corexy with bowden on top?

-

@fcwilt said in corexy with bowden on top?:

Curious.

I've been using Nimbles on all my printers and have had no problems to date.

I get a faint surface texture due to the "fingerprint" of the gears, it's generally neglectable but enough for bothering me. Apparently it's a know issue with worm gears that are also used in telescopes, where the error is compensated via software (google "worm gear periodic error"). The worm gear efficiency is also very low (even as low as 50%) bringing a 1:30 ratio close to 1:20.

But 1) I haven't tried the Nimble, 2) just my very limited experience on my self built corexy that I'm still fixing.

@fma said in corexy with bowden on top?:

I used a Bowden config for a while (not on a CoreXY), and found that parts printed with this setup where more brittle than with direct drive setup.

Could it be because of the long time the filament rest between beeing squished up beteween the gears and beeing heated up in the hotend?

this is very interesting, I would be interested in knowing if others experience the same results.

-

@matt3o said in corexy with bowden on top?:

@fma said in corexy with bowden on top?:

I used a Bowden config for a while (not on a CoreXY), and found that parts printed with this setup where more brittle than with direct drive setup.

Could it be because of the long time the filament rest between beeing squished up beteween the gears and beeing heated up in the hotend?this is very interesting, I would be interested in knowing if others experience the same results.

You can easily check that the filament, once passed through the gears, becomes more brittle. Just remove it, wait it to cool down, and try to brake it before and after the part marked by the the gears...

-

I have such a setup and one thing I noticed is that the tube needs to rotate way more, so that the couplers need to be way better or they will grind themselves and the tube on the outside, causing excessive play. If you had clogging problems, forget this setup right away. An E3D V6 and the likes are unable to cope with such play due to internal notches around the heatbreak-nozzle transition, for example (that may well be because E3D changed their design without explicitly telling anyone and I've got mismatched parts).

-

@matt3o said in corexy with bowden on top?:

I get a faint surface texture due to the "fingerprint" of the gears...

But 1) I haven't tried the Nimble

I don't understand. If you have not tried the Nimble what gears are referring to?

Frederick

-

@fcwilt the nimble is not the only flexible shaft extruder out-there

-

Im curious.

How can you say the following

<* not very happy with the quality of "remote direct" drives. Mostly the worm gear is not the most reliable of the mechanisms.

If you have not tried a zesty nimble as you admitted, It would appear you are unfairly (miss)judging a product based on a biased experience with another "remote drive" which says more about you than it does about remote direct drive extruders.

-

It would appear the op is intimating issues with what could be a "flexdrive" unit

-

@CaLviNx The nimble is not the only extruder based on flexible shaft + worm gear on the market. Not sure why you need to go personal on this, I already said I'm not a reliable source and that I haven't tried the Nimble (but I tried another remote-direct drive).

-

@matt3o said in corexy with bowden on top?:

@fcwilt the nimble is not the only flexible shaft extruder out-there

I know that. But I didn't see where you mentioned what brand/model you were using.

So let us know. There is no need to keep it a secret.

Frederick

-

@fcwilt I just didn't want to give a bad review to a product that doesn't deserve it. Anyway it was the flexdrive g5. I spent months tinkering with it and the support from the author was stellar. At the end I went back to direct drive because I couldn't get rid of some surface texture I was getting. Mind you I still get some surface texture with a direct drive, but definitely less marked.

Being the technology of this kind of extruders very simple my guess is that I wouldn't get much benefit from a Nimble, but of course I could be wrong and in a world of unlimited cash I would try them all

-

@matt3o Thanks for the info.

I have a FlexDrive kit but I have not tried it yet. It appears to be more complicated than the Nimble.

At one point I had five printers equipped with Nimble units and I was happy with the results.

Do you have a picture of this effect you are talking about?

Frederick

-

@matt3o said in corexy with bowden on top?:

@CaLviNx The nimble is not the only extruder based on flexible shaft + worm gear on the market. Not sure why you need to go personal on this, I already said I'm not a reliable source and that I haven't tried the Nimble (but I tried another remote-direct drive).

Again I'm confused ?

