Duet 3 - Cooling fan configurations

-

Tried direct wiring (bypass smart effector) - same strange result

-

Slicer is Simplify 3D, G code (or at least part of it) is shown below:

G90

M82

M106 S255

G4 P500

M106 S111

M140 S65

M190 S65

M104 S235 T0

M109 S235 T0

G28 ; home all axes

;G1 E-10 F600 ; clear nozzle

;G29

G1 Z5 F3000 ; lift

;G5 ; enable resume from power failure

G1 X100 Y100 F1500 ; move to prime

G1 Z0.4 F3000 ; get ready to prime

G92 E0 ; reset extrusion distance

G1 X60 E10 F600 ; prime nozzle

G1 X60 F5000 ; quick wipe

; process PREDATOR

; layer 1, Z = 0.250

T0

G92 E0.0000

G1 E-2.5000 F3000

; feature skirt

; tool H0.250 W0.720

G1 Z0.250 F2400

G1 X15.360 Y-12.220 F7200

G1 E0.0000 F3000

G92 E0.0000

G1 X15.360 Y12.220 E1.6827 F2354

G1 X12.220 Y15.360 E1.9884

G1 X-12.220 Y15.360 E3.6711

G1 X-15.360 Y12.220 E3.9768

G1 X-15.360 Y-12.220 E5.6595

G1 X-12.220 Y-15.360 E5.9652

G1 X12.220 Y-15.360 E7.6479

G1 X15.360 Y-12.220 E7.9536

G92 E0.0000

G1 E-2.5000 F3000

; feature outer perimeter

G1 X9.640 Y-9.640 F7200

G1 E0.0000 F3000

G92 E0.0000

G1 X9.640 Y9.640 E1.3274 F1177

G1 X-9.640 Y9.640 E2.6548

G1 X-9.640 Y-9.640 E3.9822

G1 X9.640 Y-9.640 E5.3096

G92 E0.0000

G1 E-2.5000 F3000

G1 X9.640 Y-4.640 F1177

; feature solid layer

G1 X9.120 Y-9.208 F7200

G1 E0.0000 F3000

G92 E0.0000

G1 X9.208 Y-9.120 E0.0085 F1413

G1 X9.208 Y-8.102 E0.0787

G1 X8.102 Y-9.208 E0.1863

G1 X7.084 Y-9.208 E0.2564

G1 X9.208 Y-7.084 E0.4633

G1 X9.208 Y-6.066 E0.5334

G1 X6.066 Y-9.208 E0.8393

G1 X5.047 Y-9.208 E0.9095

G1 X9.208 Y-5.047 E1.3146

G1 X9.208 Y-4.029 E1.3847

G1 X4.029 Y-9.208 E1.8889

G1 X3.011 Y-9.208 E1.9590

G1 X9.208 Y-3.011 E2.5624

G1 X9.208 Y-1.993 E2.6325

G1 X1.993 Y-9.208 E3.3351

G1 X0.974 Y-9.208 E3.4052

G1 X9.208 Y-0.974 E4.2069

G1 X9.208 Y0.044 E4.2770

G1 X-0.044 Y-9.208 E5.1778

G1 X-1.062 Y-9.208 E5.2479

G1 X9.208 Y1.062 E6.2479

G1 X9.208 Y2.080 E6.3180

G1 X-2.080 Y-9.208 E7.4171

G1 X-3.099 Y-9.208 E7.4872

G1 X9.208 Y3.099 E8.6854

G1 X9.208 Y4.117 E8.7555

G1 X-4.117 Y-9.208 E10.0529

G1 X-5.135 Y-9.208 E10.1230

G1 X9.208 Y5.135 E11.5195

G1 X9.208 Y6.153 E11.5896

G1 X-6.153 Y-9.208 E13.0853

G1 X-7.172 Y-9.208 E13.1554

G1 X9.208 Y7.172 E14.7502

G1 X9.208 Y8.190 E14.8203

G1 X-8.190 Y-9.208 E16.5143

G1 X-9.208 Y-9.208 E16.5844

G1 X9.208 Y9.208 E18.3775

G1 X8.190 Y9.208 E18.4476

G1 X-9.208 Y-8.190 E20.1416

G1 X-9.208 Y-7.172 E20.2117

G1 X7.172 Y9.208 E21.8065

G1 X6.153 Y9.208 E21.8766

G1 X-9.208 Y-6.153 E23.3723

G1 X-9.208 Y-5.135 E23.4424

G1 X5.135 Y9.208 E24.8389

G1 X4.117 Y9.208 E24.9090

G1 X-9.208 Y-4.117 E26.2064

G1 X-9.208 Y-3.099 E26.2765

G1 X3.099 Y9.208 E27.4748

G1 X2.080 Y9.208 E27.5449

G1 X-9.208 Y-2.080 E28.6440

G1 X-9.208 Y-1.062 E28.7141

G1 X1.062 Y9.208 E29.7140

G1 X0.044 Y9.208 E29.7842

G1 X-9.208 Y-0.044 E30.6850

G1 X-9.208 Y0.974 E30.7551

