Bug? In Retraction and Movement Junction

-

@jatmn said in Bug? In Retraction and Movement Junction:

I am guessing this is in relation to your set 1.5mm retraction where I was using 1.25mm or the possible slight speed differences in our retraction settings.

Yes, it's 1mm of retraction but the speeds are likely different to yours. You'd have to tune that as well.

@jatmn said in Bug? In Retraction and Movement Junction:

However, it has little to no impact on the stop points.

I'm not sure why you think that. It would have an impact on both. Think about what it's doing. It's shifting the amount of extrusion forward or back in time. It's reducing the amount of extrusion before a stop.

Do you have an example print of the perfect seam you're aiming for? I would say the settings I gave you produced a bit nicer of a seam compared to the first one, but maybe that's just what I want to see and it's hard to tell from a photo. You've got it in hand, so if you think it's no better, I'll take your word for it. But if that's no good, what does perfection look like?

-

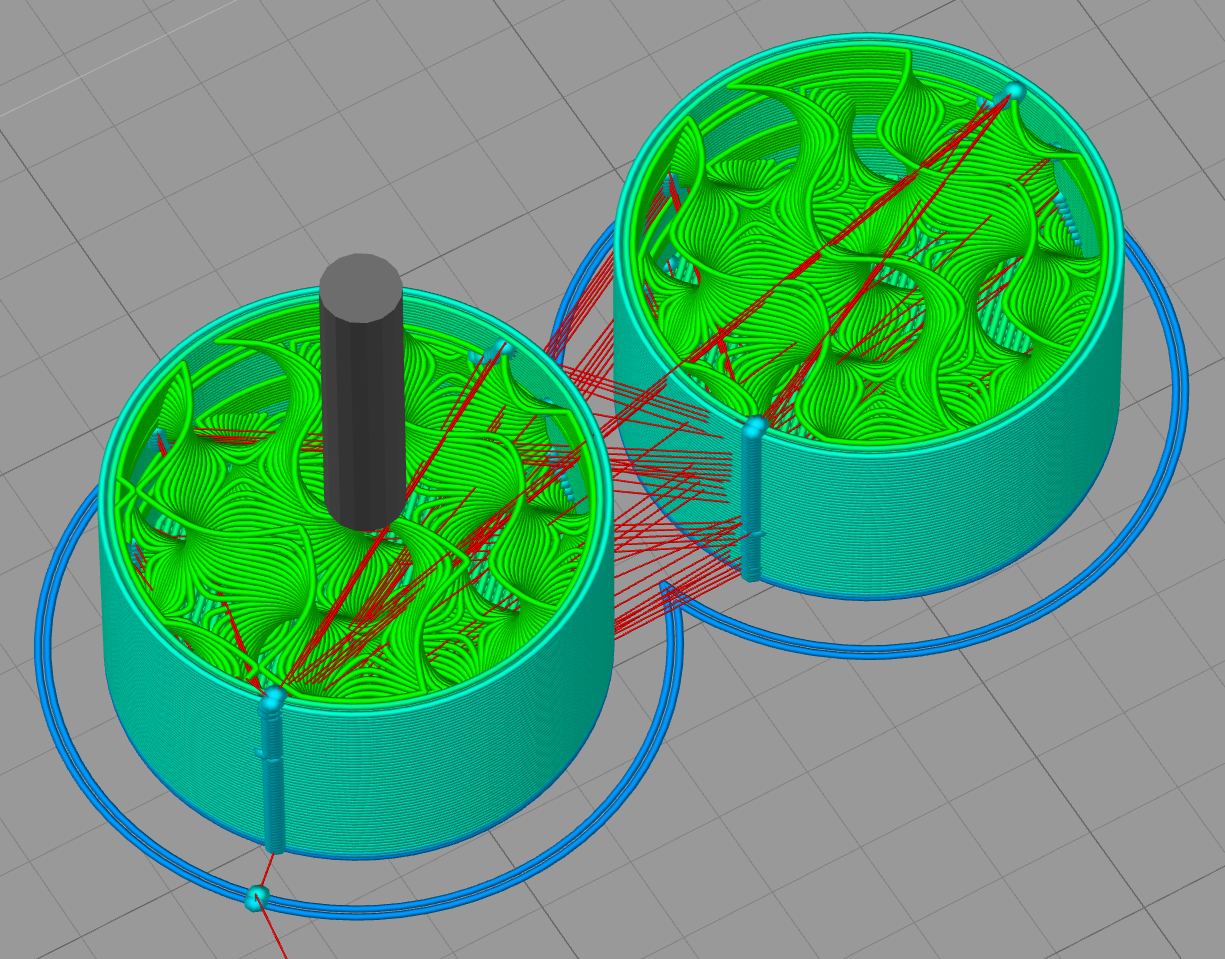

Whilst I wait for my prints to finish, I thought I'd stick this up. I opened up your gcode in simplify3d to see where the retraction points were:

You can see that you're retracting on both the inner and outer layers of the shell.

