massive overextrusion, E-Steps are calibrated

-

Hello all,

After several days of suffering i am writing here. I read in several threads about it. Maybe there is meanwhile a solution or someone knows what i am doing wrong.

I converted my Wanhao 6plus to a Duet Wifi 1.04 Setup on RRF3.

Everything works fine ( All axis are moving smoothly (after completely disassembling and reassembling), Height-Sensor is working properly, Fans are working nicely, heaters are PID tuned etc. )I use a nice flexible metalsheet-bed, included a bondtech extruder, switched to microswiss all-metal hotend. so, everything should be some kind of top-notch at least ok.

E-steps are calibrated. When i do a G92 E0 and G1 E100 F60 it moves the filament 100mm without any problems, to double check i did the same with the WebInterface. Same result. Filament moves 10cm. Perfect so far.

But now when starting to print, there is a massive overextrusion.

I have to pull down the flow rate to about 50-60% to get a result which looks like a proper first layer.

Also checked in the slicers that nozzle is set to 0.4 and filament to 1.75.

I tried different slicers ( Cura, Superslicer, Simplify3D ), all the same result - massive overextrusion . In each slicer i tried it with relative and absolute retraction.

(accordingly used M82 or M83 in config-file ) Also tried using the M82/M83 in slicers starting script.There is no M572 in my config or starting scripts.

Also tried to use different Firmware Flavors ( Reprap and Marlin)

Didnt help. Also tried M555 P2 in config , as i read somewhere he had luck with Marlin-Interpretation.Is there maybe a solution ? Here is my configfile. Maybe i miss something. Asmentioned before i tried M82 or M83 on config and set relative or absolute retraction in slicer accordingly.

; General preferences G90 ; send absolute coordinates... M82 ; ...absoulte extruder moves M550 P"Wanhao Duplicator 6 Plus" ; set printer name ; Network M551 P"notvisible" ; set password M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 = X goes reverse M569 P1 S1 ; physical drive 1 = Y goes forward M569 P2 S0 ; physical drive 2 = Z goes reverse M569 P3 S0 ; physical drive 3 = E0 goes reverse M584 X0 Y1 Z2 E3 ; set drive mapping M92 X80.04 Y80.04 Z800.96 E415.80 ; set steps per mm // von Phil: M92 X80.04 Y80.04 Z800.96 E433.80 M350 X16 Y16 Z16 E16 I1 ; configure microstepping without interpolation M566 X600.00 Y600.00 Z24.00 E20.00 ; set jerk/maximum instantaneous speed changes (mm/min) M203 X12000.00 Y12000.00 Z120.00 E3000.00 ; set maximum speeds (mm/min) M201 X600.00 Y600.00 Z200.00 E2000.00 ; set accelerations (mm/s^2) M906 X1300 Y1300 Z1200 E1200 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S10 ; Set idle timeout ;M593 F32.50 ; enable Dynamic Acceleration Adjustment with its frequency ; to make this work, you also have to set a high acc value (like M201 X10000.00 Y10000.00) and jerk value (like M566 ;X1800.00 Y1800.00 ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X190 Y180 Z170 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!^xstop" ; configure active-low endstop for low end on X via pin !^xstop M574 Y1 S1 P"!^ystop" ; configure active-low endstop for low end on Y via pin !^ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M558 P5 C"^!zprobe.in" H2 F60 T6000 A1 ; set Z probe type to switch and the dive height + speeds G31 P1000 X-2 Y50 Z2.3 ; Z-WERT GRÖSSER=Näher am bett; set Z probe trigger value, offset and trigger height M557 X0:190 Y50:200 S60:50 ; define mesh grid M376 H1 ; Set compensation taper to 5mm ; Heated Bed M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 A52.2 C59.4 D1.1 V23.9 B0 S1.00 ; disable bang-bang mode (turn on PID mode) for bed heater, set PWM limit and the PID settings M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C ; Hotend M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as thermocouple via CS pin spi.cs1 M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 ;M307 H1 A398.4 C224.6 D7.5 V24.0 B0 S1.00 ; disable bang-bang mode (turn on PID mode) for nozzle heater, set PWM limit and the PID settings ;M307 H1 A261.2 C161.4 D4.3 S1.00 V24.1 B0 ;M307 H0 A52.2 C59.4 D1.1 S1.00 V23.9 B0 M307 H1 A448.4 C273.6 D9.6 S1.00 V24.0 B0 ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off ; LED M950 F2 C"fan2" Q500 ; create LED on pin fan2 so that the brightness can be controlled via the dashboard and set its frequency M106 P2 S255 H-1 ; turn LED on (Thermostatic control is turned off) ; Tools M563 P0 S"Hotend" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0CThank you for your help,

