PT100 sensor on Duet2 sporadically hunting for target temp

-

that fluctuation of +/- .5 degree is normal

-

My macros don't seem to progress. They are stuck waiting for target temp to be reached. Do I need to specify a tolerance somewhere?

I am also still getting heater faults when printing. I will try to capture that data if I can ever get my bed leveling macro to run.

-

post the macro

-

It isn't any one macro. It is all of them.

As an example:

M291 P"Preheating the bed to 60 and nozzle to 210 for accurate probing" T0 M104 S210 ; Set nozzle to 210 and release M190 S60 ; Set bed to 60 and wait M109 S210 ; Set nozzle to 210 and waitAs just one example, the macro I am running now can never get past the M109 command as it doesn't seem to think that hotend has landed on 210C event though it is +/1 one degree.

-

@mitch

that should finish.whats the next command?

-

It doesn't get past it in any of my macros. It just sits and hunts for temp there.

I have print statements, tones, you name it. It never gets past setting temp in the macros.

example from the video:

; Preheat to probing temps ; M291 P"Preheating the bed to 60 and nozzle to 210 for accurate probing" T0 M104 S210 ; Set nozzle to 210 and release M190 S60 ; Set bed to 60 and wait M109 S210 ; Set nozzle to 210 and wait ; Tone to get user attention ; M400 ; Clear movement buffer so tones play reliably M300 S666 P500 G4 P501 M300 S1111 P300 G4 P301 ; Move nozzle to center of bed at Z10 and drop to Z1 ; M291 P"Nozzle will now move to center of bed and move close to the bed" T0 M98 P/macros/general/1_Center_Nozzle ;P move to bed center ; Reset z to 8 to allow jogging up to touch bed to nozzle ; G92 Z8 ; Dialog to allow user to job z to touch nozzle to bed gently and then move Z down 10 ; M291 P"Carefully Jog the Z Axis until the bed and nozzle are touching and click OK" R"Setting Z=0" Z1 S3 G92 Z0 ; set z = 0 -

@mitch said in PT100 sensor on Duet2 sporadically hunting for target temp:

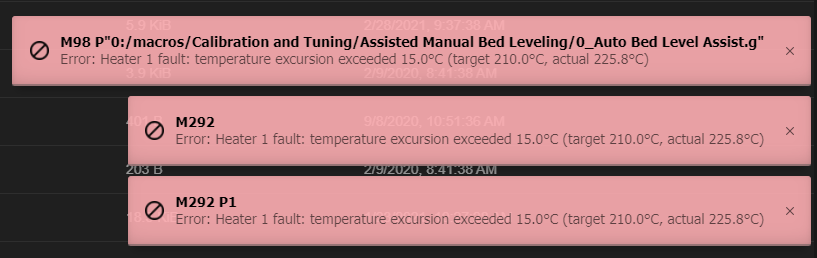

I am also getting heater faults during prints because it is not staying on temp.

please post the exact message you are getting.

did you use a special M570 command?

-

I apologize. Let me be more clear.

I believe I have two heater related issues.

-

It seems to not progress in my macros because it is hunting to hit target temp even thought it is within 2.5C

-

I have sporadic heater faults during prints. I need to capture more data on this to troubleshoot it. I have just returned to prints to find the print paused and a heater fault.

Special M570 command?

-

-

-

@Veti Thanks,

Nope, no M570 defined in config.g or config_override.g files.

-

but it does get past the M109 when you print something?

-

Yes it does.

I commented out the Tone generation and I saw this particular macro get to about line 79 and then it just drops out. Again, I think I have a few issues going on here so the troubleshooting is a bit confusing. I am trying to rule some variables out.

