Filament-Knot-Stop (KnotenStopp)

-

Thanks for your comment.

Very well thought out spool holder, I like it very much.I print out of a drying oven and my spool is horizontal.

With polycarbonate (PC) filament, it is extreme that the filament relaxes and falls off the spool. Grrrr

I also often print filament samples from a master pool, as knots occur very quickly.@jens55

I also considered installing a second microswitch that triggers when there is no more filament.

Maybe someday there will be the node stop V2?

Thanks also for your comment. -

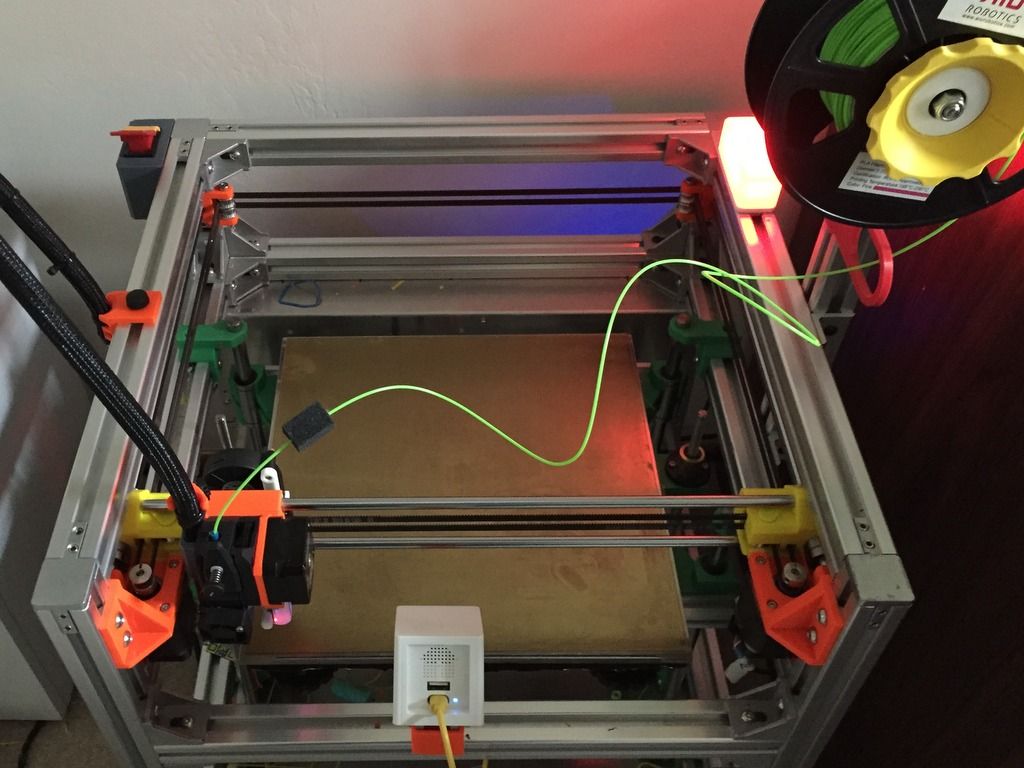

Thanks for posting the picture of the complete setup. I can now see how it senses the tension due to a tangle. This was not clear at all when you only showed the device without the surrounding setup.

-

Exactly ... Tangle is probably the right word ... English is not my language. : D

It happens very quickly that the filament jams itself.

A real knot is easier to get in if you quickly wind up the filament that has fallen off the spool.I am pleased that you like the "KnotenStopp" so much, and I hope it will help you to print your projects in the future.

Thanks for your comment.

-

@Günter-Jibben I would not orient the spool so that the axis is vertical- that's begging for tangles. Turn it so the axis is horizontal and much of the trouble will disappear.

-

That is true and I am also aware of it.

The problem is ... no filament spool fits vertically in the oven.And the oven is modular, spacer rings can be added to dry two coils at the same time.

The ball-bearing axis for the coil is also not fixed, but is in the middle of the oven and cannot move laterally.