Johannes -

M92 X80.04 Y80.04 Z800.96 E415.80 ; set steps per mm // von Phil: M92 X80.04 Y80.04 Z800.96 E433.80

from https://github.com/MarlinFirmware/Configurations/blob/import-2.0.x/config/examples/Wanhao/Duplicator 6/Configuration.h

#define DEFAULT_AXIS_STEPS_PER_UNIT { 80.0395, 80.0395, 400.48, 99.1 }is your z step correct? it differs from the default marlin config

-

@Veti He said he was using a Bondtech extruder - quote...

I use a nice flexible metalsheet-bed, included a bondtech extruder, switched to microswiss all-metal hotend. so, everything should be some kind of top-notch at least ok.415 steps per mm is about right for a BMG

-

z steps not e steps

-

Yes, looks right. G92 Z0 and then G1 Z100 is moving 100mm on Z-Axis. Just double-checked.

-

how sure are you that you have a 0.4mm nozzle?

-

I replaced my old nozzle 2 days ago (Where i also had the same problems ) with a completely new 0.4 Microswiss nozzle. Which should be ok.

-

measure the weight of 100mm filament

then extrude 100mm filament through the hotend and weight that.

if its the same, the problem must be in the slicer.

-

Veti, thx for the hint! Dont have that precise scales here atm. Will do it these days. But...my guess is, that there are some Issues with my config / Firmware. I have 3 different printers (not running with duet Wifi) where i dont have these issues. As mentioned i tried 3 different slicers (Cura, superslicer, simplify3d). The phenomen with the overextrusion is there, regardless which slicer i am using. Which makes me wonder that it is not only a few percentage... its like 50%

Also using Highquality filaments ( Filamentum, Extrudr, etc) so there shouldnt be that variance.

-

@deckingman thx for taking part in the discussion. I saw an old thread from you where there was quite a similar problem which suddenly disappeared. I love your great multicolor Printer !

-

@Enpixa said in massive overextrusion, E-Steps are calibrated:

@deckingman thx for taking part in the discussion. I saw an old thread from you where there was quite a similar problem which suddenly disappeared. I love your great multicolor Printer !

Thanks. But due to various firmware issues, it's currently just a useless pile of extrusion and motors.

-

Can you post your config.g?

Can you post your homeall.g?

Can you post the entire gcode file or at least the first 50 or so lines of it?

Can you send M122 and post the results?

Can you send M98 P"config.g" and post the results?Is this just the first layer that is over extruded or are you letting the print progress to higher layers to allow for any incorrect Z0 position to be overcome?

Might be worth going through this complete calibration? https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40

-

Is your slicer set for volumetric extrusion?

-

@Phaedrux : thx for your reply, here it comes

config.g:

