Trianglelab Matrix Extruder somebody?

-

Quality similar to E3D & co, then?

Or would trying to obtain and modify a genuine Hemera deliver a more robust extrusion? -

@DaBit It is always advisable to pay the inventor for there work.

-

It sure is, and in the end reliable operation and endurance is worth more than a few bucks, at least for me it is. Hemera uses hardened gears, what about TriangleLab, for example?

But, there are no liquid cooled Hemera's yet so if you want one you have to modify it yourself. I do have a CNC mill, so it can be done. Then there is only the next issue: try to buy one. Out of stock everywhere.

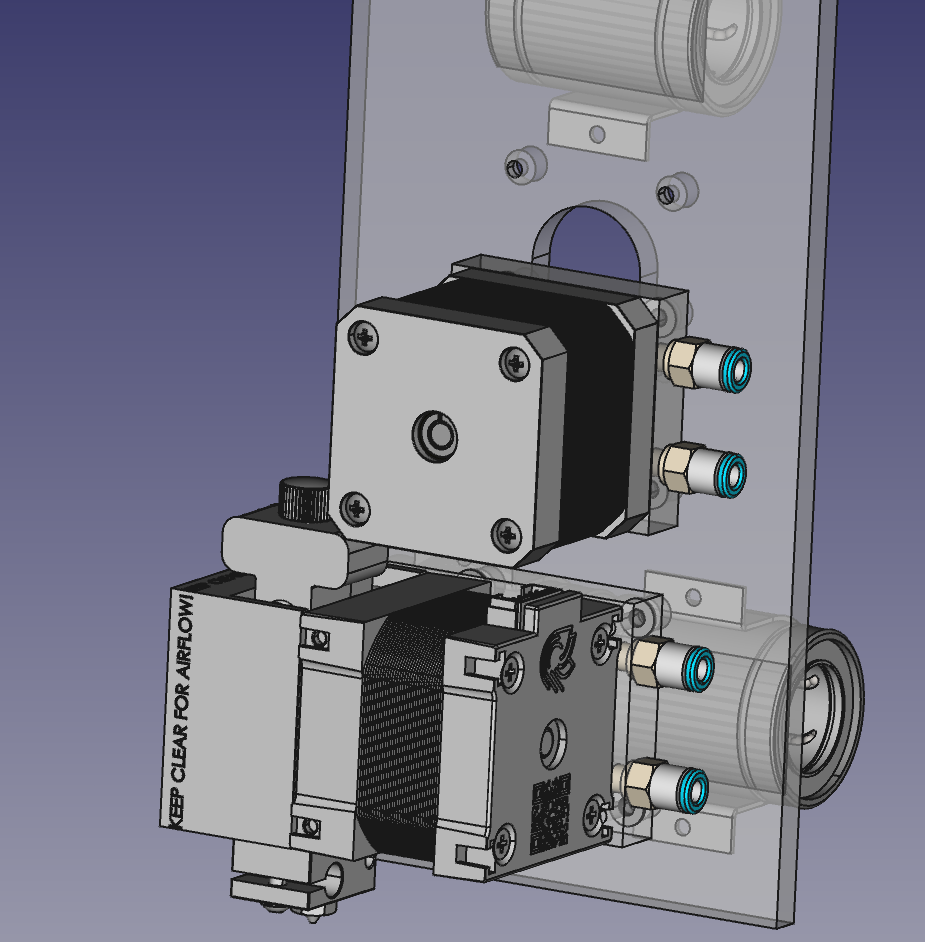

My quite unfinished idea about making the Hemera 150C-chamber-resistant (and my first FreeCAD experience; wanted to see if it is a viable alternative for Fusion, and I am only going to figure that out by doing a real project with it):

Cooling blocks are drawn as simple cross-drilled pieces of tooling plate. A bit of insulation around the stepper and they can keep cool enough. Would be fairly easy to make the Hemera block L-shaped. But still, if TriangleLab already offers a watercooled version and quality is decent...

-

@DaBit I fully agree and I do not wanted to start a clone/noclone discussion. I avoided the word clone so far for that reason.

The watercooling could be a very good reason than. I ordered two today and I will replace them with two original when they are available.That is a interesting implementation.

-

@Veti said in Trianglelab Matrix Extruder somebody?:

triangelabs is among the top stores on aliexpress if not the best store

+1. Very good quality and good reputation in general and they often improve on the brand names (e.g. better silicon socks than E3D or smaller 5i paneldue).

How does the weight ( 414g) and esteps (335.4 with x16 microsteps) compare to the Hemera?

I think that my BMG + 150g 0.9deg steppers beat it on both counts.

-

@zapta said in Trianglelab Matrix Extruder somebody?:

How does the weight ( 414g)

my hemera weighed in at 368

-

@bearer said in Trianglelab Matrix Extruder somebody?:

my hemera weighed in at 368

That's pretty good. IIRC they have a larger than needed (?) stepper for a X3 geared extruder and could go even lighter.

