"Z" axis problems CNC

-

Yes, the Z axis should go up and trip the relay but instead just grinds and slowly moves down toward the bed. I will try to send more info.

-

Please copy and paste the text instead of screenshots.

you can also use the code formatting to make it more readable

-

Sorry but I'm not sure I understand what you mean by text.

-

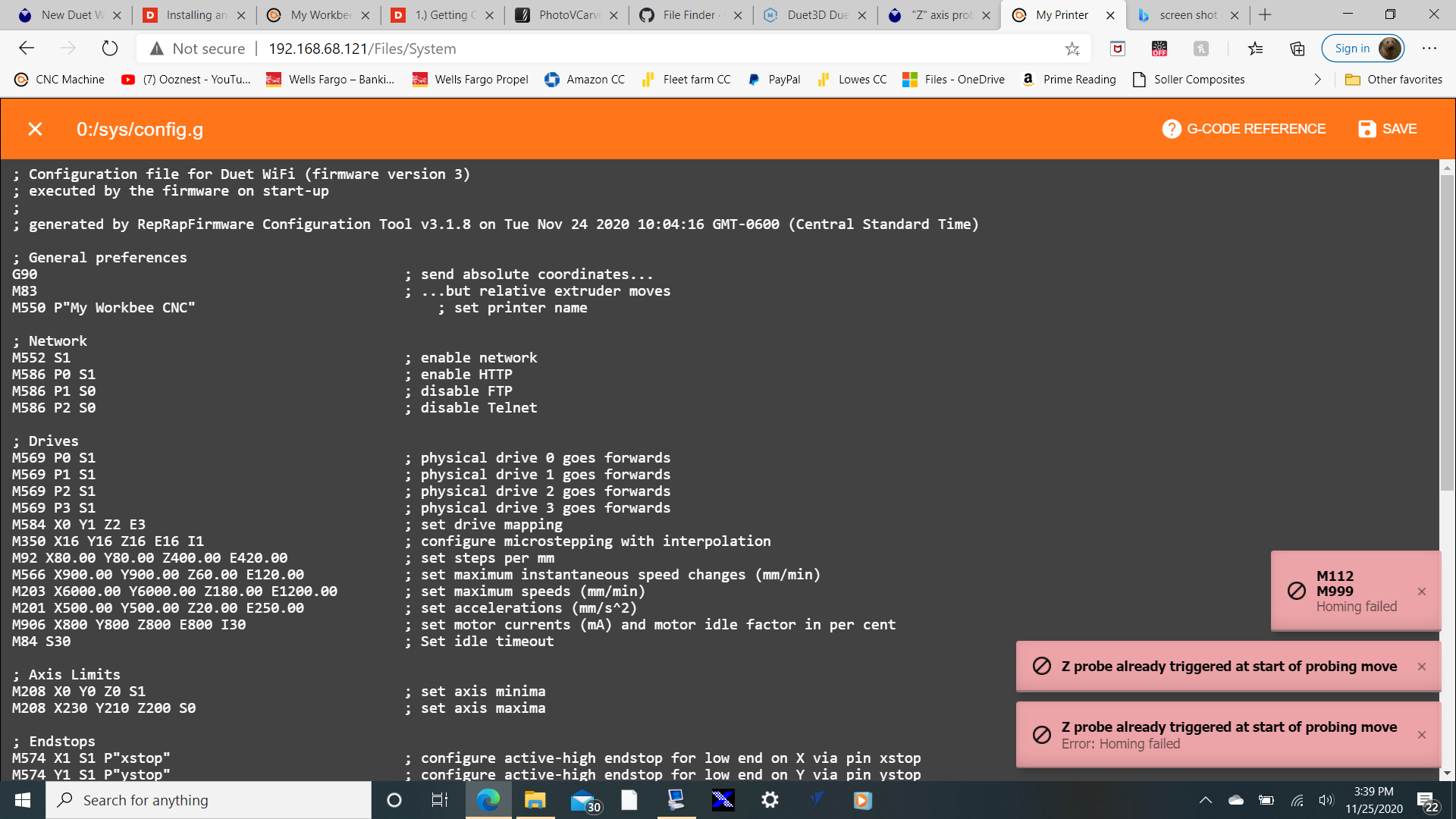

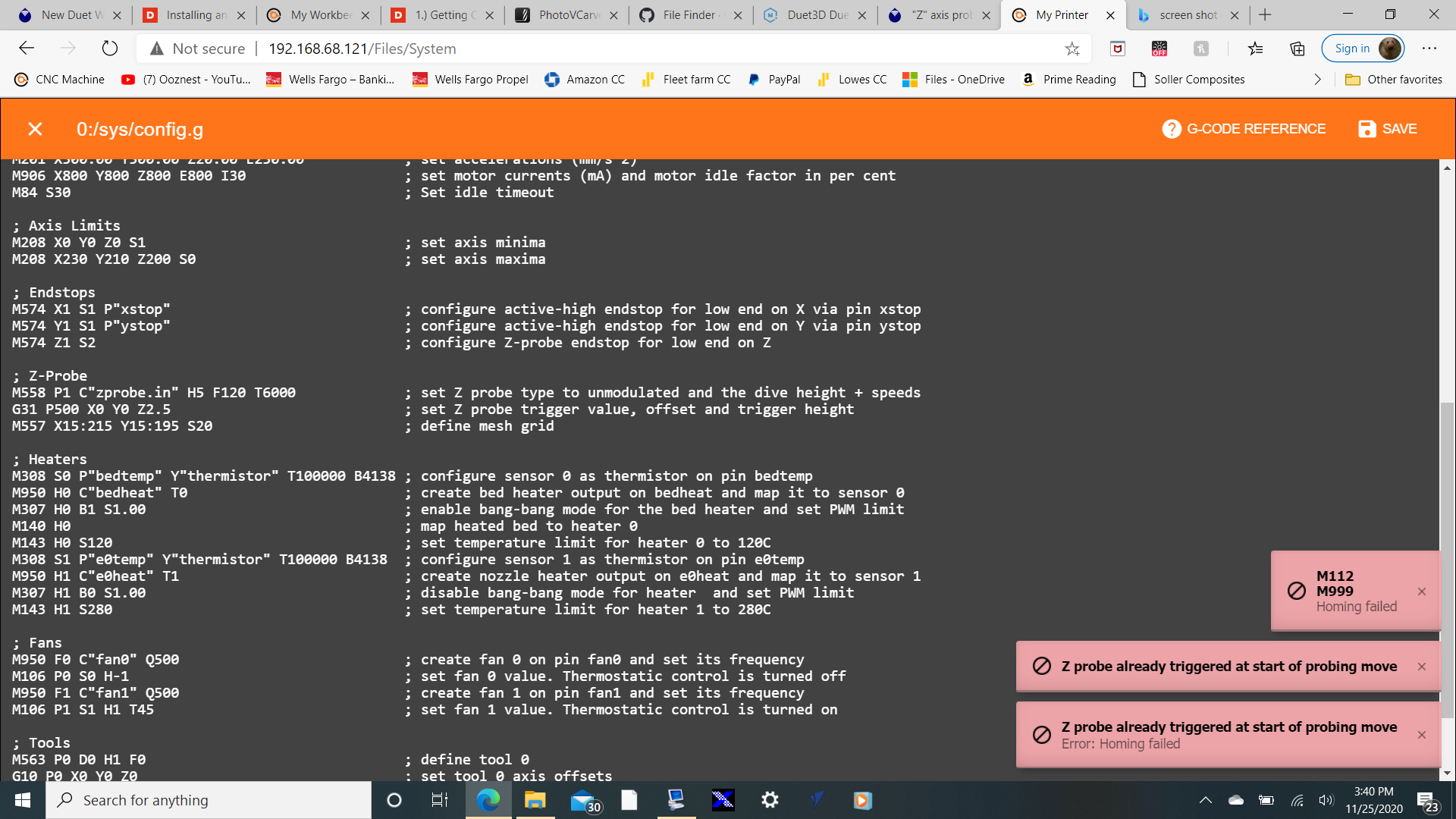

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.8 on Tue Nov 24 2020 10:04:16 GMT-0600 (Central Standard Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Workbee CNC" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X230 Y210 Z200 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M558 P1 C"zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X15:215 Y15:195 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

