Air pump too fast at minimum pwm

-

My first thought is to replace the pump motor (or SSR?) with a simple 1K Ohm resistor and look at the signal on the scope.

Fiddle around until you get a signal that makes sense and THEN hook back the pump.

That will insure you are presenting a reasonable signal to the pump.

-

@alankilian said in Air pump too fast at minimum pwm:

My first thought is to replace the pump motor (or SSR?) with a simple 1K Ohm resistor and look at the signal on the scope.

Fiddle around until you get a signal that makes sense and THEN hook back the pump.

That will insure you are presenting a reasonable signal to the pump.

The pump motor with driven straight from the e1 heateroutput, no SSR.

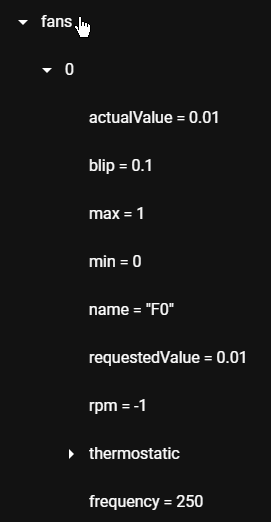

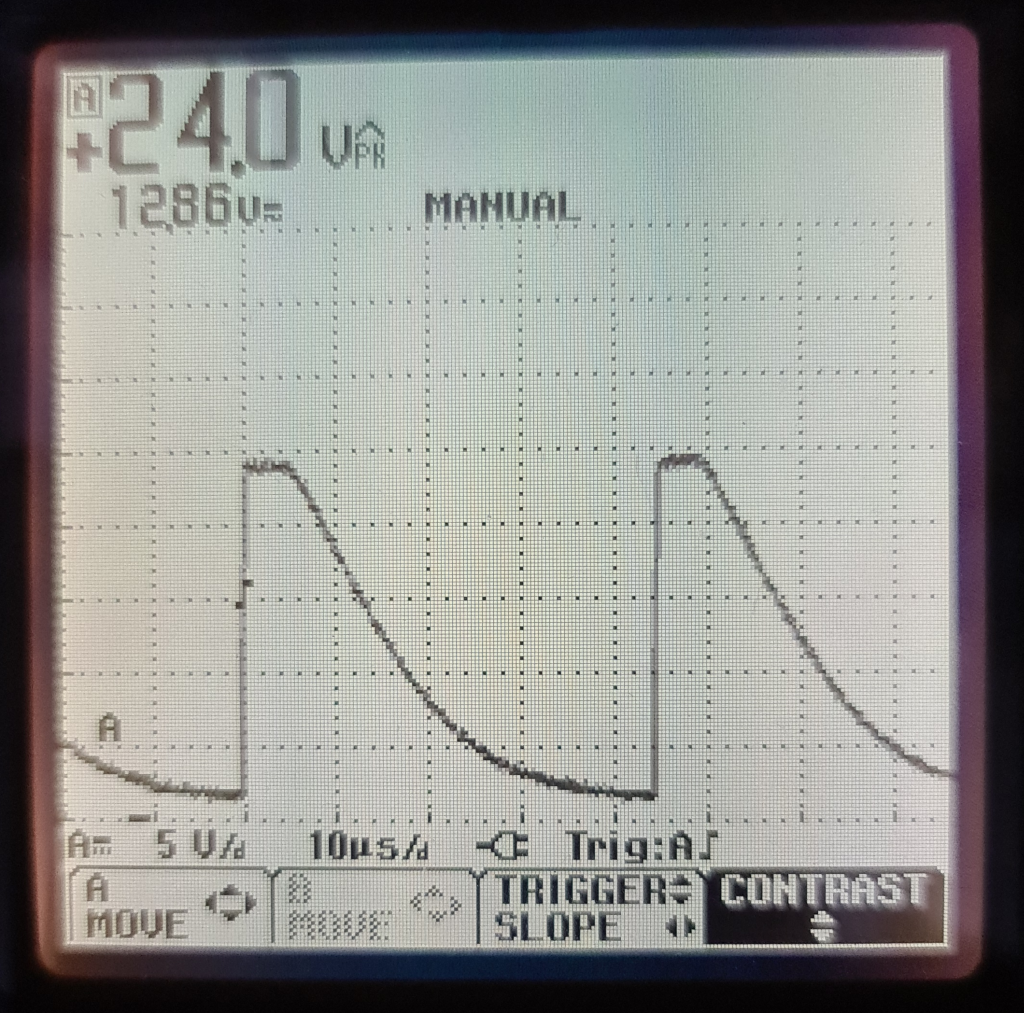

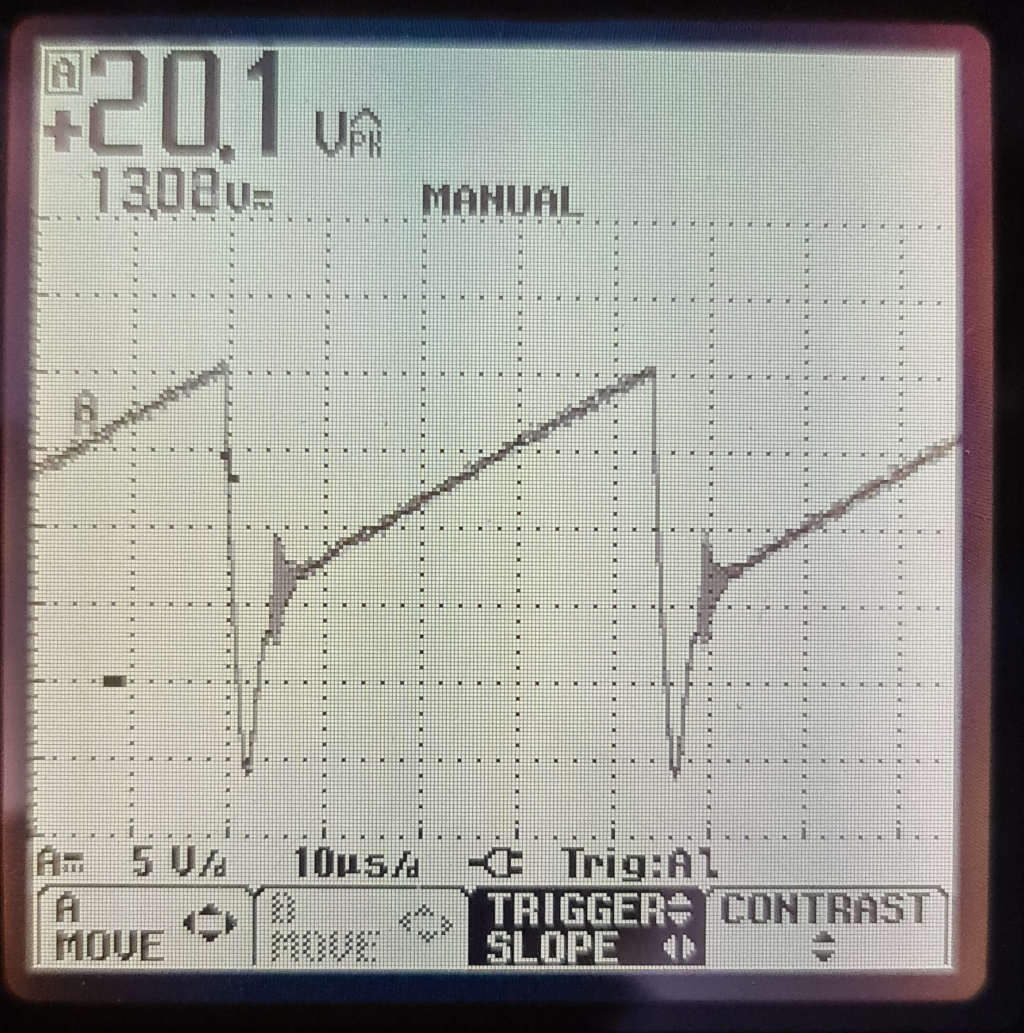

I did some desodering work and two more measurements as seen below:

PWM at 1%, nothing connected.

PWM at 1%, 550Ohm resister connected.