G1 X-0.974 Y9.208 E31.5568

G1 X-1.993 Y9.208 E31.6269

G1 X-9.208 Y1.993 E32.3294

G1 X-9.208 Y3.011 E32.3995

G1 X-3.011 Y9.208 E33.0029

G1 X-4.029 Y9.208 E33.0730

G1 X-9.208 Y4.029 E33.5773

G1 X-9.208 Y5.047 E33.6474

G1 X-5.047 Y9.208 E34.0525

G1 X-6.065 Y9.208 E34.1226

G1 X-9.208 Y6.065 E34.4286

G1 X-9.208 Y7.084 E34.4987

G1 X-7.084 Y9.208 E34.7055

G1 X-8.102 Y9.208 E34.7756

G1 X-9.208 Y8.102 E34.8833

G1 X-9.208 Y9.120 E34.9534

G1 X-9.120 Y9.208 E34.9620

G92 E0.0000

G1 E-2.5000 F3000

G1 X-9.208 Y9.120 F1413

G1 X-9.208 Y8.102

G1 X-8.102 Y9.208

G1 X-7.084 Y9.208

G1 X-7.985 Y8.306

; layer 2, Z = 0.500

M106 S255

; feature outer perimeter -

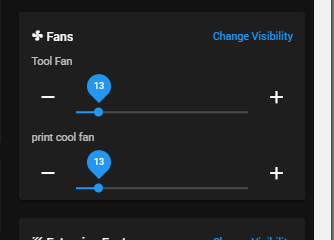

so just to be sure. when you move the tool fan in the ui the hotend part fan turns on as well?

or are you saying that tool fan and fan 0 are synced (they are both the part cooling fan)

-

If the temperature on the tool fan is below the set point (35c) then only Fan 0 (part cooling fan) turns on. If the temp on the hotend is above 35c then moving the slider in the DWC ui changes the speed in both fans

-

@kj3d said in Duet 3 - Cooling fan configurations:

If the temperature on the tool fan is below the set point (35c) then only Fan 0 (part cooling fan) turns on. If the temp on the hotend is above 35c then moving the slider in the DWC ui changes the speed in both fans

I lately observed the same here, so +1 for the problem. Thanks for posting that, because I also asked my self how this could be if only one of the two fans is an "automatic" thermostatic and the other one is only a "do nothing and wait for g-code-command" issued.

Would be great if more people would replicate the behaviour, I guess most are not paying attention to it.

BUT - currently I am not sure wether it is only DWC or also the real-world-printer that behave that way. Current print runs a few more hours so I will report later -> So first this evening I will connect a probe to each fan and then starting and stopping some files to measure independent of what DWC is "saying it does" and how this relates to what the board "actually does".

See the screenshots: Heat-break-fan should be 100% above 60°C on the hotend (which you can see the extruder surely has with 220°C) but everytime the printfile increases the part-cooling (I usually start with low part-cooling and increase it over some layers to the desired "top"-value e.g. in this case around 70%) at least DWC told me the heatbreak-fan has the same val which if it is true is an error:

EDIT: O.K.: Mixed up the OP original problem this particular thing is answered already by VETI and PHAEDRUXMy setup: duet2ethernet1.0.4 running RRF3.2, single extruder with thermostatic-heatbreak-fan & g-code-partcooling-fan, single heatplate (of course), PSU 24V, fans are 12V, PanelDue7i connected. Slicer is also currently Simplify3D-4.1.2.

