Indirect Laser Monitor Remix II - working!

-

Sweet, thanks for duplicating the order list here!

-

Just ordered what I didn't have to make this. Can't wait to finally have a reliable sensor!

-

Well it doesn't work for me. the actual hob gear doesn't grip the filament at all so the rod barely rotates. I'll try with different hob gears I have here. But no luck so far. (I manually pushed the limit switch all the way down to no avail).

Also, the transparent filament channel is right on top of the screw hole, which means the screw is in the way of the filament. I had to bend the filament, but it is now not in line with the LED.

-

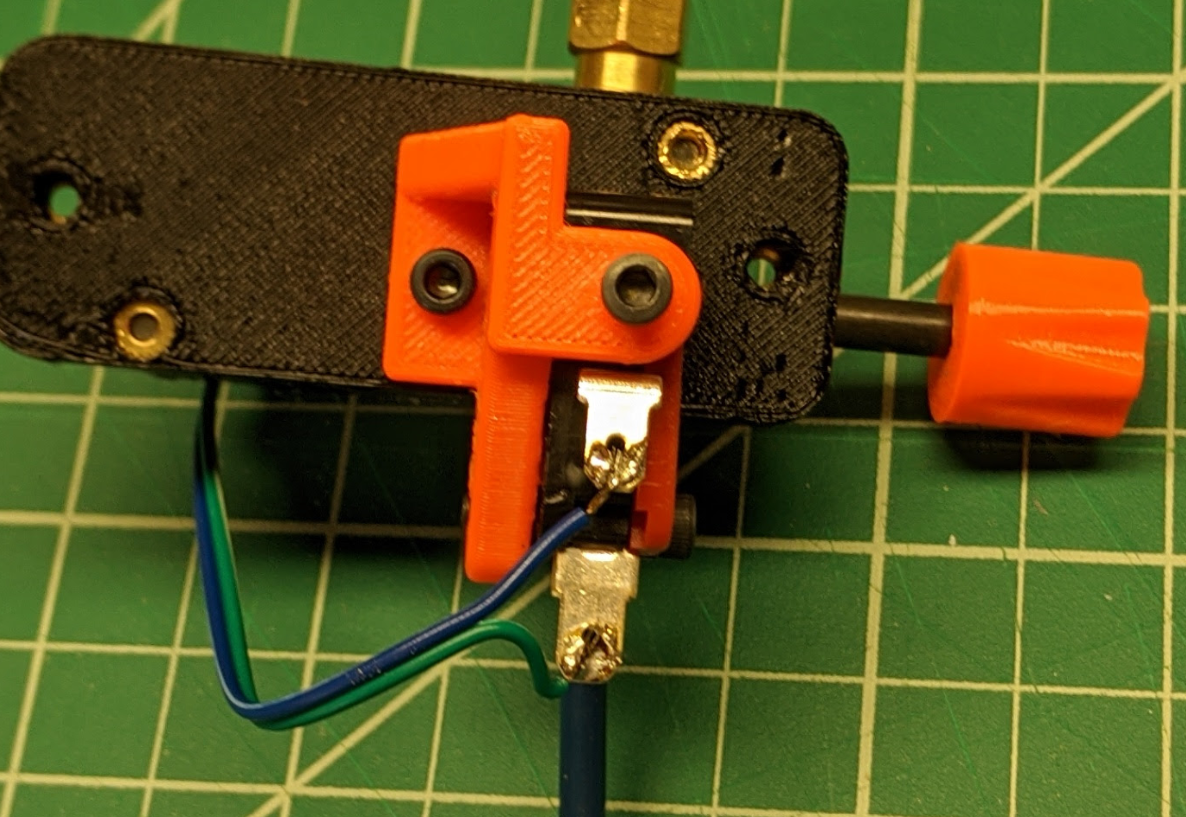

found a way to put more pressure on it (tilted down the switch and redrilled the mounting holes for it).

Now works, but still getting shitty readings.

Duet3D laser filament monitor v2 with switch on pin io3.in, disabled, allow 200% to 3000%, check every 3.0mm, version 2, quality 223, brightness 255, shutter 91, measured min -2% avg 152% max 273% over 466.5mm -

@Thalios can you post a pic? Did you use flat head screws. The screws should be countersunk so the filament goes right over them.

-

@Thalios The hob gear is the key. I tried three different ones before I found one that worked well which was the MK3 gear in black.

you shouldn't have to redrill any holes. Which gear did you use? I am on travel but I can post some more images if that would help. The thing is that you need the switch to have enough room to release when filament is not present. Should be able to just adjust the height screw.

-

This looks great and I've got all the parts I need.

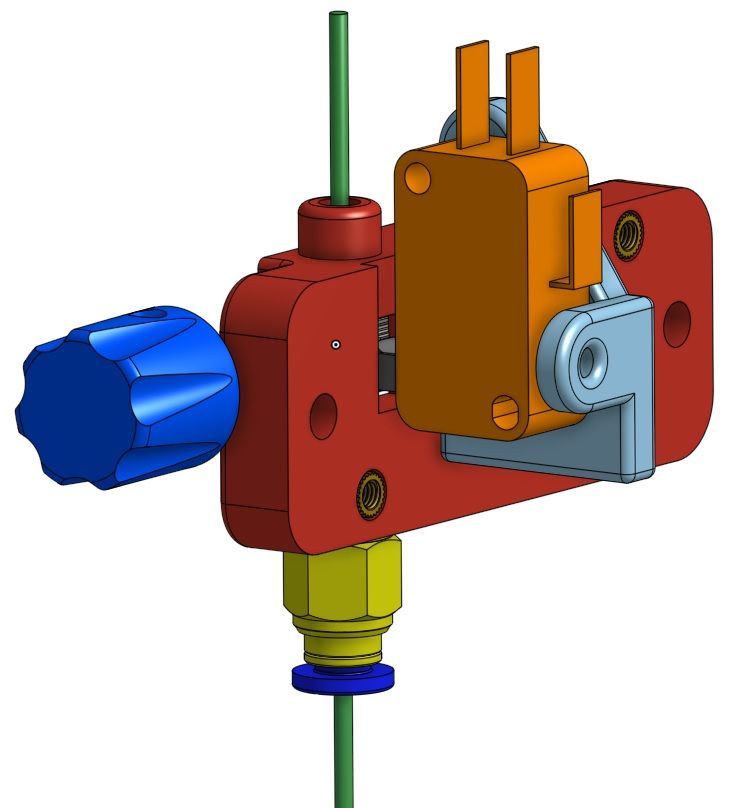

The only issue is that it seems like the "microswitch holder" (which you have in two parts in your render) is missing from thingiverse. Any chance you can upload it? (orange part in your render).

-

Orange part here

-

the orange part IS the limit switch.

-

@makemerush No problem. The orange part is that limit switch which is was specifically chosen because of it's activation distance as well as the tension it provides. Essentially this is killing two birds with one stone. The switch acts as an idler assembly to provide tension against the hob and at the same time also acts as a switch to statically detect filament presence.

The switch can be purchased here:

https://amzn.to/2SkgX9UThe switch is attached to the switch assembly with a single screw so it can pivot. The hole on the top side of the switch assemble is used so you can insert a screw to increase or decrease tension and activation distance to tweak your setup. The screw just pushes the switch tighter against the hob.

The second thing that may not be obvious. Is the mount. I got great results once I used a rigid mount. You don't want this flopping around and only held on by the tube. I hope that helps.

BTW, with the new firmware beta released the L parameter can be used in the config.g to normalize the results between 0-100%.