Could 220VAC Silicon bed heater be dangerous?

-

@theruttmeister You're right, I think that grounding the alluminum plate is unuseful too....the silicon beds that you can find online have almost all the power of 750W wich is, in my opinion, a "lot" of power in terms of maximum reachable temperature....my alluminum bed is 3mm thick...

-

My heated bed is 2000w and 10mm thick

-

@the_dragonlord All good advice given above. I'll just add that if you resist the urge to fit a heater that is too powerful, then you'll avoid the possibility of the bed getting so hot that it will cause a fire. I elected to use 12mm of semi rigid insulation under mine which helps with the warm up time whilst using modest heater power.

As well as earthing everything (the plate and the frame in several places) I use an RCD which will help to minimise the risk of electrocution should the worse happen. -

@the_dragonlord said in Could 220VAC Silicon bed heater be dangerous?:

grounding the alluminum plate is unuseful

Hoping for your health and safety that that is a typo....

Here are some inspirations.....

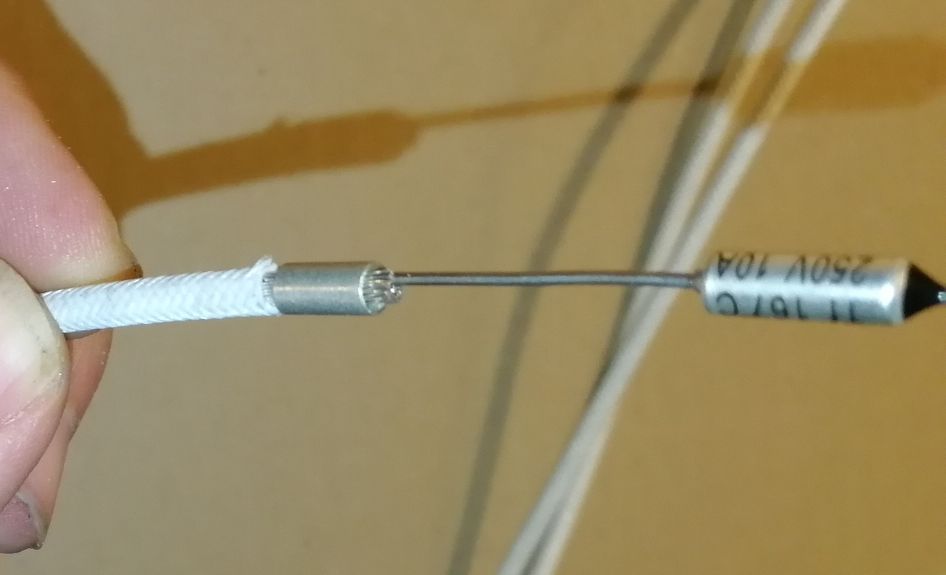

That is the uncrimped view !

-

There are devices intended for bolt mounting, e.g. https://www.digikey.com/catalog/en/partgroup/b12-series/6415

-

@the_dragonlord if the thermistor fails open, the controller will report a high temperature (2000C) and will shut off the heater. If it fails shorted it may detect that condition (does it?) and shut off the heater, too. All that assumes the controller is working properly. You should still use a TCO for protection against the controller going insane or SSR failure.

