Inconsistent results with optical encoder wheel filament sensor

-

@JohnOCFII What version are you running?

I can make a test build with a "Filter-time" parameter in the setup that ignores multiple edges for a minimum time before counting progress again.

I think you could set the time to 0.2 Seconds and you'd then get good results.

How fast were you extruding compared to the range of extrusion speeds you expect to use?

-

@JohnOCFII Or I could make you a test build with a new filament sensor type that says: "Filament is present if I get an edge at least every <Q> millimeters of filament when extruding."

-

@alankilian said in Inconsistent results with optical encoder wheel filament sensor:

@JohnOCFII What version are you running?

Board: Duet 2 Ethernet (2Ethernet)

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.1.1 (2020-05-19b2)I can make a test build with a "Filter-time" parameter in the setup that ignores multiple edges for a minimum time before counting progress again.

I think you could set the time to 0.2 Seconds and you'd then get good results.

How fast were you extruding compared to the range of extrusion speeds you expect to use?

That capture was made at 15mm/sec. My standard profile goes up to 150mm/sec for infill.

-

@alankilian said in Inconsistent results with optical encoder wheel filament sensor:

@JohnOCFII Or I could make you a test build with a new filament sensor type that says: "Filament is present if I get an edge at least every <Q> millimeters of filament when extruding."

Hmm... Yes, that might be the most straightforward thing to try.

-

bouncing is 70-100ms .. that's long, but if that analog capture is any good the signal is actually pretty straightforward and just using ST as mentioned by @alankilian might solve 99% of the issues ... it will not solve them all, but if that analog part is true ST will get it to usable state.

74LVT14

power with 3v3, output will be 0/3v3, and input is 5V tolerable (actually survives up to 7V)

-

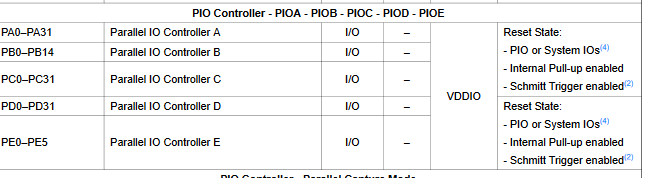

you are using connlcd3 or ENC_B and that's from what I see PC7 pin

from the datasheet

I think PC7 can be configured and Schmitt input directly in the firmware. I can't find here if we can configure pin as Schmitt input by addingt something to the name like we can for invert and pullup. IMHO any endstop input should be configured with Schmitt input, dunno if it is or not...

-

@arhi said in Inconsistent results with optical encoder wheel filament sensor:

you are using connlcd3 or ENC_B and that's from what I see PC7 pin

IMHO any endstop input should be configured with Schmitt input, dunno if it is or not...

I'm thinking I should try a different end stop connection to test. I can do that tomorrow afternoon.

In the meantime, I was winding down for bed with a little light reading: https://www.digikey.com/htmldatasheets/production/386707/0/0/1/74lvt14.html

-

Well, this is interesting.

I moved the filament sensor from the

CONN_LCDconnection to theE1_STOPconnection. I ran a similar vase mode cylinder (no top or bottom) and my DUET M591 results were much more consistent than anything I've seen. Speed was 15mm/sec.Pulse-type filament monitor on pin e1stop, disabled, sensitivity 1.200mm/pulse, allowed movement 30% to 1500%, check every 5.0mm, measured sensitivity 4.054mm/pulse, measured minimum 28%, maximum 32% over 527.0mmI can update the L parameter to be 4 and try again.

I also captured a trace, and the Saleae still sees the messy start and end of the pulse. If these tests hold up, does that imply that the Duet RRF firmware is treating the CONN_LCD connection differently the the other endstops?

Here's a link to the Saleae capture for the above test: https://1drv.ms/u/s!ApuOkxTDmZEzgf2ue8OdskJFAV4KT9Q?e=ucEW8v

-

@JohnOCFII maybe when pin for e1stop is configured the schmitt trigger input is turned on.. or there's input buffer with schmitt trigger input on the board already... but 28-32% seems very good

-

@arhi said in Inconsistent results with optical encoder wheel filament sensor:

@JohnOCFII maybe when pin for e1stop is configured the schmitt trigger input is turned on.. or there's input buffer with schmitt trigger input on the board already... but 28-32% seems very good

Could be. Now to do a few more tests to confirm that wasn't a fluke. I'll do another vase mode test, then move on to a regular print that includes a variety of moves up to 150mm/sec. I may also try the original wheel with more, thinner spokes.

John

-

Here's a longer vase mode cylinder. Not quite as tight as the last one, but still a reasonable range, it would seem.

