Fine tunning setup for Ender 5 plus

-

Where are your endstops physically located?

M574 X2 S1 P"io0.in" ; configure active-high endstop for high end on X via pin io0.in

M574 Y2 S1 P"io1.in" ; configure active-high endstop for high end on Y via pin io1.inThat indicates they are on the high end of travel, meaning based on a 0,0 origin in the front left corner the endstops would be at the right and back sides.

Have you leveled your bed and calibrated your extruder recently?

Have you done G29 to get a heightmap of your bed surface?

-

@Veti said in Fine tunning setup for Ender 5 plus:

https://forum.duet3d.com/topic/6962/m48-measure-z-probe-repeatability-and-print-to-serial-output

Hello,

Tired this on getting errors:

Z Probe already triggered at the start of probing move.

-

remove M401 and M402

-

Hi @Phaedrux

The endstop switches are in the right side for X and Y is at the back right side hand side when looking at the printer from the front.

When the head goes to the 0,0 origin the probe is outside of the bed, so my probe location based on the nozzle seems to be incorrect.

-

@aldiallo said in Fine tunning setup for Ender 5 plus:

When the head goes to the 0,0 origin the probe is outside of the bed, so my probe location based on the nozzle seems to be incorrect.

That's typical of using a high end endstop. You can measure your actual axis length by homing the nozzle to be where you want 0,0 to be. Then sending G92 X0 Y0, then you can send G1 H3 X400 which will move the x axis to the endstop and set the current position as the axis max. Whatever the X axis position is should be what your M208 maxima is. Then you can do the same for the Y axis.

-

I based the M208 maxima on the bed size so 350 for X and Y shouldn't that be correct??

Thanks

-

Measure as I described to find out

-

I did what you indicated, should I be seeing any results on the web interface? I've sent both commands and the print head moved to the end stop each time but that's it, not sure if I should have get a result for each axis that I should then input to the config.g file?!

on the tool position status I see X at 163,8 and Y at 174,4 and this is with the printhead at the endstop switch of both X and Y axis.

-

If you started at 0,0 and moved to the endstop from there then that's your axis length that should be in m208.

168 is far from 350. You moved the nozzle to the front corner of the bed and sent g92 x0 y0?

-

I did a home all first to bring the print head to the front left hand side and then executed the G92 X0 Y0 prior to running the G1 H3 on both X and Y axis as per your suggestion.

Something is not right but I don't know what.

-

Are you saying that homeall brings your printer to the front left side?

After you've done a homeall, manually jog the print head to place then nozzle at the front left corner of the printable area. Then send G92 X0 Y0. That way when you jog the print head over to the other end of the axis you'll have the actual length of the printable area.

-

When I do a home all the printhead moves to the right and back until hitting the endstop switches for X and Y the it moves to the front left side and deploys the bltouch, as the BLTouch is outside of the printable area I touch it when the bed is at the level of the ouch deployed tip is just after that that I send the G92 X0 Y0 and then the G1 H3 for the X and Y axis; I also tried moving the X to the right to get the BLTouch inside the printable area but still getting the similar results for X and Y in the tool status section.

-

Ok based on your homeall and your described behaviour your M208 axis length is way off or your steps per mm for X and Y is way off.

When you hit the endstops it takes the value from M208, so it thinks it's at 350. Then your homeall tries to move to the center of the bed but you say it's actually trying to move off the edge of the far left and front.

So how big is your bed actually? Do you have a ruler?

If you tell the printer to move X10 does it actually move 10mm?

-

The printable area is 350 * 350 * 400 but the physical size of the bed from what I've mesure is about 380 for X and 372 for Y; not sure what other Ender 5 Plus users using duet hardware are using but when I builded the firmware I entered 350 for X and Y and 400 for Z.

When I ask the printer to move 10mm for example x+10, it does move, but haven't mesured how much it moves thought but seems to me that it's moving around 10mm but will check that; now not sure if the issue is on the config.g or on the home*.g files

