'The Hitchhiker' = IDEX for *everyone* ?

-

Hi guys,

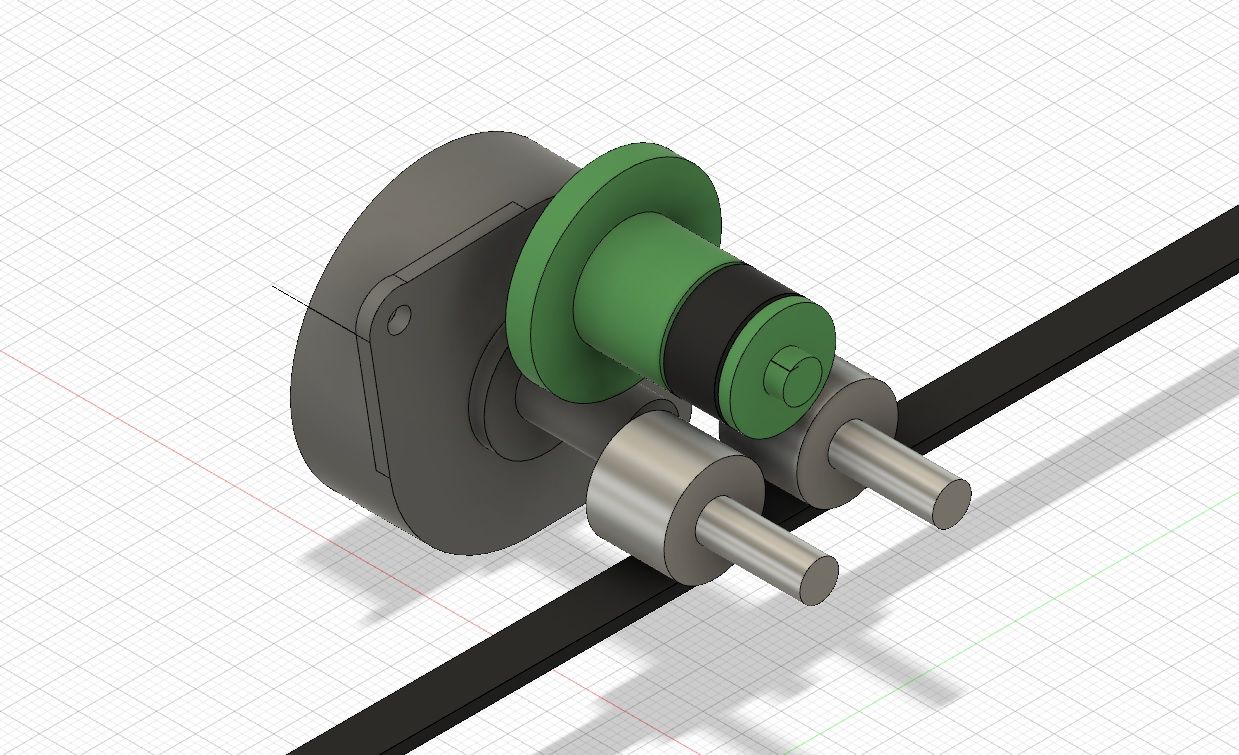

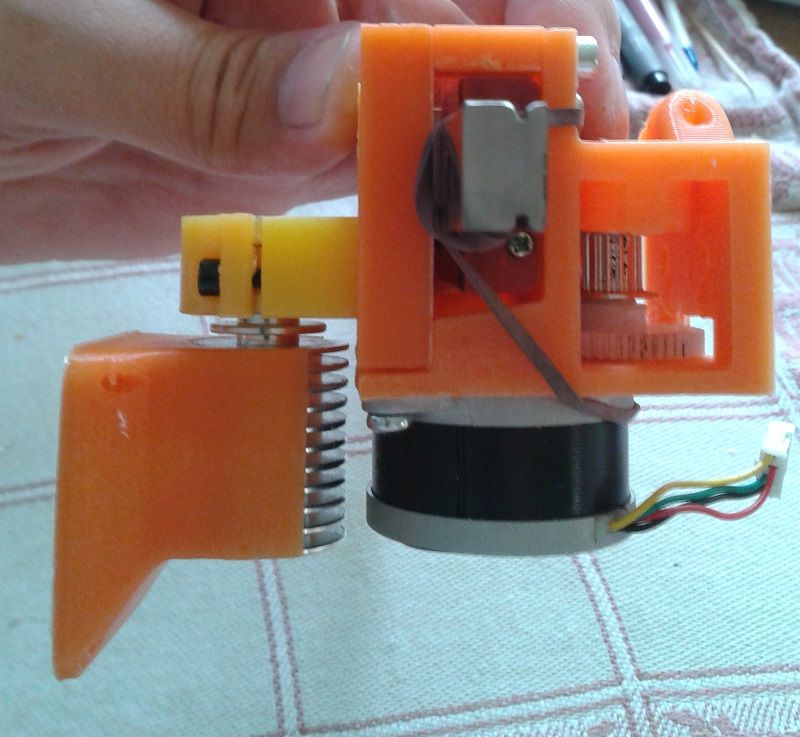

influenced by the discussion here and tinkering with the idea to have a second or even third tool on the same X-axis, I made a drawing for a parasitic tool, riding on the same belt than the main tool.

Originally I thought to fit it in between the smooth rods of a Prusa i3 and use a N20 DCmotor converted to stepper. (see here). But to have a proof of concept I took the next best stepper I had and used the gears from a BMG extruder. I replaced the filament gear with a GT2 belt pulley.

