Problem with rear side of Test Cube

-

Hi,

The probing issue that I recently posted about was my penultimate issue, this is my ultimate one .

.

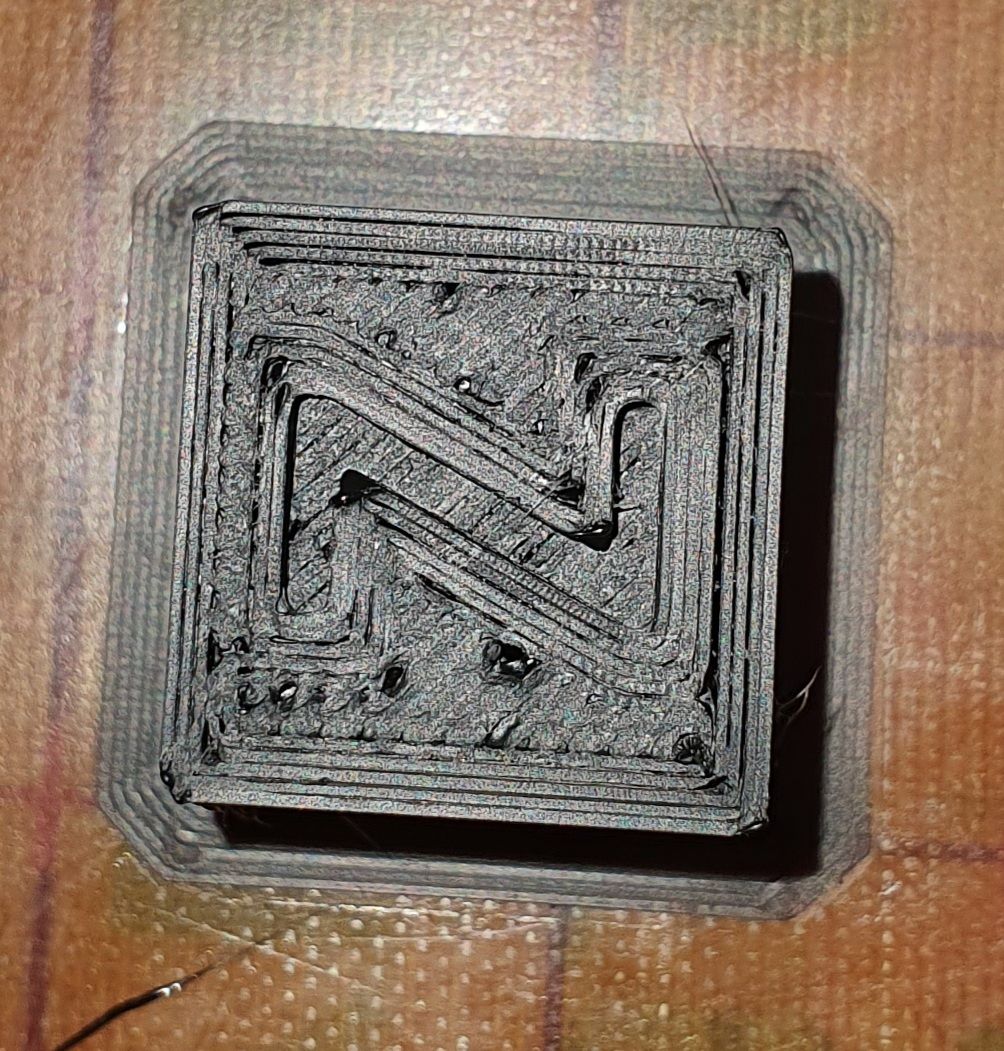

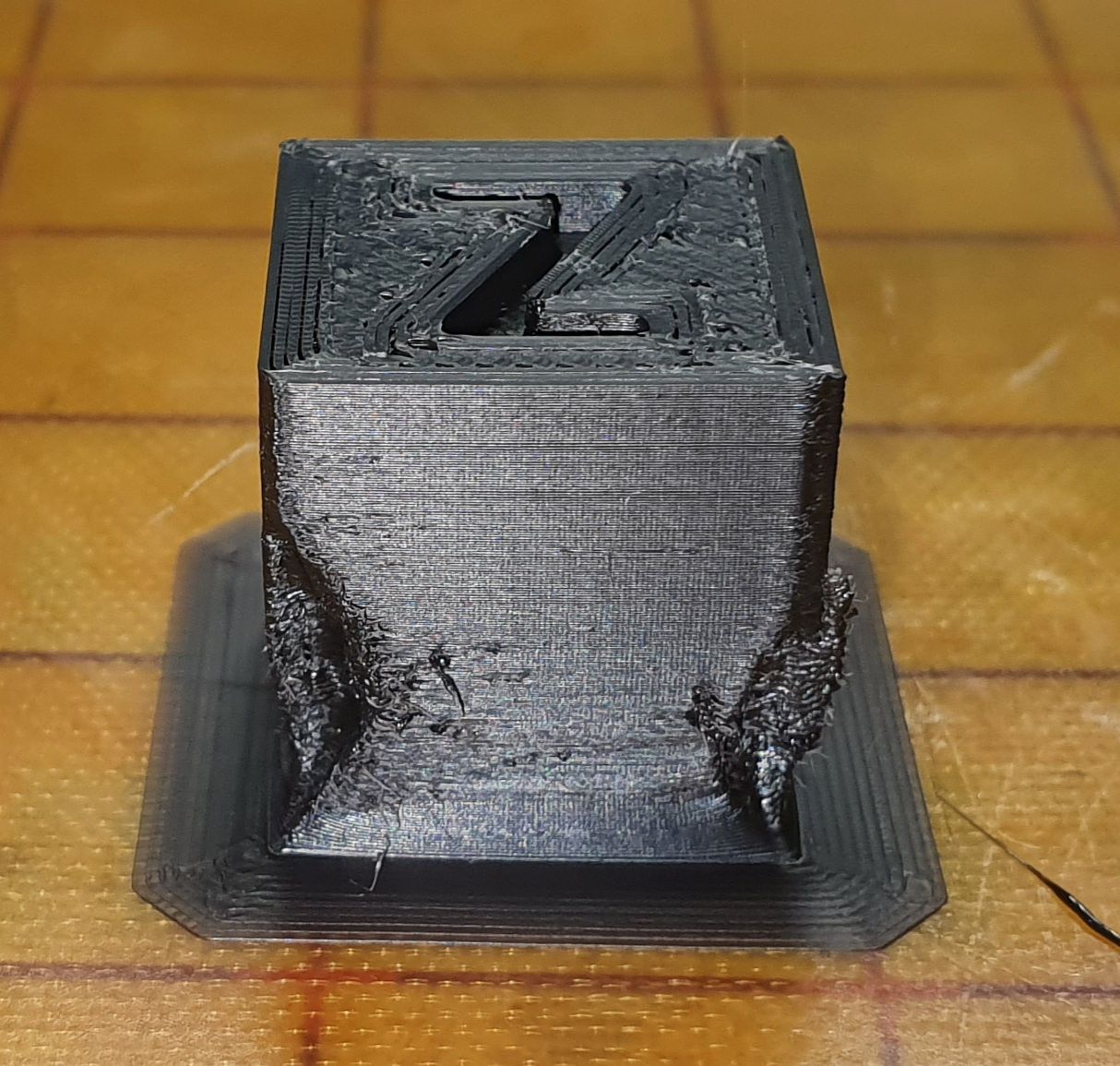

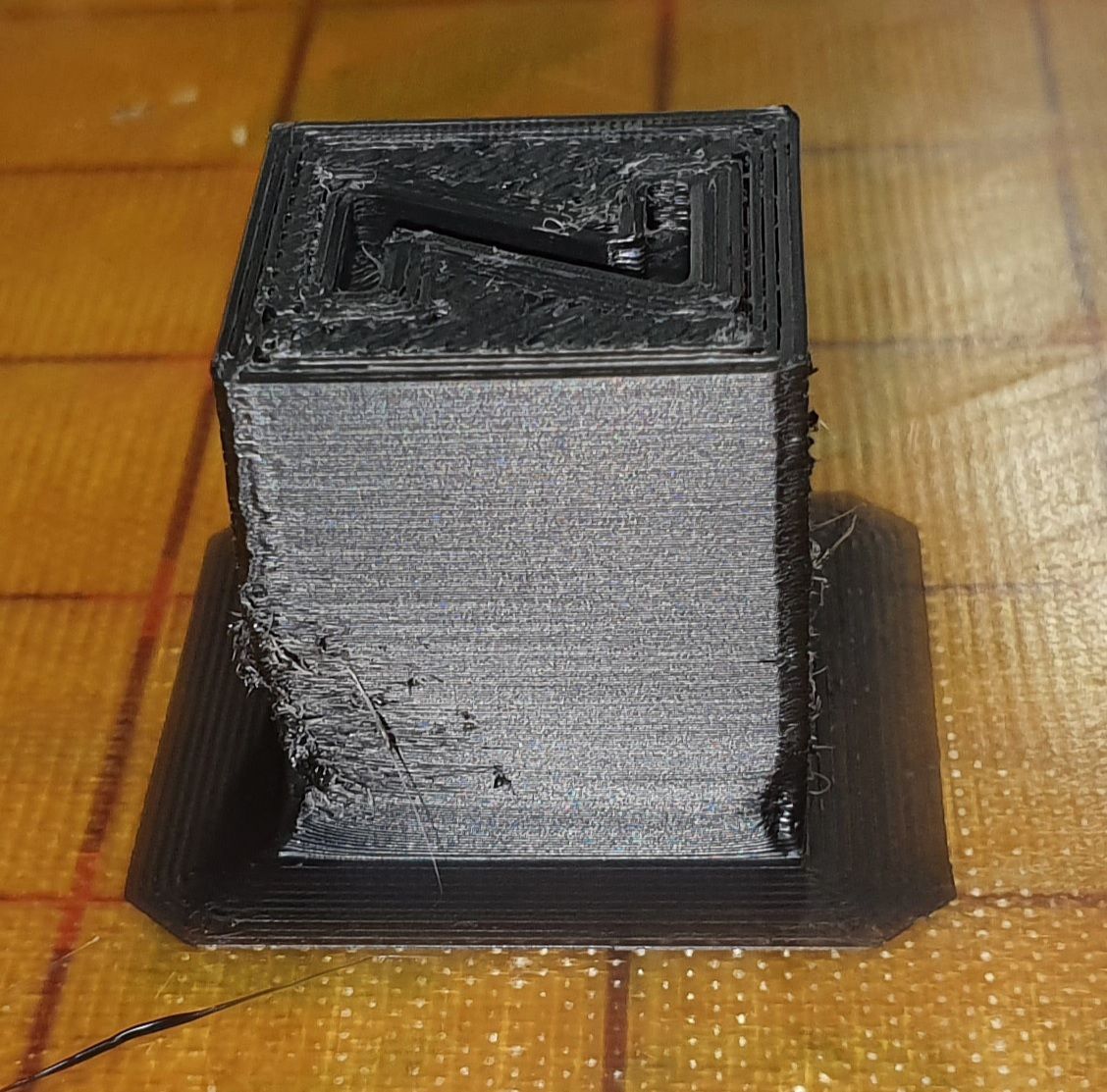

When I print a Test Cube, the lower half of the cube is distorted, curved and in places missing altogether. The upper part is much better.

I have tried the following solutions, but none of them seem to really address the problem:

1/ Lowered extrusion amounts from 100% down to 50% in 10% increments, (best results seemed to be at 100% extrusion).

2/ Altered printing speed, I have tried 60mm/s, 30mm/s and 15mm/s, (I definiftely noticed an improvement when I changed from 60mm/s to 30mm/s, but not much change going to lower speeds).