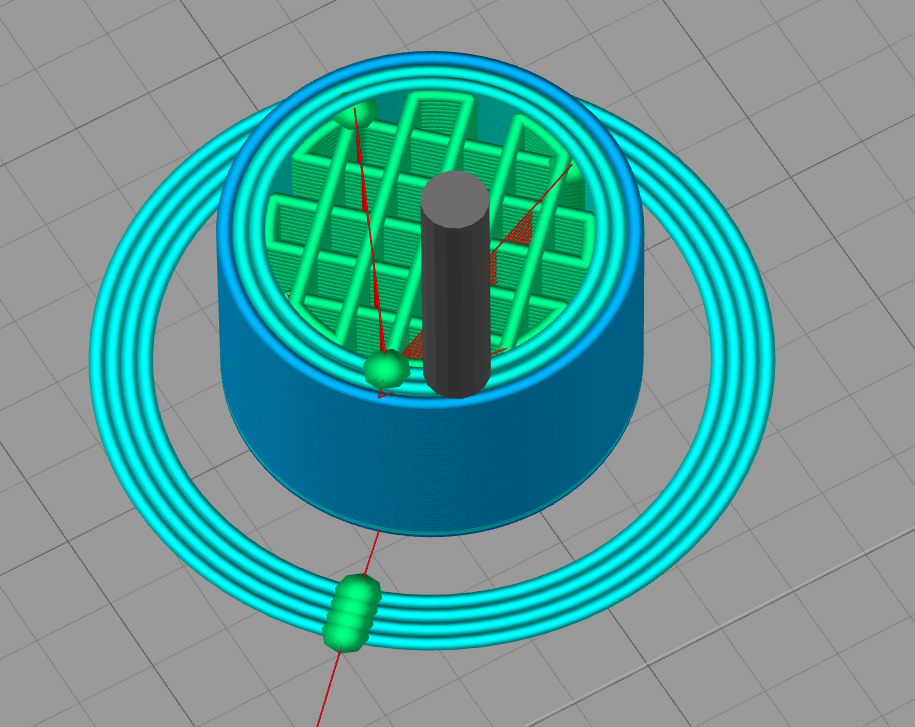

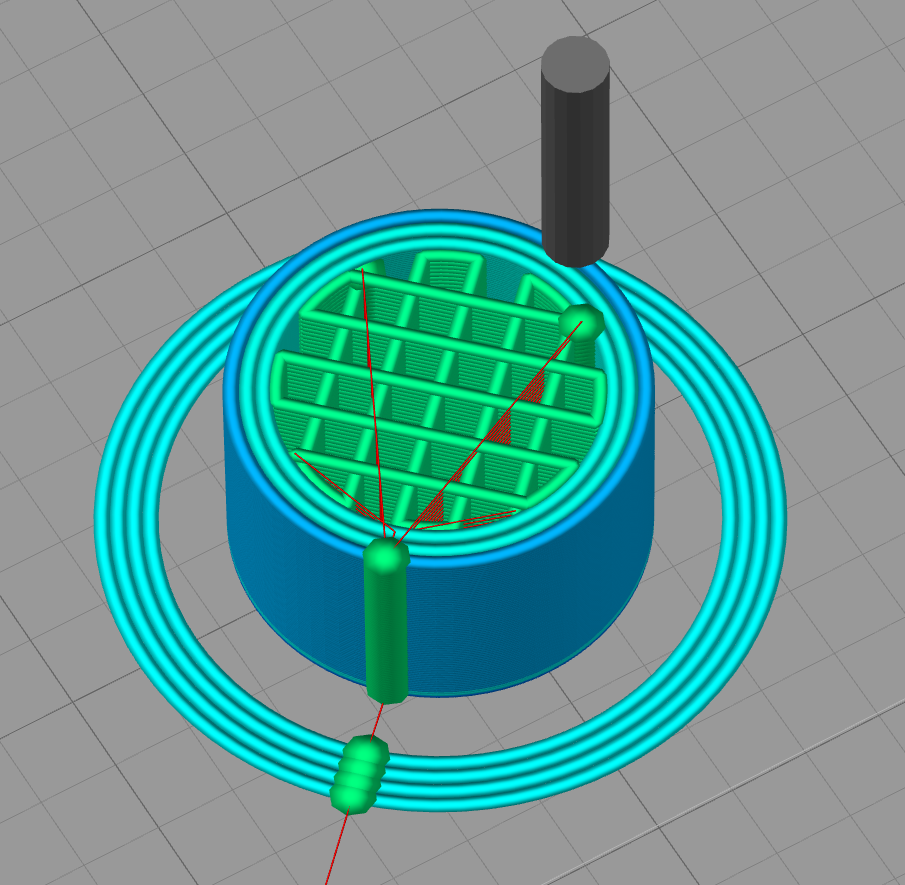

With my stock simplify3d settings a single print of your STL looks as follows:

Yes I'm doing three shells, but I'm only retracting at movements and layer changes (both turned on). There is no alignment of retractions.

I'm currently printing one inside-out, and one outside-in print to see how they differ.

At least according to the slicer, for outside-in I'll see retractions on the outer shell of the print:

-

I scaled down the model so I could get the prints out a little faster. Cut it down to 10mm and was more than enough to show the behavior. Top print is outside-in, bottom print is inside-out. The results don't match what I would have anticipated from the slicer here. Both have visible seams. With inside-out looking marginally worse.

-

Anyone can view the configuration for this printer here:

https://github.com/opsensai/sk-go-duet-config/blob/master/config.g

-

@jatmn said in Bug? In Retraction and Movement Junction:

However, it has little to no impact on the stop points.

I'm not sure why you think that. It would have an impact on both. Think about what it's doing. It's shifting the amount of extrusion forward or back in time. It's reducing the amount of extrusion before a stop.

I know this is how it's supposed to work in theory. (or by design)

However literally every one of my tests proves otherwise, or at least the results of the print are proven otherwise.

This is significantly more clearly shown when you run a 1.75mm or 2.85mm Filament on a 1mm nozzle (Which I have noted to have done already)

