CNC Screw Mapping

-

@dc42 I've forked and updated the github repo. You can see the code changes at: https://github.com/MZachmann/RepRapFirmware/tree/v3.2-screwmap

and it forks from the 3.02-dev branch (3.2 retail).

Let me know where you'd like to go from here. Implement (pull request)? Move to M-codes? Change syntax?

The only thing I couldn't yet figure out from the code base was how to correctly have the ui update the user position when the screw map definition changes.

Mark

-

Here's a doc file describing the current implementation of screw mapping.

-

I've posted a video showing a calibration run (in X). It took about 1/2 hour to gather X and Y error terms and improved the CNC accuracy from .033" to .002".

-

Nicely done!

I just had a thought, though. Make sure your yard-stick is straight. You could be compensating for an error in the yard stick.

-

Sorry, I should have posted that. You're absolutely right.

The yardstick is one of the most expensive hand tools I own since it's so important.

-

@markz Oh!!!! That's a nice "yard stick" lol!!!

-

@bot Yeah, Starrett would probably not be happy me calling it that.

-

I also spit coffee on my laptop when I saw that price.

-

I suddenly want a yard stick like that... but I couldn't even use such a large one! My print bed is only ~11" x 11". I'll look for it's younger sibling. And possibly metric, too.

-

@bot Yeah, I wish I had a metric one - if you watch the video I spend a lot of time converting inches. Kinda dumb.

backstory - when I first realized about 10 years ago my CNC had so much error I did this measurement with a normal yardstick, couldn't believe the results (especially the Y error), so in order to root-cause I had no choice.

-

I've cleaned up the code so setting a screw map entry changes the DRO readout in real-time.