; Helps guide leveling the bed mechanically, and calibrate the ZProbe trigger height before running a grid bed compensation routine.. ; ; Preamble to tell the user to prepare the printer before continuing ; ;M291 P"Before proceeding make sure the printer is mechanically sound and properly functioning." R"Prepare printer for leveling routine" S3 ; User must click OK ;M291 P"ZProbe should be configured and working. Clear the print bed of any obstacles or debris." R"Prepare printer for leveling routine" S3 ; User must click OK ;M291 P"This routine will take about 10-20 minutes and heat both the bed and nozzle." R"Prepare printer for leveling routine" S3 ; User must click OK ;M291 P"You will need a piece of paper. Filament will be unloaded." R"Prepare printer for leveling routine" S3 ; User must click OK ;M291 P"Make sure you have successful Gcodes logged to the console before proceeding." R"WARNING" S3 ; User must click OK or cancel ;M291 P"Make a note of your M558 Z value and backup current heightmap before proceeding." R"WARNING" S3 ; User must click OK or cancel M929 S1 ; start logging ; Clear compensation map and Zprobe trigger height ; M291 P"Grid bed compensation map will be disabled. Ok or Cancel?" R"WARNING" S3 ; User must click OK or cancel. M561 ; Disable any current bed compensation G29 S2 ; Clear mesh bed compensation perameters G31 Z0 ; Reset zprobe trigger height ; Heat up bed and nozzle to PLA temps in prep for filament removal and probing ; M291 P"Bed and nozzle will preheat and home all axis." R"Preheat and Home" S3 T0 ; User must click OK or cancel M104 S130 ; Set nozzle to 130 and release M140 S55 ; Set bed to 55 and release ; home all axis ; G28 XY G28 Z ; Home all axis G90 ; Absolute positioning T0 ; Activate first tool ; Set lower speeds for Z homing and lower Z motor current ; M566 Z10 ; Set maximum instantaneous speed changes (mm/min) (Jerk) M203 Z400 ; Set maximum speeds (mm/min) M201 Z100 ; Set maximum accelerations (mm/s^2) M913 Z40 ; Drop motor current to prevent damage in case of head crash ; Move nozzle forward for filament removal ; ;M291 P"Moving nozzle to the front for filament removal and cleaning." T0 ;G1 X50 Y5 Z100 ; Moves print head to front left and drops the bed down for easy access ;M109 S130 ; Set nozzle to 130 and wait ; Tone to get user attention ; ;M400 ; Clear movement buffer so tones play reliably ;M300 S666 P500 ;G4 P501 ;M300 S1111 P300 ;G4 P301 ; Unload filament and clean nozzle ; ;M291 P"Unload filament if loaded and clean nozzle, then press OK to continue" R"Unload Filament" S3 T0 ; User must click OK or cancel M702 ; Unload Filament ; Preheat to probing temps ; M291 P"Preheating the bed to 60 and nozzle to 210 for accurate probing" T0 M104 S210 ; Set nozzle to 210 and release M190 S60 ; Set bed to 60 and wait M109 S210 ; Set nozzle to 210 and wait ; Tone to get user attention ; ;M400 ; Clear movement buffer so tones play reliably ;M300 S666 P500 ;G4 P501 ;M300 S1111 P300 ;G4 P301 ; Move nozzle to center of bed at Z10 and drop to Z1 ; M291 P"Nozzle will now move to center of bed and move close to the bed" T0 M98 P/macros/general/1_Center_Nozzle ;P move to bed center ; Reset z to 8 to allow jogging up to touch bed to nozzle ; G92 Z8 ; Dialog to allow user to job z to touch nozzle to bed gently and then move Z down 10 ; M291 P"Carefully Jog the Z Axis until the bed and nozzle are touching and click OK" R"Setting