With an excessively high Pressure Advance value you can cause a significantly delayed start point resulting in a measurable gap between the stop and start points. (on one test I had a 1.5mm gap between the points!)

However, with that, you can still have this over extrusion effect on the stop point even with those settings.

Sorry, I don't have a picture of that, it was a test I had done about 2-3months ago.As for the result I am looking for, something like this.

Top is Original #1 test from this thread

Bottom is a random print I just did on my Prusa mini

Here is a video that details the 2 prints above

Grey is off mentioned test machine, Red is Prusa mini

Video Link(also screw Akismet.com spam checker flagging my posts as spam when I edit them)

-

@davekeogh Those are some clean prints, but I do clearly see my issue on them.

-

@jatmn Just had a quick flick through this thread so I might have missed something. But in a recent post, you mentioned a 1mm nozzle. Is that what you are using? If so, that is the most likely cause of your issues. It most certainly explains why you don't need to use pressure advance because it is highly unlikely that there would be any build up of pressure that needs to be compansated for.

Have you tried a more "normal" size nozzle?

Another thing, have you ruled out all mechanical defects? Are all the gears and hobbed bolts secure on their shafts inside the extruder? -

@jatmn cheers. I do try. I'll try the same print on my skr running RRF tomorrow.

Do you have shots from prints running Marlin?