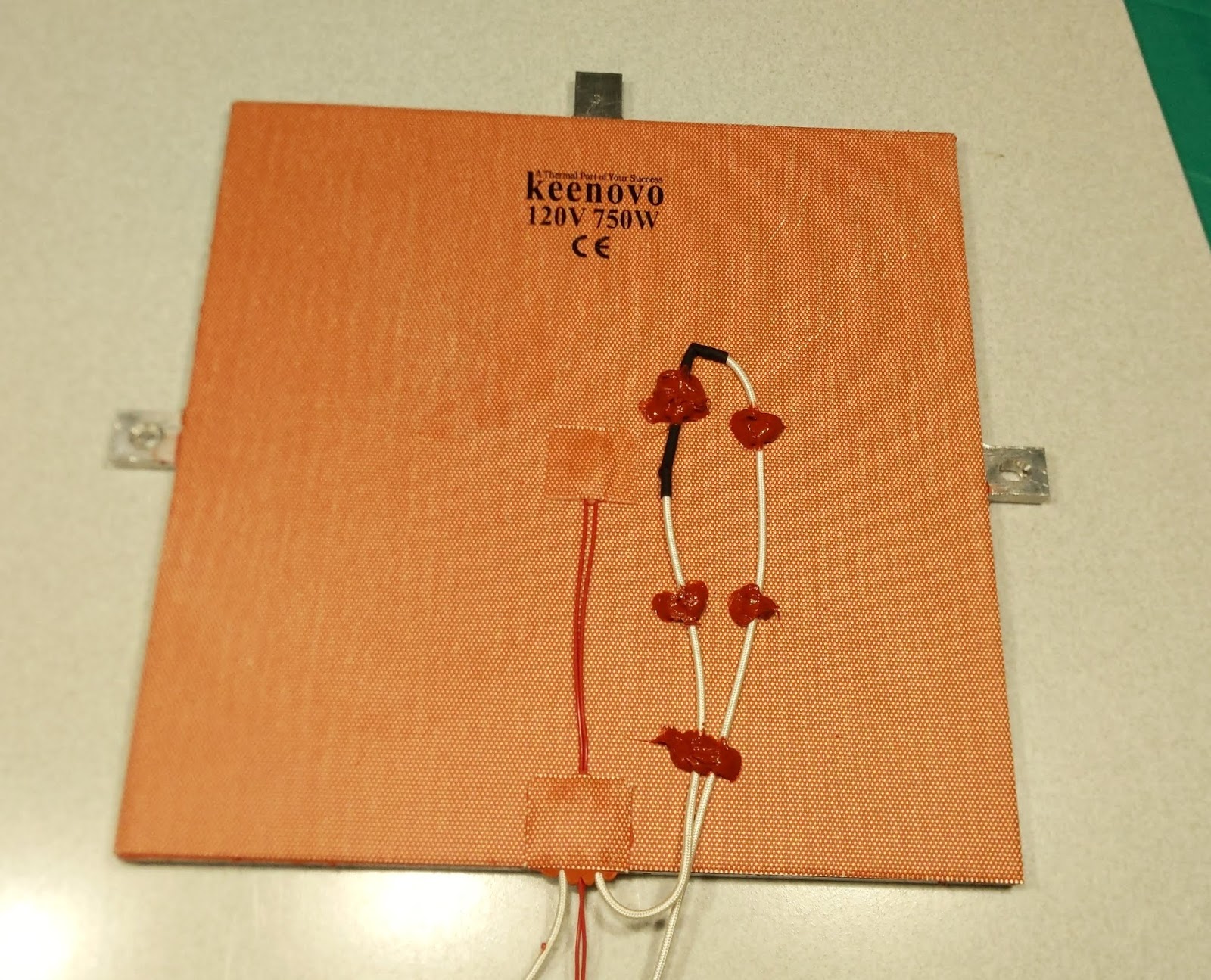

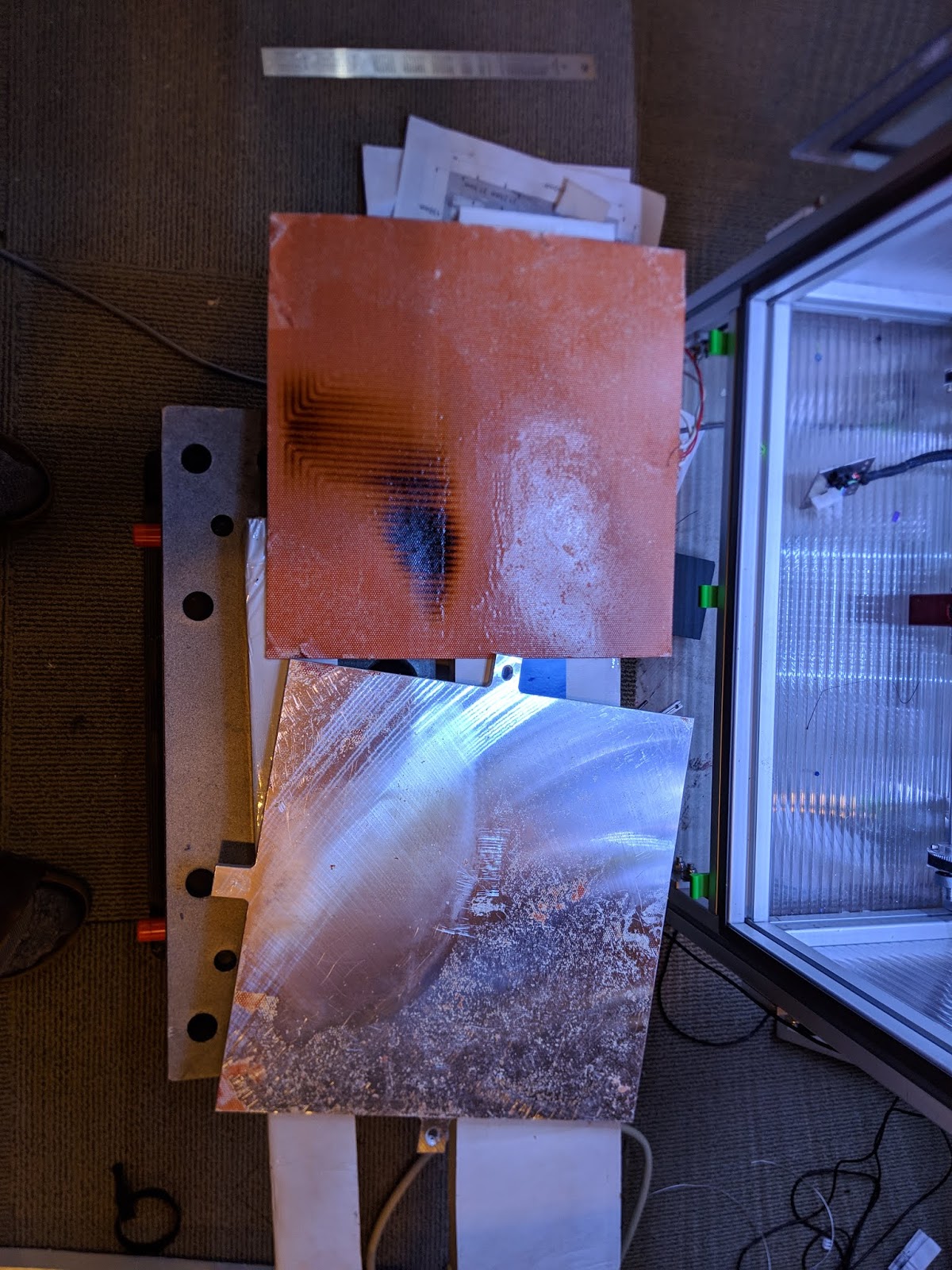

@achrn If the adhesive holding the heater on the plate fails, the heater will instantly get extremely hot and burn. If the TCO is bolted to the plate and the heater is hanging by its wires, it won't prevent a fire. It's much better to mount the TCO on the heater (if its glued to the plate) so that the TCO stays with the heater if it comes off the plate. If the heater is mechanically fixed to the plate you can mount the TCO on the plate.

The 468MP adhesive that come on some Keenovo heaters is only good for a couple years if you don't seal the edges with silicone, per Keenovo's manual, when you mount the heater. I don't know if sealing the edges per the manual extends the life of the adhesive. As the adhesive lets go, it will create air gaps between the heater and the plate that will get very hot (the plate is a heatsink for the heater).

It is better to order a heater that has no adhesive and glue it to the plate using high temperature silicone.

TCOs, fuses, and switches go on the live side of the line, not the neutral side. Opening up the neutral side gives the false impression that everything is safe but you still have line voltage applied to the circuit. That can be dangerous for anyone trying to troubleshoot or repair the machine.

Don't get cheap when buying the TCO. Fully spec'd and safety certified TCOs cost about $1 at DigiKey and other parts suppliers. This is not something to buy from the cheapest vendor on ebay or ali-express.

-

Keenovo also recommends a backing structure that applies pressure to keep the heater and heatsink in close contact. I did that using some ceramic mat normally used for repacking moped/motorcycle mufflers.

-