Z=0" Z1 S3 G92 Z0 ; set z = 0 ; Move nozzle to leveling points and prompt user to level bed at each ; M291 P"Nozzle will now move to the 4 leveling points twice." S1 T2 ; Move to leveling point 1 G1 Z2 ; move to z2 for travel G1 X26 Y25 F6000 ; Move to front left corner M400 M291 P"Adjust point 1 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension." R"Adjustment Point 1" S2 Z1 ; Move to leveling point 2 G1 Z2 ; Move to Z2 for clearance G1 X195 Y195 F6000 ; Move to rear right corner M400 M291 P"Adjust point 2 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension." R"Adjustment Point 2" S2 Z1 ; Move to leveling point 3 G1 Z2 ; Move to Z2 for clearance G1 X195 Y25 F6000 ; Move front right corner M400 M291 P"Adjust point 3 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension." R"Adjustment Point 3" S2 Z1 ; Move to leveling point 4 G1 Z2 ; Move to Z2 for clearance G1 X26 Y195 F6000 ; Move rear left corner M400 M291 P"Adjust point 4 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension." R"Adjustment Point 4" S2 Z1 ; Repeat to verify ; M291 P"The adjustment sequence will now repeat for fine adjustment." S1 T2 ; Move to leveling point 1 G1 Z2 ; move to z2 for travel G1 X26 Y25 F6000 ; Move to front left corner M400 M291 P"Adjust point 1 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension." R"Adjustment Point 1" S2 Z1 ; Move to leveling point 2 G1 Z2 ; Move to Z2 for clearance G1 X195 Y195 F6000 ; Move to rear right corner M400 M291 P"Adjust point 2 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension." R"Adjustment Point 2" S2 Z1 ; Move to leveling point 3 G1 Z2 ; Move to Z2 for clearance G1 X195 Y25 F6000 ; Move front right corner M400 M291 P"Adjust point 3 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension." R"Adjustment Point 3" S2 Z1 ; Move to leveling point 4 G1 Z2 ; Move to Z2 for clearance G1 X26 Y195 F6000 ; Move rear left corner M400 M291 P"Adjust point 4 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension." R"Adjustment Point 4" S2 Z1 ; Move nozzle to center of bed at z10 ; M291 P"Nozzle will now move to center of bed to reset Z0" S3 G1 Z1 ; Drop bed for nozzle clearance ;G1 X112.5 Y112.5 Z2 F4000 ; Move to bed center M98 P/macros/general/1_Center_Nozzle ;P define the parameter and is not part of the name ; Reset z to 5 to allow jogging up to touch bed to nozzle ; G92 Z5 ; Dialog to allow user to jog z to touch nozzle to bed gently and then move Z down 10 ; M564 S0 ; To allow movement lower than where the firmware thinks Z=0 is. M291 P"Jog the Z Axis until the bed and nozzle are touching and click OK" R"Setting Z=0" Z1 S3 G92 Z0 ; Set z = 0 G1 Z1 ; Drop bed for nozzle clearance M291 P"The bed has been mechanically leveled and Z0 set." S2 ; Tone to get user attention ; M400 ; Clear movement buffer so tones play reliably M300 S666 P600 G4 P601 M300 S1511 P300 G4 P301 M291 P"Probing complete. Turning off heaters and homing axis." ; Turn off heaters ; M104 S0 ; Set nozzle to 0 and release M140 S0 ; Set bed to 0 and release G28 XY ; Home XY ; Set normal settings after stall detection probing ; M98 P/macros/general/Normal_Settings ;P define the parameter and is not part of the name ; Tone to get user attention M400 ; Clear movement buffer so tones play reliably M300 S666 P600 G4 P601 M300 S1511 P300 G4 P301 M291 P"Run Trigger Height Macro to determine trigger height" M929 S0 ; stop logging -

