PT100 sensor and Daughter Board issue

-

@Veti said in PT100 sensor and Daughter Board issue:

@sozkan said in PT100 sensor and Daughter Board issue:

M308 S1 P"e0temp" Y"pt1000" R4700 ; configure sensor 1 as PT1000 on pin e0temp

M308 S2 P"e1temp" Y"pt1000" R4700 ; configure sensor 2 as PT1000 on pin e1tempyou configured pt1000 not pt100

try

M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as thermocouple via CS pin spi.cs1

M308 S2 P"spi.cs2" Y"rtd-max31865" ; configure sensor 2 as thermocouple via CS pin spi.cs2The final value actually the same as your recommendation. The only thing I have now R-value: "R4700".

"pt100" is not recognised ( temperature display was n/a)However, I will try tomorrow again by copying your code.

Thanks. -

Please also send M115 to confirm you have firmware 3.1.1 installed.

Also send M98 P"config.g" to see if there are any syntax errors in your config.g

-

@sozkan said in PT100 sensor and Daughter Board issue:

M308 S1 P"spi.cs1" Y"rtd-max31865" R4700 ; configure sensor 1 as PT100 on pin e0temp

Remove R4700, but not sure it will cause a problem.

Also the jumpers on the board is present?

-

@Phaedrux said in PT100 sensor and Daughter Board issue:

Please also send M115 to confirm you have firmware 3.1.1 installed.

Also send M98 P"config.g" to see if there are any syntax errors in your config.g

@Phaedrux

This te response from :10/25/2020, 12:13:00 PM M115 FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 3.1.1 ELECTRONICS: Duet WiFi 1.02 or later FIRMWARE_DATE: 2020-05-19b2However M98 P"config.g" did not respond from the DWC interface. On the latest beta version was responding and this macro code was working.

-

@bearer said in PT100 sensor and Daughter Board issue:

@sozkan said in PT100 sensor and Daughter Board issue:

M308 S1 P"spi.cs1" Y"rtd-max31865" R4700 ; configure sensor 1 as PT100 on pin e0temp

Remove R4700, but not sure it will cause a problem.

Also the jumpers on the board is present?

Thank you all! Temperature issue 99% is solved. 1% is the temperature difference. Which is actually a success. R4700 was the problem! However, in the Duet documentation, this "R4700 " was recommended!

Heat bed and Hotend temperatures slightly different. I assume PT100 cable length resistance might cause the difference right?

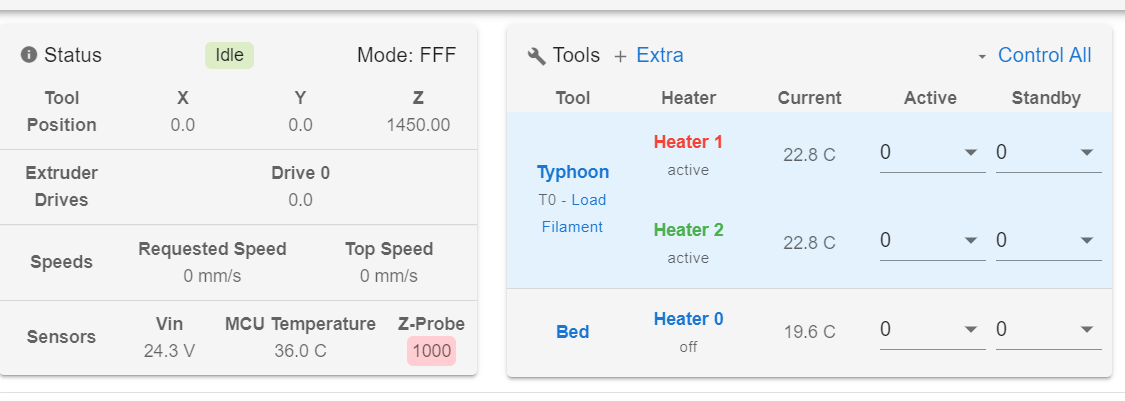

Here is the result :