@DaBit Thanks for all of your answers....you made me change my mind...I'll keep my 24VDC bed...too many risks for me and they're not worth it....thanks guys

-

Your call.

I hugely prefer the lower overall energy consumption (230V->24V conversion is not 100% efficient after all), more reasonable wiring cross-section and faster heatup of a 230VAC powered bed heater.

A 24VDC heater also burns to ashes when it separates from the build plate, and grounding the build plate (and other metal parts) is always a good idea, also in a 24VDC environment.

-

@the_dragonlord said in Could 220VAC Silicon bed heater be dangerous?:

@DaBit Thanks for all of your answers....you made me change my mind...I'll keep my 24VDC bed...too many risks for me and they're not worth it....thanks guys

It's not the voltage that makes for the risks - it's the power - and the heat that it generates.

If two heaters had the same wattage rating, one low voltage the other line voltage, they both would present the same risk in regards to over heating.

Frederick

-

@mrehorstdmd said in Could 220VAC Silicon bed heater be dangerous?:

@achrn If the adhesive holding the heater on the plate fails, the heater will instantly get extremely hot and burn. If the TCO is bolted to the plate and the heater is hanging by its wires, it won't prevent a fire. It's much better to mount the TCO on the heater (if its glued to the plate) so that the TCO stays with the heater if it comes off the plate. If the heater is mechanically fixed to the plate you can mount the TCO on the plate.

My heater is fixed mechanically - six bolts or a 2mm backing aluminum plate would need to fail for the heater to detach from the plate. I followed Keenovo's recommended arrangement (heated plate - heater - insulation - structural backing plate), except that my insulation is reconstituted cork rather than their recomendation of a foam.