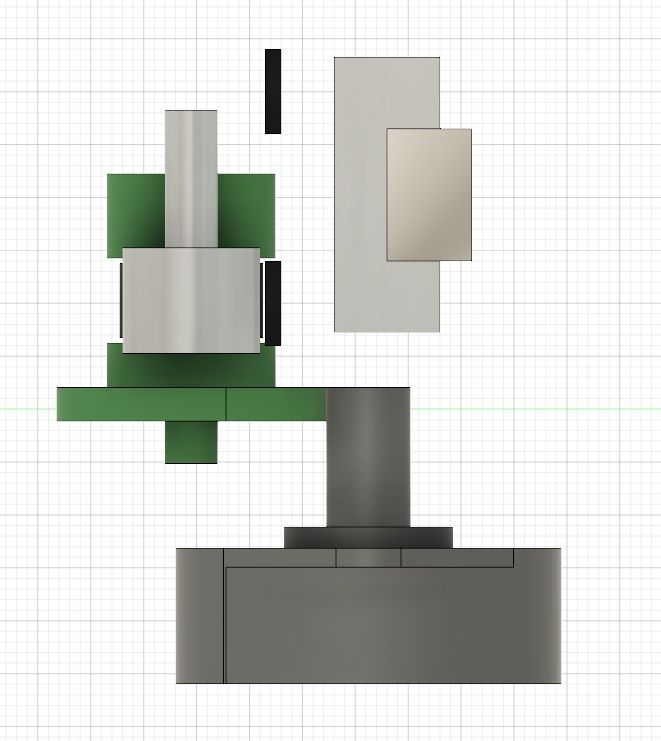

Unfortunately, the gears and idlers won't fit between Prusa's smooth rods, but it's pretty simple to make a bracket for my CoreXY.

I'm planning to use it for dual extrusion with a Bowden tube volcano hotend and a big nozzle. Bowden tube, because I want to keep the weight low and the big nozzle is for infill only.

I could also make a feltpen bracket and follow my plans to implement texture mapping.It seems all these previous projects lead to this one. Maybe one day it's useful for a few people here?

It all started with @RichardDuke 's idea. Thank you for triggering my interest! -

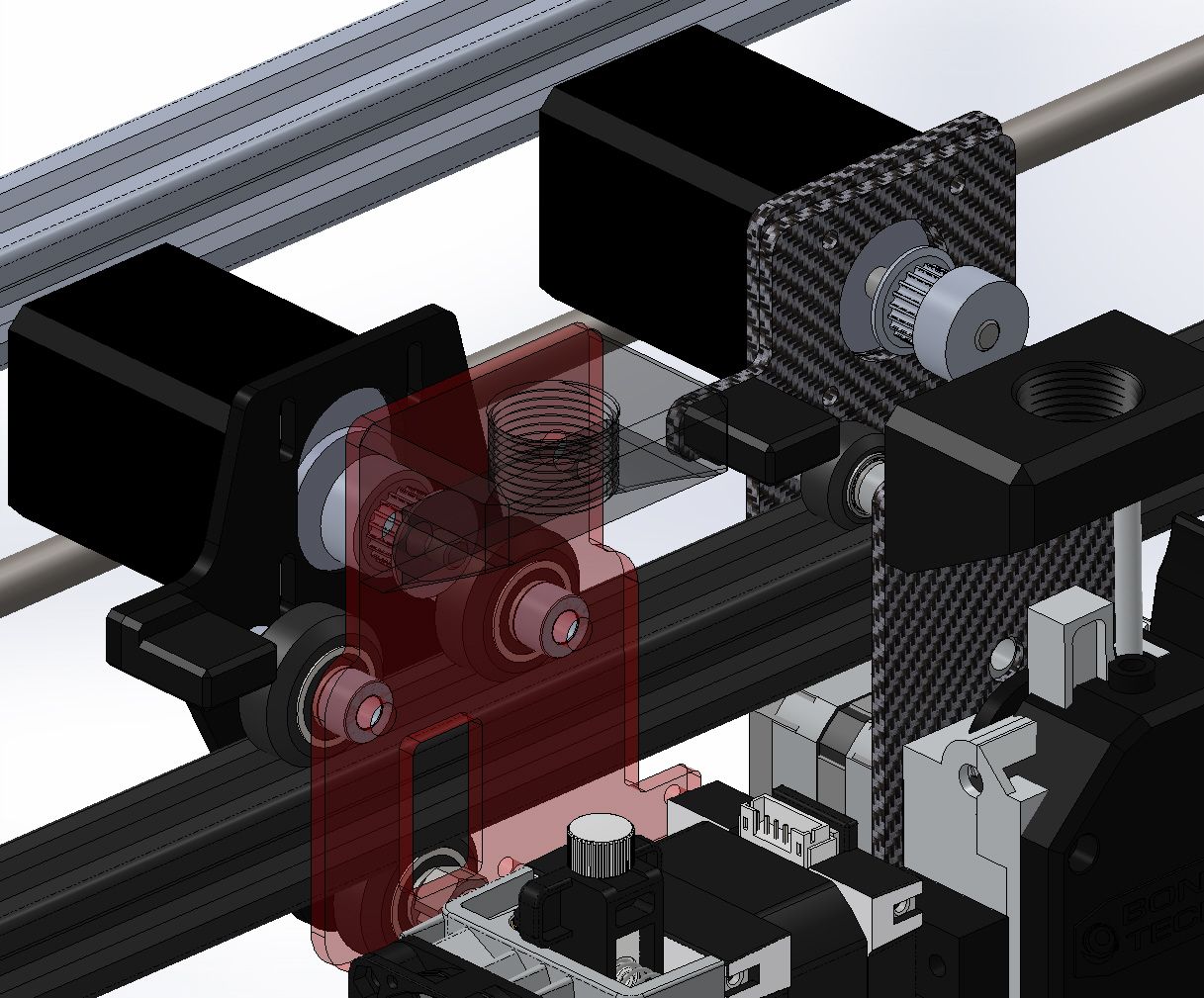

Do you mean something like this? Rack & Pinion type drives with one belt?

I use nema 14's to drive my X & U heads on one belt. Been working great for years.

-

Yes that looks great. Nema14 is strong enough for direct drive? The V-wheels act as idlers too and the belt runs in the extrusion slot? Amazing...

What's your travel speed with these direct drive extruder? -

The difference between my concept and yours is, that I use the belt of a conventional toolhead. It's easy to implement into existing printers, I hope.

-

@o_lampe said in 'The Hitchhiker' = IDEX for *everyone* ?:

Yes that looks great. Nema14 is strong enough for direct drive? The V-wheels act as idlers too and the belt runs in the extrusion slot? Amazing...

What's your travel speed with these direct drive extruder?Thanks,

The nema 14's move the heads in the X axis (and U axis for the IDEX part). But I have the max travel speeds set at 300mms for rapid moves. Never had any issues with missed steps thus far. I use regular nema 17's to drive my direct drive extruders. I have had titam aero heads, bondtech direct drives and now currently hemera heads on this Y axis bar.Yes the V wheels are the belt idlers.

The set up or conversion is very easy, Just lock a section of belt down inside the groove of the v slot with a tee nut on each end along with a set screw in the tee nuts. The set screw pinches the belt down to the bottom of the slot. My belt hasn't slipped in 3 years of printing, many hours on this configuration so far.

-

@timcurtis67

sigh I must have missed a lot the past few years... -

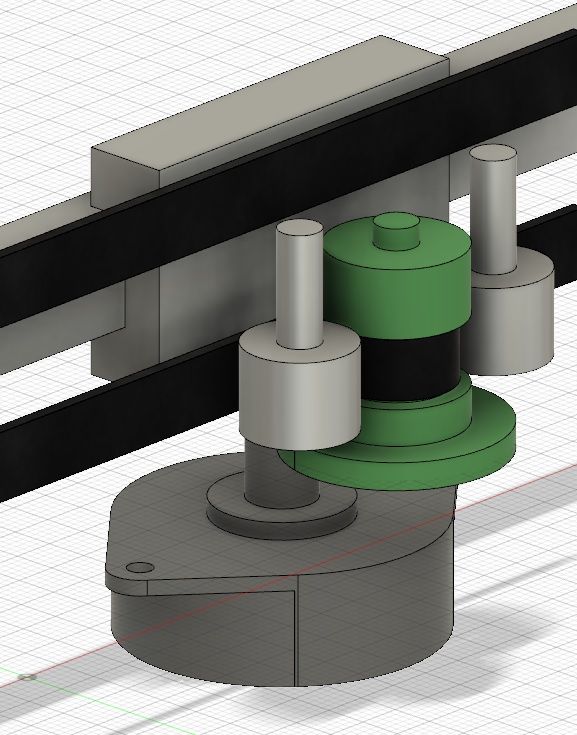

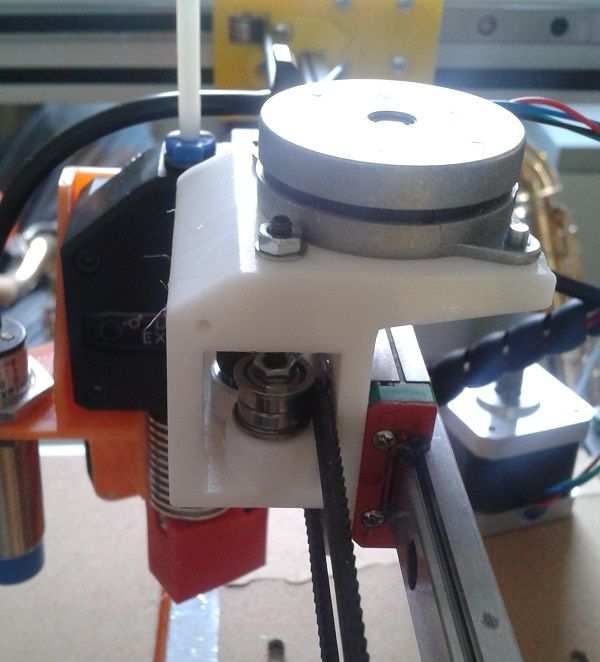

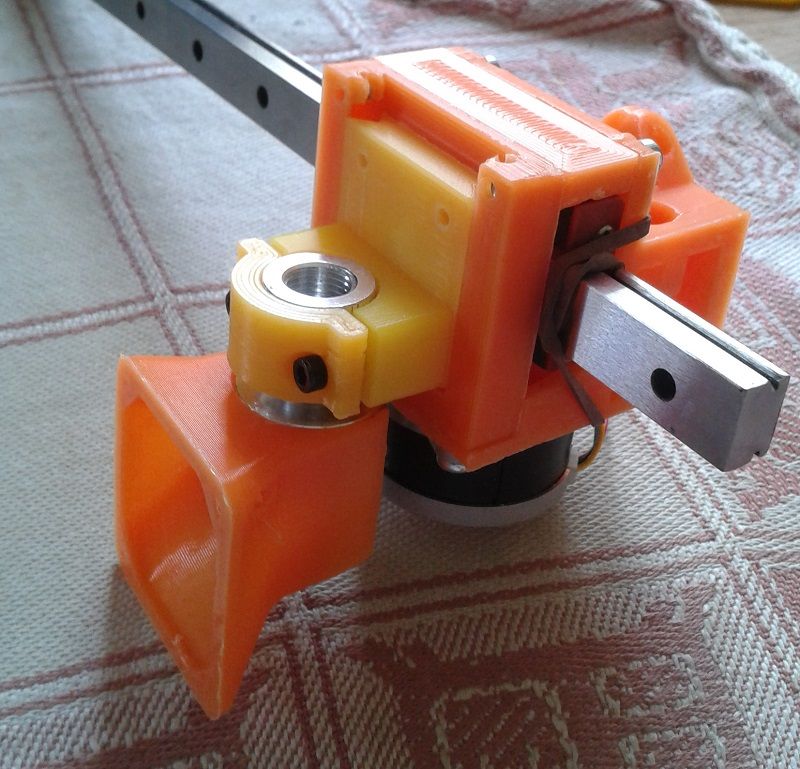

Nevertheless, I made a setup with mgn12 linear rail for size comparison. It fit's neatly around the carrier.