homeall

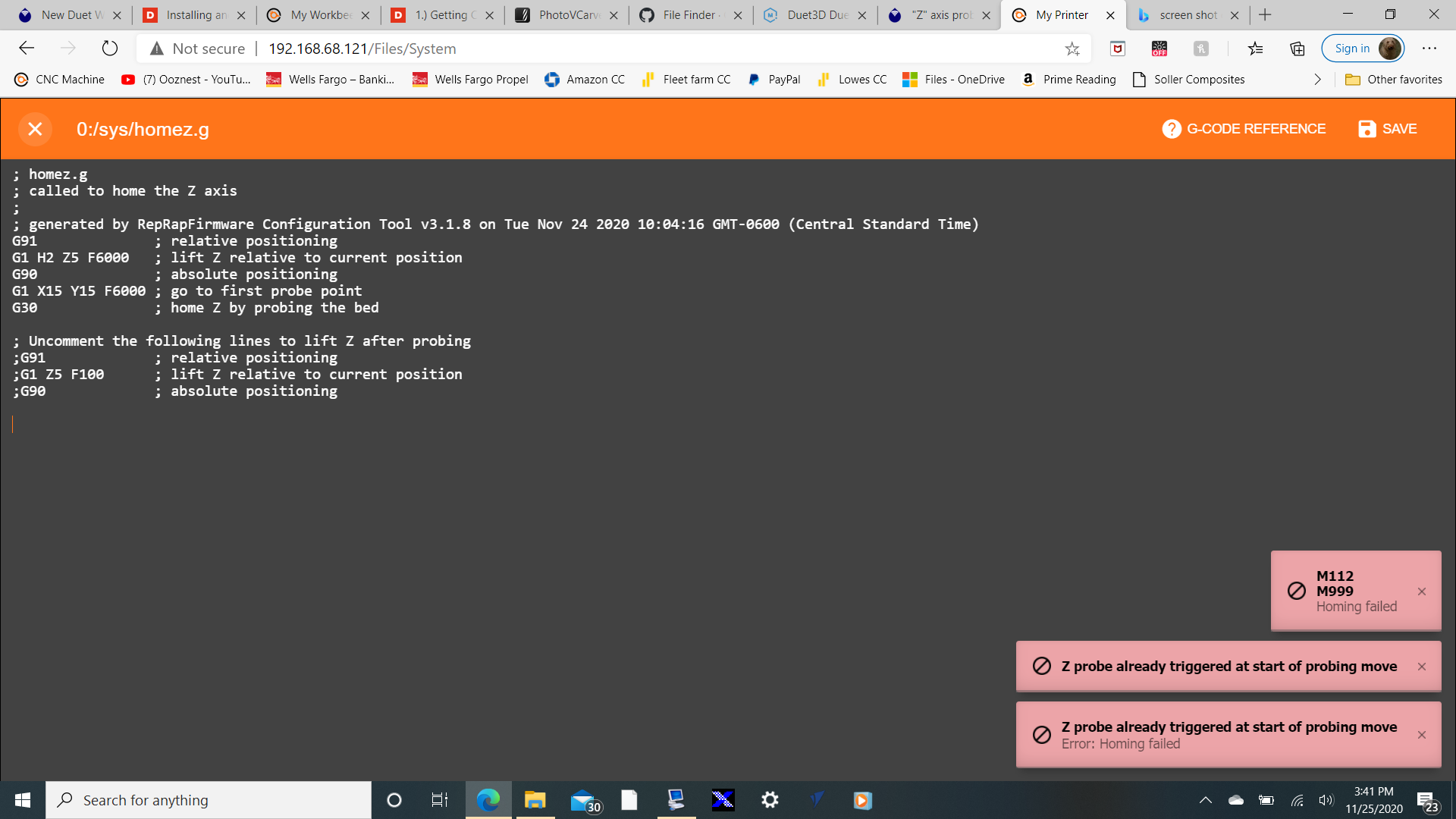

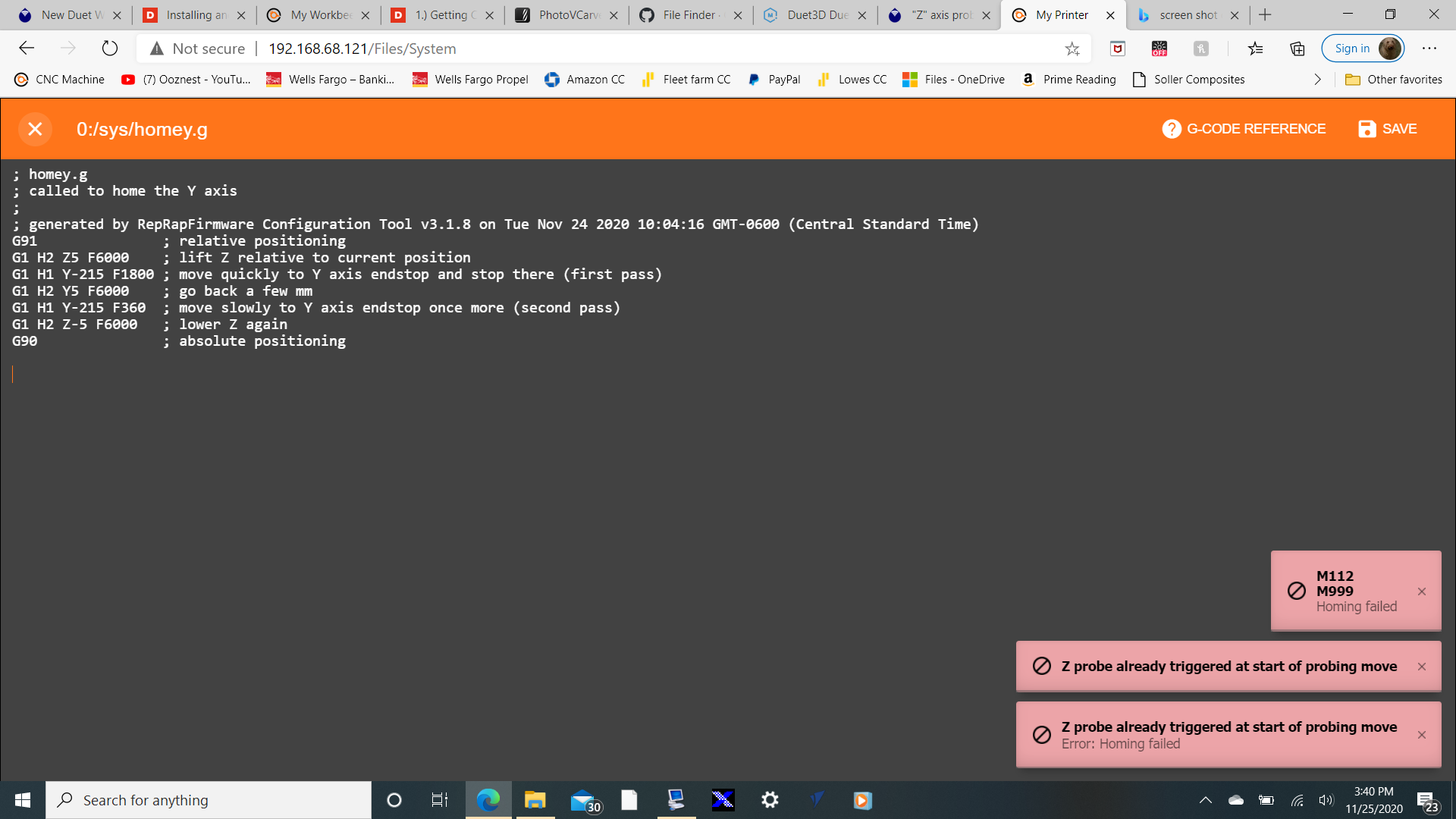

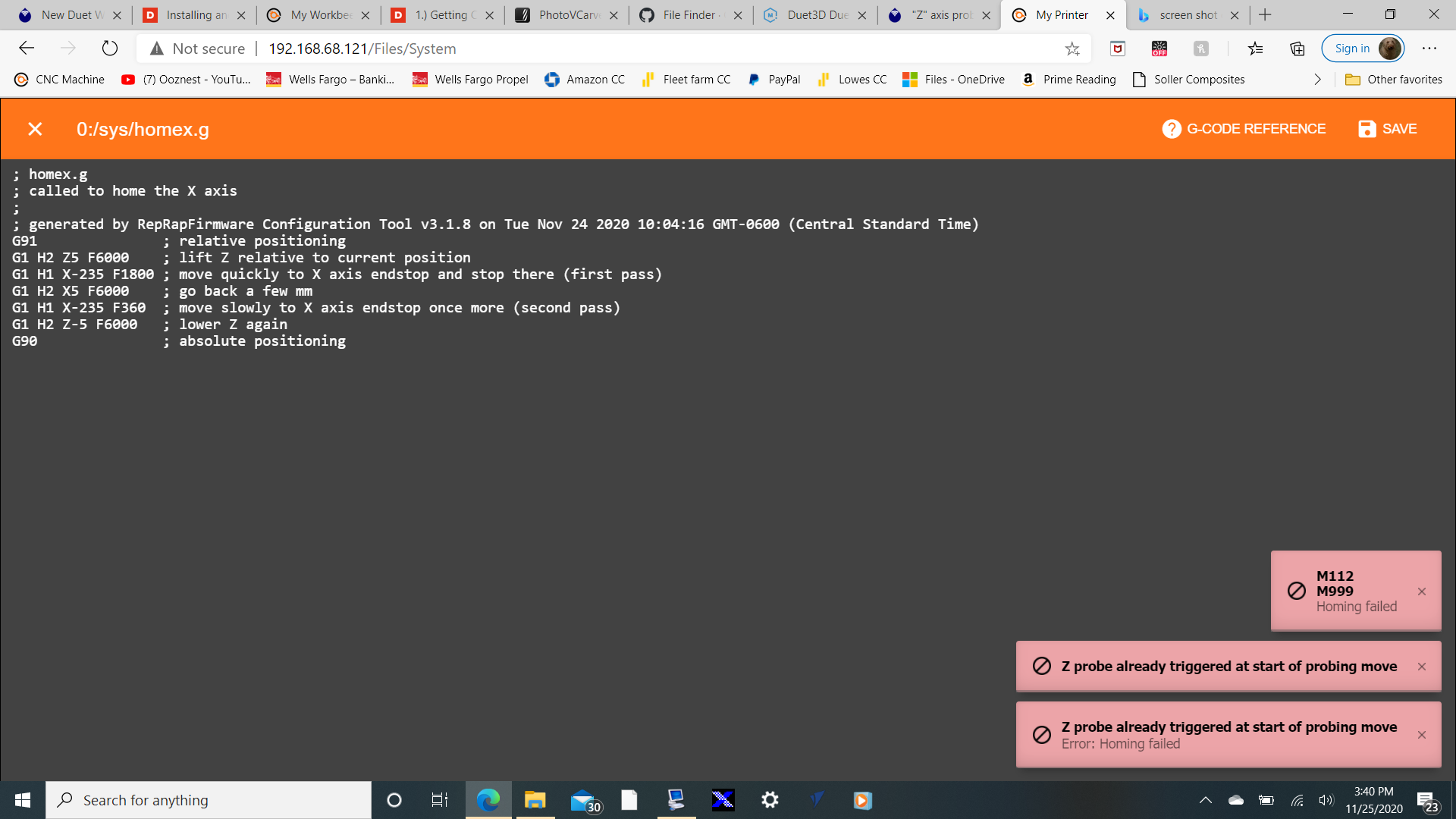

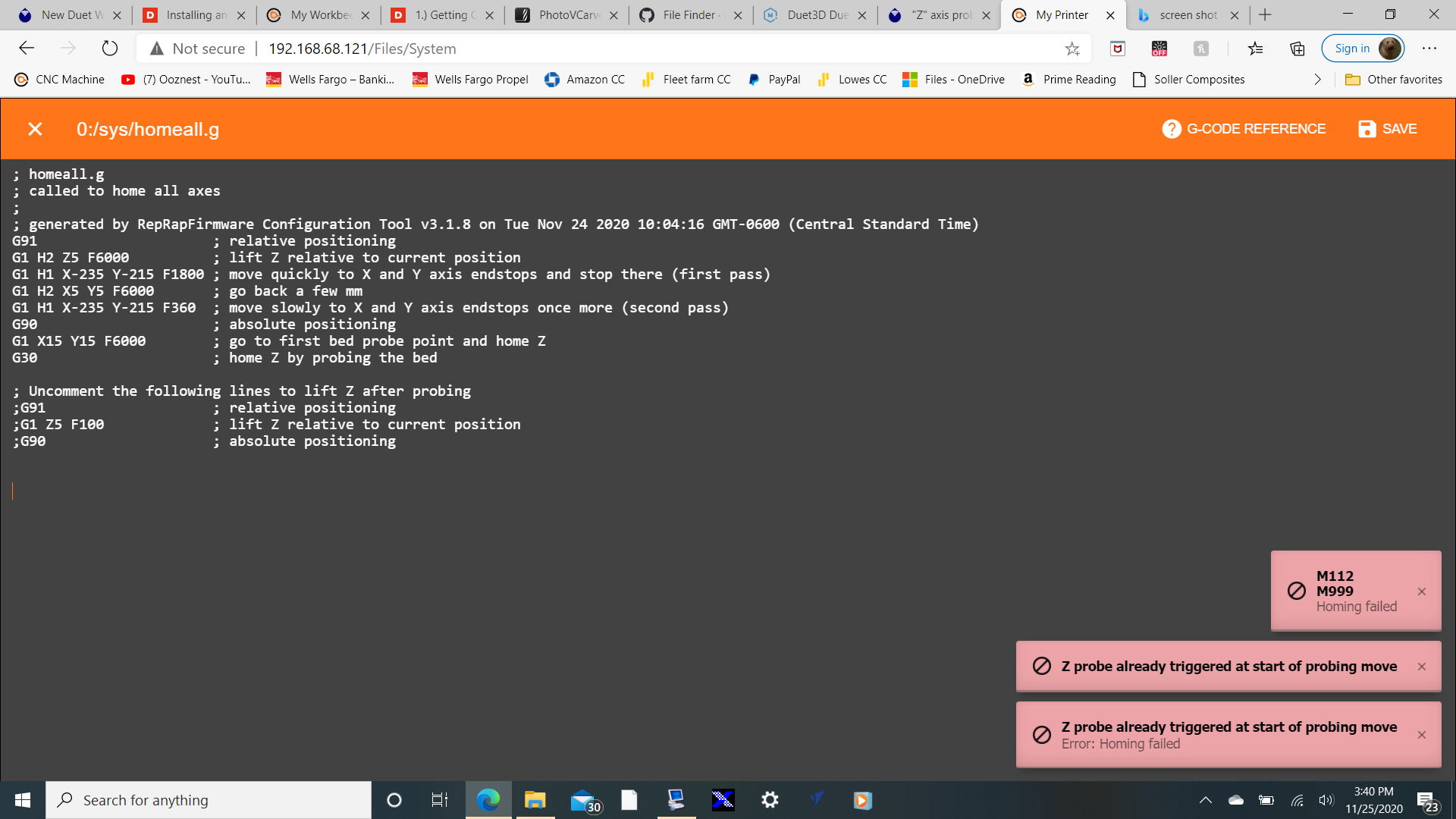

; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v3.1.8 on Tue Nov 24 2020 10:04:16 GMT-0600 (Central Standard Time)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-235 Y-215 F1800 ; move quickly to X and Y axis endstops and stop there (first pass)

G1 H2 X5 Y5 F6000 ; go back a few mm

G1 H1 X-235 Y-215 F360 ; move slowly to X and Y axis endstops once more (second pass)

G90 ; absolute positioning

G1 X15 Y15 F6000 ; go to first bed probe point and home Z

G30 ; home Z by probing the bed; Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioning -

@onescentpro said in "Z" axis problems CNC:

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mappingI take it you're using stepper motors with the built in drivers and not servo motors?

If z is going the wrong way the simple explanation is perhaps to have plugged it the wrong way around (although if using the supplied connectors that's not something you do by accident)

if you've tried another motor and another board then you're left with the wiring, one of the conductors coming loose sounds like it could be a good fit, but the duet normally alerts to a disconnected phase.

-

@onescentpro might be a result of the issue rather than the cause, but given your screenshot show an error message 'Z probe already triggered at start of homing move' I'd start there. What type of probe are you using? What value does the probe show in DWC normally/when you tap it by hand?

Maybe try using the R parameter in your M558 so there is a pause for it to settle?

https://duet3d.dozuki.com/Wiki/Gcode#Section_M558_Set_Z_probe_typeI'd also double check the wiring to it

RE Bearer's posting comment, there is a formatting option on the forum when putting your coding which puts it in nice boxes etc to make it easier to read (like the line of text he put). The option is two over from bullet points at the top (you can see in his screenshot).

-

@bearer , Good morning, I saw and old post from you that mentioned you could log into my computer and take a look. Is that a possibility for you?

-

@engikeneer Thanks for the reply. I am using the endstops supplied by Ooznest. I have checked the wiring to the stepper motor and its fine. The endstop appears to working fine when I manually close it the light comes on on the Duet so I think it's fine.

-

@bearer I am using everything that was supplied for the Workbee from Ooznest. Yes, I am using steppers controlled by the Duet

-

@onescentpro said in "Z" axis problems CNC:

I am using the endstops supplied by Ooznest

So no Z probe at all?

Your config.g and homing files are setup as if you had a Z probe. Please let me know if that is the case or not.

-

Thanks for all the input. I got everything up and running. So thanks to all who helped me with this problem.