The "fan"-section in my config.g:

;print/part cool fan: M950 F0 C"fan0" ;Q200 ; create F=fan(x) with "!" to invert, on pin C; opt set frequency(Q) e.g. for most real 4-wire pwm-fans 25000 (max 65535), ordinary 2-wire must be kept low around 100-500, default seems to be 250 M106 P0 C"print cool fan" B1.0 H-1 S0 ; P=num; s=set speed 0-255/0.0-1.0; limit L min & X max; H=heater monitored+Thermostatic control, -1=off or Hx(:__...) monitored; B=blip time in ms; if not thermostatic (H-1) define a board-boot-start-up speed S=fan speed; ;extr heat-sink/-break fan: M950 F1 C"fan1" ;Q200 ; create F=fan(x) with "!" to invert, on pin C; opt set frequency(Q) e.g. for most real 4-wire pwm-fans 25000 (max 65535), ordinary 2-wire must be kept low around 100-500, default seems to be 250 M106 P1 C"extr heat sink fan" B1.0 H1 L0.5 T40:60 ; P=num; s=set speed 0-255/0.0-1.0; limit L min & X max; H=heater monitored+Thermostatic control, -1=off or Hx(:__...) monitored; B=blip time in ms; if not thermostatic (H-1) define a board-boot-start-up speed S=fan speed; ;chamber fan: M950 F2 C"fan2" T3 ;Q500 ;! ;Q25000 ; create F=fan(x) with "!" to invert, on pin C; opt set frequency(Q) e.g. for most real 4-wire pwm-fans 25000 (max 65535), ordinary 2-wire must be kept low around 100-500, default seems to be 250 ; set some default vals to start e.g. from PETG 35°C to PC UL 45°C, but override it in the print-file with the specific filament-config.g: M106 P2 C"chamber fan" B1.0 L0.9 T35:45 H10 ;X1.0 ; P=num; s=set speed 0-255/0.0-1.0; limit L min & X max; H=heater num monitored->Thermostatic control, -1=off or Hx(:__...) monitored; B=blip time in ms; if not thermostatic (H-1) define a board-boot-start-up speed S=fan speed; ;-> We start with a summer-cooldown temp above 35°C with thermostatic control enabled -> and define the optimum value for each filament in the filament-config.gSome samplecode how a file starts:

111582-01 Temperatursensorabdeckung 9997 WLFM-01.gcode.txtWhat is your hardware-setup again running which firmware on which volts?

Will report back!

-

@LB

Thanks for your post - its good to know that the problem is not just with me. After quite a few hours checking wiring, configurations and simply scratching my head the problem is a strange one.