Connecting a diode in that second setup has no effect on the waveform, as one would expect. Connecting the pump+diode again still results in the 1st post behaviour. Which leaves me with a diode that does not seem to behave very diode'y as @dc42 pointed out.EDIT: I did try connect a 2nd diode in parallel, that I measured good out of circuit. Just to make sure that I was not dealing with an actually faulty diode before.

-

@dc42 said in Air pump too fast at minimum pwm:

The PWM frequency appears to be about 22kHz, which is very high. I suggest you use a much lower PWM frequency

I have since also tried with 5kHz PWM frequency and this still results in a terrible fall time and relatively huge voltages

-

This post is deleted! -

The last two tests I did before going to bed are 1) connecting a 1N4001 in parallel, just to try it out, 0 difference. 2) remove all diodes completely, voltage spikes up 50V, yikes.

-

You've got the pump (or 1KOhm resistor) connected from the heater-out to ground right?

And the scope connected from the heater-out to ground also right?

I'm trying to understand that slowly-falling edge first and I'm confused, so I want to check.

-

Hi,

I don't know if it really matters but according to the docs the I parameter in M106 is not supported in v3 firmware.

From the docs:

Innn Invert PWM (I1), disable fan (I-1), or normal mode (I0, default) (not supported in RRF_3, use M950)

Could you connect just the 1K on the output and show the waveform for 1% at 1000 Hz?

Thanks.

Frederick

-

Do those traces you posted show the voltage at the Heater- terminal? Or did you take a differential measurement of the voltage across the pump motor?

-

@alankilian said in Air pump too fast at minimum pwm:

You've got the pump (or 1KOhm resistor) connected from the heater-out to ground right?

And the scope connected from the heater-out to ground also right?

I'm trying to understand that slowly-falling edge first and I'm confused, so I want to check.

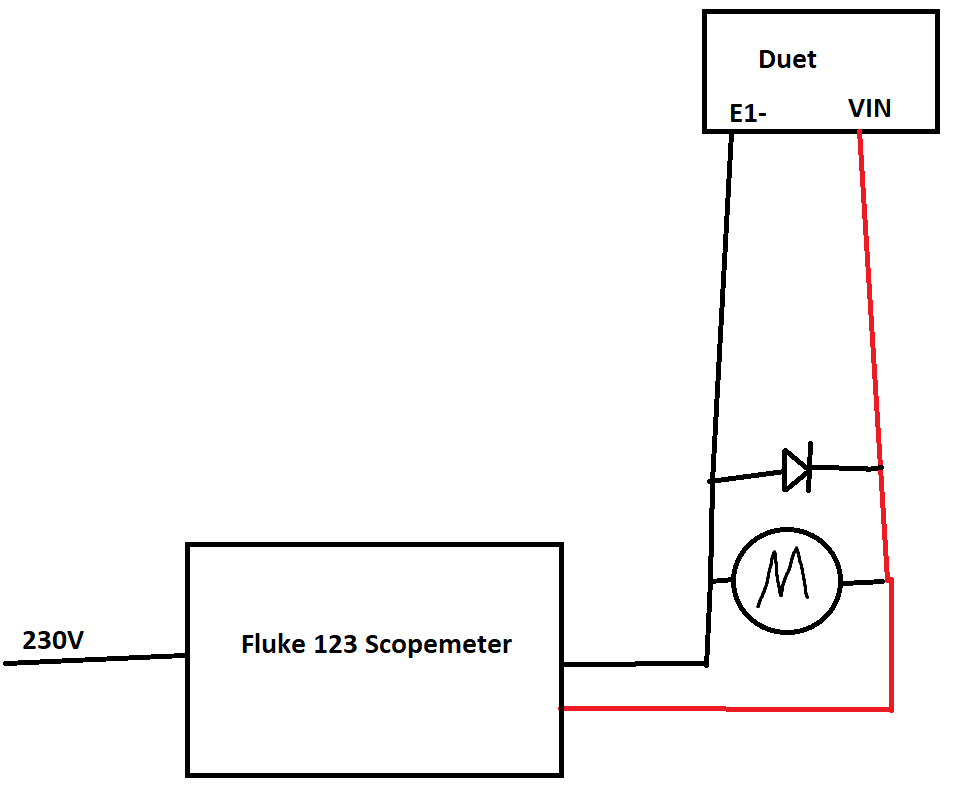

Forgive the crudity of the schematic, apparently I did not renew my DaveCAD licence

@dc42 said in Air pump too fast at minimum pwm:

Do those traces you posted show the voltage at the Heater- terminal? Or did you take a differential measurement of the voltage across the pump motor?