-

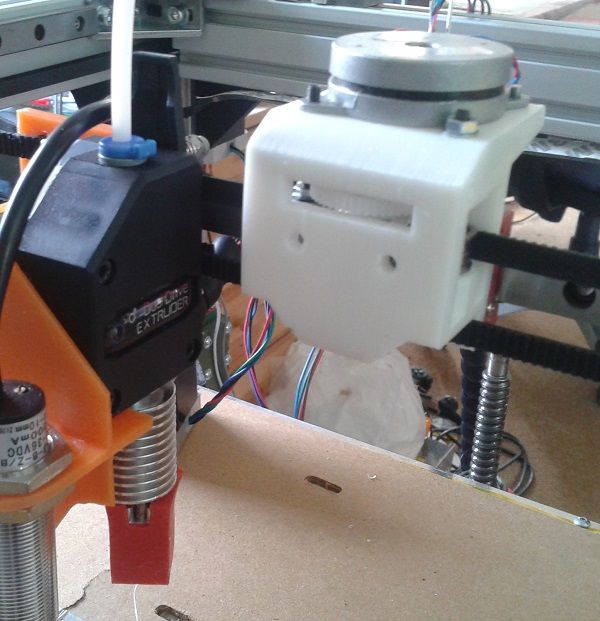

Here's the first real Hitchhiker bracket, I dared to install.

I had to flip the belt and that was best possible on the upper belt. So I had to flip over the whole bracket, too.With this 0.5A NEMA14 motor, I can reach only 200mm/s travel speed. (without tool)

I found a different motor 36HS2418 which looks a lot like the overpriced LDO motor but has 1.88A max. current.

I can't confirm yet, it has the same pinion, but if it works with the BMG spurgear, I have a 120gr. motor ready to boss around any tool I attach.

If not, there is still the option to use a NEMA17 pancake motor. The screw-pattern is the same.

-

@o_lampe

Looking good! -

So for clarity, the second head can be re-positioned on the moving belt of the first head to give a varying gap between them for Ditto prints, but for mirror prints the second heads drive would have to work twice as hard?

Also if you wanted to park the second head then it's drive would have to mirror the drive movements of the first head to keep it still.

Like the concept, just thinking there is a lot of mass on that second head that's always affecting the first unless it's actively parked.

Good to see some out of the box thinking

Good luck with your design development!

All the best

Barry M -

@cncmodeller

Yes, you nailed it.

Mirrored prints aren't possible unless you print very slow. I haven't had the need for it anyway. If I'd need mirrored parts, I'd use netfabb or meshmixer. (forgot which one has mirror-function)

The weight of the second tool only counts when it moves in X-direction. I also plan to use a Bowden extruder or a dual-feltpen* tool. Not much more weight, tho.*) Yes, the feltpen texture mapping idea is still alive

-

@o_lampe said in 'The Hitchhiker' = IDEX for *everyone* ?:

I found a different motor 36HS2418 which looks a lot like the overpriced LDO motor but has 1.88A max. current.

I can't confirm yet, it has the same pinion, but if it works with the BMG spurgear, I have a 120gr. motor ready to boss around any tool I attach.I almost don't dare to post it on April 1st, but the pinion of the big NEMA14 motor matches the BMG spur gear

I have to redesign the Hitchhiker bracket to fit the shorter and smaller pinion, but it's definitely worth it.//edit the selling add says 120gr, but my scale shows 82gr. It gets better and better...

-

Don't wanna spam the forum, so I just link an update for the Hitchhiker

-

I made a slider for a Bowden tube extruder. A nice side effect: the hotend cooler blows air around the motor, too.

-

I spent the whole day to calibrate the dual extruder setup with tool changes and Slicer settings.

Tuning the Z- and X-axis was easy, but the Y/V axis puzzles me. I had a very good calibration-grid, then printed a dual color testcube which showed signs of overextrusion, but was 'spot on' otherwise. The next print should've been an appetizer to show off, but there was an offset in Y/V again?

I'm too tired now, will see how it behaves tomorow.

-

undefined o_lampe referenced this topic

undefined o_lampe referenced this topic