As feedback:

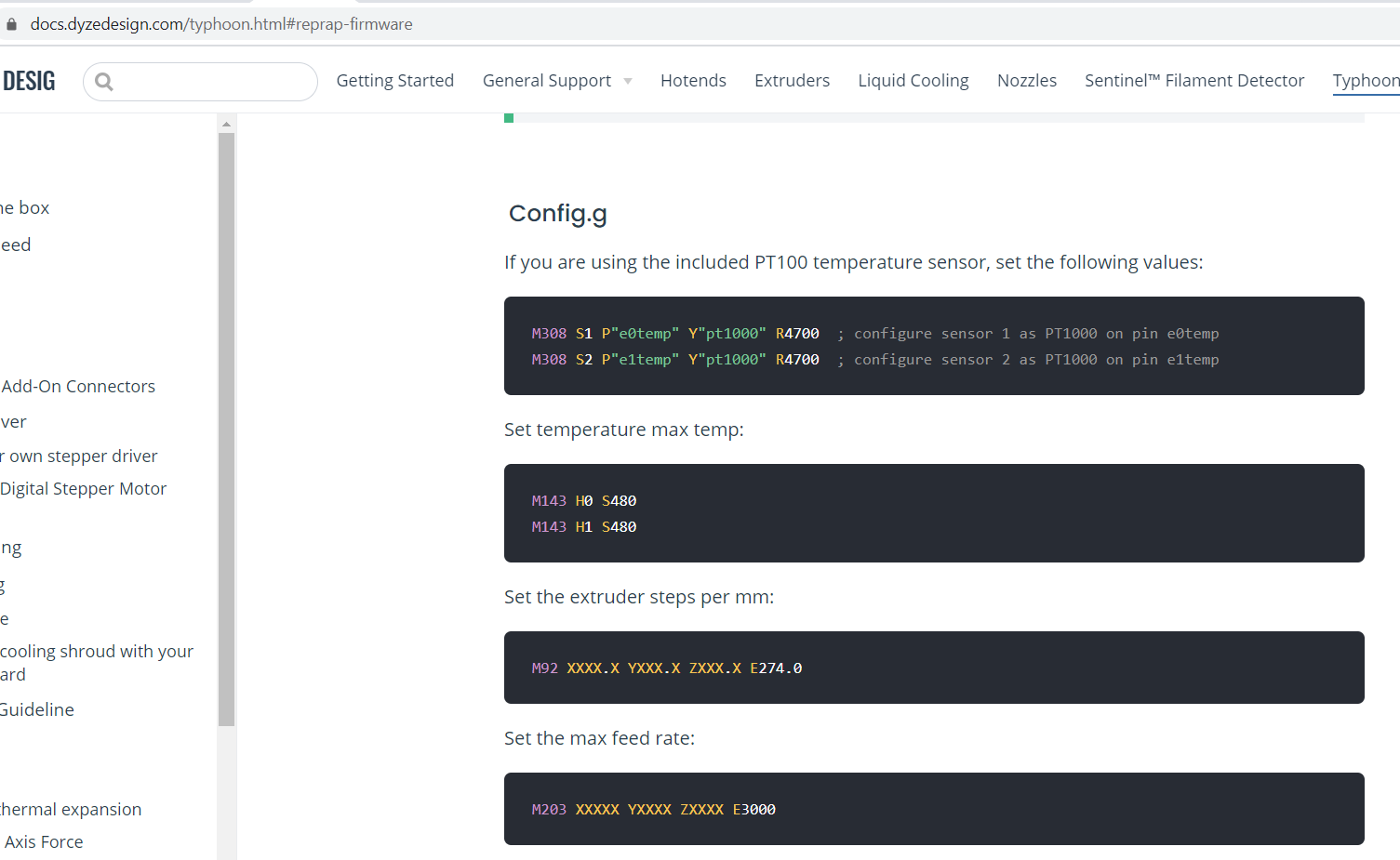

"S" values sometimes represent the function and Hardware channel and "P" values the same. That is confusing. Am I wrong? There are similar problems with different solutions and it is also confusing.As you may look Dyze -Design Typhoon Hotend documentation gives wrong guiding as well...

