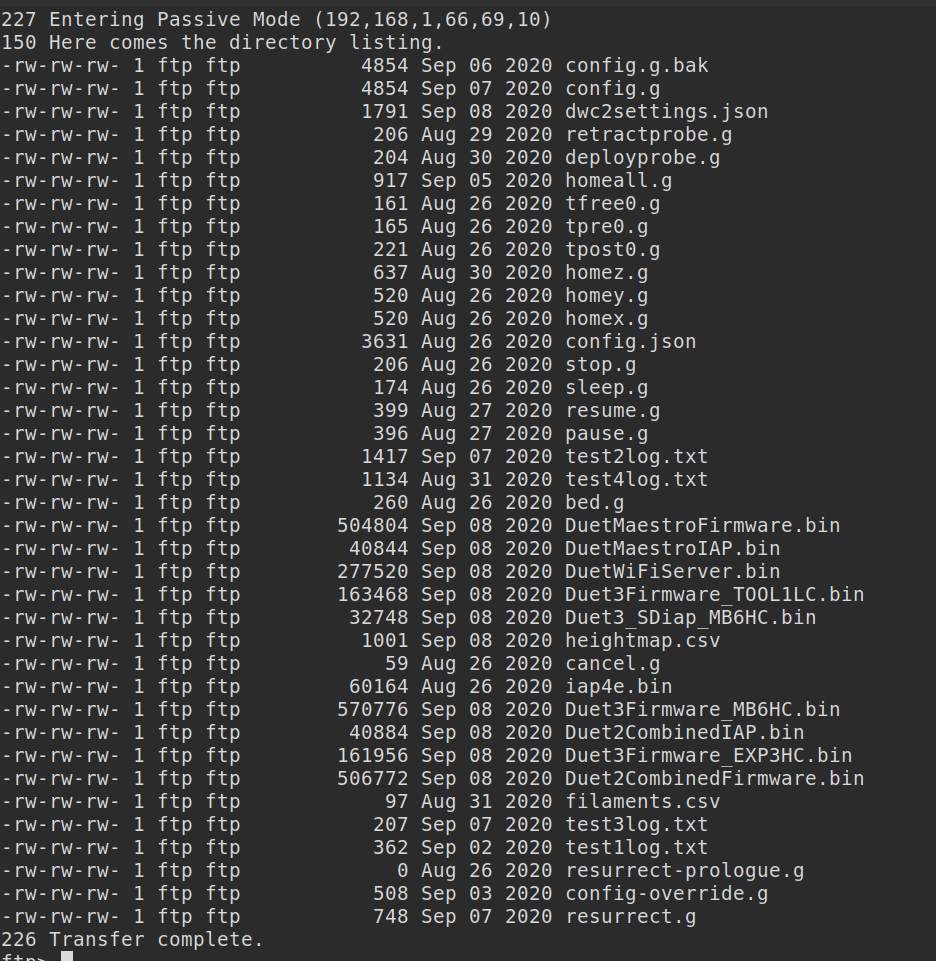

2 things someone let me know i am running 3.1.1 but i have It seems A Log more in there and i needed. Here is a list of files i have in the 0/sys/ folder?

And What files do i need to Download, I am i little confused of what to download to make sure i have a good copy!

Thanks John G.

-

The reason for the BIG number we still playing around and i just keep it there till o get around to getting the HOLE bed to print from .. my still big problem is that it is still only printing on the left side

thanks John G

-

@n3ovo your first tool should have no XYZ offset. Everything else is referenced from the first tool. You’re not going to be able to print to the whole bed with that offset. Set it to zero.

Ian

-

@n3ovo said in BL-Touch and problems:

And What files do i need to Download, I am i little confused of what to download to make sure i have a good copy!

Download it all.

@n3ovo said in BL-Touch and problems:

told cura to print in the centre of bed, Still no good same outcome ...

No you don't want cura to use a center origin. "Origin at center" should be unchecked.

Your problem is the tool offset of X45, unless you have a specific reason for that?

-

Hello All I Am Back with some small problems that i sure could us some help ..

So one problem, is the fan i must have it switch and when i run the job the cooling fan does not start on it own. It works with "FAN 0" i just turned it on now and it works. Have my Config.g below...

Another one is i added this the picture below started printing and had to babby step - 0.520mm to get it printing right seems good now would i adjust the

G31 P45 X25 Y25 Z2.270 ; Z probe trigger value,

in the config file to see the right z-height

Thanks as Allways .... John G. N3OVO

; General preferences M29 S0 ; Load height map from file, activate bed compensation default name 0:/sys/heightmap.csv G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"CR10s_Pro" ; set printer name M918 P1 E4 F2000000 ; configure direct-connect display ; Network M551 P"n3ovo3" ; set password M552 P192.168.1.66 S1 ; enable network and set IP address M553 P255.255.255.0 ; set netmask M554 P192.168.1.1 ; set gateway M586 P0 S1 ; enable HTTP M586 P1 S1 ; enable FTP M586 P2 S1 ; enable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S0 ; physical drive 3 goes backwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E136.00 ; set steps per mm started at 93 M566 X1200.00 Y1200.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z180.00 E6000.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E1000 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S100 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S 1 ; set axis minima M208 X300 Y300 Z400 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe ; BLTouch - via exp.heater7 M558 P9 C"^zprobe.in" H4 R0.2 F1000 T4000 ; Set Z probe type/mode 9. H=Dive Height. F=Speed the bed M950 S0 C"exp.heater7" ; G31 P45 X25 Y25 Z2.270 ; Z probe trigger value, offset in relation to nozzle. And trigger height adjustment M557 X55:300 Y50:300 S16:16 ;M557 X55:290 Y25:290 P6S:16 ; Define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M140 H0 ; map heated bed to heater 0 M143 H0 S150 ; set temperature limit for heater 0 to 150C M308 S1 P"e0temp" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q600 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency M106 P2 S1 H1:0 T45 ; set fan 2 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets was 45 G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M591 D0 C3 P1 E1 S1 ; Turn on functionality for a filament run-out switch ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M501 ; M501: Read all stored parameters ;M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

-

@n3ovo said in BL-Touch and problems:

the fan i must have it switch and when i run the job the cooling fan does not start on it own. It works with "FAN 0" i just turned it on now and it works.

I'm not really sure what you mean with this.

What do you have connected to fan port 0 and 1? Are those meant to both be part cooling fans? Are they supposed to both work together?

Is Fan port 2 for your hotend heatsink fan?

For the baby stepping, if you want to make that adjustment permanent, add the value to your G31 Z.

G31 P45 X25 Y25 Z2.270 would become G31 P45 X25 Y25 Z2.790

-

This post is deleted! -

@kareka please start your own thread