6 Red flashes in the duet monitor sensor v1.7a. Duet 2 Wifi

-

I looked it up:

From THIS link.

6 flashes: Magnet not detected. Typically this means that the magnet is too far away from the sensor chip.

Did you buy this with a plastic housing or did you print your own housing?

-

This came with the plastic housing. I did see this documentation but they do not go into detail on how to solve this.

-

@DomMilan You need to get the magnet closer to the sensor on the PCB.

Can you send a photo of the magnet attached to the shaft?

That will help us see that the magnet is placed properly.Then you should tighten the two long bolts and see if you can get the six flashes to go away.

-

Long bolts are as tight as they will go.

-

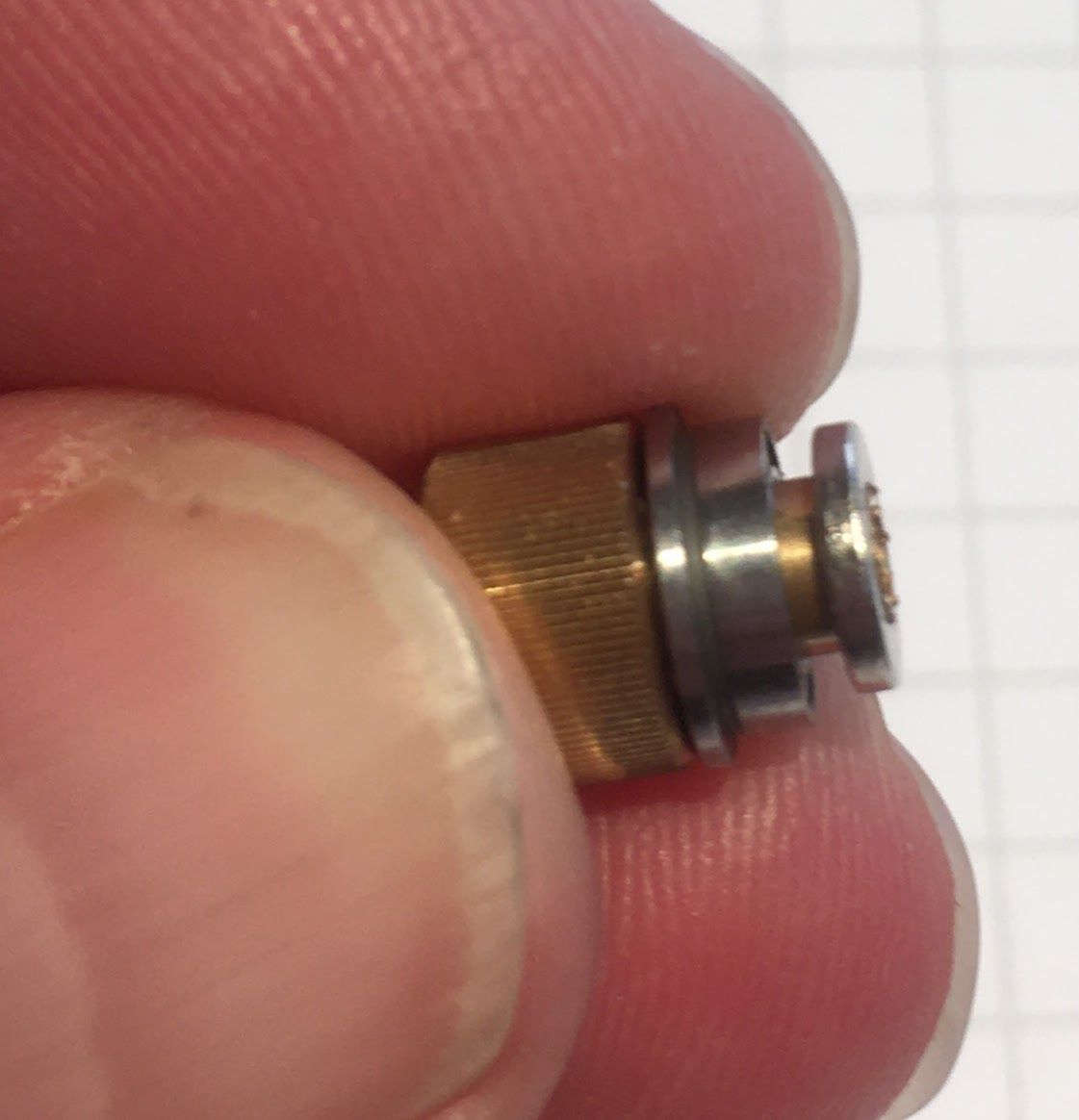

Take the PCB off and put the magnet back on the end of the brass part.

It's a ring and it fell off when you removed the back-half of the sensor.

-

@alankilian That did not resolve the issue

-

Sorry, can you send a photo of the magnet attached to the brass part with it all assembled into the housing, but with the PCB removed?

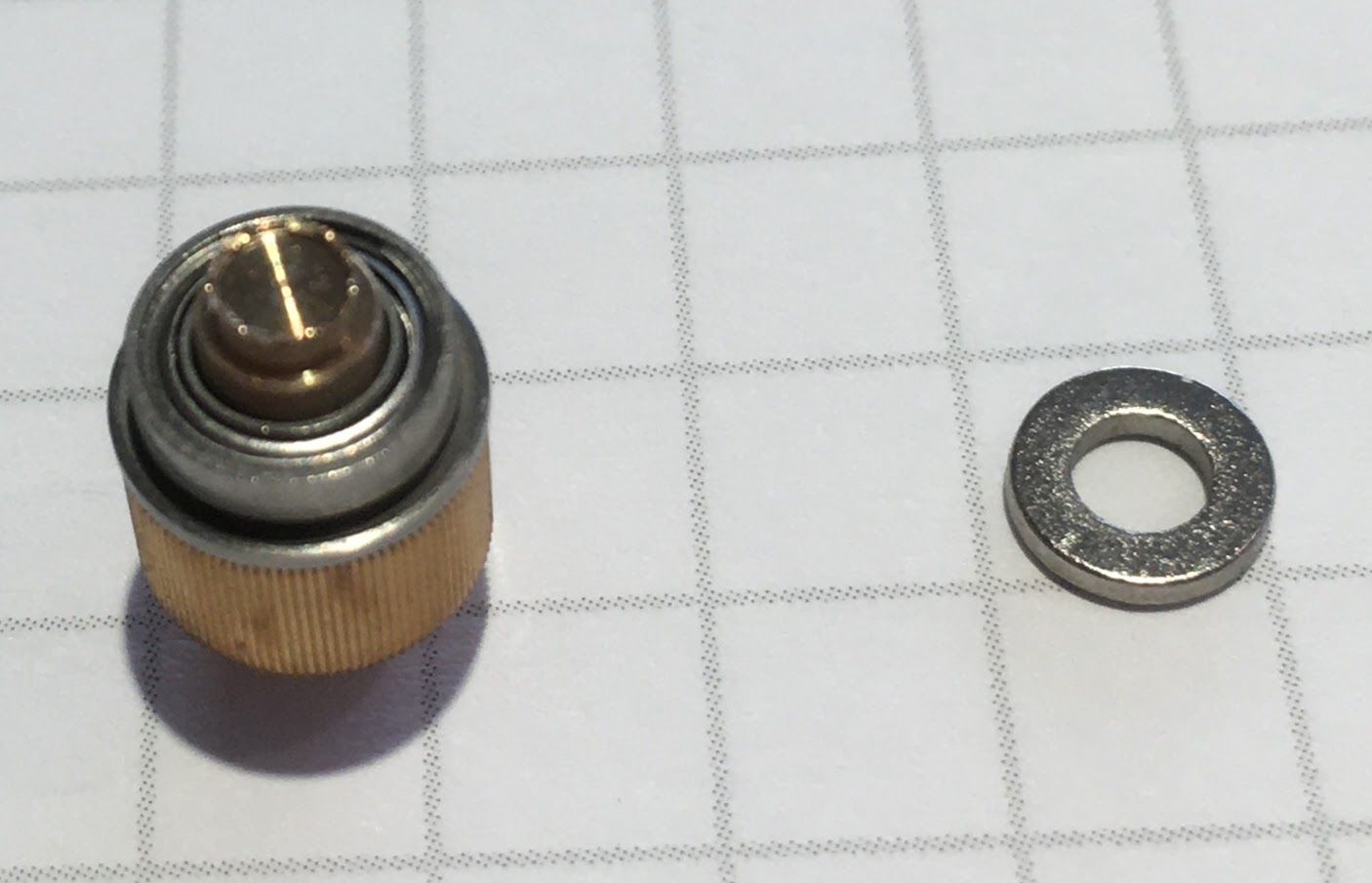

Here's a photo of the brass part and the ring magnet taken apart.

There are some "fingers" on the brass part that hold the ring magnet firmly.

Here's an image of them assembled properly:

-

@alankilian Thank you that picture. It seems at one point I reversed the direction of the idler. I am getting an short green flash with a long red flash now. When I move filament thru it it becomes green. I will try to test with it shortly and see if that does it.

-

@DomMilan Oh MAN, you're getting the correct type of flashes now!

I hope it works for you.

-

@alankilian It works when I am printing but whenever I get retractions it goes into a pause state.

-

@DomMilan Post the result of M591 D0 after it pauses due to retract.

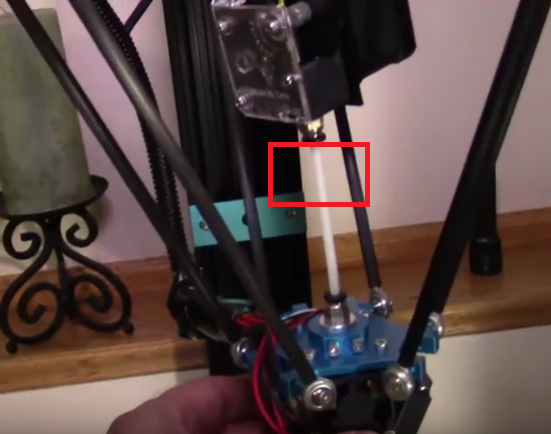

What kind of printer is this used on and where is it installed?

Mine is on a delta right after the extruder and it's working well.We'll be able to tell better once you post the numbers to see if it's just a little too sensitive or if it's something else.

-

@alankilian

M591 D0 returns:

Duet3D magnetic filament monitor on input 3, enabled, sensitivity 24.80mm/rev, allow 70% to 130%, check every 3.0mm, version 3, mag 132 agc 108, measured sensitivity 26.31mm/rev, min 53% max 106% over 100.2mmI am using this on a Tevo Little Monster with a real e3D Titan Extruder.

-

Where do you have your filament monitor installed?

I would recommend installing it as close to the extruder as possible.

Down here in red:

It looks like you got underextrusion.

You've got the lower limit set to 70% and it hit 53% and triggered.You could first try setting the limits to something like 20% to 150% and see if that's wide enough to stop the false triggering.

-

@alankilian I have it right before the extruder, I am trying to avoid placing it in line between the Hotend and Extruder as I have had issues with that with the BTT smart F sensor on my other machines. Changing the sensitivity seemed to do it. I was able to print with it. Sensitivity can be adjusted later should it be too weak. My esteps look good so I have my doubts about that being a root cause. I am happy with the progress made on this now. Took me a year to figure out what we did in these few days. Ill play with the settings but the root issue has been solved.

Thanks so much!