By the way, Is it worth upgrading to Board version 3? Because we have plans to integrate a camera onboard, a Realtime printed part simulation that shows work in progress in actual part viewed on-screen display interface using RasberyPi integrated ( if possible) with duet board resources.

Kind Regards

-

@sozkan

I will make a conclusion for newcomers especially PT100 or dyze-design Typhoon users.- Hardware: Duet 2 Wifi v1.04

- Daughter Board: v1.1 (max31865)

- Heat Bed Sensor: an NTC 100k Thermistor connected to the board heat bed connector.

- Hotend Sensors: 2 Piece of 2 wire PT100 type sensors comes with Dyze-Design Typhoon HotEnd.

Working Configuratuin Code :

; Bed Heater M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C ; HotEnd M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as PT100 on pin e0temp M308 S2 P"spi.cs2" Y"rtd-max31865" ; configure sensor 2 as PT100 on pin e1temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2 M307 H1 B0 S0.50 ; disable bang-bang mode for heater and set PWM limit M307 H2 B0 S0.50 ; disable bang-bang mode for heater and set PWM limit M143 H1 S480 ;Set temperature max temp: M143 H2 S480 ;Set temperature max temp: ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S1 H2:1 T45 ; set fan 0 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1:2 F0 S"Typhoon" ; define tool 0 -

However, in the Duet documentation, this "R4700 " was recommended!

Only for pt1000? If not please point to where you found it so it can be corrected.

. I assume PT100 cable length resistance might cause the difference right?

Could be, use (3 or) 4 wire measurements to eliminate cable lenght as an issue

-

@bearer said in PT100 sensor and Daughter Board issue:

for pt1000? If not please point to where y

It is here in the DyzeDesign documentation:

https://docs.dyzedesign.com/typhoon.html#reprap-firmware

-

that is not the official duet documentation.

the official duet documentation says

https://duet3d.dozuki.com/Wiki/Gcode#Section_M308_Set_or_report_sensor_parametersRnnn Series resistor value. Leave blank to use the default for your board.

-

@Veti said in PT100 sensor and Daughter Board issue:

that is not the official duet documentation.

the official duet documentation says

https://duet3d.dozuki.com/Wiki/Gcode#Section_M308_Set_or_report_sensor_parametersRnnn Series resistor value. Leave blank to use the default for your board.

I believe it is Official documentations; R values for the Duet Wifi "R4700" But it did not work with our case. That`s what I mean.

https://duet3d.dozuki.com/Wiki/Connecting_thermistors_or_PT1000_temperature_sensors#Section_The_M305_M308_R_parameterI don`t blame, that's just feedback from the user perspective.

-

@sozkan said in PT100 sensor and Daughter Board issue:

R values for the Duet Wifi "R4700" But it did not work with our case.

that is true for the normal thermistor on the duet.

its not true for the dautherboard. -

@sozkan said in PT100 sensor and Daughter Board issue:

I believe it is Official documentations; R values for the Duet Wifi "R4700" But it did not work with our case. That

s what I mean. https://duet3d.dozuki.com/Wiki/Connecting_thermistors_or_PT1000_temperature_sensors#Section_The_M305_M308_R_parameter I dont blame, that's just feedback from the user perspective.but that does say PT1000 not PT100; different beasts.

in any case it should be ammended I guess as the current reccomendation is to leave out R unless you've modified the board or have a very early board. firmware will apply the correct value for a given board - maestro and duet 3 have different value to duet 2 wifi/ethernet

-

@bearer The header starts with; "Connecting thermistors or PT1000 temperature sensors

The Duet series supports 4 types of temperature sensor: thermistor and PT1000, thermocouple, and PT100. "Since I don`t see specifically PT100 example, When I see this header, I consider this is a kind of group of sensors.