-

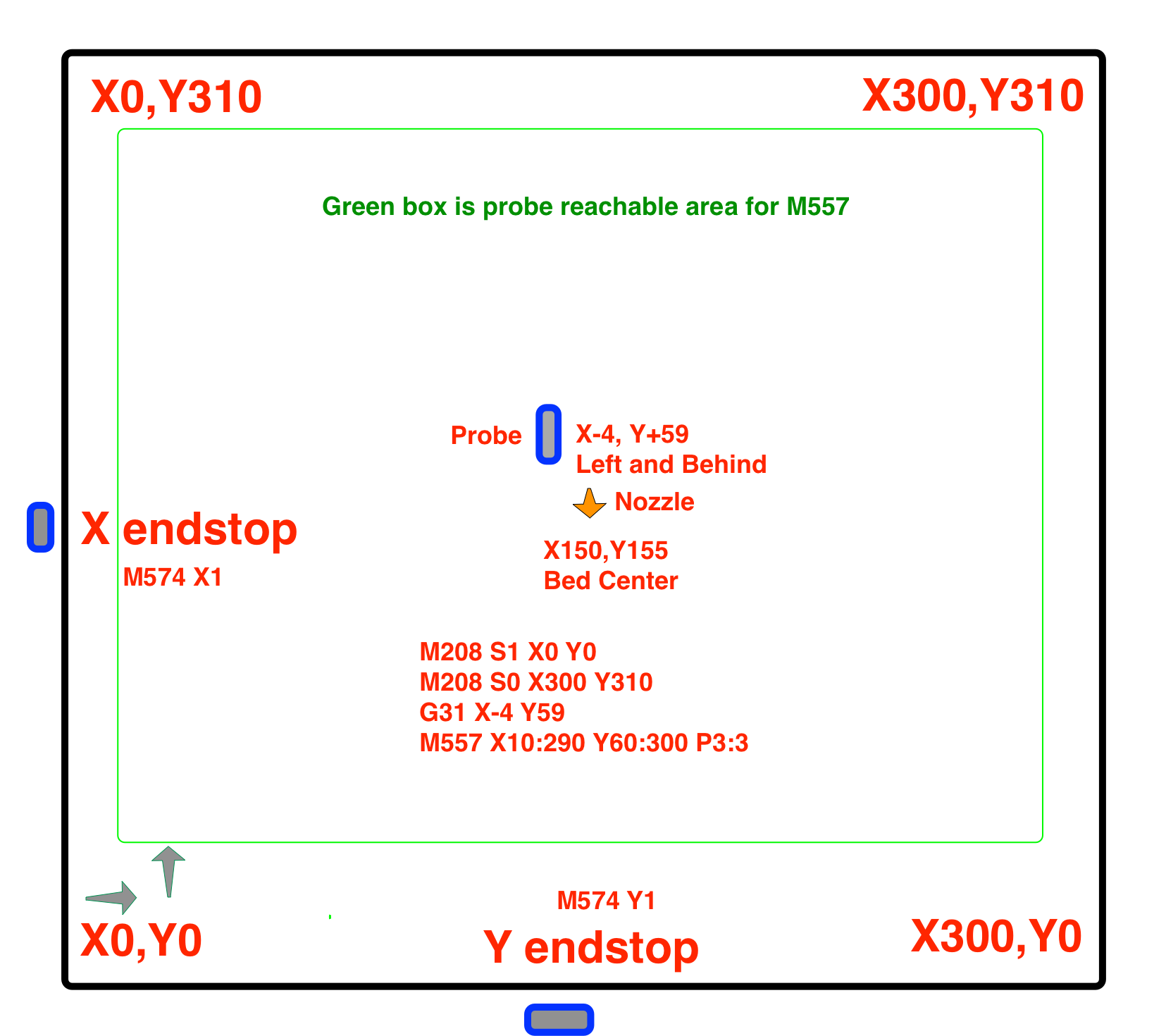

See if you can create yourself a diagram like this that shows all the relevant positions and distances and offsets for the XY plane.

Maybe capture a video of what you're trying to do to show what's happening. That can be a huge help for understanding what's actually going on there.

-

ok, will do that and report back.

thanks

-

Hi all,

Took some time as been quite busy lately but print is now done correctly without manual intervention, and it sticks fine.

Still need to do some fine tuning here and there in order to redo a proper level calibration.

I assume that I can enable auto home and autobed level calibration and also enable resume printing on power loss by adding relevant commands on my config.g file, correct?

Additional question, I'm used to use Octoprint and that the fact that we can access everything on the duet web interface makes Octoprint irrelevant on some aspects, but there à lot of very useful, for example I used Octoprint ot power up a smart plug to turn the printer on, also the spaghetti detective to stop the printer if it detects that the printer is failing, is this something that can be done with the duet Interface or in the case this is not possible s there any concerns on using them in tandem?

-

@aldiallo said in Fine tunning setup for Ender 5 plus:

I assume that I can enable auto home and autobed level calibration and also enable resume printing on power loss by adding relevant commands on my config.g file, correct?

I'm not exactly sure what you're asking.

https://duet3d.dozuki.com/Wiki/Using_mesh_bed_compensation

https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors

https://duet3d.dozuki.com/Wiki/Setting_up_to_resume_a_print_after_a_power_failure@aldiallo said in Fine tunning setup for Ender 5 plus:

is this something that can be done with the duet Interface or in the case this is not possible s there any concerns on using them in tandem?

Not at the moment. Plugins and using an rpi with the duet are in the works.

You can use octoprint with the duet, though it's not recommended and you do lose some features.

-

This post is deleted! -

@Phaedrux said in Fine tunning setup for Ender 5 plus:

Hi Phaedrux,

My question is if those "features" are enabled by adding the relevant commands in the config.g file, for example to resume printing after power loss, do I just add the below in config.g or this should be on it's own file:

M911 S21.0 R23.0 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000

The above is just the example on the link you provided.