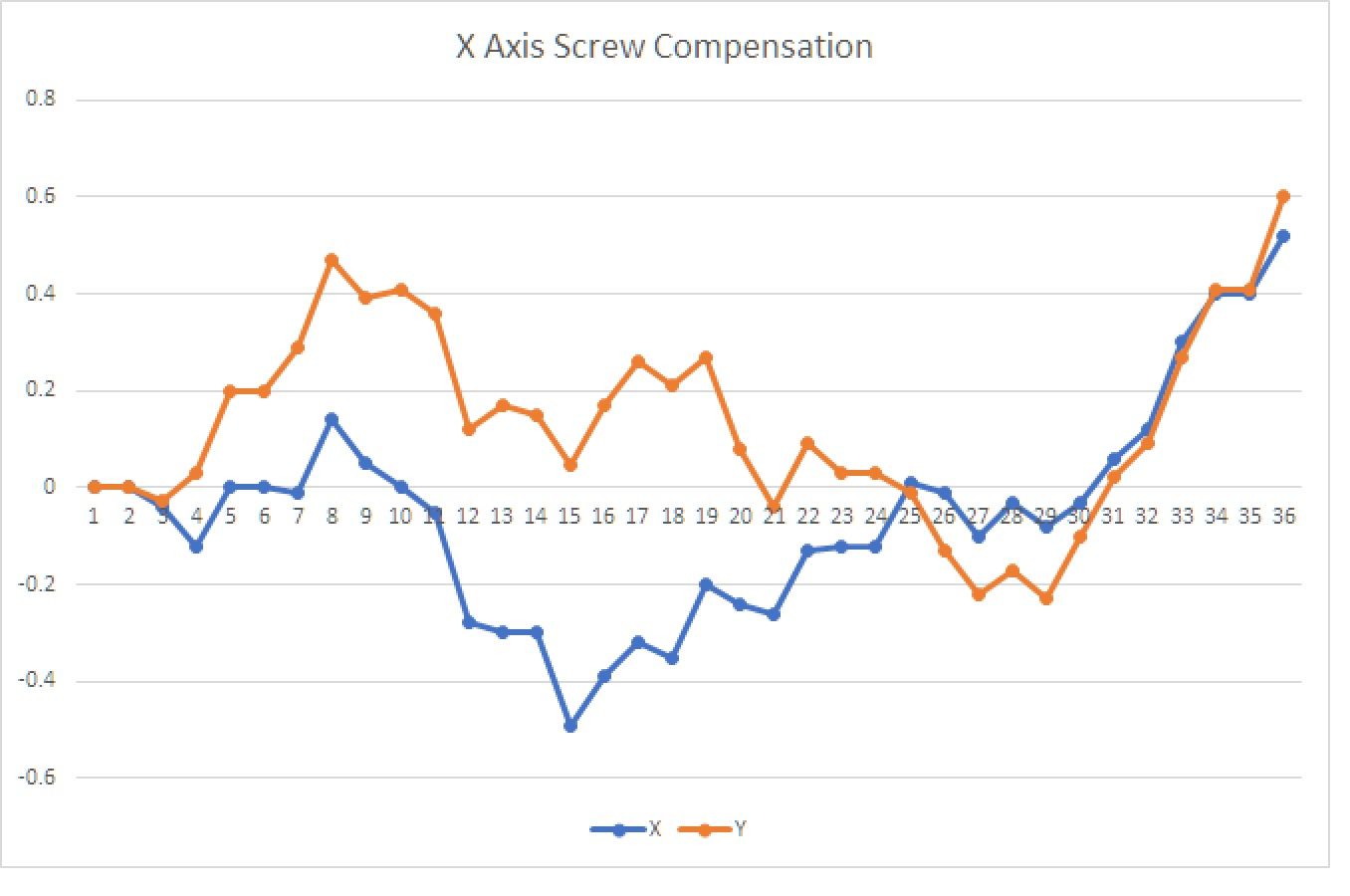

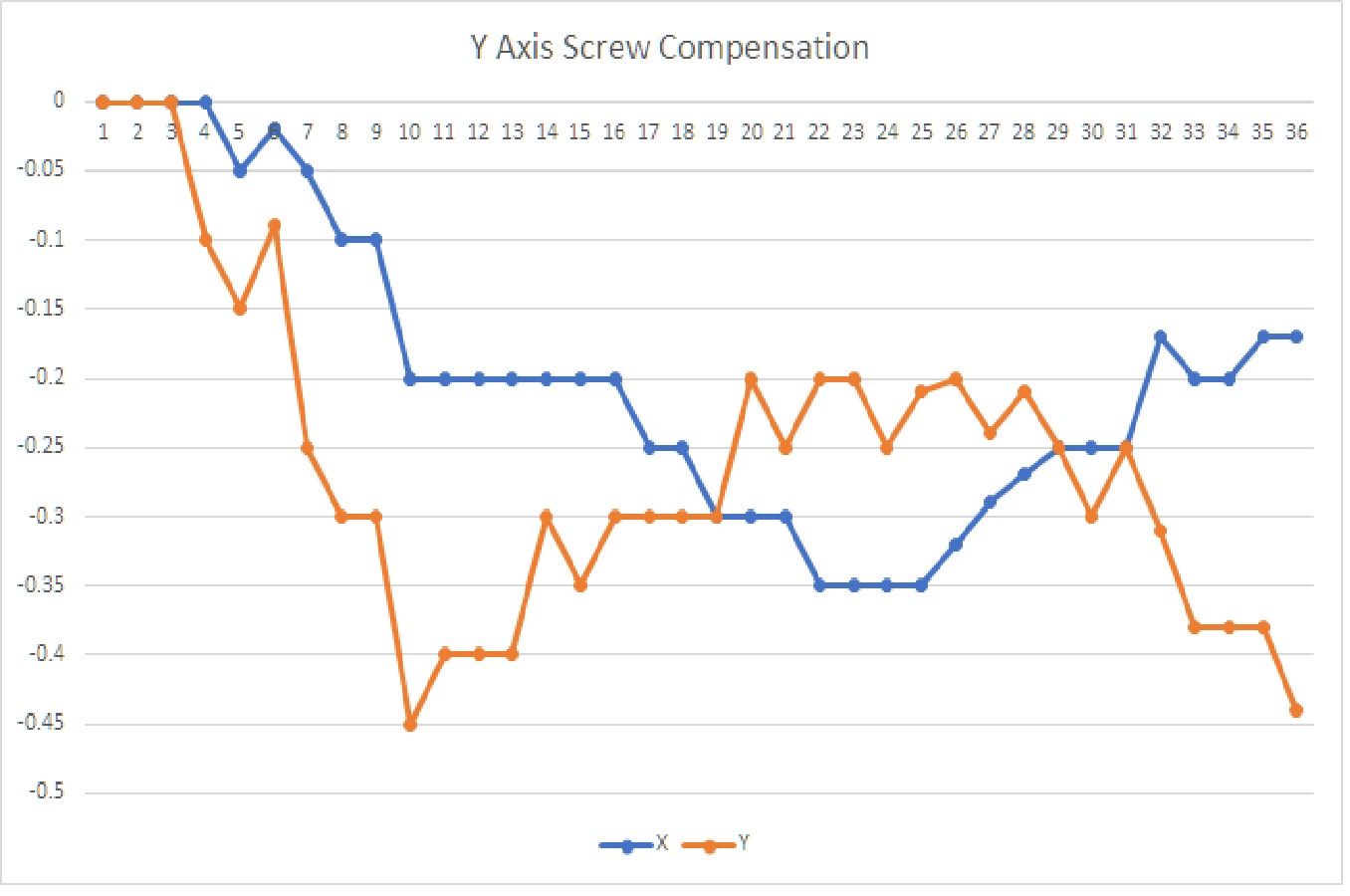

Here are a couple of plots of my CNC error curves with increment=25.4mm (1 inch). Note the 2d-ishness of the whole thing.

To put this in a worst case if I were just drilling holes the largest X error pre-compensation would be about 1.5mm (or 1/16th of an inch for US). Post-compensation error is 2*repeatability + test measurement error (~.03mm).