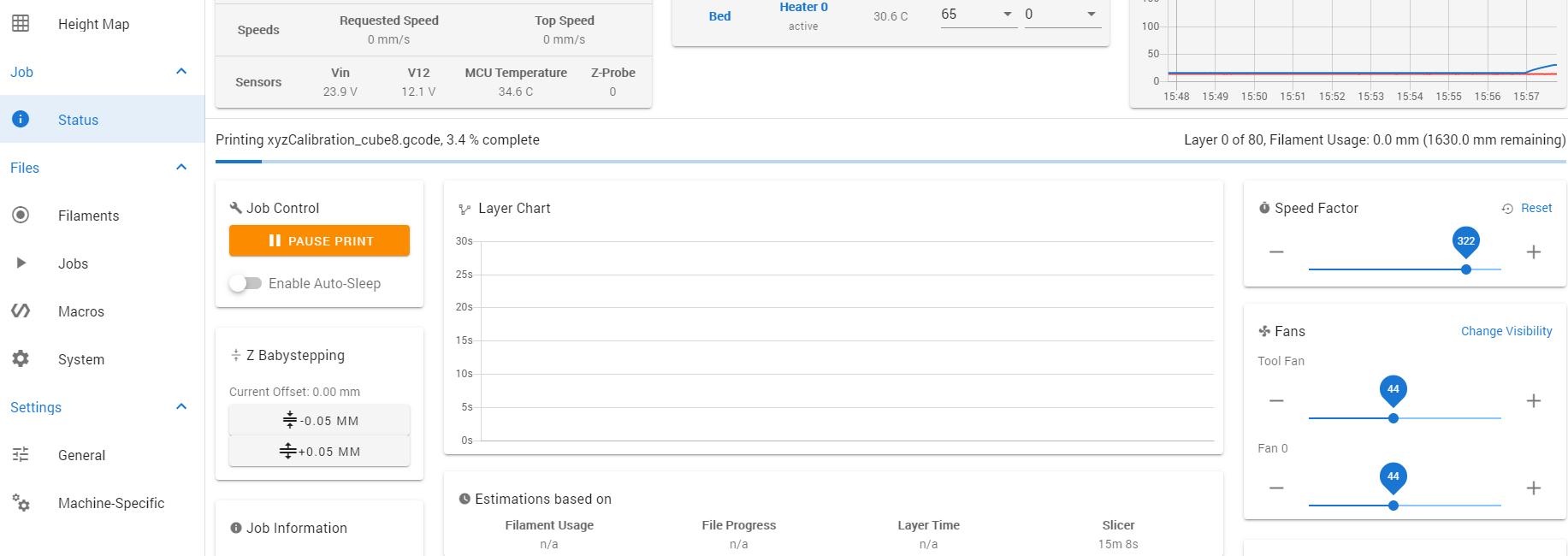

I can confirm that the problem of the two fans being interlinked is present when printing. I printed the xyz calibration cube with different part cooling settings every 5 layers (0 % first five layers printing at 235c with PLA+ Hotbed 65c) then increasing the fan speed by 10% every five additional layers.

Layers 0 to 5 all ran with the hotend fan at 100% (part cooling set to 0%) As soon as the first change in part cooling applied then the hotend fan started to follow the setting for the part cooling (down at that point to 50%. This was confirmed with an optical tacho to measure motor / fan speeds

My conclusion is that its a problem with both DWC and the real world running of files outside DWC

My setup is 6HC Motherboard, Panel Due 7, Volcano 24v hotend, 24v hotbed, 24v fans smart effector for Z sensing, Simplify 3d 4.1.2 for the slice software

Latest release of Firmware.

-

Regarding hardware and firmware the only things we have in common seem to be:

- RRF3.2

- Simplify3D-4.1.2

- thermostatic heat-break-fan

- gcode-partcooling-fan

- EDIT (see conversation): PanelDue

Right?

-

Other than the Panel Due then yes you are right

Looking at your GCODE have you tried switch on the hotend fan using M106 (from DWC) BEFORE it reaches the preset start temp?

I tried and mine just sat there without starting. However once the preset start limit is reached it seems to follow the M106 command for anything (irrespective of what fan the M106 command targets)

-

The tool fan slider will mirror what your part cooling fan is set to. They are the same fan. Thermostatically controlled fans don't show up in the UI at all. Click on change visibility to hide the tool fan if you wish. It only makes sense on machines with multiple tools where it will control the fan of the currently selected tool.

If the UI slider is changing the speed of your heat sink fan, it's either a configuration or wiring problem.

-

I was just looking here https://duet3d.dozuki.com/Wiki/Gcode#Section_M106_Fan_On

and this section made me curious:

Hnn:nn:nn... Enable thermostatic mode and select heaters monitored. H-1 disables thermostatic mode. (In RRF_3 relates to the sensor number(s) created by M308, not the temperature sensor pin number on the board)

-

@Phaedrux said in Duet 3 - Cooling fan configurations:

The tool fan slider will mirror what your part cooling fan is set to.

?

Does that make any sense or doesn´t that mean that the "part cooling fan" should be kicked out forever once and for all from the firmware?

EDIT: Moved, see conversation

-

I don't know what you mean by that.

-

@Phaedrux said in Duet 3 - Cooling fan configurations:

I don't know what you mean by that.