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ;M555 P2 ; emulate Marlin ; General preferences G90 ; send absolute coordinates... M82 ; ...absoulte extruder moves M550 P"Wanhao Duplicator 6 Plus" ; set printer name ; Network M551 P"*hidden*" ; set password M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 = X goes reverse M569 P1 S1 ; physical drive 1 = Y goes forward M569 P2 S0 ; physical drive 2 = Z goes reverse M569 P3 S0 ; physical drive 3 = E0 goes reverse M584 X0 Y1 Z2 E3 ; set drive mapping M92 X80.04 Y80.04 Z800.96 E415.80 ; set steps per mm // von Phil: M92 X80.04 Y80.04 Z800.96 E433.80 M350 X16 Y16 Z16 E16 I1 ; configure microstepping without interpolation M566 X600.00 Y600.00 Z24.00 E20.00 ; set jerk/maximum instantaneous speed changes (mm/min) M203 X12000.00 Y12000.00 Z120.00 E3000.00 ; set maximum speeds (mm/min) M201 X600.00 Y600.00 Z200.00 E2000.00 ; set accelerations (mm/s^2) M906 X1300 Y1300 Z1200 E1200 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S10 ; Set idle timeout ;M593 F32.50 ; enable Dynamic Acceleration Adjustment with its frequency ; to make this work, you also have to set a high acc value (like M201 X10000.00 Y10000.00) and jerk value (like M566 ;X1800.00 Y1800.00 ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X190 Y180 Z170 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!^xstop" ; configure active-low endstop for low end on X via pin !^xstop M574 Y1 S1 P"!^ystop" ; configure active-low endstop for low end on Y via pin !^ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M558 P5 C"^!zprobe.in" H2 F60 T6000 A1 ; set Z probe type to switch and the dive height + speeds G31 P1000 X-2 Y50 Z2.3 ; Z-WERT GRÖSSER=Näher am bett; set Z probe trigger value, offset and trigger height M557 X0:190 Y50:200 S60:50 ; define mesh grid M376 H1 ; Set compensation taper to 5mm ; Heated Bed M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 A52.2 C59.4 D1.1 V23.9 B0 S1.00 ; disable bang-bang mode (turn on PID mode) for bed heater, set PWM limit and the PID settings M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C ; Hotend M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as thermocouple via CS pin spi.cs1 M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 ;M307 H1 A398.4 C224.6 D7.5 V24.0 B0 S1.00 ; disable bang-bang mode (turn on PID mode) for nozzle heater, set PWM limit and the PID settings ;M307 H1 A261.2 C161.4 D4.3 S1.00 V24.1 B0 ;M307 H0 A52.2 C59.4 D1.1 S1.00 V23.9 B0 M307 H1 A448.4 C273.6 D9.6 S1.00 V24.0 B0 ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off ; LED M950 F2 C"fan2" Q500 ; create LED on pin fan2 so that the brightness can be controlled via the dashboard and set its frequency M106 P2 S255 H-1 ; turn LED on (Thermostatic control is turned off) ; Tools M563 P0 S"Hotend" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue T0 ; select first tool M501config-overwrite.g:

; config-override.g file generated in response to M500 at 2021-01-22 02:51 ; This is a system-generated file - do not edit ; Heater model parameters M307 H0 A52.2 C59.4 D1.1 S1.00 V23.9 B0 M307 H1 A448.4 C273.6 D9.6 S1.00 V24.0 B0 ; Workplace coordinates G10 L2 P1 X0.00 Y0.00 Z0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 G10 L2 P9 X0.00 Y0.00 Z0.001st Lines of Gcode of the File:, atm in Cura set to Marlin-Style, but same issue with Reprap-Style.

;FLAVOR:Marlin ;TIME:22400 ;Filament used: 14.1189m ;Layer height: 0.1 ;MINX:25.453 ;MINY:6.229 ;MINZ:0.3 ;MAXX:112.584 ;MAXY:176.376 ;MAXZ:7 ;Generated with Cura_SteamEngine 4.8.0 M140 S60 M105 M190 S60 M104 S205 M105 M109 S205 M82 ;absolute extrusion mode G21 ;metric values G90 ;absolute positioning M82 ;set extruder to absolute mode M107 ;start with the fan off G28 X0 Y0 ;move X/Y to min endstops G28 Z0 ;move Z to min endstops G29 G1 Z15.0 F100 ;move the platform down 15mm G92 E0 ;zero the extruded length G1 F200 E6 ;extrude 6 mm of feed stock G92 E0 ;zero the extruded length again G1 F100 ;Put printing message on LCD screen M117 Printing... G92 E0 G92 E0 G1 F1500 E-3 ;LAYER_COUNT:68 ;LAYER:0 M107 G0 F2400 X40.217 Y24.157 Z0.3 ;TYPE:SKIRT G1 F1500 E1.24726 G1 F1800 X41.609 Y21.834 E1.38236 G1 X42.958 Y19.433 E1.51976 G1 X44.245 Y16.98 E1.65796 G1 X45.453 Y14.513 E1.79501 G1 X45.734 Y13.901 E1.8286 G1 X45.881 Y13.596 E1.8455 G1 X46.139 Y13.091 E1.87379 G1 X46.215 Y12.953 E1.88165 G1 X46.472 Y12.509 E1.90724 G1 X46.781 Y12.022 E1.93602 G1 X46.872 Y11.888 E1.9441 G1 X47.216 Y11.411 E1.97344 G1 X47.579 Y10.951 E2.00267M98 :