Ideal for quickly changing the filament.In order to be able to mount the oven on the wall or to be able to set it upright, I have to completely rebuild the oven and rebuild all rings and the lid so that they hold by themselves.

My plan is ... to build a base cabinet where my filaments can be stored and dried at the same time.

So I can print them directly from there.

The printer is mounted on the base cabinet.

The complete electronics (Duet-Wifi with PT500-daughterboard, Raspberry Pi, power-adapter etc.) are on the backsite, encapsulated by the heated printer room.

The Hotend and the stepper-motors get ... if necessary ... common water cooling ... but only maybe and if really not otherwise possible.

It will have an enclosure made of side glass walls and the front door will be made of Makrolon (clear plastic pane made of polycarbonate (PC) - heat-resistant and very stable).A time- and temperature controlled heater is placed under the base cabinet, it first dries the filament (and the drying granulate) and then heats the print-chamber and is led into the living room through a HEPA-Filter in winter ... in summer it is passed through an exhaust-pipe out of the house.

Maybe someone has a good idea to use the waste heat in summer ?

And then the whole thing in beautiful

... So with a lot of fine wood (at least it should look like this), brass, stone (black granite plate ... on which the printer is mounted so that it can stand without torsion ... I still have a bulletproof glass pane, maybe I use it, then I can also see from above how much filament is on the rolls) etc. ... so no Ikea table with plexiglass panes and such ... it's a simple and good solution, but it's not nice.

... So with a lot of fine wood (at least it should look like this), brass, stone (black granite plate ... on which the printer is mounted so that it can stand without torsion ... I still have a bulletproof glass pane, maybe I use it, then I can also see from above how much filament is on the rolls) etc. ... so no Ikea table with plexiglass panes and such ... it's a simple and good solution, but it's not nice.

It's kind of part of the hobby to pimp your printer.

It was all very expensive, so it should look good too.

If my plan has been implemented, I will post some photos here.

Maybe this year ?By the way ... the holding-frame for the Extruder and the Hotend is printed out of CoPA from Polymaker.

It can withstand temperatures up to 180 ° C.

I have this filament in my "collection".

As can be seen in the photo, the air nozzle for component cooling is made of brass.

The Hotend from Dyze-Design (Dyze EXtruder Pro / Dyzend Pro) are designed for 500°C ... because an air nozzle made of plastic quickly "slackens".

------------------------ Original Text --- German --------------------------

Das stimmt und es ist mir auch bewusst.

Das Problem ist... in dem Ofen passt keine Filament-Spule vertikal hinein.Und der Ofen ist modular aufgebaut, es können Distanzringe hinzugefügt werden um zB zwei Spulen gleichzeitig zu trocknen.

Auch die kugelgelagerte Achse für die Spule ist nicht fest montiert sondern sie steht mittig im Ofen und kann sich nicht seitlich bewegen.

Ideal für das schnelle wechseln des Filament's.Um den Ofen an die Wand montieren zu können bzw hochkant aufstellen zu können, muss ich den Ofen komplett umbauen und alle Ringe und auch den Deckel so umbauen das sie von alleine halten.

Mein Plan ist... mir einen Unterschrank zu bauen, wo meine Filamente aufbewahrt und gleichzeitig getrocknet werden können.

So kann ich sie direkt von dort aus drucken.

Der Drucker wird auf dem Unterschrank montiert.

Die komplette Elekronik (Duet-Wifi mit PT500 Tochterboard, Raspberry Pi, Netzteil etc.) kommt auf die Rückseite, abgekapselt vom beheizten Druckerraum.

Das Hotend und die Stepper-Motoren bekommen... falls nötig... eine gemeinsame Wasserkühlung... aber nur vielleicht und wenn wirklich nicht anders möglich.

