Z calibration offset

-

Greetings,

I need help with my calibration file or with other words with my machine.

I don't know what the hell is going on. I printed two parts 300mm diameter with no problem, and then i didn't change anything and this happens. The bed calibration was off. Can somebody tell me what to change that the machine will work. I know the bed is curved, but i will solve this first ( Bl-touch,CR105S)

Here is my config file:

homeall.g config.g bed.gThank you.

-

your coming file does not use the bltouch. ( missing g30 command instead of switch command)

also the height map must be loaded after z=0 determination

-

-

there is no g30 in your home script.

-

@Thunder said in Z calibration offset:

Ok did some changes, would you take a look a the new files.

homeall.g config.g bed.g

homeall.g config.g bed.gHi,

If you get in the habit of using the </> tag to post your gcode files then we don't have to download them to look at them.

Here is your config.g file using the tag:

; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Sun May 24 2020 20:05:38 GMT+0200 (Central European Summer Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Printer" ; set printer name ; Network M551 P"GoBevk" ; set password M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y80.00 Z800.00 E837 ; set steps per mm M566 X900.00 Y900.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X1400 Y1700 Z1400 E800 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S50 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X500 Y500 Z500 S0 ; set axis maxima ; Endstops M574 X1 Y1 Z1 S1 ; set active high endstops ; Z-Probe M307 H3 A-1 C-1 D-1 ; disable heater on PWM channel for BLTouch M574 X1 Y2 S1 ; X home to min. Y home to max. Normally Closed limit switches M574 Z 1 ; Define Z to use Probe. Home to Min M558 P5 H5 F500 T4000 X0 Y0 Z1 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X-66.4 Y-10.2 Z2.15 ; set Z probe trigger value, offset and trigger height M557 X70:430 Y70:450 S50 ; define mesh grid ; Heaters M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power lossHere is your homeall.g file using the tag:

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Sun May 24 2020 20:05:38 GMT+0200 (Central European Summer Time) G91 ; relative positioning G1 H2 Z10 F24000 ; lift Z relative to current position G1 H1 X-505 Y-505 F12000 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X5 Y5 F24000 ; go back a few mm G1 H1 X-505 Y-505 F240 ; move slowly to X and Y axis endstops once more (second pass) G1 H1 Z-505 F240 ; move Z down stopping at the endstop G90 ; absolute positioning G92 Z-5.10 ; set Z position to axis minimum (you may want to adjust this) ; Uncomment the following lines to lift Z after probing G91 ; relative positioning G1 Z10 F400 ; lift Z relative to current position G90 ; absolute positioning -

@Thunder said in Z calibration offset:

Ok did some changes, would you take a look a the new files.

homeall.g config.g bed.g

homeall.g config.g bed.gWhere is the your code to create the height map?

Frederick

-

Ok, how about now ?[0_1612359597243_homeall (1).g](Uploading 100%)

-

@fcwilt Ok will do that

-

@Thunder said in Z calibration offset:

@fcwilt Ok will do that

Great.

It looks like you attempted to post an updated homeall.g file but something went wrong.

Frederick

-

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Sun May 24 2020 20:05:38 GMT+0200 (Central European Summer Time) G91 ; relative positioning G1 H2 Z10 F24000 ; lift Z relative to current position G1 H1 X-505 Y-505 F12000 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X5 Y5 F24000 ; go back a few mm G1 H1 X-505 Y-505 F240 ; move slowly to X and Y axis endstops once more (second pass) G1 H1 Z-505 F240 ; move Z down stopping at the endstop G90 ; absolute positioning G1 X100 Y100 F2000 ; put head over the centre of the bed, or wherever you want to probe G30 ; lower head, stop when probe triggered and set Z to trigger height ; Uncomment the following lines to lift Z after probing G91 ; relative positioning G1 Z10 F400 ; lift Z relative to current position G90 ; absolute positioningHere is my file, also i dont understand "Where is the your code to create the height map?" ? I was folowing this guide :link text

-

@fcwilt said in Z calibration offset:

M574 Z 1

I don't use v2 firmware but I think that command above should be M574 Z1 S2

Frederick

-

@Thunder said in Z calibration offset:

G1 X100 Y100 F2000 ; put head over the centre of the bed, or wherever you want to probe

G30 ; lower head, stop when probe triggered and set Z to trigger heightI don't think X100 Y100 is going to put your probe over the center of the bed which is really the best place.

i dont understand "Where is the your code to create the height map?" ?

