Pressure advance Slow down

-

Make sure there are no entries in the config-override.g that supersede things.

-

If enabling pressure advance slow down the print, this is caused by either the extruder acceleration or extruder jerk being set too low. Your extruder acceleration is already set very high in the M201 command, but the jerk set in the M566 command is very low. So try increasing it as @JamesM suggested.

You can send M201 and M566 without parameters (even during a print) to check what values are being used.

-

Thanks for the suggestions!

I set a E value of 2000, then added the 2.2 pressure advance and max speed was still 15mm/s

nothing listed in override config. I think im just going to tune my slicer around the lack of PA.Now to work on this filament runout sensor!

-

Do you have Z hop on retraction? Wipe on retraction or coasting enabled?

-

yes,

0.18mm Zhop

wipe enabled 75%

did have retract on layer but im tweaking that. -

@dc42 does E acceleration play a role in pressure advance slowdowns? I was under the impression that only E jerk played a role in the pressure advance slowdown. E acceleration being low would slow down a print regardless of pressure advance, correct? The E and X/Y movement is synchronized, so any slow down would happen regardless of PA, no? And PA, while it uses the E acceleration to determine advancement amount, wouldn’t cause slow down with low acceleration. Actually, in some cases wouldn’t a combination of too high of acceleration combined with too low of jerk cause slowdowns? As in: if E jerk is slowing down the print with PA, wouldn’t increasing E(/X/Y) acceleration cause the print to slow even more because the PA is trying to advance even further?

-

@MadMonkey said in Pressure advance Slow down:

wipe enabled 75%

If you're going to use Z hope you might want to increase the max speed, accel and jerk for the z axis as well.

And it's recommended to disable wipe/coasting when using pressure advance.

-

im open to trying whatever.. honestly this seam is my issue, its causing bulges down stream from seam moves.

i did that test and found 2.20 to be my magic number, but cant make it work..What should i adjust on the M566/M201/M203 area?

-

M566 X900 Y900 Z60 E3000 ; Set maximum instantaneous speed changes (mm/min)

M203 X18000 Y18000 Z600 E6000 ; Set maximum speeds (mm/min)

M201 X3000 Y3000 Z200 E10000 ; Set accelerations (mm/s^2) -

@Phaedrux inputed those, restarting a new test. ill let ya know how it goes

Thanks again

-

@MadMonkey How did it go

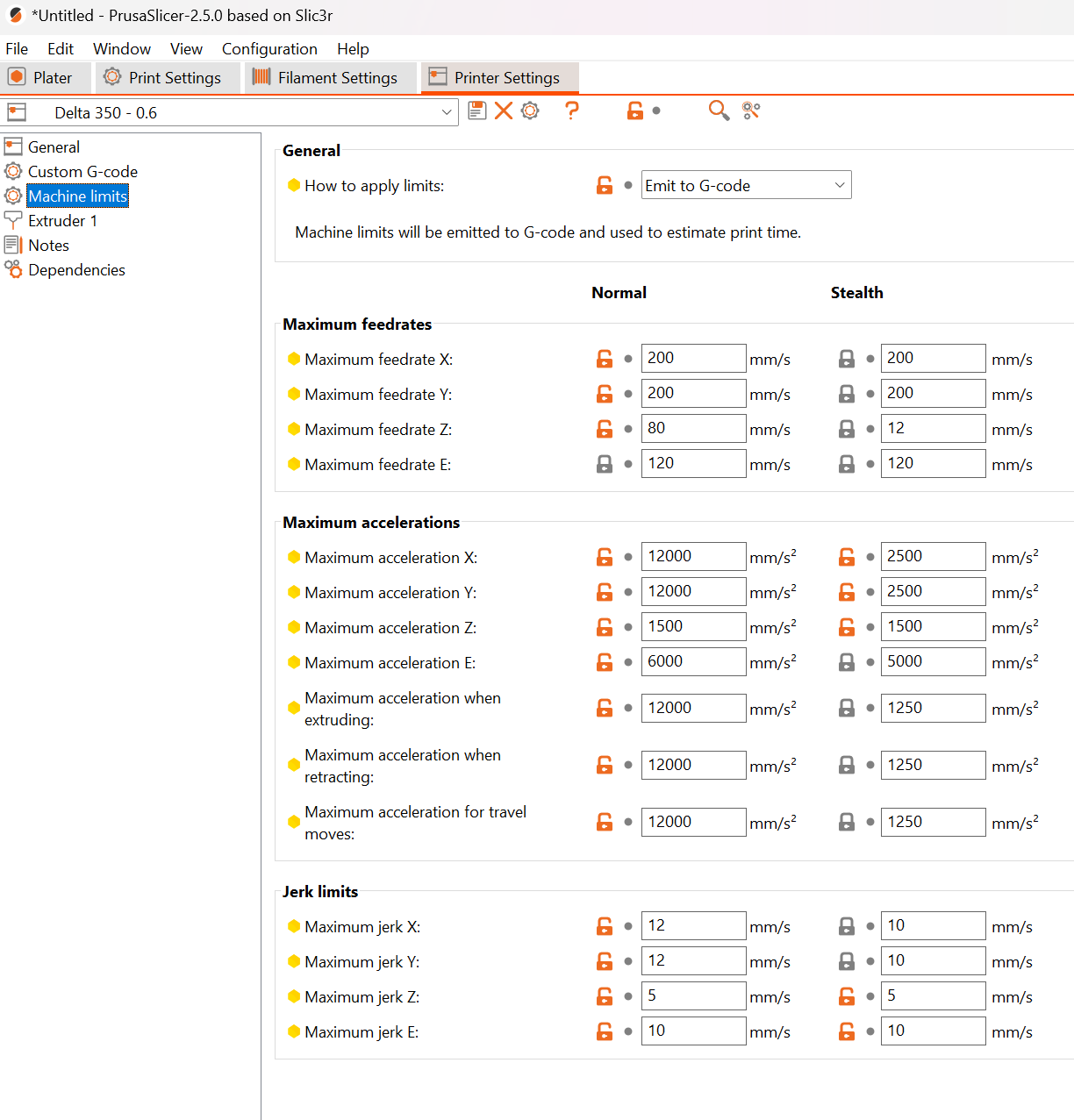

I had the same problem, and found that I had set very low jerk values in prusaslicer

I had the same problem, and found that I had set very low jerk values in prusaslicer

I had set minimum E jerk to 1 mm/s, then changed it to 10 mm/s as in the picture, and now it prints fast as if I don't have pressure advance enabled. My settings are for a self built delta printer.

-

@Velvia

IMO best practice would be NOT to emit the limits to the g-code with PrusaSlicer. Tune them for your printer, and set them in config or as part of your job/print-start routine. Then input the values from your tuning into PrusaSlicer and just use them for time estimations.That way you avoid having a "second" source of potential fuckup for your settings

😅(don't ask me how i know😒) -

@Velvia as @Exerqtor suggests you must configure PrusaSlicer not to emit those parameters to GCode. The reason is that whoever implemented M203 (set max speeds) in Marlin ignored established precedent and chose mm/sec for the units, instead of mm/min which is standard in GCode and had been used by RepRapFirmware for several years already in M203. So if you allow PrusaSlicer to mut those commands, the maximum speeds will be forced to very low values.