-

@deckingman said in Bug? In Retraction and Movement Junction:

@jatmn Just had a quick flick through this thread so I might have missed something. But in a recent post, you mentioned a 1mm nozzle. Is that what you are using? If so, that is the most likely cause of your issues. It most certainly explains why you don't need to use pressure advance because it is highly unlikely that there would be any build up of pressure that needs to be compansated for.

Have you tried a more "normal" size nozzle?

Another thing, have you ruled out all mechanical defects? Are all the gears and hobbed bolts secure on their shafts inside the extruder?Uhm.. please read just the first post, forget all the rest of the thread it will give a more clear answer of whats going on.. unfortunately non of your comments applied to anything going on at all.

-

@davekeogh said in Bug? In Retraction and Movement Junction:

@jatmn cheers. I do try. I'll try the same print on my skr running RRF tomorrow.

Do you have shots from prints running Marlin?

my post just before my comment to you has a link to a video showing a print off my prusa mini vs my first print shown in tests here off the RRF test machine.

-

honesty , i read the thread and i'm yet to understand what the actual issue is ?

whats wrong with those seams ?

your mini print and the other look almost identical to me .

am i missing something ? -

@hackinistrator if you watch the last I think 5 seconds of the video I posted this appears to have the best shot at the very end of the video showing the issue.

In the video if you turn the sound up you can hear my finger nail catch on the red print (prusa mini) this is my nail catching inside the seam which is otherwise even on both sides. The grey print which is the one in question you can clearly see my nail get stuck on the seam but only going over it from one direction. This is the step in the surface between stop and start point, not a gap between the 2 that my nail catches. This is why it's only catching from one direction.

The stop point where retraction is triggered is over extruded. This results in a "bump" in the surface of the shell of the model which generally causes significant issues with parts I print as it causes issues for round objects and thru holes.

It also results in a square having one corner being budged out while the other 3 are clean. -

@jatmn ok , so you are trying to get rid of the bulge at the seam , right ?

does this happens when filament de-retracts ?

if so , use negative extra restart distance. if you have simplyfy 3d , try setting extra restart distance to -0.1 , if not enough set -0.3 , -0.6 etc ...on some filaments , i sometimes have this bulge at the start of the perimeter due to excessive pressure , even without retractions . in this case , in s3d again , go to layer change script and set G1 E-0.2 . if not good enough set G1 E-0.5 etc...

-

@hackinistrator it only happens on the stop point. Not the start point or "de-retraction"

Coasting and wiping does not resolve the issue either. -

if it happens at the end of perimeter , why are you retracting there? retraction before infill start ? for what .

show me your s3d gcode please . -

@hackinistrator I have posted gcode in this thread of 2 different examples.

And why would you not retract leaving a perimeter? Just because you leave a perimeter it does not mean the layer has completed. Im sorry I don't quite follow your logic on this one.

-

@jatmn said in Bug? In Retraction and Movement Junction:

@hackinistrator I have posted gcode in this thread of 2 different examples.

And why would you not retract leaving a perimeter? Just because you leave a perimeter it does not mean the layer has completed. Im sorry I don't quite follow your logic on this one.

the gcode file you added (from ideamaker) has firmware retraction enabled . but you didnt set any parameters in firmware retraction with m207 command .

so its using your default values (whatever they are)

so your slicer retraction setting actually DO NOTHING .

you need to decide if you want to use firmware or slicer retraction setting , them calibrate settings per need .G1 X116.010 Y94.820 E0.0458 G10 G0 F9000 X115.667 Y94.528 ;TYPE:WALL-OUTER ;WIDTH:0.450 G11 G1 F720 X116.320 Y93.820 E0.0473 G1 X117.028 Y93.167 E0.0473see G10 and G11 commands in your gcode are firmware retract and de-retract. slicer settings irrelevant

-

@hackinistrator Uhm please refer to the start of the thread. You appear to not be understanding the root issue or the tests already preformed in this discussion. As your disputing findings unrelated to your assumptions on a test that was already discussed and reviewed with the person that requested it.

-

then please upload your s3d factory file , without firmware retraction .

-

@hackinistrator

1, gcode you want is in this thread already

2, don't assume everyone uses S3D just because you do

3, it's 3am here I'm going to bed and not wasting more time on this back and forth with you.