Error: attempting to extrude with no tool selected

-

@Phaedrux Well, the ground wire read 0.2, but the resolution on my multimeter is only 0.1, so not sure how accurate it is. Length is less than the 1000mm, it's only about 750mm.

Any way I can mitigate this until we find the issue? I can't get a print completed.

-

@Surgikill said in Error: attempting to extrude with no tool selected:

Any way I can mitigate this until we find the issue?

This may be inconvenient but could try disable or disconnect the paneldue. What version of PanelDue is it? What PCB version of Duet?

-

Duet 2 wifi PCB V1.04.

Paneldue 7i.I did a print, couldn't see any garbage errors on the paneldue, but I didn't get any tool unselected errors. I cut my wire in half and re-terminated it, so hopefully that mitigates any issues. The wire is running decently close to a stepper motor and a drivers (around 2-3 inches) and there's not much I can do about that. I have some shielded wire coming, so that might help.

-

@Surgikill said in Error: attempting to extrude with no tool selected:

The wire is running decently close to a stepper motor

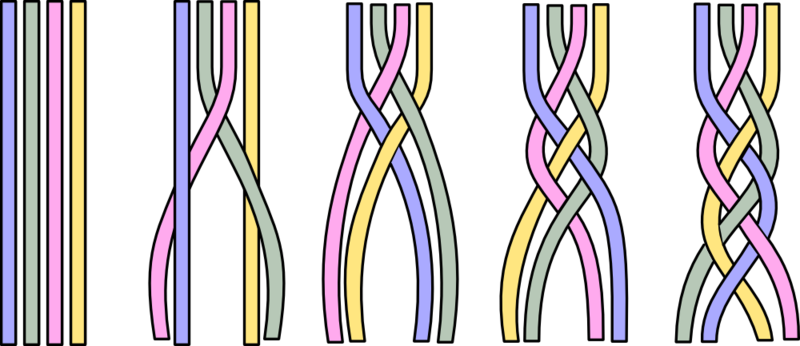

A braid for both wires might help. I've got my PanelDue wire running along side a stepper for ~1 meter since it's right next to the CorexY B motor and they run down the frame and back to the Duet box. I think I have a braid in the panelDue wire and pairs of the stepper motor are twisted together. So for interference I think I'm in worst case, but the braid/twist seems to help.

-

@Phaedrux I believe the stepper wire is braided, not sure. It might just be the paneldue wire. The stuff I got from filastruder is like 30ga. Re-wiring with shielded 22 gauge should hopefully fix it.

-

@Surgikill The plan going forward is to change from using a checksum to CRC, but that has not been implemented yet.

-

@Phaedrux Hopefully it happens soon. Even with the shortened 4 pin cable I'm still getting errors. No issues when the paneldue is disconnected. Kind of sucks that it's pretty much unusable.

-

@Surgikill said in Error: attempting to extrude with no tool selected:

No issues when the paneldue is disconnected. Kind of sucks that it's pretty much unusable.

Seeing what else can be done.

Can you share photos of the cable run? General printer photos? Maybe something will jump out.

-

The paneldue wire is 2-3 inches from that stepper wire. The only thing I can think of is I might be getting back EMF through the IR sensor wire which is messing with it. Sometimes my IR sensor will throw weird readings during travel moves, it will jump around. I'm going to re-wire this mess when I get the new cable in, but all wires are twisted (cat5 cable) so that should cancel anything out.

Also please excuse the berd air wiring. Still trying to figure out exactly how I want to wire it and mount it.

-

@Surgikill said in Error: attempting to extrude with no tool selected:

was not having this issue before the upgrade to RRF V3, which I performed a few days ago.

What firmware version were you using before upgrading to RRF3? And when you updated did you go straight from 2.x to 3.0 and 3.2.2?

Would you be willing to flash back to 2.05.1 to verify that the problem goes away?

Can you also test rolling back the Paneldue firmware to 1.24?

Also, would you be able to try doing a 4 strand braid on that PanelDue cable?

I'd be surprised if being that close to the stepper motor wire for such a short run would cause a problem. As I said I've got a PanelDue running along side a stepper motor for nearly 2 meters.

-

@Phaedrux I went from 2.03 to 3.0 to 3.2.2. I can try to flash back, I still have my old config but it might be a pain in the ass re-configuring some things in my slicer.

I can try the 4 strand braid, but I have the shielded wire coming here in a few days.

The only changes that were made from 2.03 to 3.2.2 were a berd air pump and the firmware upgrade. Maybe the berd air pump is causing some sort of issue? The wires are nowhere near the paneldue. I printed a good amount on 2.03, and never had any sort of issue with the tool being de-selected. I may have had it display some type of garbage command once or twice, but nothing as bad as this.

-

@Phaedrux Well the shielded cable I got is pretty shit. Seems like after I crimp the connectors they just break off. Not sure what to do.

-

Is the crimper tightening down too much and cutting the wire?

-

@Phaedrux I tried it on a larger crimp setting but I think the wire is just shit. It's not that flexible and breaks pretty easily. I did re-wire the entire gantry, braided the stepper wires (twisted pairs for each coil and then twisted those twisted pairs together) braided the paneldue wire, twisted pairs for the thermistor and endstop on the gantry, and replaced the stationary stepper wires with the shielded wire. I'll let you know what happens. If I'm still having interference issues then I'll have to get some ferrite cores to wrap my wires around. If that doesn't fix it then I'm lost. Maybe if I get the 10 pin wire for the paneldue it would help?

-

@Surgikill said in Error: attempting to extrude with no tool selected:

Maybe if I get the 10 pin wire for the paneldue it would help?

At that point it might be worth a shot.

-

@Phaedrux Well I've done a few prints now and it seems to be much better. I think the wiring I had for the toolhead was causing some issues, and the braiding probably helped as well.

-

@Surgikill said in Error: attempting to extrude with no tool selected:

I think the wiring I had for the toolhead was causing some issues

What do you mean?

What has changed to improve it? Would be great to see what helped to use as an example for others with similar issues.

-

@Phaedrux I had 2 cat5 cables that were wired for the toolhead. The stepper motor as well as wires for other items (fans, limit switches, z-probe, filament sensor) were in the cat cable. The IR z-probe was in the same bundle as the stepper motor, and they went through the same quick disconnect automotive connector. I think I was getting interference on the IR sensor, because I could see it jump around when the printer was homing. It wouldn't trigger the IR sensor, but it would jump between random values from 0-467 (sometimes it would throw 150, 200, or 350. This is not how the IR sensor works so I had to be getting interference) The IR sensor plugs into the duet right next to the paneldue header. I'm not sure where the traces are, but they may be running near the paneldue traces. This is probably where the interference was coming from for the paneldue. I can test it some more by extending the cable for the paneldue to see if I still get interference with a longer cable, but I think that's what my issue was. Now the stepper motor wires are twisted in pair with the coils on the motor.

-

@Surgikill Thanks for the info.