It may be an issue with the slicer settings, I am using Simplify3d ver 4.1.2.

Here are some photos of the issue:

-

Wow, that really IS terrible.

Can you save your factory file and post it here so I can load it and take a look?

What filament are you using and what temperature are you setting the bed and extruder to?

-

Thank you for agreeing with me about the quality @alankilian

Here is the *.gcode file xyzCalibration_cube-brim-100%-opt-start.gcode -

I don't think you can attribute that to the slicer settings.

I think you have extruder hardware problems.

Have you calibrated the extruder multiple times to see if it remains consistent.

Have you watched the extruder temperature readout during printing to see if it is remain consistent.

Frederick

-

The extruder temp is 235C and I have experimented with bed temps from 80C to 120C. I didn't really notice much change, except that with a bed of 80C, adhesion was deteriorating.

-

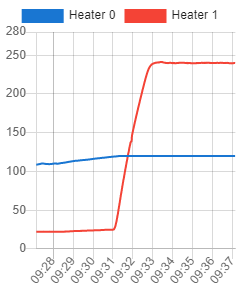

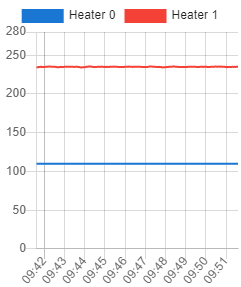

I haven't recalibrated the extruder, but I think my temperature is consistent. The window in the browser that shows the temp is consistent. I'm just running the cube now, so that I can post the temp readouts.

-

@dmbgo said in Problem with rear side of Test Cube:

I haven't recalibrated the extruder, but I think my temperature is consistent. The window in the browser that shows the temp is consistent. I'm just running the cube now, so that I can post the temp readouts.

I didn't see that you mentioned the kind of filament you are using.

For PLA I use 200 for the extruder and 60 for the bed but keep in mind my 200/60 may not match you 200/60 - it all depends on the thermistors and how correct the thermistor configuration values are.

For speed I use 60 mm/s to 90 mm/s depending on desired quality with the first layer at 15 mm/s.

Frederick

-

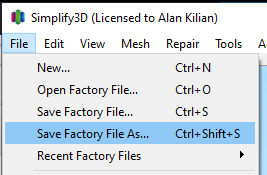

@dmbgo Can you File->Save Factory File as... and post it?

That way I can see your slicer settings and all that.

-

Thanks Fredrick, I am using ABS.

-

No worries @alankilian here it is:

[0_1610836772941_xyzCalibration_cube.factory](Uploading 100%) -

@dmbgo Try that upload again please.

Also, what filament are you using?

-

I print PLA at 60C bed and 205C extruder, so you're significantly hotter than I am.

-

I'll try renaming it to *.txt, you'll have to change it to *.factory:

xyzCalibration_cube.factory.txt -

I am using ABS filament.

-

On the filament roll, it recommends Extruder 220 to 260C Bed 100 to 110C

-

-

@dmbgo said in Problem with rear side of Test Cube:

I am using ABS filament.

Do you have a heated enclosure?

Frederick

-

I'm afraid I'm out of my experience zone with ABS.

I have read not to use fans for the first 3 layers, but that's not your problem.

Do you see filament extruding on the back cornets?

Do you hear your extruder struggling/clicking when that happens?

Can you rotate the cube 180-degrees to see if it then happens on the front?

Can you rotate the entire printer 180-degrees to see if it changes due to airflow?

Do you have an enclosure?

My only ABS experience is using a Stratasys where everything is controlled for me and it works perfectly.

Someone with more ABS experience will probably jump in next and hopefully be able to help you more than I can.

-

I do have, but the printer isn't in it at present while I'm working on it. I usually drop the bed temp down when the printer's in there.

-

From what I have read ABS really needs a heated enclosure BUT I don't know if that is related to your problem.

Frederick