I believe the above sketch answers your question as well? If it makes a difference, I physically connected the scopemeter probes at the pump terminals.

@fcwilt said in Air pump too fast at minimum pwm:

Hi,

I don't know if it really matters but according to the docs the I parameter in M106 is not supported in v3 firmware.

From the docs:

Innn Invert PWM (I1), disable fan (I-1), or normal mode (I0, default) (not supported in RRF_3, use M950)

Could you connect just the 1K on the output and show the waveform for 1% at 1000 Hz?

Thanks.

Frederick

Are you sure M106 is not supported in rrf3? Because the docs I read here specifically mention that is how it should be done with rrf3

I will post the trace of the 1K or similar at 1kHz tomorrow. -

@fcwilt I see I read your post to quickly and missing that you specifically called the I paramter in M106. Good spot, I removed it but no difference.

-

Yeah, that's going to give you some strange traces.

Connect the scope ground to a Ground pin, not to E1-

Since E1- is connected to the drain-side of a FET, it becomes floating when the output is not being driven and you lose your ground reference.

I think things will look better if you connect the scope ground to ground and scope-signal to E1-.

You'll see a zero-volt signal when the pump is "on" and a woozy-doozy signal probably getting up to 24 Volts when the pump is "off".

-

@alankilian said in Air pump too fast at minimum pwm:

Yeah, that's going to give you some strange traces.

It depends on the design of the scope.

I use a battery powered scope and I could connect it as shown and get a pseudo-differential view of the voltage across the motor.

A line powered scope can be designed to allow the same though a true differential probe would be preferred.

How you connect the scope depends mostly on the signal you wish to view.

Frederick

-

@fcwilt True, but the voltage across the motor without a ground reference isn't going to tell you things about the risetime and falltime of the control signal.

That's likely why you see 39 Volts across the motor. It's just inductive kickback.

Maybe you should add a very small value series resistor attached to the VIN side of the motor and measure from VIN to the other side of the resistor. That would get you motor current which is probably what you're looking for.

To get back to your problem, what kind of motor is in the air pump?

It might not even be able to be speed-adjusted much by varying the PWM of it's power supply.Maybe you'd be better off looking into an adjustable blowoff valve to toss some of the air overboard.

I'm thinking as hard as I can about how to get you what you want and I'm not coming up with great ideas, I'm sorry.

-

One other thought is to use a high-current medium-value inductor in series with your pump motor.

I've used those in systems where the motor's armature inductance was too low to get good speed control from a PWM signal.

Something to try anyway.