If that is the same fan:

why is it occupying screen-space 2 times? hey, I do not know, I am a single-extruder-single-tool-user, maybe somebody can explain it to me - could be that there is a benefit for multi-tool-users I guess?EDIT: Moved, see conversation

-

As I explained, in machines with multiple tools the tool fan slider will always control the fan of the currently selected tool.

In machines with only a single tool you can hide either the tool fan or the print cool fan slider if you wish with the change visibility button.

-

Maybe for our kind (the OP and me) why not only have within DWC "Tool Fan (your current print cool fan)" and that´s it? If it is really the same why have 2 sliders when you can do it with one. If you insist to have 2 sliders then they are not the same? Or am I wrong here (maybe time for a 2nd tool to try out and see?)

EDIT: Moved, see conversation

-

Because the Duet is built around the concept of flexible tools. Some of those decisions and functions only become usefully apparent when multiple tools are apparent.

I would agree that it would be clearer for new users with only a single tool to show only a single slider, but it's really not such a big deal is it? You can hide it if you wish. There is a button right above it that says change visibility.

Here's another use case that might make more sense even if you have only a single tool, you may have 2 part cooling fans. left and right for instance. The tool fan will control the fans configured in the tool definition, so both fans at once. But you would also have an independant slider for each fan in case you wanted to adjust only one or the other.

-

Thanks for the example! So basically "all" tool fans i guess.

EDIT: I moved this side-talk to https://forum.duet3d.com/topic/21300/tool-fans-representation-within-dwcBut I deraild now what the OP had as problem! He actually sat down and tried different values and there seems to be some intertwining with the fans anyway (let´s keep DWC out from now on):

"

If the temperature on the tool fan is below the set point (35c) then only Fan 0 (part cooling fan) turns on. If the temp on the hotend is above 35c then moving the slider in the DWC ui changes the speed in both fans

"

Sorry @kj3d -

@kj3d Can you post your config.g as copy and paste text?

Can you also send M122 and post the results, along with M98 P"config.g"?

your config appears to be correct. Usually if the heat sink fan is changing speed along with the part cooling fan that would indicate either the tool definition is incorrectly mapping both fans, or there is a wiring problem.

-

If you happen to have a permanent marker or a sticker I like to put that on the fan, that helps to be able to vaguely judge the running speed beside wetting a finger and putting it in front of it

-

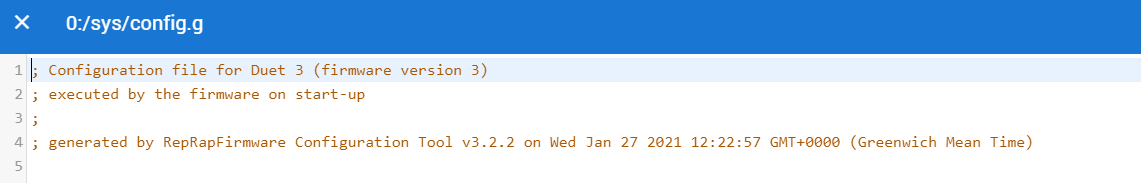

config.g:

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.2 on Wed Jan 27 2021 12:22:57 GMT+0000 (Greenwich Mean Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"KJ3D Delta" ; set printer name

M665 R227 L440 B185 H405 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them; Network

M551 P"freddy5363" ; set password

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S1 ; physical drive 0.2 goes forwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M584 X0.0 Y0.1 Z0.2 E0.3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z80.00 E335.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; set minimum Z; Endstops

M574 X2 S1 P"io1.in" ; configure active-high endstop for high end on X via pin io1.in

M574 Y2 S1 P"io2.in" ; configure active-high endstop for high end on Y via pin io2.in

M574 Z2 S1 P"io3.in" ; configure active-high endstop for high end on Z via pin io3.in; Z-Probe

M558 P5 R0.4 C"io4.in+io4.out" H5 F1200 T6000 ; set Z probe type to effector and the dive height + speeds

;M558 H30 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved

G31 P500 X0 Y0 Z-0.232 ; set Z probe trigger value, offset and trigger height

M557 R185 S20 ; define mesh grid; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"out4" Q500 ; create fan 0 on pin out4 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"out5" Q500 ; create fan 1 on pin out5 and set its frequency

M106 P1 S1 H1 T35 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss