6 Red flashes in the duet monitor sensor v1.7a. Duet 2 Wifi

-

I bought this rotary sensor a while back for my Duet 2 and could not get it to work for the life of me. I keep getting 6 red flashes even after running the trouble shooting steps. I have it on a Tevo Little Monster (Titan Extruder). I do not get any green LEDs when initializing. Printing with it returns the pause code.

M591 D0 retuns:

Duet3D magnetic filament monitor on input 3, enabled, sensitivity 24.80mm/rev, allow 70% to 130%, check every 3.0mm, no data receivedConfig is as follows:

; Configuration file for Duet WiFi (firmware version 2.03)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.8 on Thu Apr 30 2020 15:44:36 GMT-0400 (Eastern Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"The Fortune Teller" ; set printer name

M665 R155 L397.19 B155 H520 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them; Network

M551 P"Turnip123!" ; set password

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S1 ; enable FTP

M586 P2 S1 ; enable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z80.00 E420 ; set steps per mm

M566 X1200.00 Y1200.00 Z1200.00 E3000.00 ; set maximum instantaneous speed changes (mm/min)

M203 X40000.00 Y40000.00 Z40000.00 E3000.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z1000.00 E1500.00 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z1800 E1500 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

M915 X Y Z S20 F1 R3; Axis Limits

M208 Z0 S1 ; set minimum Z; Endstops

M574 X2 Y2 Z2 S1 ; set active high endstops

M591 D0 P3 C3 S1 R70:130 L24.8 E3.0 ; Duet3D rotating magnet sensor for extruder drive 0 is connected to E0 endstop input, enabled, sensitivity 24.8mm.rev, 70% to 130% tolerance, 3mm detection lengthM591 D0 ; display filament sensor parameters for extruder drive 0

; Z-Probe

M307 H3 A-1 C-1 D-1 ; disable heater on PWM channel for BLTouch

M558 P9 H5 F120 T6000 R0.2 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X0 Y20 Z1.37 ; set Z probe trigger value, offset and trigger height

M557 R150 S45 ; define mesh grid; Heaters

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M106 P0 S0 I0 F500 H-1 X0.75 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

M501Override is as follows:

; config-override.g file generated in response to M500 at 2020-09-15 14:08

; This is a system-generated file - do not edit

; Delta parameters

M665 L400.659:400.659:400.659 R157.354 H523.578 B155.0 X0.417 Y0.551 Z0.000

M666 X0.650 Y-1.210 Z0.560 A-0.25 B-0.21

; Heater model parameters

M307 H0 A90.0 C700.0 D10.0 S1.00 V0.0 B0

M307 H1 A286.1 C196.6 D4.9 S0.50 V23.8 B0

M307 H2 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H4 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H5 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H6 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H7 A340.0 C140.0 D5.5 S1.00 V0.0 B0

G10 L2 P1 X0.00 Y0.00 Z0.00

G10 L2 P2 X0.00 Y0.00 Z0.00

G10 L2 P3 X0.00 Y0.00 Z0.00

G10 L2 P4 X0.00 Y0.00 Z0.00

G10 L2 P5 X0.00 Y0.00 Z0.00

G10 L2 P6 X0.00 Y0.00 Z0.00

G10 L2 P7 X0.00 Y0.00 Z0.00

G10 L2 P8 X0.00 Y0.00 Z0.00

G10 L2 P9 X0.00 Y0.00 Z0.00I have gotten the Bigtree Smart sensor to run on Marlin boards without issue, so I am not sure what is going on here. Open to suggestions.

Thanks,

Dom -

I got one working with my Duet2 running RRF 3.2 firmware.

Here's my config:

M591 D0 P4 C"e0_stop" S1 R10:200 L27 E20I've got P4 since I have a switch also. Your P3 is fine.

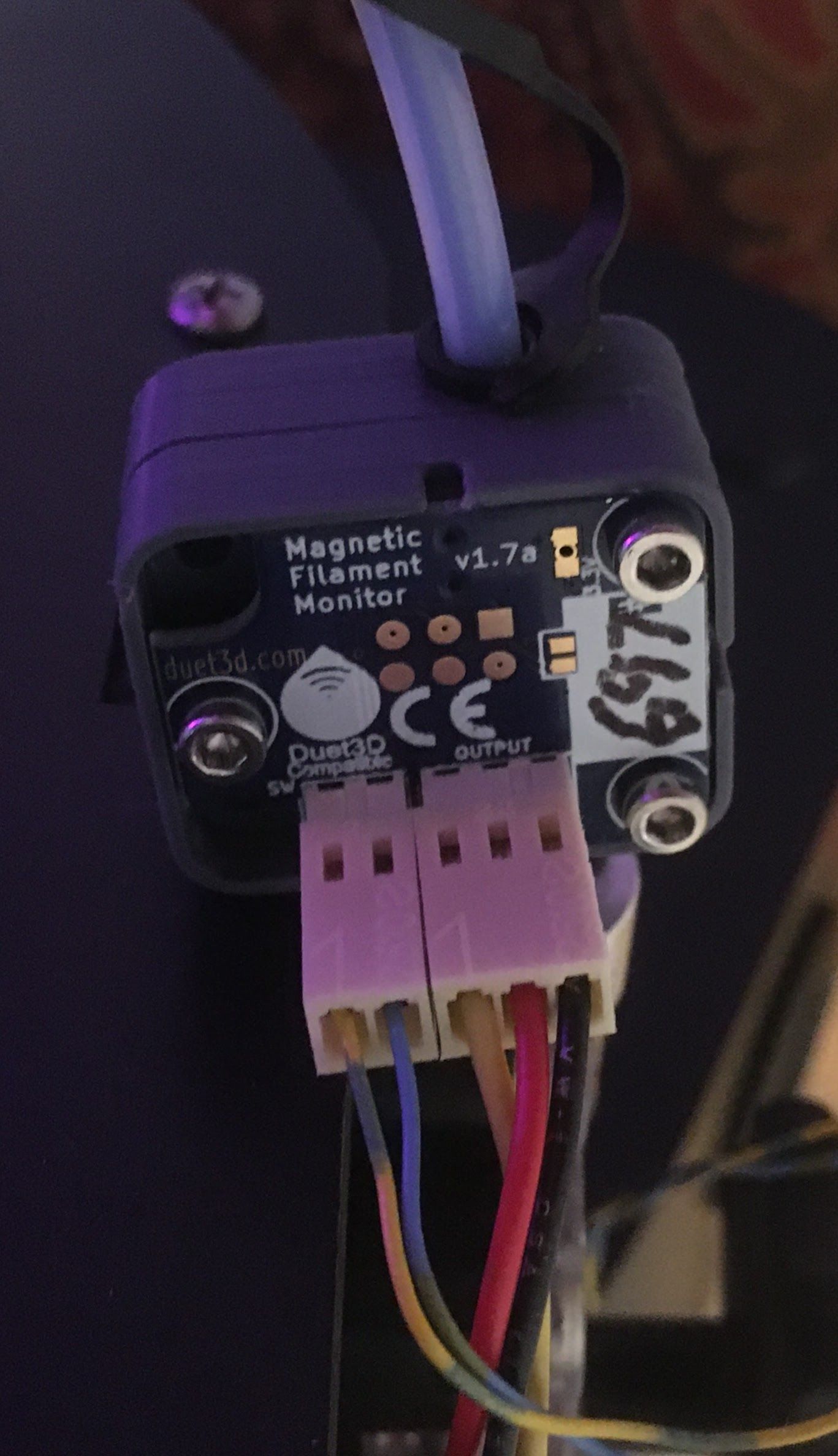

My C"e0_stop" is the same as your C3Here's a photos of the wires on my sensor and on my Duet if that helps you.

-

I do not have the two pin connector connected to anything. Could that be the issue? I am trying to avoid switching firmwares as it quite a challenge for me the first time.

-

I looked it up:

From THIS link.

6 flashes: Magnet not detected. Typically this means that the magnet is too far away from the sensor chip.

Did you buy this with a plastic housing or did you print your own housing?

-

This came with the plastic housing. I did see this documentation but they do not go into detail on how to solve this.

-

@DomMilan You need to get the magnet closer to the sensor on the PCB.

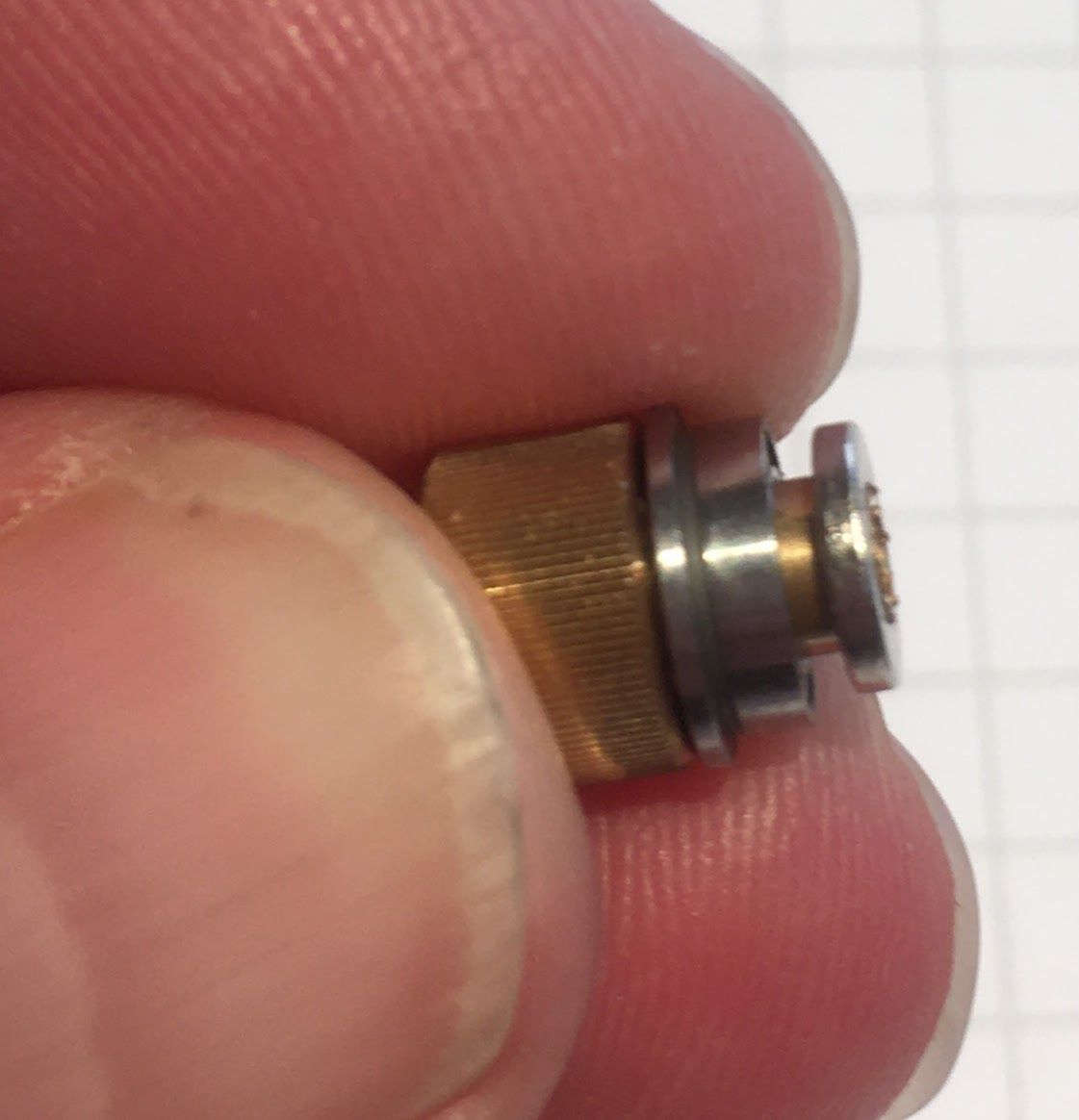

Can you send a photo of the magnet attached to the shaft?

That will help us see that the magnet is placed properly.Then you should tighten the two long bolts and see if you can get the six flashes to go away.

-

Long bolts are as tight as they will go.

-

Take the PCB off and put the magnet back on the end of the brass part.

It's a ring and it fell off when you removed the back-half of the sensor.

-

@alankilian That did not resolve the issue

-

Sorry, can you send a photo of the magnet attached to the brass part with it all assembled into the housing, but with the PCB removed?