24.1.2021, 14:00:54 M98 P"config.g" HTTP is enabled on port 80 FTP is disabled TELNET is disabled Warning: Heater 1 appears to be over-powered. If left on at full power, its temperature is predicted to reach 473C Warning: Heater 1 appears to be over-powered. If left on at full power, its temperature is predicted to reach 473CM122:

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.1.1 running on Duet WiFi 1.02 or later Board ID: *hidden* Used output buffers: 3 of 24 (12 max) === RTOS === Static ram: 27980 Dynamic ram: 93888 of which 20 recycled Exception stack ram used: 264 Never used ram: 8920 Tasks: NETWORK(blocked,368) HEAT(blocked,1224) MAIN(running,1824) IDLE(ready,80) Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:02:47 ago, cause: power up Last software reset at 2021-01-23 14:38, reason: User, spinning module GCodes, available RAM 8672 bytes (slot 2) Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0441f000 BFAR 0xe000ed38 SP 0xffffffff Task MAIN Error status: 0 MCU temperature: min 15.9, current 23.1, max 23.3 Supply voltage: min 23.8, current 24.1, max 24.3, under voltage events: 0, over voltage events: 0, power good: yes Driver 0: standstill, SG min/max not available Driver 1: standstill, SG min/max not available Driver 2: standstill, SG min/max not available Driver 3: standstill, SG min/max not available Driver 4: standstill, SG min/max not available Date/time: 2021-01-24 13:57:47 Cache data hit count 292974609 Slowest loop: 3.30ms; fastest: 0.12ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 12.0MBytes/sec SD card longest read time 1.0ms, write time 0.0ms, max retries 0 === Move === Hiccups: 0(0), FreeDm: 169, MinFreeDm: 169, MaxWait: 0ms Bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === AuxDDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === Heat === Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 15.78ms; fastest: 0.00ms Responder states: HTTP(2) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 - WiFi - Network state is active WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.23 WiFi MAC address 24:62:ab:15:71:3c WiFi Vcc 3.37, reset reason Unknown WiFi flash size 4194304, free heap 20968 WiFi IP address 192.168.0.133 WiFi signal strength -76dBm, reconnections 0, sleep mode modem Socket states: 0 4 0 0 0 0 0 0Sometimes i let it run higher, but only possible, when i set to 50-60% flow. otherwise there are huge blobs etc on first layer.

-

@OwenD said in massive overextrusion, E-Steps are calibrated:

Is your slicer set for volumetric extrusion?

No, not set to volumetric

-

@Enpixa said in massive overextrusion, E-Steps are calibrated:

M906 X1300 Y1300 Z1200 E1200 I50 ; set motor currents (mA) and motor idle factor in per cent

which motor is on your bondtech?

-

@Veti said in massive overextrusion, E-Steps are calibrated:

@Enpixa said in massive overextrusion, E-Steps are calibrated:

M906 X1300 Y1300 Z1200 E1200 I50 ; set motor currents (mA) and motor idle factor in per cent

which motor is on your bondtech?

Veti, it is the original Wanhao motor. But it is not getting hot when printing. it seems ok.