-

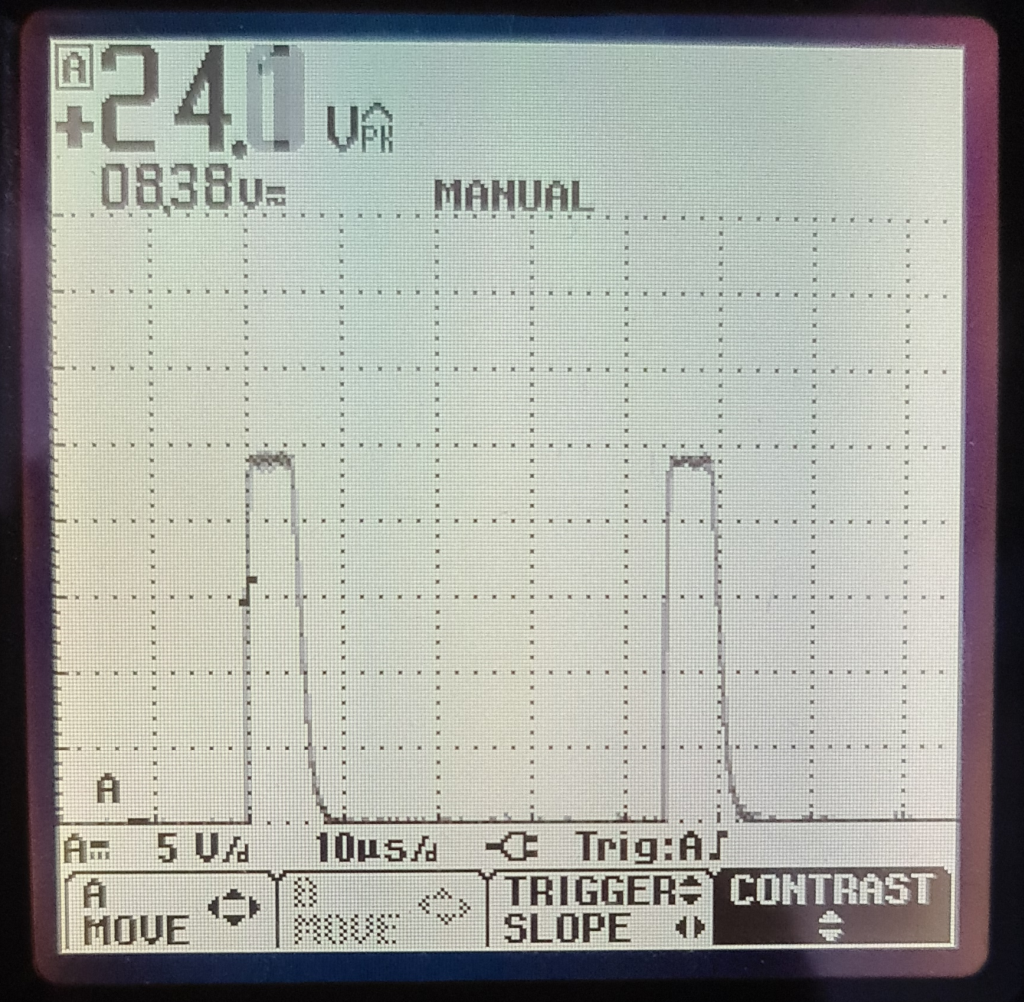

@alankilian You are right, the low side switching has gotten me several times over the years. Below is a trace of the motor running at 1% pwm with the scope gnd connected to actual gnd and the signal probe to the negative terminal of the motor.

For those who requested it, here a link to the pump I got.

-

Hi,

How are you setting the 1%?

The scope image simple doesn't look like 1% to me - unless I'm completely looking at it wrong.

Thanks.