"This section describes how to connect thermistors or PT1000."isn't it confusing?

However, it seems like my setup working on the ambient temperature as I share the conclusion, I don`t worry much about what it was saying.

Thanks for all your contribution. -

@sozkan said in PT100 sensor and Daughter Board issue:

However, in the Duet documentation, this "R4700 " was recommended!

Where in the documentation did you see it recommended?

PT100 documentation is at https://duet3d.dozuki.com/Wiki/Connecting_PT100_temperature_sensors.

-

@dc42 said in PT100 sensor and Daughter Board issue:

Where in the documentation did you see it recommended?

https://duet3d.dozuki.com/Wiki/Connecting_thermistors_or_PT1000_temperature_sensors

The Duet series supports 4 types of temperature sensor: thermistor and PT1000, thermocouple, and PT100.

maybe that could be re-written to something like

The Duet series supports 4 types of temperature sensor: PT1000, as well as PT100, NTC thermistor and thermocouple.

with links to the three other pages, maybe it would be clearer to those not intimately familiar with types of sensors.

-

@bearer said in PT100 sensor and Daughter Board issue:

@dc42 said in PT100 sensor and Daughter Board issue:

Where in the documentation did you see it recommended?

https://duet3d.dozuki.com/Wiki/Connecting_thermistors_or_PT1000_temperature_sensors

The Duet series supports 4 types of temperature sensor: thermistor and PT1000, thermocouple, and PT100.

maybe that could be re-written to something like

The Duet series supports 4 types of temperature sensor: PT1000, as well as PT100, NTC thermistor and thermocouple.

with links to the three other pages, maybe it would be clearer to those not intimately familiar with types of sensors.

Right

Thanks.

Thanks. -

@dc42 said in PT100 sensor and Daughter Board issue:

@sozkan said in PT100 sensor and Daughter Board issue:

However, in the Duet documentation, this "R4700 " was recommended!

Where in the documentation did you see it recommended?

PT100 documentation is at https://duet3d.dozuki.com/Wiki/Connecting_PT100_temperature_sensors.

Thank you very much. That`s exactly what I have done. It seems like working. I will share the youtube video on action.

-

@sozkan said

Heat bed and Hotend temperatures slightly different. I assume PT100 cable length resistance might cause the difference right?

- Heat Bed Sensor: an NTC 100k Thermistor connected to the board heat bed connector.

- Hotend Sensors: 2 Piece of 2 wire PT100 type sensors comes with Dyze-Design Typhoon HotEnd.

Without knowing exactly where Dyze get their PT100 chips from (and hence what class they are)...

RTD's (PT100 and PT1000's) are normally laser trimmed, platinum resistors. At room temperature they will typically be accurate to about 0.3 degrees of each other. And they are be read by a chip specifically designed to do that, so it can get better resolution across the usable range of an RTD.

A Thermistor on the other hand is a much lower quality device, that will probably vary by 2-3 degrees even at room temp, and due to the way it changes resistance, has less resolution at room temp. (Its not unusual for thermistors to vary by up to 20 degrees at 220C).As @bearer said, 4 wire sensors would eliminate any error due to cable resistance, but for 3D printing you don't need that level of accuracy.

The biggest advantage of an RTD is that if you ever replace one, you'll still get the same reading at the same temperature. -

@theruttmeister Thank you for informative writing.

I have an extra 8-meter length after the hot end. However, try to make ohmic losses as low as possible by using 0.75 mm cable. It seems like working ( with a 2-3 celsius difference from the Thermistor on the heat bed at room temperature) I also think that`s not an issue.

B. Regards.