-

as for watercooling, I do have a spare heatsink but haven't bothered milling it flat as the bearing support protrudes a little on the surface limiting the available area for potential flattening so bolting a cots water block to is probably won't fly. soldering a section of tubing to it proper-printing-style might work but

@zapta said in Trianglelab Matrix Extruder somebody?:

IIRC they have a larger than needed (?) stepper

i think there has been talk of a pancake version, but whatever issues they're having seems to push that back. my next hemera will be the pankcake version and direct drive (maybe)

-

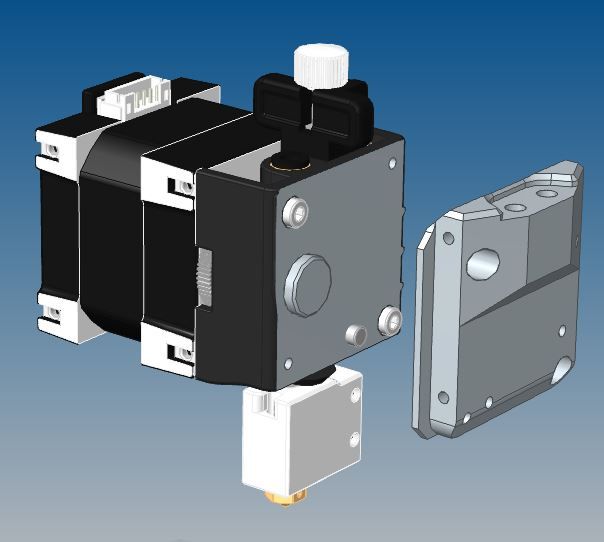

Here is a watercooling mod for hemera I've build for my printer Hydra:

-

@rabbit : Now THAT is quite a nice design! Would you mind sharing it if I manage to find a Hemera?

Does anyone know if the Hemera gear train is for sale anywhere? The stepper, heat break and heat sink seem to be available in local shops, I don't need the V6 hotend stuff since I have plenty of that, so about the only part missing to build up a Hemera is the gears.

-

nsfw! but not easily replicated with basic tools/skills i guess

your rending perfectly illustrates why my optimistic idea of just milling a flat and bolting on a cheap water block isn't practical with the porturtion for the bearing.

-

@bearer said in Trianglelab Matrix Extruder somebody?:

your rending perfectly illustrates why my optimistic idea of just milling a flat and bolting on a cheap water block isn't practical with the porturtion for the bearing.

well now you have a reason to build a cnc machine

-

@Veti said in Trianglelab Matrix Extruder somebody?:

well now you have a reason to build a cnc machine

i have one of the finest 300x400 cnc routers made from chinesium, it just needs a lot of tlc

tbh i'd be more likely to try to cast it in alu using lost pla, some day

-

After an exhaustive search for a Hemera or a Hemera in replacement parts I gave up and ordered a Matrix LC. We shall see.

If E3D stocks Hemera's again before I need the second extruder I have some comparison. -

Mine is now at my country. Will Post Pictures!

-

@Chriss said in Trianglelab Matrix Extruder somebody?:

I will pass the deep dell of doom aka "china noble scrap"

There are all kind of metal-extruder-body-as-heatsink extruders in the market, some predated Hemera. For example, those metal BMG's that are available for some time.

-

My 3D-printer adventure started when somebody gave me a Geeetech extruder and another guy gave me some 40x40mm aluminium extrusion. That Geeetech thing was The Definition Of Crap. Now, I know that most China stuff is at best a good starting point; they gave you a bunch of parts that they pre-assembled so you know how they shoudl fit together, but it is your task to deburr, clean and grease everything. But seriously, in the end the only thing that could be recycled was the heater cartridge. A complete waste of materials.

Switched to a Bondtech QR extruder, created my own hotend, and had a flawless experience which is worth more than a few bucks.

We'll see what happens this time.

-

@bearer said in Trianglelab Matrix Extruder somebody?:

i think there has been talk of a pancake version, but whatever issues they're having seems to push that back

The explanation I heard here (from dc42?) was that a larger stepper simplifies upgrades since it can use the existing current setting (not easy to change on some controllers).

Bondtech seems to do the 'right' thing and go with a smaller motor on their upcoming integrating direct extruder. Probably similar to the 150g LDO they recommend for their BMG. It may be a nice upgrade for my printer.

They team with Slice Engineering to compete with E3D in the extruder + hotend market.

-

@zapta said in Trianglelab Matrix Extruder somebody?:

They team with Slice Engineering to compete with E3D in the extruder + hotend market.

very nice. i think this will be better than the hermera.

copperhead heatsink

smaller footprint.but i kind of wish they included some screw holes in the from to mount a part cooling fan.

-

I like the Bondtech stuff. Was running the QR, now I am running the BMG-X2. Exactly zero issues with those.

The only thing I don't like about them is the plastic they use (lasersintered nylon?). It is fairly soft and it tends to deform slightly when used above a 100-110C bed in an enclosed chamber which also heats up to 60C or so in those conditions. Internal stresses I suppose.That is why I am interested in the Hemera above Bondtech; housing is made of metal, gears are made of metal.