Frederick

-

@fcwilt I am setting the 1% in the DWC machine control dashboard tab

-

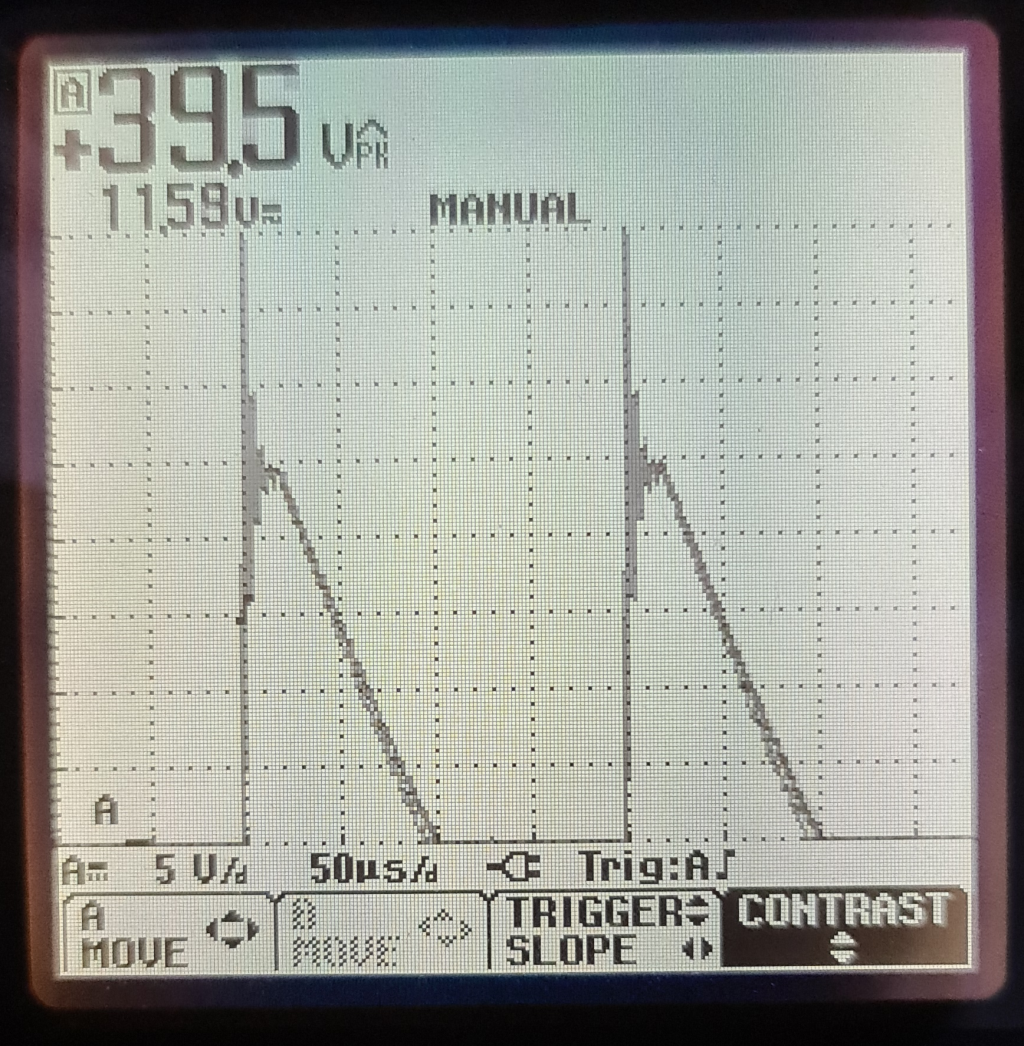

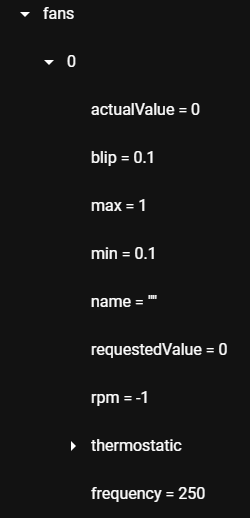

I wonder if this is part of the problem.

This is a screen shot of the DWC Object Model showing the fan data for a Duet 3 Mini 5 I am testing running firmware 3.2.

Notice the min and max values.

IF they are being enforced this fan cannot be set to 1%.

That might explain why the scope image doesn't look like 1% to me.

I need to do some testing.

Frederick

-

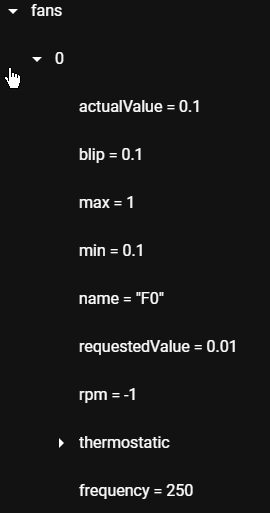

OK I issued M106 P0 S0.01

This is what the object model shows now.

Does this object model reflect what the fan output is actually doing?

I don't know.

But if the object model DOES correctly indicate what the fan output is doing it would explain why 1% is as not slow as you expected.

Frederick

-

To the M106 command in my config.g file for this fan I added this parameter and value L0.

Then I issued the M106 P0 S0.01.

This is the object model now.

At this point it might help if @dc42 would jump in and clarify default fan settings like min speed when no M106 L parameter is present.

In the meantime add L0 to the appropriate M106 in your config.g file and see it it makes a difference in the behavior of the pump.