-

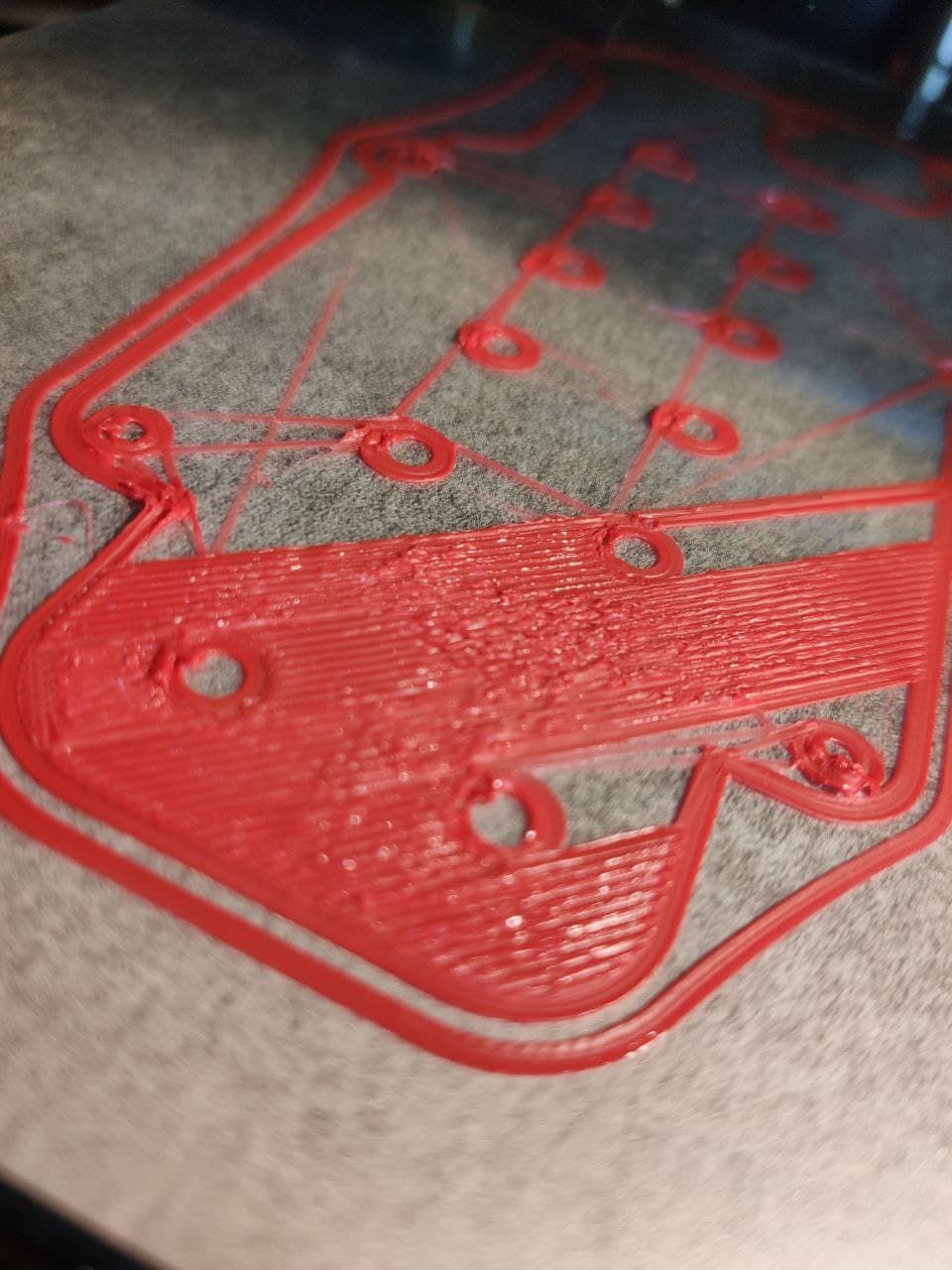

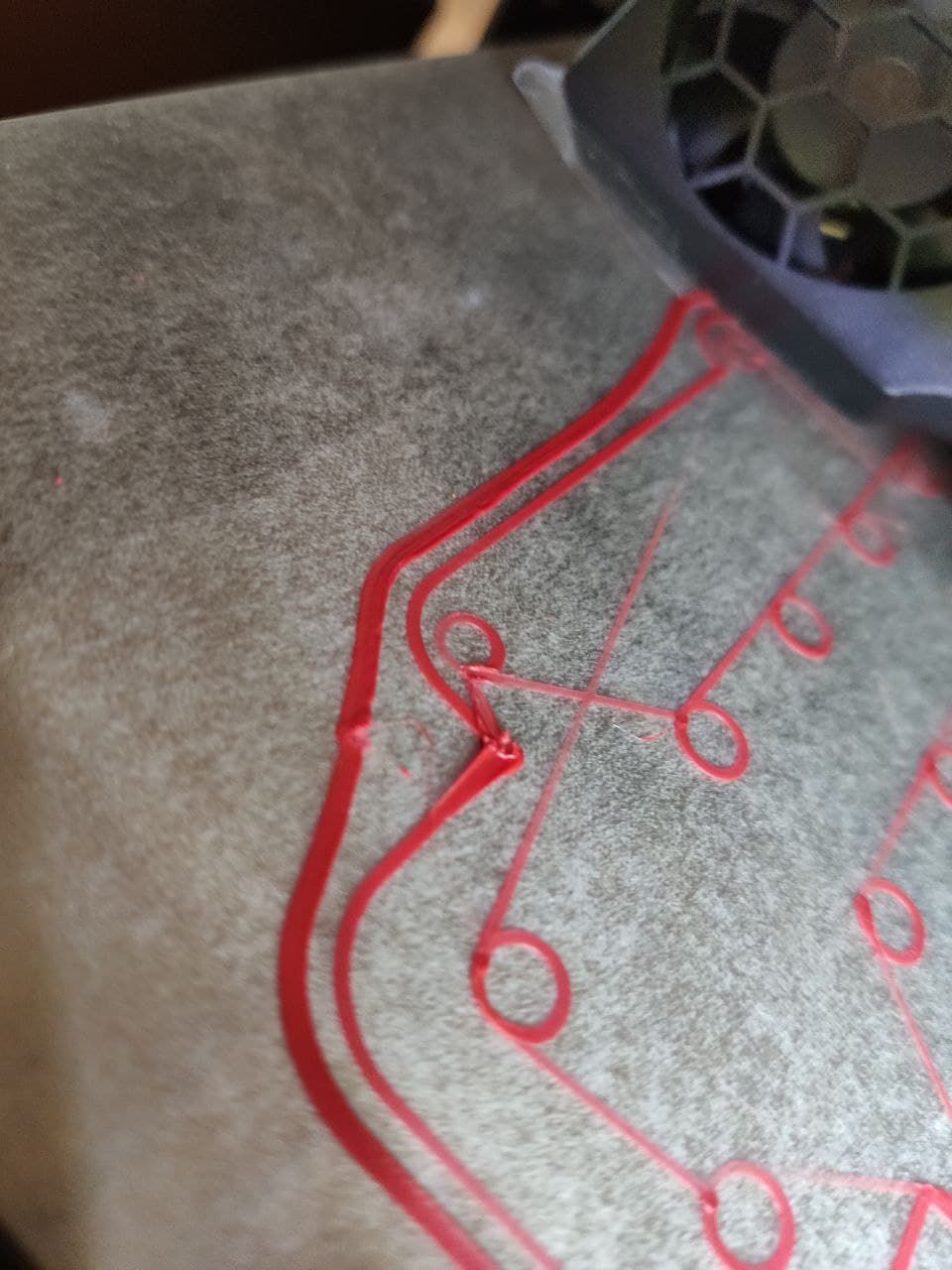

Here are some Photos with 100% flow. Retraction: tried everything between 2-8mm, makes a difference, but doesnt avoid overextrusion.

and some settings screenshot:

as mentioned before the "Marlin-Style" Favor was only a test, made no difference compared to "reprap-style"

-

Hi,

Is the slicer set to use absolute or relative extrusion mode?

Frederick

-

This post is deleted!