I guess you are issuing the G29 command from the DWC?

-

Yes, this is right. Ok, came home and started the machine and a couple of settings were wrong. Now I have managed the home all to touch the probe for z and started the G29 S0

but I still get the same result. Can anybody point out what I am doing wrong? I am new to programming and this kind of setup.System My Printer g29 s0 Status Busy Tool Position X 346.4 Y 320.2 Z 7.15 Extruder Drives Drive 0 0.0 Speeds Requested Speed 3 mm/s Top Speed 3 mm/s Sensors Vin 12.0 V MCU Temperature 28.4 C Fan RPM 0 Z-Probe 0 Tools Extra Control All Tool Heater Current Active Standby Tool 0 T0 - Load Filament Heater 1 off 16.9 C 0 0 Bed Heater 0 off 18.2 C 0 0 Temperature Chart System Directory 0:/sys/config.g ; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Sun May 24 2020 20:05:38 GMT+0200 (Central European Summer Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Printer" ; set printer name ; Network M551 P"GoBevk" ; set password M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y80.00 Z800.00 E837 ; set steps per mm M566 X900.00 Y900.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X1400 Y1700 Z1400 E800 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S50 ; Set idle timeout ;Bl-touch heaters M307 H3 A-1 C-1 D-1 ; disable heater on PWM channel for BLTouch ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X500 Y500 Z500 S0 ; set axis maxima ; Endstops M574 X1 Y1 S1; ; set active high endstops M574 Z1 S2; ; Z-Probe M558 P9 H5 F500 T4000 X0 Y0 Z1 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X-66.4 Y-10.2 Z2.15 ; set Z probe trigger value, offset and trigger height M557 X70:433.6 Y70:498.8 S30 ; define mesh grid ; Heaters M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v2.0.4 on Sun Sep 15 2019 21:01:39 GMT+0200 (Central European Summer Time) G91 ; relative positioning G1 Z5 F6000 S2 ; lift Z relative to current position G1 S1 X-500 Y-500 F1800 ; move quickly to X and Y axis endstops and stop there (first pass) G1 X5 Y5 F6000 ; go back a few mm G1 S1 X-235 Y-215 F360 ; move slowly to X and Y axis endstops once more (second pass) G90 ; absolute positioning G1 X250 Y250 F6000 ; go to first bed probe point and home Z G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing G91 ; relative positioning G1 S2 Z20 F100 ; lift Z relative to current position G90 ; absolute positioningThanks in advance