Pulse-type filament monitor on pin e1stop, disabled, sensitivity 4.000mm/pulse, allowed movement 30% to 1500%, check every 5.0mm, measured sensitivity 4.060mm/pulse, measured minimum 86%, maximum 109% over 1023.1mm -

@arhi said in Inconsistent results with optical encoder wheel filament sensor:

dunno that sound really bad, maybe move the connection to the

C"^e0stop"connector, dunno if it makes a difference but I'm not getting that big span on that pin

-

Sure - I can try e0stop. I'll do that tomorrow. I'd agree the result isn't great - but it was better than those results I had racing above 1000.

-

@JohnOCFII e0stop is for sure identical as e1stop

no need to test e0stop if you are already found that e1stop will work ok

no need to test e0stop if you are already found that e1stop will work ok

-

@arhi said in Inconsistent results with optical encoder wheel filament sensor:

@JohnOCFII e0stop is for sure identical as e1stop

no need to test e0stop if you are already found that e1stop will work ok

no need to test e0stop if you are already found that e1stop will work ok

Yeah, I certainly hope e1stop and e0stop are treated the same in the firmware.

Now to do more testing and see what sort of range I'll get. I'm sure as I move back to a normal profile with Z-hop, pressure advance, etc, the bounds will get larger. I figure I'll do a few more of these consistent 15mm/sec tests, perhaps with different encoder wheels, to see what range I'll get under ideal conditions. It is also worth watching the logic analyzer to see if I'm getting consistent patterns.

-

[EDIT] I got myself confused into thinking these bounces were incoming signals on this pin and tht the filter would help reduce them.

BUT the bounces are really just threshold-crossings due to a slowly-moving signal and so this filter will not improve it. It actually makes the situation worse (depending on how much is due to the LED/Receiver slowly changing and how much due to noise on the signal wire.)

So, don't listen to what I say below.

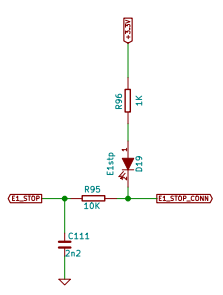

@JohnOCFII The schematic shows a lowpass filter on the E1_STOP input pin that is not on the ENC_B pin.

It's got a cutoff frequency of about 8000 Hz which would get rid of some of those bounces.

If you want to, you could try to probe one of C111 or R95 and you could see the signal that's actually getting to the micro controller.

-

Wow you've gone hard at it; it's been incredibly valuable going through the thread

I always had wide range but fairly consistent with mine; so I settled with increased tolerances and call it a day

It seems that RRF 3.2 changes the way it deals with filament sensor; could any of the changes be relevant to improving sensor accuracy?

https://github.com/Duet3D/RepRapFirmware/blob/v3-dev/WHATS_NEW_RRF3.md

-

@alankilian said in Inconsistent results with optical encoder wheel filament sensor:

[EDIT] I got myself confused into thinking these bounces were incoming signals on this pin and tht the filter would help reduce them.

BUT the bounces are really just threshold-crossings due to a slowly-moving signal and so this filter will not improve it. It actually makes the situation worse (depending on how much is due to the LED/Receiver slowly changing and how much due to noise on the signal wire.)

So, don't listen to what I say below.

So -- it might still be worth building the separate debouncing Schmitt trigger?

-

@JohnOCFII Yes, I think adding a Schimtt-Trigger would be the best way for you to get repeatable results.

Any old Schmitt-trigger input device will work for you as long as it can deal with 3.3 Volts. You don't need a fancy high-speed one.

CD40106 would work well. If you want a DIP package, here's one:

https://www.digikey.com/en/products/detail/texas-instruments/CD40106BE/376602Also, I had lunch with Otto Schmitt one time. He was an interesting fellow.

If you want help wiring it up, let me know.

-

@alankilian said in Inconsistent results with optical encoder wheel filament sensor:

@JohnOCFII Yes, I think adding a Schimtt-Trigger would be the best way for you to get repeatable results.

Any old Schmitt-trigger input device will work for you as long as it can deal with 3.3 Volts. You don't need a fancy high-speed one.

CD40106 would work well. If you want a DIP package, here's one:

https://www.digikey.com/en/products/detail/texas-instruments/CD40106BE/376602Also, I had lunch with Otto Schmitt one time. He was an interesting fellow.

If you want help wiring it up, let me know.

I'll order a couple from DigiKey. Need to think up a few others things to add to the order. It just feels weird to order something for under a dollar, than pay $8 in shipping...

I'll post my guess at wiring after looking at the datasheet and before I power up anything.

Thanks!

John