Er bekommt eine Umhausung aus seitlichen Glaswänden und die vordere Tür wird aus Makrolon (Klare Kunststoffscheibe aus Polycarbonat (PC) - hitzebeständig und sehr stabil) bestehen.Eine Zeit- und Temperaturgesteuerte Heizung wird unter dem Unterschrank platziert, sie trocknet zuerst das Filament (und das Trocknungsgranulat) und beheizt danach den Druckraum und wird im Winter durch ein HEPA-Filter in den Wohnraum geleitet... im Sommer wird sie durch ein Abluftrohr aus dem Haus geleitet.

Vielleicht hat jemand noch eine gute Idee die Abwärme im Sommer zu nutzen ?

Und das Ganze dann in Schön

... also mit viel edlem Holz (zumindest soll es so aussehen), Messing, Stein (Platte aus schwarzem Granit... auf dem der Drucker montiert ist, damit er verwindungsfrei stehen kann... ich habe noch eine Panzerglasscheibe, vielleicht nutze ich diese dazu, dann kann ich auch von oben sehen wieviel Filament auf den Rollen ist) etc. ... also kein Ikea-Tisch mit Plexyglas-Scheiben und so... es ist eine einfache und gute Lösung, aber sie ist nicht schön.

... also mit viel edlem Holz (zumindest soll es so aussehen), Messing, Stein (Platte aus schwarzem Granit... auf dem der Drucker montiert ist, damit er verwindungsfrei stehen kann... ich habe noch eine Panzerglasscheibe, vielleicht nutze ich diese dazu, dann kann ich auch von oben sehen wieviel Filament auf den Rollen ist) etc. ... also kein Ikea-Tisch mit Plexyglas-Scheiben und so... es ist eine einfache und gute Lösung, aber sie ist nicht schön.

Es gehört irgendwie zum dem Hobby dazu, sein Drucker zu pimpen.

Es ist alles sehr teuer gewesen, also soll er auch gut aussehen.

Wenn mein Plan in die Wirklichkeit umgesetzt wurde, poste ich hier einige Fotos dazu.

Vielleicht dieses Jahr noch !?Übrigens... den Halterahmen für den Extruder und das Hotend wird aus CoPA von Polymaker gedruckt.

Es hält Temperaturen bis 180°C stand.

Ich habe dieses Filament in meiner "Sammlung".

Wie auf dem Foto zu erkennen, ist die Luftdüse für die Bauteilkühlung aus Messing gefertigt.

Das Hotend von Dyze-Design (Dyze EXtruder Pro / Dyzend Pro) sind für 500°C ausgelegt... da macht eine Luftdüse aus Kunststoff sehr schnell "schlapp".

-

Hemera from e3d is good... but Dyze EXtruder Pro by Dyze-Design ist better... for World's !

To see ... the air nozzle for component-cooling made of brass.

It is held magnetically and can be exchanged very quickly for differently shaped air nozzles.The fan runs between 1% and 20% for me.

On average around 3% of its performance.

It is a 24 volt fan -

@Günter-Jibben, you seem to have quiet a lot of bowden like tube restriction along the path from the spool to the extruder. I found that with my printer, I get better results with a zero friction approach. The spool rotates over two bearings and the springiness of the filament maintains a fixed and minimal tension. It works very well even if its seems a little bit chaotic.

-

@zapta

Since I installed the KnotenStopp, it has become a little more Bowden.

I have a Direct-Extruder and the Bowden is supposed to protect the filament from moisture on the way from the oven to the extruder.

I print a lot of PC, Nylon and ABS.

PETG would also work without Bowden. I don't use PLA at all.I will soon mount the KnotenStopp directly on the stove, so I save a few centimeters on Bowden.

I also don't like it when there is too much hanging around the printer

Thx for your Comment, zapta.

P.S.:

The DyzeXtruder Pro pulls over 10kg weight.

The Bowden should be three times as long and still pull the filament without problems.

The DyzeXtruder Pro has a 5.65 : 1 gear ratio. -

@Günter-Jibben Hi, do you have that fan design posted anywhere ?

-

if ever there was a solution looking for a problem...................