-

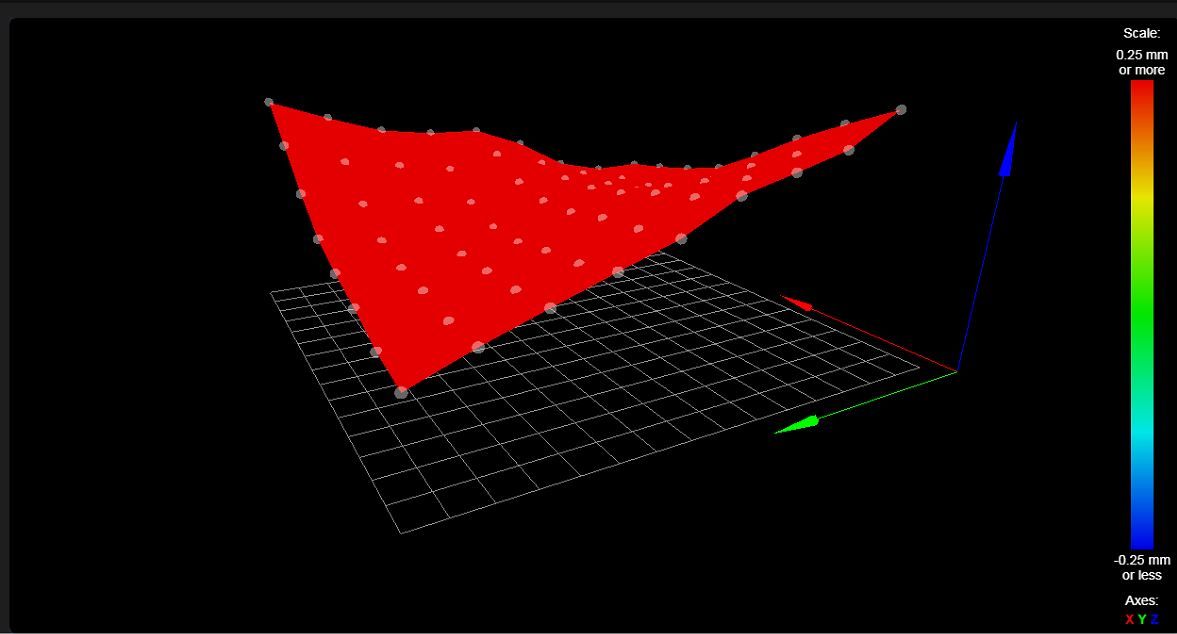

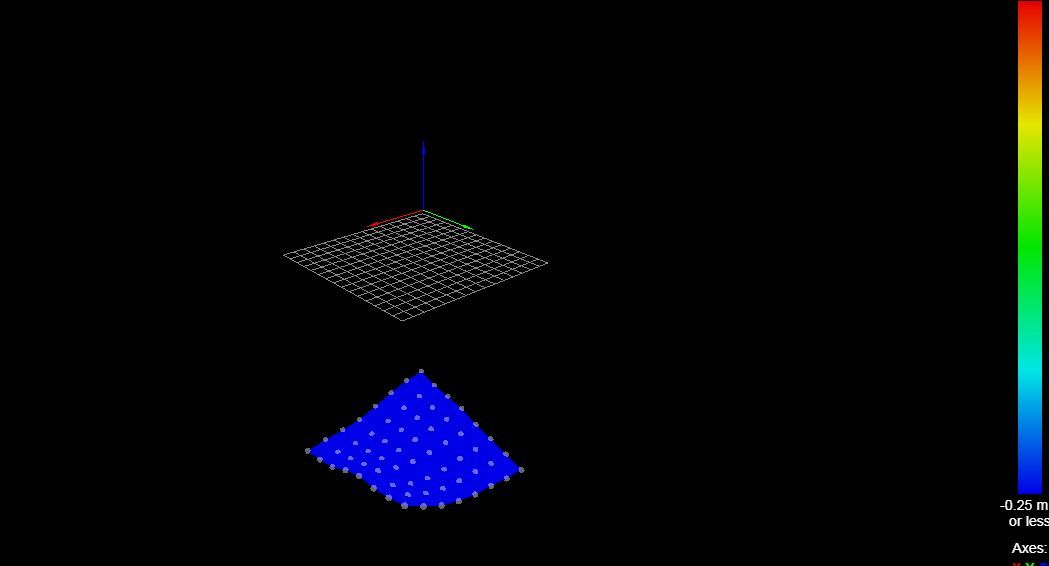

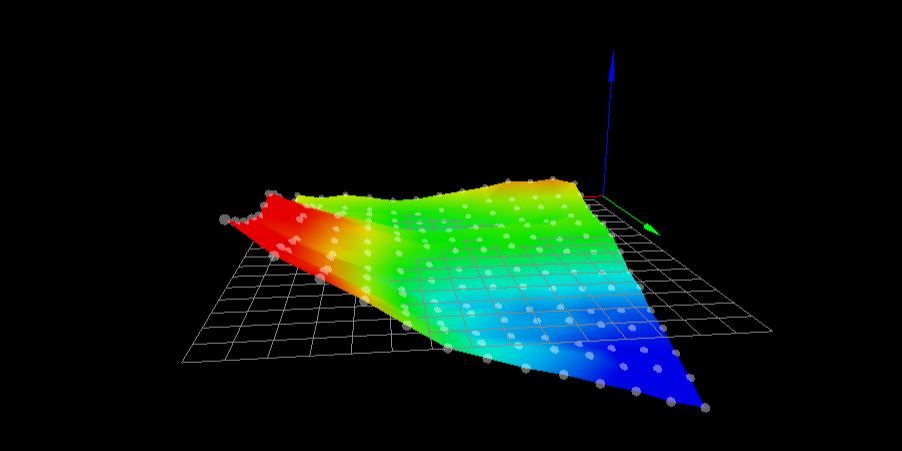

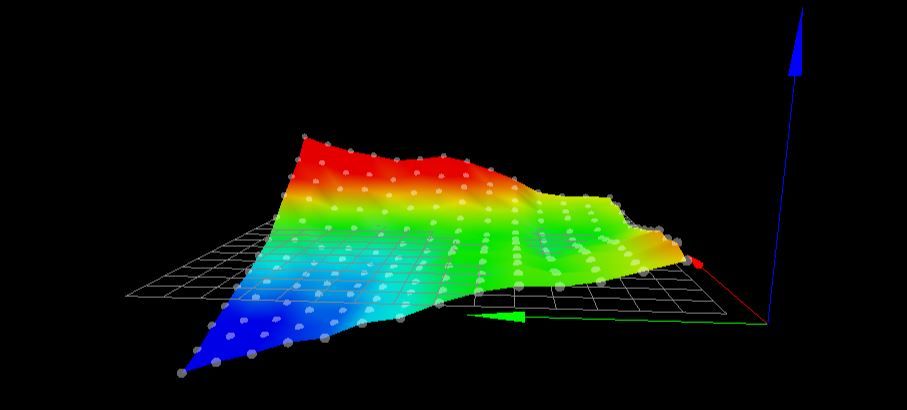

And here is the picture

-

@Thunder said in Z calibration offset:

G1 X250 Y250 F6000 ; go to first bed probe point and home Z

For now that G1 command above is OK but it doesn't take into account the z probe X and Y offsets - so you're getting close to the center of the bed but you're not at the center.

You have to be sure that G30 is setting the Z co-ordinate correctly before G29 will work as desired.

So do the following:

After the G30 in homeall.g comment out the G91 and the G1 commands.

Run homeall.g and see what the Z co-ordinate readout in the DWC is after the execution of G30.

Verify that it is correct either by measuring the gap between the nozzle and the bed OR jog down to Z=0 and see if the nozzle is just touching the bed.

Let me know what you find.

Frederick

-

Ok, I have now managed the calibration. But when I start the program from the slicer I get the Error: M375: Heightmap file bareplate.csv not found I think this means my startup code is not ok

thank you

-

Well you must have a command somewhere like this G29 S1 P"bareplate.scv".

For that to work at some point you would have to created that file with G29 S3 P"bareplate.csv".

Did you do so?

Frederick

-

Ok i checked and you are right. In the startup i had a M375 command. I deleted the line and replaced the command with G29 S1. And now my next question if load the g code of a part for printing the machine homes and makes the printer use the height map that i did eariler with G29 S0. But my nozzle is stil a few 0.1 mm from build plate. Do i correct this with baby steps ?

Thanks for all of your input

-

@Thunder said in Z calibration offset:

And now my next question if load the g code of a part for printing the machine homes and makes the printer use the > height map that i did eariler with G29 S0. But my nozzle is stil a few 0.1 mm from build plate. Do i correct this with baby

Refresh my memory please.

When creating the height map do you have commands something like these:

G90 G1 Xaaa Ybbb ; move the z probe to the center of the bed G30 ; set the Z=0 datum G29 ; probe the bed and create the height mapWhen loading the height map do you have commands something like these:

G90 G1 Xaaa Ybbb ; move the z probe to the center of the bed G30 ; set the Z=0 datum G29 S1 ; load the height mapFrederick

-

Yes like the last one, this code is in slicer start program.