@mitch said in PT100 sensor on Duet2 sporadically hunting for target temp:

M98 P/macros/general/1_Center_Nozzle

This is just acting really strange. I can put the lines into the console one by one starting at line 79 and it all works fine. But when I run the macro it just seems to get to around Line 79 and then just exit. No errors or warnings.

-

you don't have your macro in line 80 in ""

@mitch said in PT100 sensor on Duet2 sporadically hunting for target temp:

M98 P/macros/general/1_Center_Nozzle

move to bed center

move to bed centerM98 P"/macros/general/1_Center_Nozzle" -

After trying numerous times the macro just started running. Part way through I got the heater fault.

Log:

2021-02-28 10:59:51 [info] Event logging started at level debug 2021-02-28 10:59:51 [info] Running: Duet Ethernet 1.02 or later: 3.2 (2021-01-05) 2021-02-28 10:59:51 [info] M291: - WARNING - Grid bed compensation map will be disabled. Ok or Cancel? 2021-02-28 10:59:53 [info] M292: cancelled: false 2021-02-28 10:59:53 [info] M291: - Preheat and Home - Bed and nozzle will preheat and home all axis. 2021-02-28 10:59:54 [info] M292: cancelled: false 2021-02-28 11:00:15 [debug] {"beep_freq":666,"beep_length":500} 2021-02-28 11:00:16 [debug] {"beep_freq":1111,"beep_length":300} 2021-02-28 11:00:16 [info] M291: - [no title] - Preheating the bed to 60 and nozzle to 210 for accurate probing 2021-02-28 11:00:35 [info] M291: - [no title] - Nozzle will now move to center of bed and move close to the bed 2021-02-28 11:00:36 [info] M291: - Setting Z=0 - Carefully Jog the Z Axis until the bed and nozzle are touching and click OK 2021-02-28 11:01:16 [info] M292: cancelled: false 2021-02-28 11:01:16 [info] M291: - [no title] - Nozzle will now move to the 4 leveling points twice. 2021-02-28 11:01:18 [info] M291: - Adjustment Point 1 - Adjust point 1 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension. 2021-02-28 11:03:00 [info] M292: cancelled: false 2021-02-28 11:03:03 [info] M291: - Adjustment Point 2 - Adjust point 2 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension. 2021-02-28 11:04:05 [info] M292: cancelled: false 2021-02-28 11:04:07 [info] M291: - Adjustment Point 3 - Adjust point 3 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension. 2021-02-28 11:04:45 [info] M292: cancelled: false 2021-02-28 11:04:48 [info] M291: - Adjustment Point 4 - Adjust point 4 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension. 2021-02-28 11:05:36 [info] M292: cancelled: false 2021-02-28 11:05:36 [info] M291: - [no title] - The adjustment sequence will now repeat for fine adjustment. 2021-02-28 11:05:38 [info] M291: - Adjustment Point 1 - Adjust point 1 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension. 2021-02-28 11:06:21 [info] M292: cancelled: false 2021-02-28 11:06:24 [info] M291: - Adjustment Point 2 - Adjust point 2 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension. 2021-02-28 11:06:38 [info] M292: cancelled: false 2021-02-28 11:06:40 [info] M291: - Adjustment Point 3 - Adjust point 3 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension. 2021-02-28 11:07:13 [info] M292: cancelled: false 2021-02-28 11:07:16 [info] M291: - Adjustment Point 4 - Adjust point 4 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension. 2021-02-28 11:07:21 [warn] Error: Heater 1 fault: temperature excursion exceeded 15.0°C (target 210.0°C, actual 225.8°C) 2021-02-28 11:07:23 [info] M292: cancelled: false 2021-02-28 11:07:23 [info] M291: - [no title] - Nozzle will now move to center of bed to reset Z0 2021-02-28 11:07:30 [info] M292: cancelled: false 2021-02-28 11:07:32 [info] M291: - Setting Z=0 - Jog the Z Axis until the bed and nozzle are touching and click OK 2021-02-28 11:10:40 [info] M292: cancelled: false 2021-02-28 11:10:40 [info] M291: - [no title] - The bed has been mechanically leveled and Z0 set. 2021-02-28 11:11:01 [info] M292: cancelled: false 2021-02-28 11:11:01 [debug] {"beep_freq":666,"beep_length":600} 2021-02-28 11:11:02 [debug] {"beep_freq":1511,"beep_length":300} 2021-02-28 11:11:02 [info] M291: - [no title] - Probing complete. Turning off heaters and homing axis. 2021-02-28 11:11:17 [debug] {"beep_freq":666,"beep_length":600} 2021-02-28 11:11:17 [debug] {"beep_freq":1511,"beep_length":300} 2021-02-28 11:11:18 [info] M291: - [no title] - Run Trigger Height Macro to determine trigger height 2021-02-28 11:11:18 [info] Event logging stopped -

@jay_s_uk Thanks,

I updated the file. Seems to still run the same. But I will make sure to find all the macros that have this command and add the quotes.

Just seems like sporadic behavior.

-

This may be a combination of some macro issues due to recent firmware updates as well as an intermittent connection near the hotend probe.

Thanks for the help. I am going to try to nail down the probe issue first to start to rule out some variables and make this easier to figure out.

-

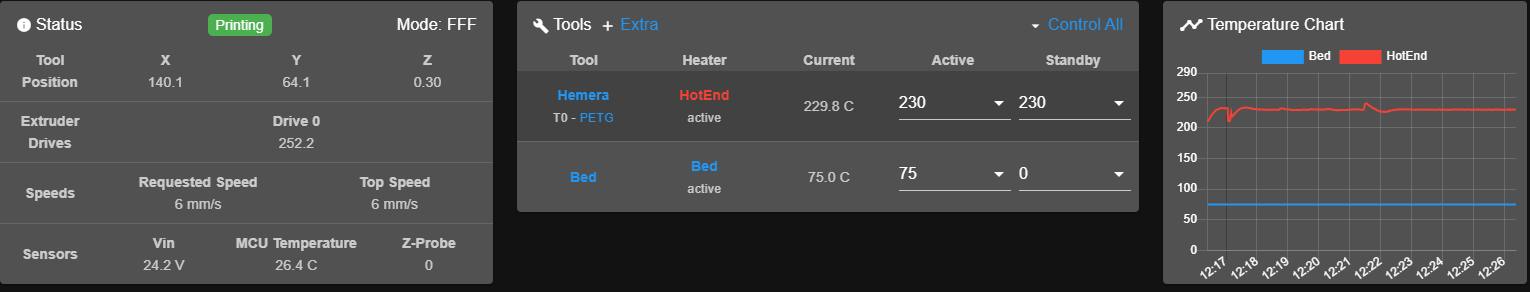

post a picture of the temperature graph

-

I am attempting to run a print right now. The blips in the graph are heater faults I have had to clear. The temp just seems to stay on and then drift, clear it, it works again. Not spikes to 2000 or anything like that.

-

those are spikes none the less.

this points to either noise in the pt100 cabling. try to isolate the cables from other cables especially motor cables.