Please show me where is said that the Zesty Nimble WAS the only flexible shaft & worm gear extruder on the market ?

And As an engineer I was not getting personal (trust me you would soon know if I was getting personal) I was merely pointing out the fact that you are tarring all flexible shaft extruders with the same negative brush without having experience of them all, logic would then dictate that you do not base your experience on facts to say

<not very happy with the quality of "remote direct" drives. Mostly the worm gear is not the most reliable of the mechanisms.

You should have said "I have not had a good experiencing with a certain brand of remote direct drive extruder"

And as i already stated above I would hazard to say you had a negative experience with the "flexdrive" extruder, I have one and it is terrible.

-

@fcwilt said in corexy with bowden on top?:

Do you have a picture of this effect you are talking about?

You can see an example here . If you try the flexdrive please let me know how it works compared to the Nimble. A friend of mine has both and he finds the flexdrive better (he says the flexible shaft is better built).

@CaLviNx said in corexy with bowden on top?:

And as i already stated above I would hazard to say you had a negative experience with the "flexdrive" extruder, I have one and it is terrible.

you are probably right, but for every 10 people who say that the nimble is better I find 10 who say the flexdrive is better, so at the end I guess it's not that objective (by that I mean that it probably depends on your machine/configuration and ultimately experience).

-

@matt3o said in corexy with bowden on top?:

@fcwilt said in corexy with bowden on top?:

Do you have a picture of this effect you are talking about?

You can see an example here . If you try the flexdrive please let me know how it works compared to the Nimble. A friend of mine has both and he finds the flexdrive better (he says the flexible shaft is better built).

@CaLviNx said in corexy with bowden on top?:

And as i already stated above I would hazard to say you had a negative experience with the "flexdrive" extruder, I have one and it is terrible.

you are probably right, but for every 10 people who say that the nimble is better I find 10 who say the flexdrive is better, so at the end I guess it's not that objective (by that I mean that it probably depends on your machine/configuration and ultimately experience).

I bought the flexdrive before I bought the nimble I could never get the flexdrive to extrude properly, one minute it would over/under extrude even with the same settings.

I went to a nimble and it "just worked" I would like to buy more Nimbles but due to the current state of the world they are not shipping

-

@matt3o said in corexy with bowden on top?:

You can see an example here .

Thanks for the picture.

How did you know what was causing that effect?

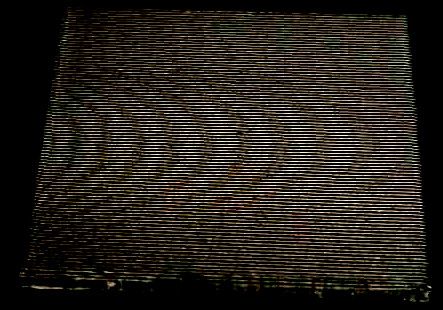

I'm currently testing a Dragon hotend and am still tweaking things but here is a recent test print.

Thanks.

-

@fcwilt said in corexy with bowden on top?:

How did you know what was causing that effect?

literally months of trials and errors. I tried to replace every single piece of my poor little machine

(and still working on it, bowden is the only thing I still have to try)

(and still working on it, bowden is the only thing I still have to try)PS: I'm currently on a mosquito and can only say good things about it

-

-

@CaLviNx looks very good from your picture. My texture was actually visible only in certain light conditions (otherwise it looked good).

I tried to "enhance" your picture to see if I could simulate those conditions and got this.

It's not what I expected but interesting nonetheless

Did you increase speed in the middle on the cube?

Did you increase speed in the middle on the cube? -

I dont quite get why you "enhanced" my picture to show a pattern that isn't actually there, you can play with this cube under a light and no pattern shows up and no pattern can be felt to the touch or with a nail.

Unless i missed that you are trying to show the issue you had of course?

I printed this at a constant speed on one of my delta's

The pattern you have simulated is usually cased by a resonant frequency of something

-

@CaLviNx said in corexy with bowden on top?:

The pattern you have simulated is usually cased by a resonant frequency of something

Every extruder has a fingerprint, that is the one on your printer. I'm not trying to find the flaw, I was trying to see if the pattern was similar to mine, but it's completely different.