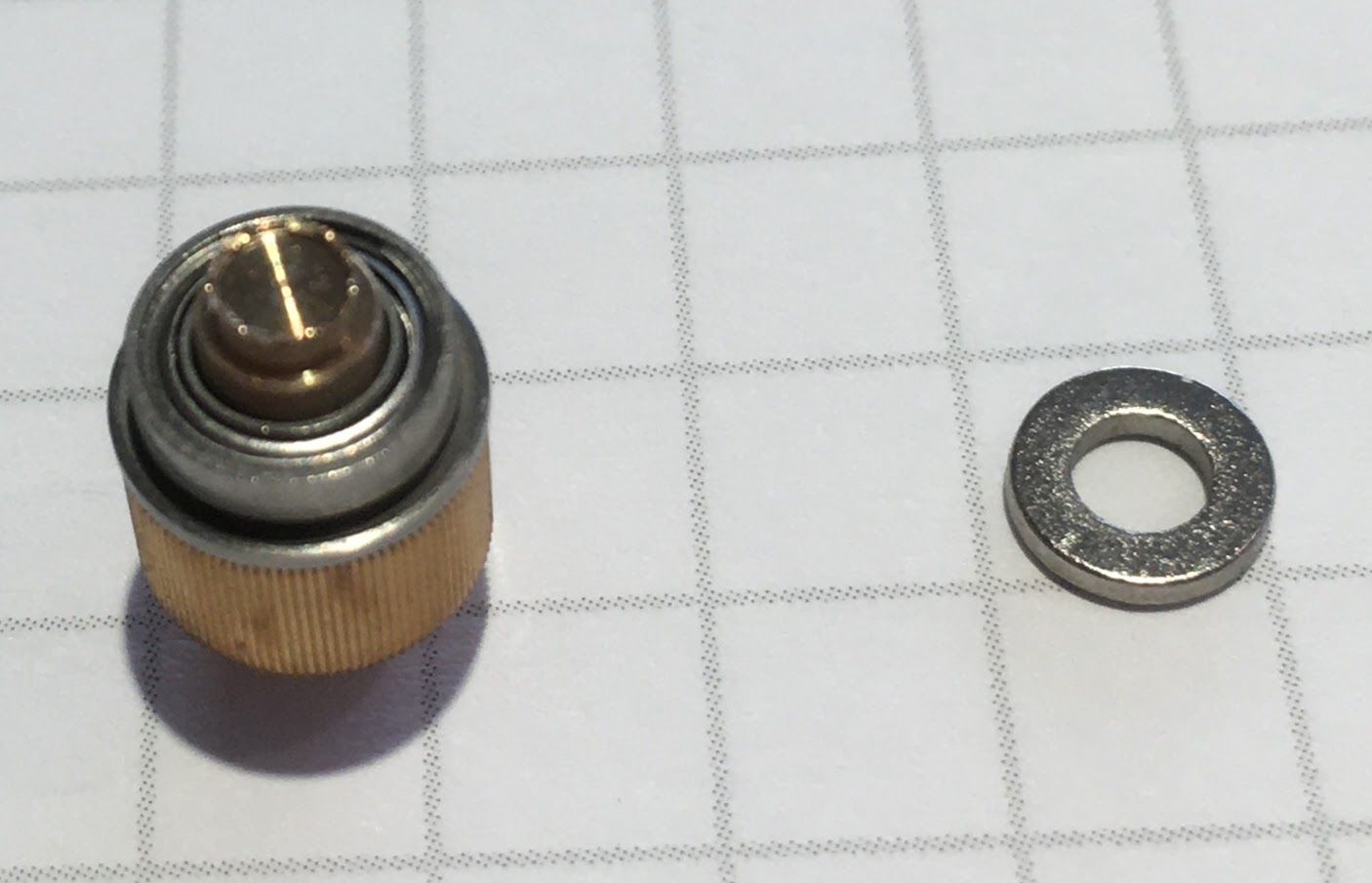

Here's a photo of the brass part and the ring magnet taken apart.

There are some "fingers" on the brass part that hold the ring magnet firmly.

Here's an image of them assembled properly:

-

@alankilian Thank you that picture. It seems at one point I reversed the direction of the idler. I am getting an short green flash with a long red flash now. When I move filament thru it it becomes green. I will try to test with it shortly and see if that does it.

-

@DomMilan Oh MAN, you're getting the correct type of flashes now!

I hope it works for you.

-

@alankilian It works when I am printing but whenever I get retractions it goes into a pause state.

-

@DomMilan Post the result of M591 D0 after it pauses due to retract.

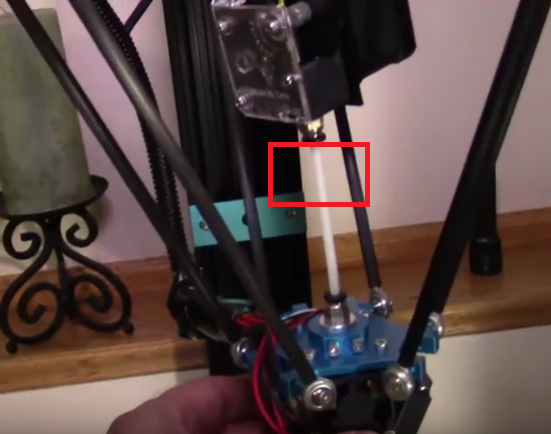

What kind of printer is this used on and where is it installed?

Mine is on a delta right after the extruder and it's working well.We'll be able to tell better once you post the numbers to see if it's just a little too sensitive or if it's something else.

-

@alankilian

M591 D0 returns:

Duet3D magnetic filament monitor on input 3, enabled, sensitivity 24.80mm/rev, allow 70% to 130%, check every 3.0mm, version 3, mag 132 agc 108, measured sensitivity 26.31mm/rev, min 53% max 106% over 100.2mmI am using this on a Tevo Little Monster with a real e3D Titan Extruder.

-

Where do you have your filament monitor installed?

I would recommend installing it as close to the extruder as possible.

Down here in red:

It looks like you got underextrusion.

You've got the lower limit set to 70% and it hit 53% and triggered.You could first try setting the limits to something like 20% to 150% and see if that's wide enough to stop the false triggering.

-

@alankilian I have it right before the extruder, I am trying to avoid placing it in line between the Hotend and Extruder as I have had issues with that with the BTT smart F sensor on my other machines. Changing the sensitivity seemed to do it. I was able to print with it. Sensitivity can be adjusted later should it be too weak. My esteps look good so I have my doubts about that being a root cause. I am happy with the progress made on this now. Took me a year to figure out what we did in these few days. Ill play with the settings but the root issue has been solved.

Thanks so much!